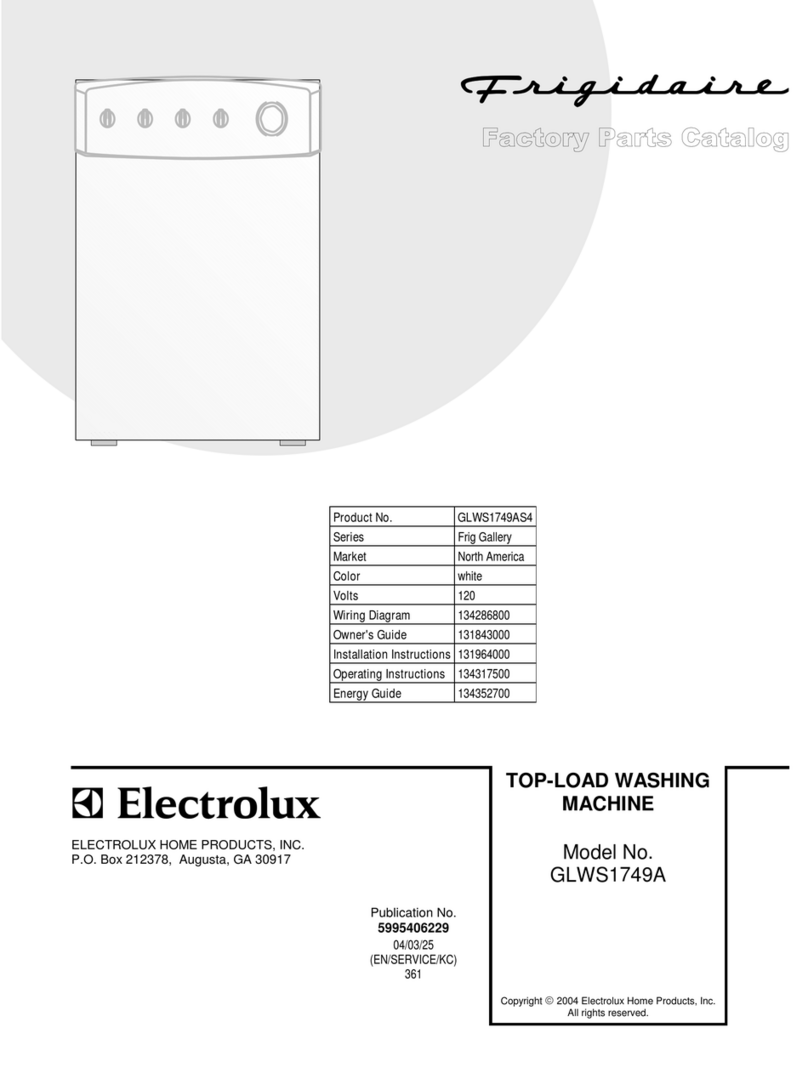

WIRING DIAGRAM

If grounding wires, screws or clips used to complete a path to ground are removed

for service, they must be returned to their original position and properly fastened.

Certain internal parts are intentionally NOT grounded and may present a risk of

electric shock only during servicing. Do not contact the following parts while the

appliance is energized: pump, drive motor and electronic control boards.

This information is intended for use by technicians possessing

adequate background of electrical, electronic and mechanical

experience. Any attempt to repair a major appliance may result in

personal injury and property damage. The manufacturer or seller

cannot be responsible for the interpretation of this information, nor

can it assume any liability in connection with its use.

IMPORTANTIMPORTANT SAFETY NOTICE

TECH SHEET - RETAIN FOR SERVICE TECHNICIAN

Disconnect from Electrical Supply Before Servicing Washer.

134390200 0402

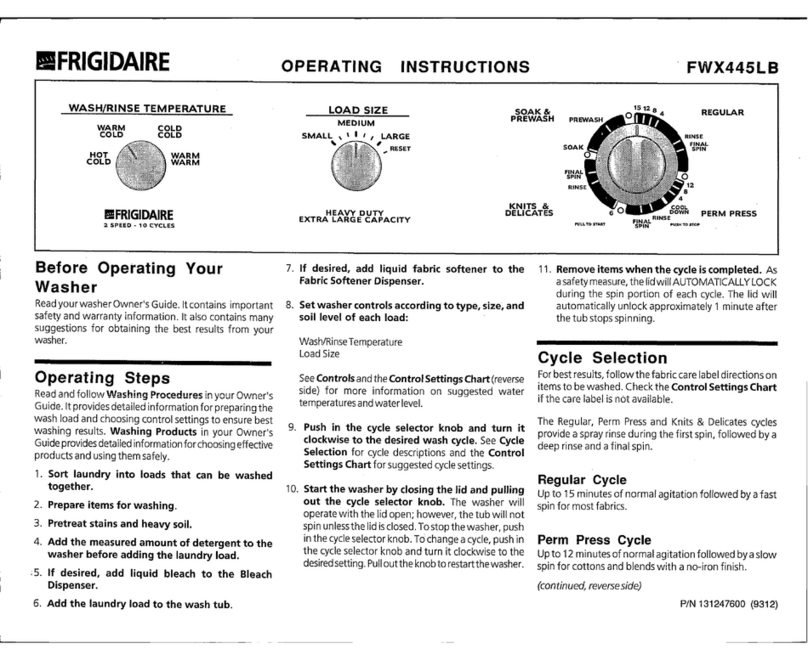

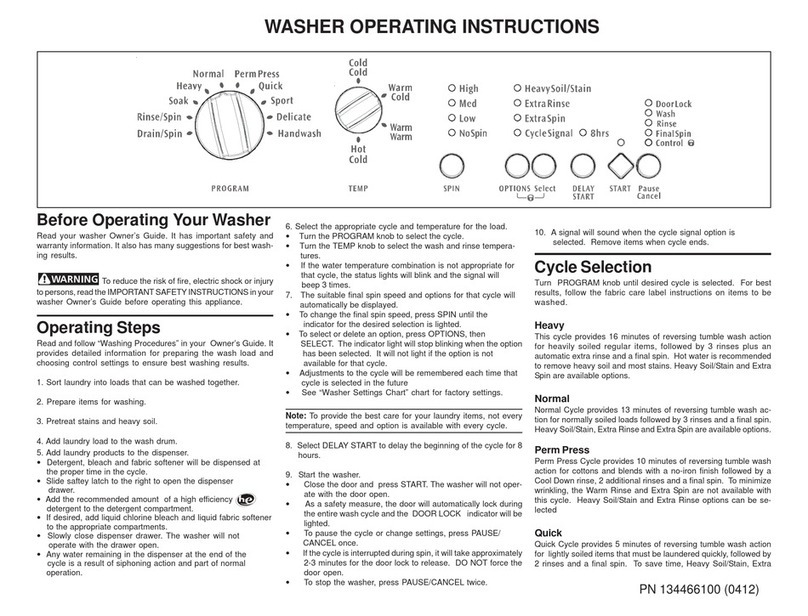

Motor Will Not Run

Timer/off

Drawer/open

Door/open

SWITCH

POSITION CIRCUIT

WATER TEMP SWITCH

H/C X X

X

W/C

XX

X

C/C XW/W

1 - 3 1 - 5 2 - 4W/R

C10.10 (D)

C10.9 (E)

C10.6 (C)

C10.1 (B)

C10.2 (A)

C10.5 (TM)

C10.8 (F)

SIGNAL

DOOR

LOCK

COIL

DOOR

LAMP

TIMER

MOTOR

C6.5 (AC)

C6.6 (AC)

C6.2 (P2)

C6.3 (P3)

C6.1 (P1)

C6.4

C10.3 (T2)

C10.4 (T1)

T

B

RINSE

WATER

CYCLE

SIGNAL

TIMER

DIRECT

RINSE

WATER

WASH

WATER

WASH

WATER

BLK/WHT BLK

2

2

1

1

WHT

WHT/RED

BLUE

RED/YEL

ORG

BROWN

RED/BLK

TAN/WHT

YEL/WHT

YELLOW

YEL/RED

BLK

BLK/RED

YEL/BLK

AQUA

TAN/BLK

ORG/WHT

TAN

BLUE

YEL

BLUE

PINK/BLK

WHT/RED

BROWN

RED

YEL/BLK

BLU/WHT

BLU/WHT

B

2B 4

2

MOTOR CONTROL

B

T

10

2

5

3

1 4

8

T12 B

T

0T 0C

BLEACH SOFTENER

TEMP

SWITCH

HOTCOLD

#4

L1

BLEACH SOFTENER

MS

4.4

2.1

WATER

VALVES

DISPENSER

VALVES

WATER LEVEL

PRESSURE

SWITCH

2.2 4.3

DOOR

LOCK

SWITCH

LINE SWITCH

PUSH-PULL

DISPENSER

DRAWER

REED SWITCH

7B5B3B1B

6T

7C5C3C1C

6C

1

23

M

EXTRA

RINSE

SWITCH

PUMP

MOTOR

T

GRAY

B14

#2

#5

#6

WAX

MOTOR

PTC

+t

2

1

ORG/BLK

GREEN

6 53 24 1

TACHO-

GENERATOR

T

MOTOR

WINDING

1. Advance the timer knob to the drain

increment. If the drain pump does not run,

check household safety circuit. If the drain

pump runs go to step 2.

2. Turn the water off to the washer. Remove

electrical power from the washer and

remove the back panel. Remove the motor

drive belt. Reconnect electrical power and

set the timer to the start of the Regular wash

cycle and pull the knob out. If motor does

not rotate, check for a poor connection in the

timer line switch or door lock switch. If good,

and moto r does not run go to step 3.

3. Remove the six pin plug from the speed

control unit. Measure the voltage between

pins 5 and 6 on the harness. If the meter

reads 0 check the connection in the timer

line switch or door lock. If the meter

reads 120 Vac go to step 4.

CHECK FOR POWER:

CHECK FOR MOTOR MOVEMENT:

MEASURE VOLTAGES:

4.Set the timer to the Heavy Wash position of

the Regular wash cycle. Remove the ten pin

plug from the speed control unit. Measure

the voltage between pins 1, 2, 6 and 10 of

the ten pin plug to pin 5 of the 6 pin plug on

the harness. The voltage at pins 2, 6, and

10 should read 120 Vac and 0 Vac at pin 1.

If not, check timer contacts 1C to 1B, 5C to

5B, and 7C to 7B for closed contacts, and

3C to 3B for open contacts. If the voltage

readings are correct, go to step 5.

5.

6.Remove the 6 pin plug from the sp eed

control unit. Measure the resistance

between pins 1 and 2, 2 and 3, and 3 and 1

of the speed control unit. If the meter reads

other than 3 Meg ohms ± 10%, replace the

speed control board.

MEASURE RESISTANCES:

Check the fuse on the speed control board.

If the fuse is open, replace the speed control

board. If good, go to step 6.

7.Remove electrical power from the washer.

With an ohmmeter check the resistance

between pins 1 and 2, 2 and 3, and 3 and 1

of the six pin plug on the harness. If the

meter reads other than 2.6 ohms ± 7%,

replace the motor.

Quick Facts

•The timer motor will not run continuously.

The speed control unit controls the timer

motor and advances the timer when needed.

•In some tumble modes, the tub may not

tumble for the first 16 to 20 seconds after

start-up.

•Extremely low water pressure may cause

tub rotation to stop until WLC satisfied.

Speed

Control

Speed

Control

Speed

Control

GRN

WHT

WHT

WHT

#1 #7

N

GND CABINET

CHASSIS

#3

6

1

6

1

5 10

1 6

6

1

Not on all models

*

*

PINK