LOCATION & INSTALLATION

2.1 SAFETY PRECAUTIONS

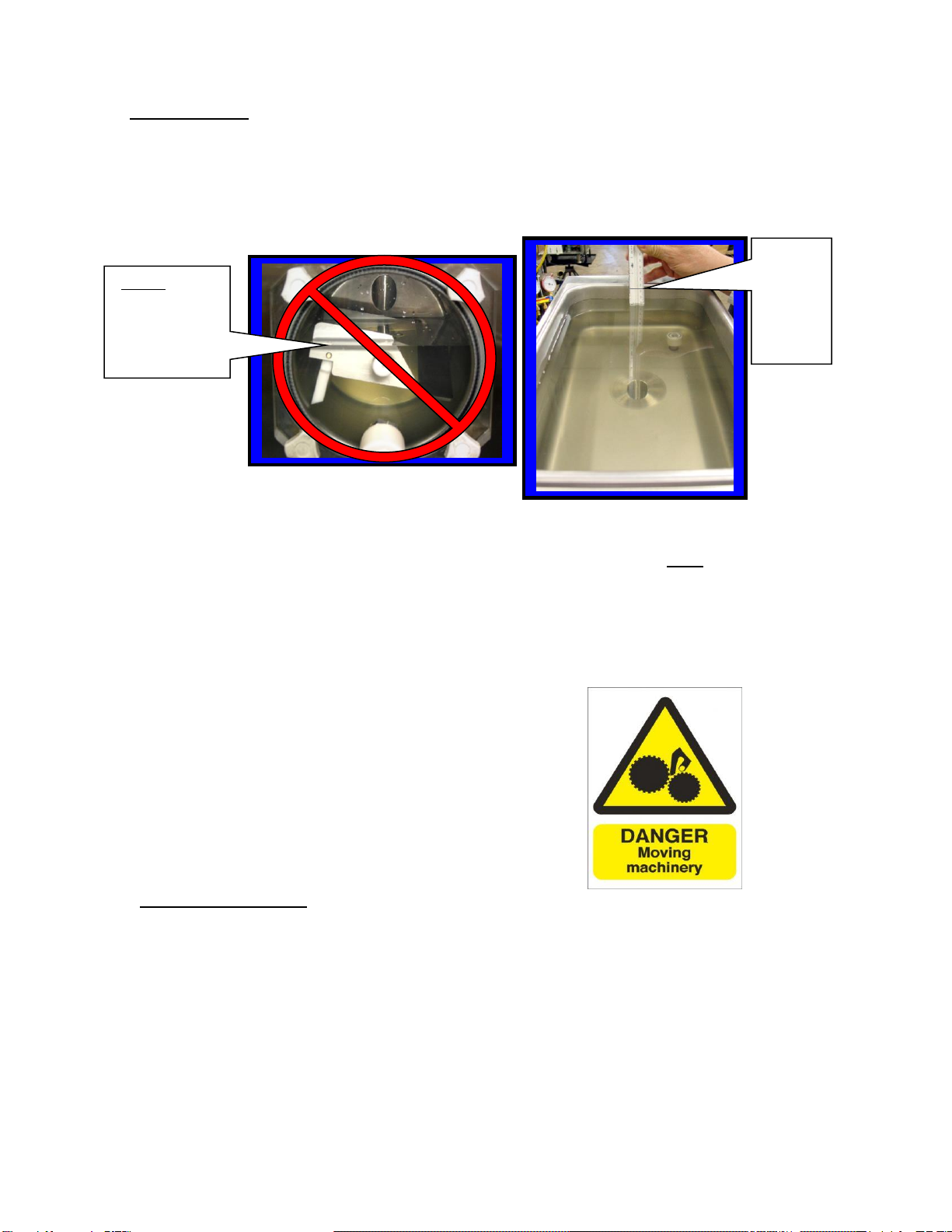

Do not attempt to operate your machine until the safety precautions and operating instructions in this

manual are read completely and are thoroughly understood.

Take notice of all warning labels on your machine. The labels have been put there to inform and protect

persons operating or servicing your equipment. Care must be taken not to damage or destroy labels during

installation and servicing. The labels have been designed to withstand routine cleaning and handling.

Damaged or missing labels should be promptly replaced with approved labels from Frosty Factory of

America Inc.

2.2 INSTALLATION

Placing your machine in a highly visible area will enhance sales. A suitable station will be able to support

500 pounds and will have a dedicated electrical outlet.

CAUTION: Do not attempt to share the dedicated electrical outlet with any other appliance; this will cause

the circuit breaker to trip.

1. Uncrate your equipment.

2. The machine must be placed on a sturdy platform able to hold the weight of the machine when full of

product. Level the machine by turning the adjustable part of the leg. The machine must be level front to

back as well as left to right and the counter must we deep enough to amply support all four legs and the

complete machine.

3. Frozen Drink Machines equipped with air cooled condensers (289A) must have correct ventilation. Air

intake and discharge of the Frozen Drink Machine is through the sides; both require 24” clearance. Rear

clearance for 289A is 4”. Rear clearance for 289W& 289R is 6”. No side clearance is required for 289W

& 289R. All Frozen Drink Machines require 6” clearance at the top.

NOTE: Locating the unit in direct sunlight, near cooking facilities or any high heat area will

reduce the performance of your machine.

CAUTION: Extended operations under severe heat condition can damage the cooling system.

NOTE: Establishments that serve beverages from frozen drink machines are responsible for

providing the necessary facilities for cleaning and sanitizing their food service

equipment.

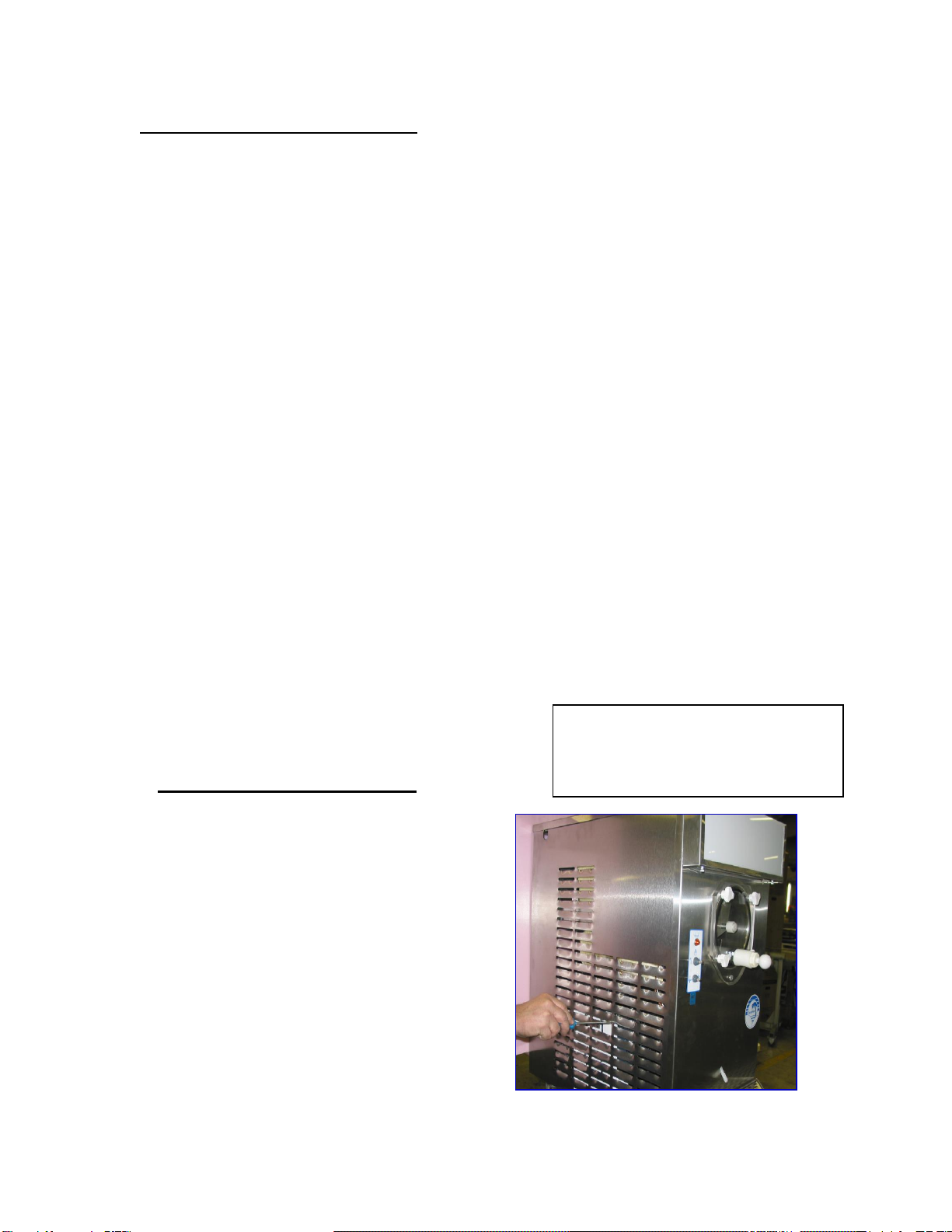

4. Place the three-position switch in the OFF position (center).

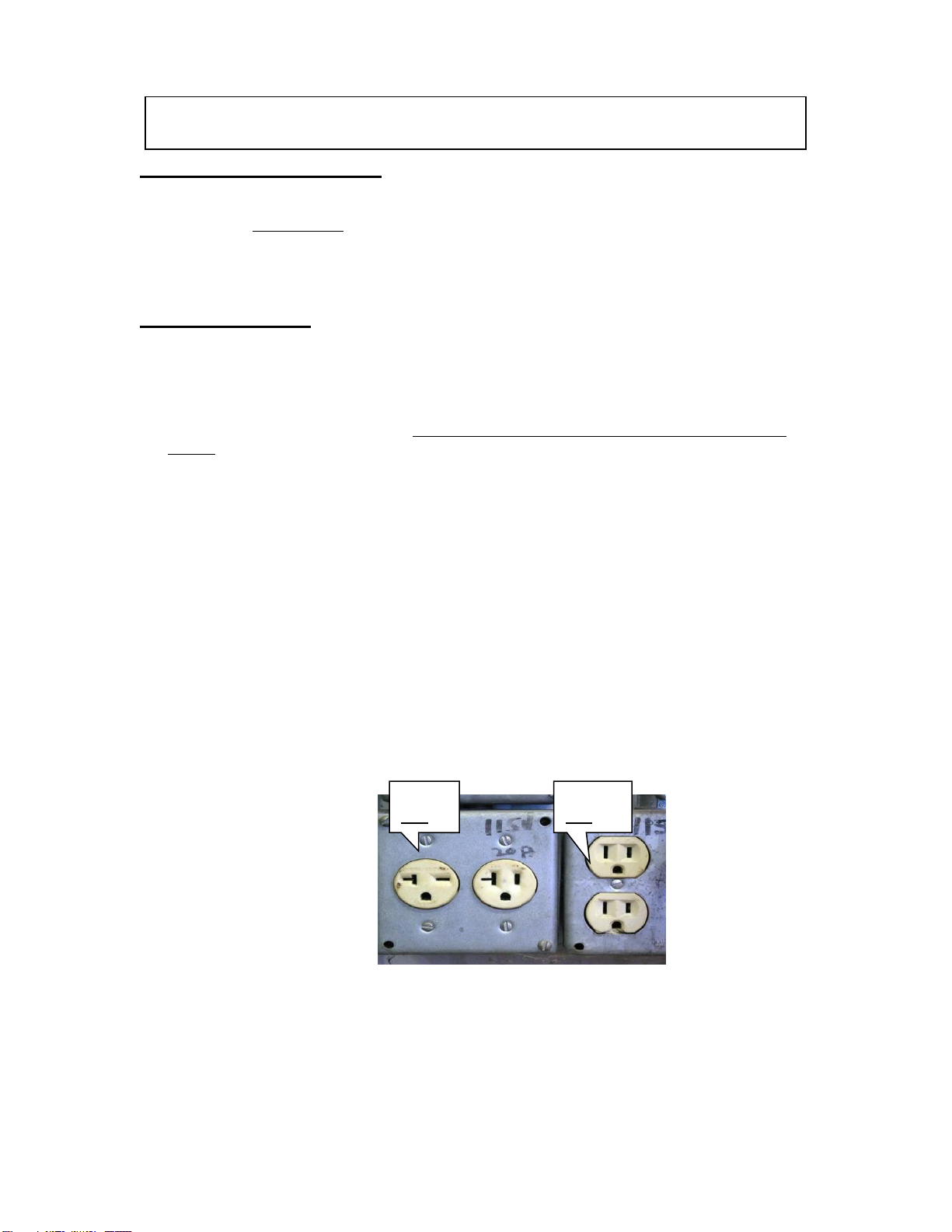

5. Connect the power cord. The Frozen Drink Machine must be connected to a properly grounded

receptacle. The electrical cord furnished as part of the Frozen Drink Machine has a three or four prong

grounding type plug. The use of an extension cord is not recommended. If one must be used, consult

the national and local electrical codes. Do not use an adapter to get around grounding requirements.

289A 289R

289W