2

SECTION 1. OWNER INFORMATION

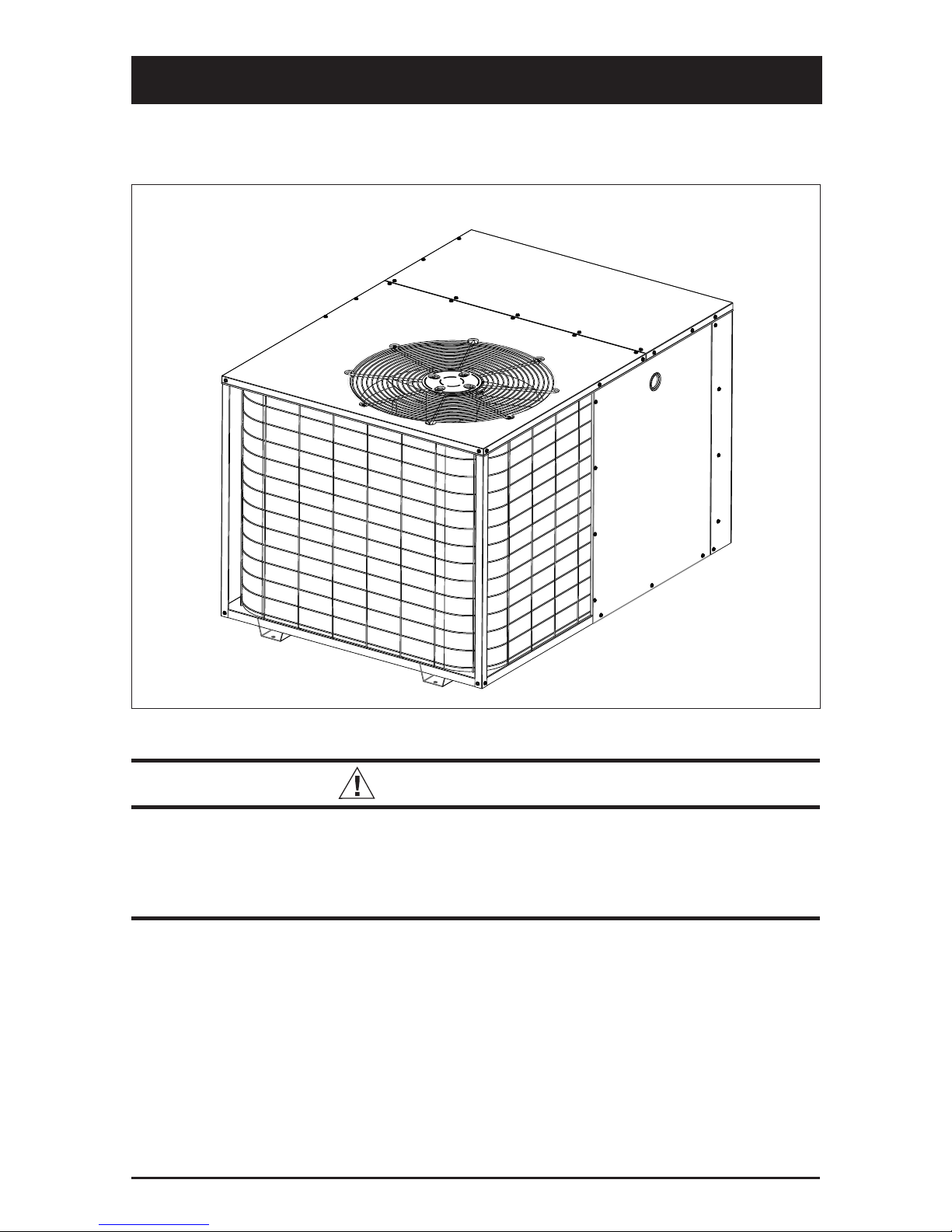

Your heat pump will heat and cool your home

year round, saving your energy dollars.During the

summer, a heat pump performs like any normal

air conditioner. That is, the excess heat energy

inside the home is absorbed by the refrigerant

and exhausted outside the home. During the

winter months, a heat pump performs like an

air conditioner run in reverse. That is, available

heat energy outside the home is absorbed by

the refrigerant and exhausted inside the home.

This is an efficient heating means because you

only pay for “moving” the heat from the outdoors

to the indoor area. You do not pay to generate

the heat, as is the case with more traditional

furnace designs.

It is the sole responsibility of the homeowner

to make certain that the heat pump has been

correctly set up and adjusted to operate

properly.

A warranty certificate with full details is included

with the heat pump. However, the manufacturer

will not be responsible for any costs found neces-

sary to correct problems due to improper setup,

improper installation, adjustments, improper op-

erating procedure on the part of the user, etc.

Some specific examples of service calls which

are not included in the limited warranty are:

1. Correcting wiring problems in the electrical

circuit supplying the heat pump.

2. Resetting circuit breakers or other switches.

3. Adjusting or calibrating of thermostat.

To avoid misunderstandings at a later date,

carefully review these responsibilities with your

dealer or service company.

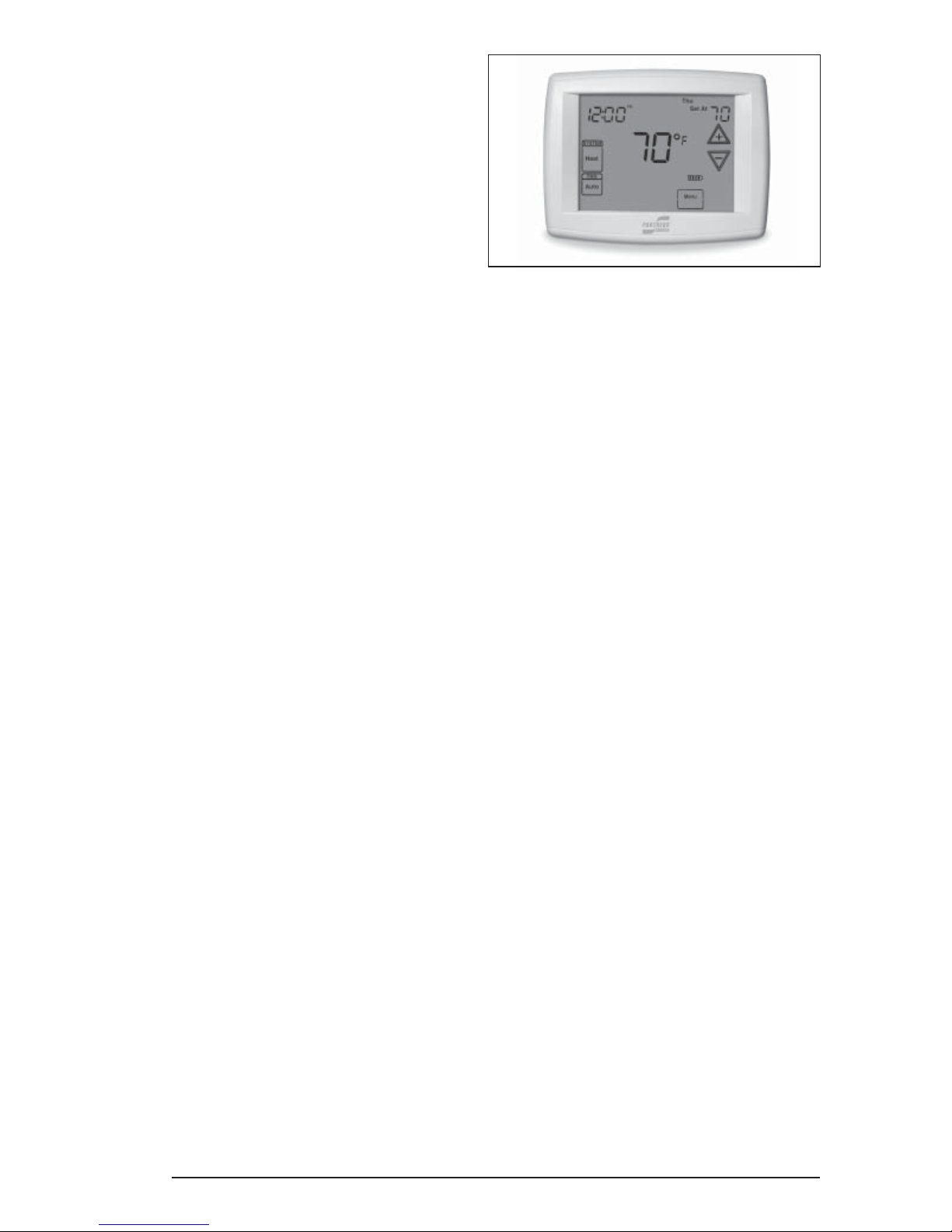

OPERATING INSTRUCTIONS

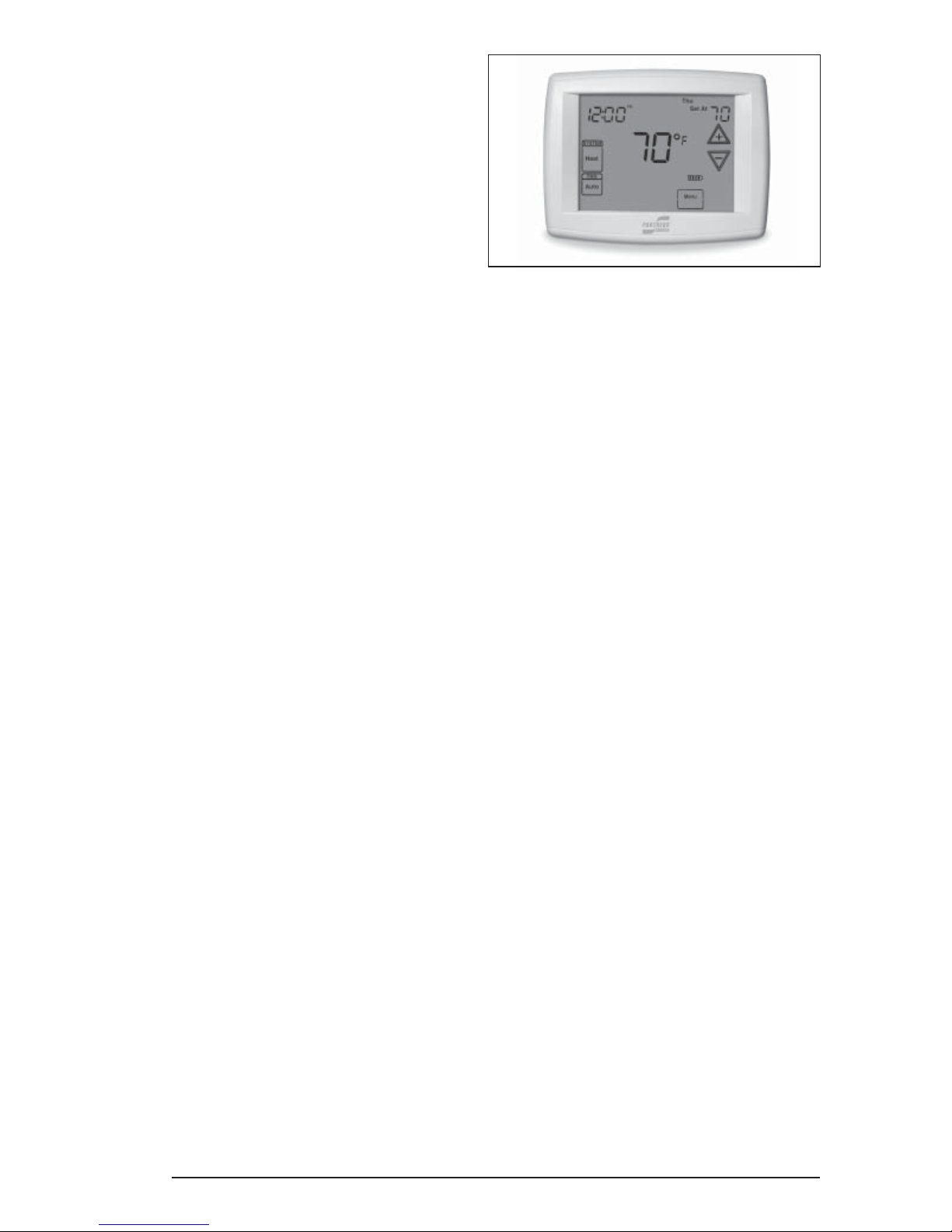

To Operate Your Heat Pump For Cooling —

1. Set the thermostat system switch to COOL

and the thermostat fan switch to AUTO. (See

Figure 1)

2. Set the thermostat temperature selector to the

desired cooling temperature.The outdoor unit

fan, the indoor blower, and the compressor

will all cycle on and off to maintain the indoor

temperature at the desired cooling level.

NOTE: If the thermostat temperature level is

re-adjusted, or if the thermostat system switch

is re-positioned, the outdoor unit fan and the

compressor may not start immediately. A

protective timer circuit holds the compressor and

the outdoor fan off for approximately five minutes

following a previous operation or the interruption

of the main electric power.

To Operate Your Heat Pump For Heating —

1. Set the thermostat system switch for HEAT

and the thermostat fan switch to AUTO. (See

Figure 1)

2. Set the thermostat temperature selector to the

desired heating temperature.The outdoor unit

fan, the indoor blower, and the compressor

will all cycle on and off to maintain the indoor

temperature at the desired heating level.

NOTE: If the thermostat temperature level is

re-adjusted, or if the thermostat system switch

is re-positioned, the outdoor unit fan and the

compressor may not start immediately. A

protective timer circuit holds the compressor and

the outdoor fan off for approximately five minutes

following a previous operation or the interruption

of the main electrical power.

Emergency Heat — Some thermostats will

include a system switch position termed EM HT

or AUX HT, etc. This is a back-up heating mode

to be used only if there is a suspected problem.

With the system switch set to EM HT, etc., the

compressor and outdoor fan will be locked off and

supplemental heat (electric resistance heating)

will be used as a source of heat. Sustained

use of electric resistance heat in place of the

heat pump will result in an increase in electric

utility costs.

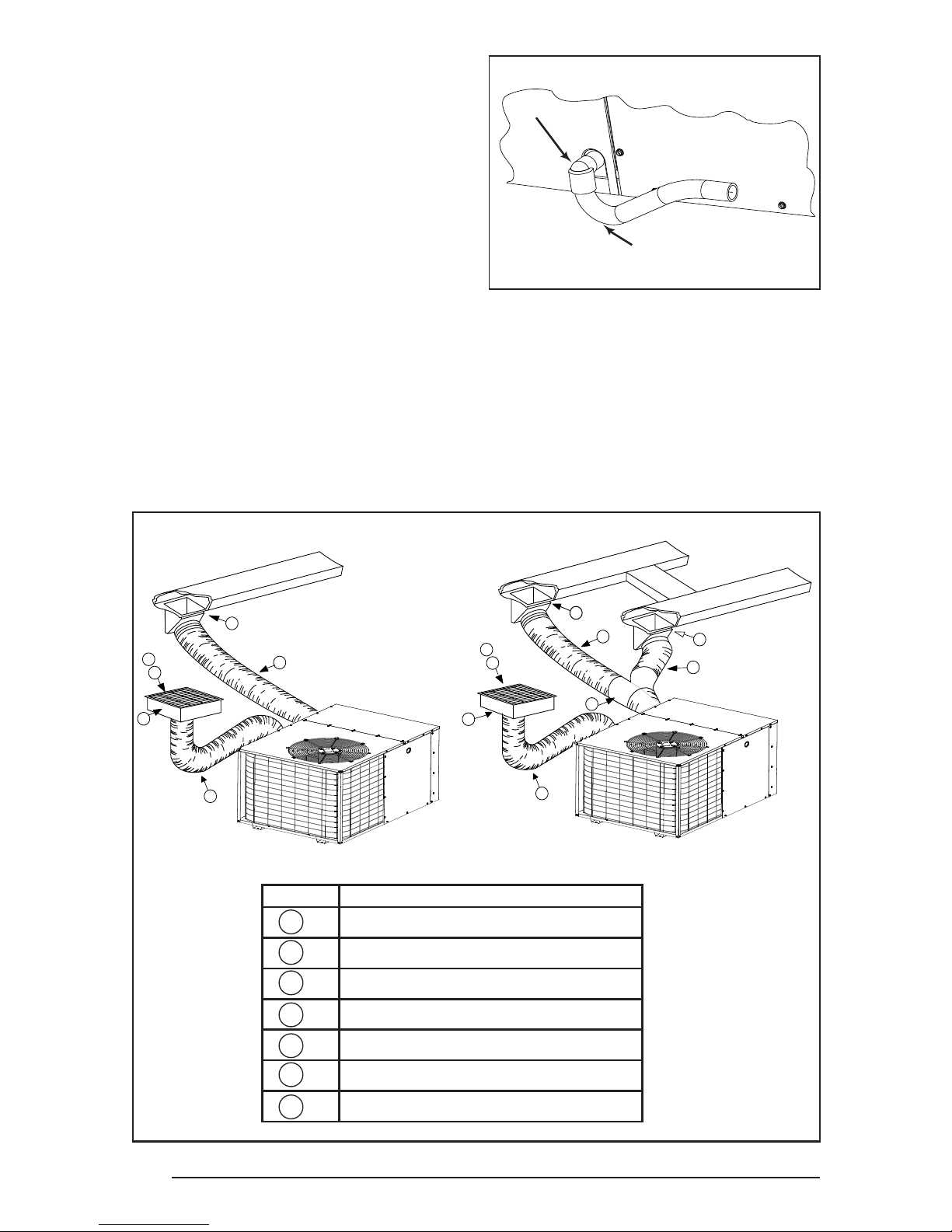

Defrost — During cold weather heating opera-

tion, the outdoor unit will develop a coating of

snow and ice on the heat transfer coil. This is

normal and the unit will periodically defrost itself.

During the defrost cycle, the outdoor fan will stop,

while the compressor continues to run and heat

the outdoor coil, causing the snow and ice to melt.

During defrost, there may be some steam rise

from the outdoor unit as the warm coil causes

some melted frost to evaporate.

Figure 1. Typical Thermostat