SECTION 4

MAINTENANCE

4.1 CLEANING

The following cleaning procedure should be used for initial start-up and on an as

needed basis to comply with the minimum cleaning and sanitizing frequencies

specified by the federal, state or local regulatory agency having jurisdiction.

(1.)Turn the machine to the off, “hand” position then remove hopper cover.

(2.)If applicable, drain mix into a sanitized container as per local health code

procedures.

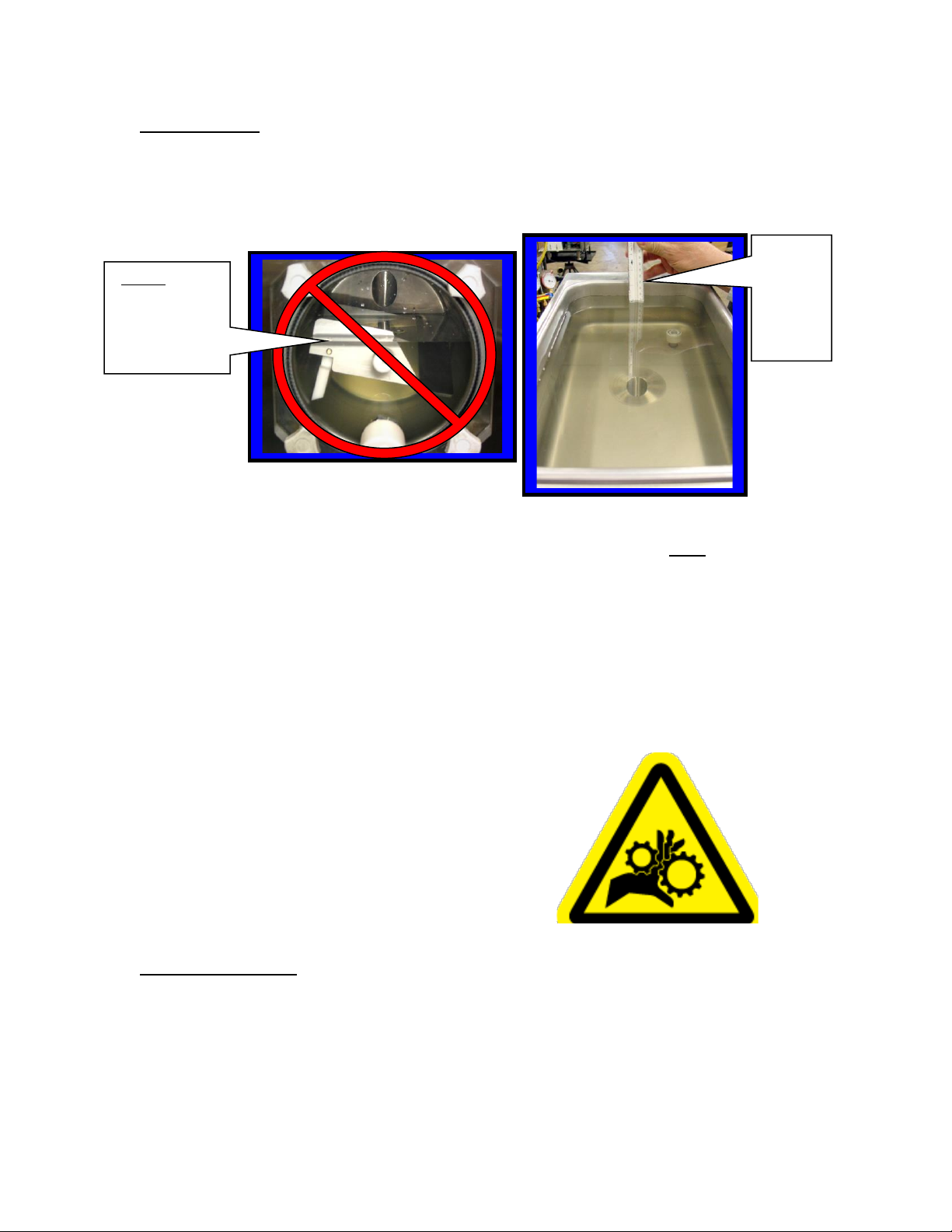

NOTICE: Do not put hands or foreign matter into mix.

(3) Pour two gallons of cool (75ºF.) water into the hopper. Place upper switch in

“faucet” position to let the machine stir for 2 minutes. Turn machine “OFF”, drain

and dispose of the rinse water. Repeat until water is clear.

NOTICE: Do not unscrew faucet body from faceplate

to clean. (Leak free service after disturbing the Teflon

seal cannot be assured).

(5) All parts removed during the above steps plus the drip tray and insert can now be

cleaned in your warm (100ºF) cleaning solution. Rinse all parts in clean water and

allow to air-dry before re-assembly.

(6) Use cloth and cleaning solution to wipe any residue from cylinder and hopper.

(7) Re-assemble as shown in section 4.2 (next page).

(8) Mix two gallons of warm water (approximately 100ºF) with two ounces of

sanitizing powder to achieve 100 parts/million (PPM) sanitizing solution.

(9) Pour the sanitizing solution into the hopper.

(10) Place upper switch in “faucet” position. Let solution stir for 5 minutes. Turn

upper switch “OFF” (hand) position. Drain all solution.

Notice: Do not leave the solution in the machine for more than 5 minutes.

(11) Pour product into hopper. Replace hopper cover. Place both switches in right

(snowflake) position when ready to freeze product.

(4) Remove the knobs from the faceplate by turning in

a counter clockwise direction. Carefully pull the

faceplate straight away from the front of the machine.

Remove the beater bar assembly from the cylinder.

Then slide the spring seal off the rear of the beater bar.

Unscrew white faucet cap to remove faucet plunger

from faucet body. Remove all O-rings for cleaning.