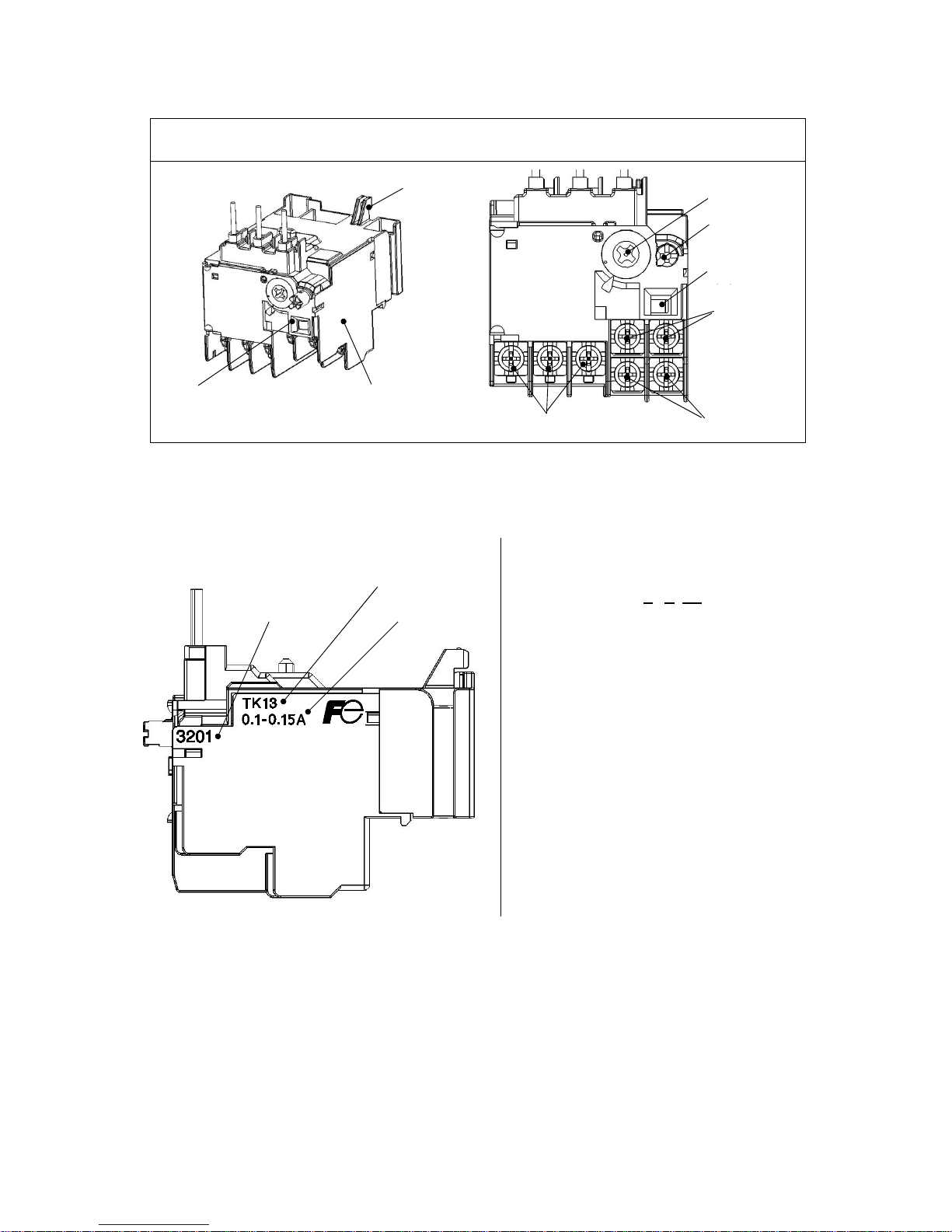

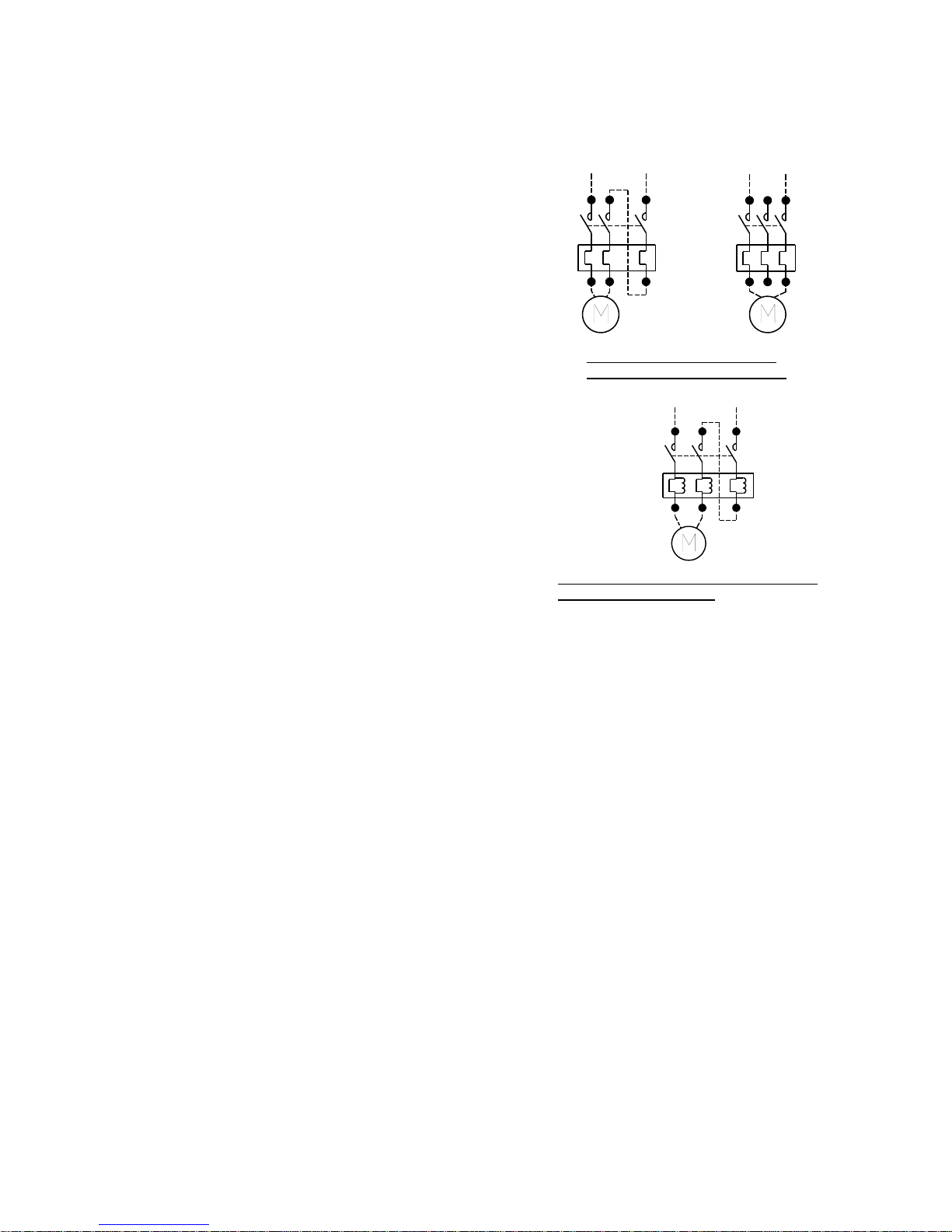

(3) Current setting method (Figure 8.4)

• Turn the adjustment dial within its scale and set the full load current of the motor to the downward triangle mark

(▼). If it is used outside the scale, the product performance will not be satisfied.

• When the inverter is used in the secondary side, a faulty tripping may be caused by leakage current. When

using the inverter, measure the current at the place where the thermal overload relay is mounted and select an

appropriate one.

• When using a serge prevention device in the secondary side of the thermal overload relay, set the current to a

value with leakage current added.

• Depending on the type of motor to be used, the thermal overload relay may make unnecessary actions at the

startup. In such a case, increase the current value set by the dial to approximately 5% or less. If it is increased

higher than that guideline, the motor may not be properly protected.

Also, select an appropriate thermal overload relay such as long-time operating type or quick operating type

depending on motor characteristics and load conditions.

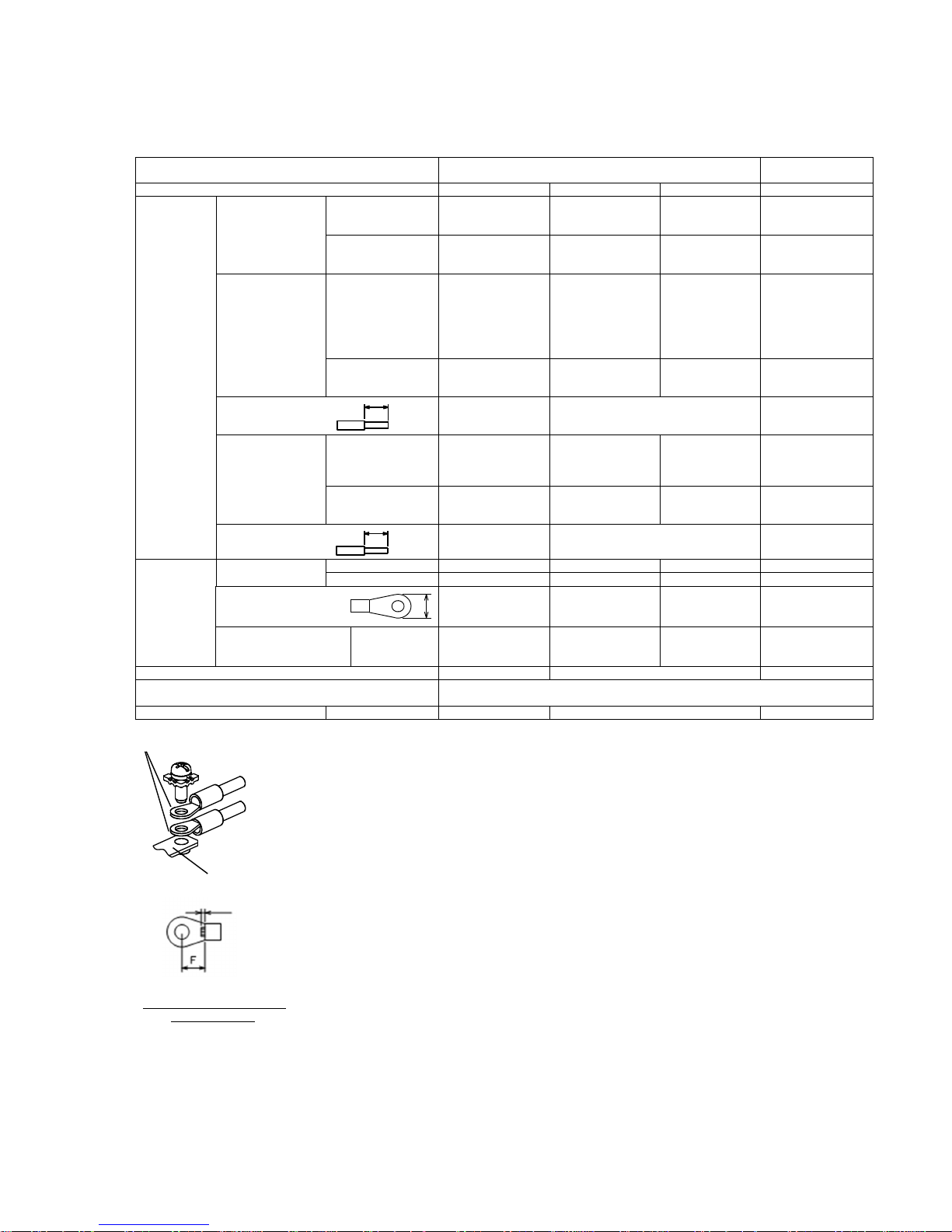

(3)-1 When using as a separate mounting type

• When TK26 and TK26Q are used under the following ratings as a separate mounting type (TK26H

or TK26QH), the thermal overload relay tends to remain in a non-operation state compared with the

case when used as a magnetic starter. In such a case, correct the dial set current as shown in the

following table.

Type Rating Correction value

TK26H 16-22A Set to a value 5% lower than the dial set

value.

TK26H 20-26A Set to a value 10% lower than the dial

set value.

TK26QH 12-18A Set to a value 10% lower than the dial

set value.

(4) Operating indicator (Figure 8.4)

When the thermal overload relay operates, the white trip indicator in the operating indicator window will be

hidden.

(The white trip indicator will not be hidden when tripped in the automatic reset state.)

(5) Sequence checking (Figure 8.4)

Press the white trip indicator in the direction shown by an arrow to perform sequence checking.

(6) Resetting method (Figure 8.4)

When the thermal overload relay operates, first remove the cause of an error such as overload and then press

the reset bar. Press the reset bar until it comes to a stop.

(Resetting will not be possible unless the thermal overload relay is sufficiently cooled down.)

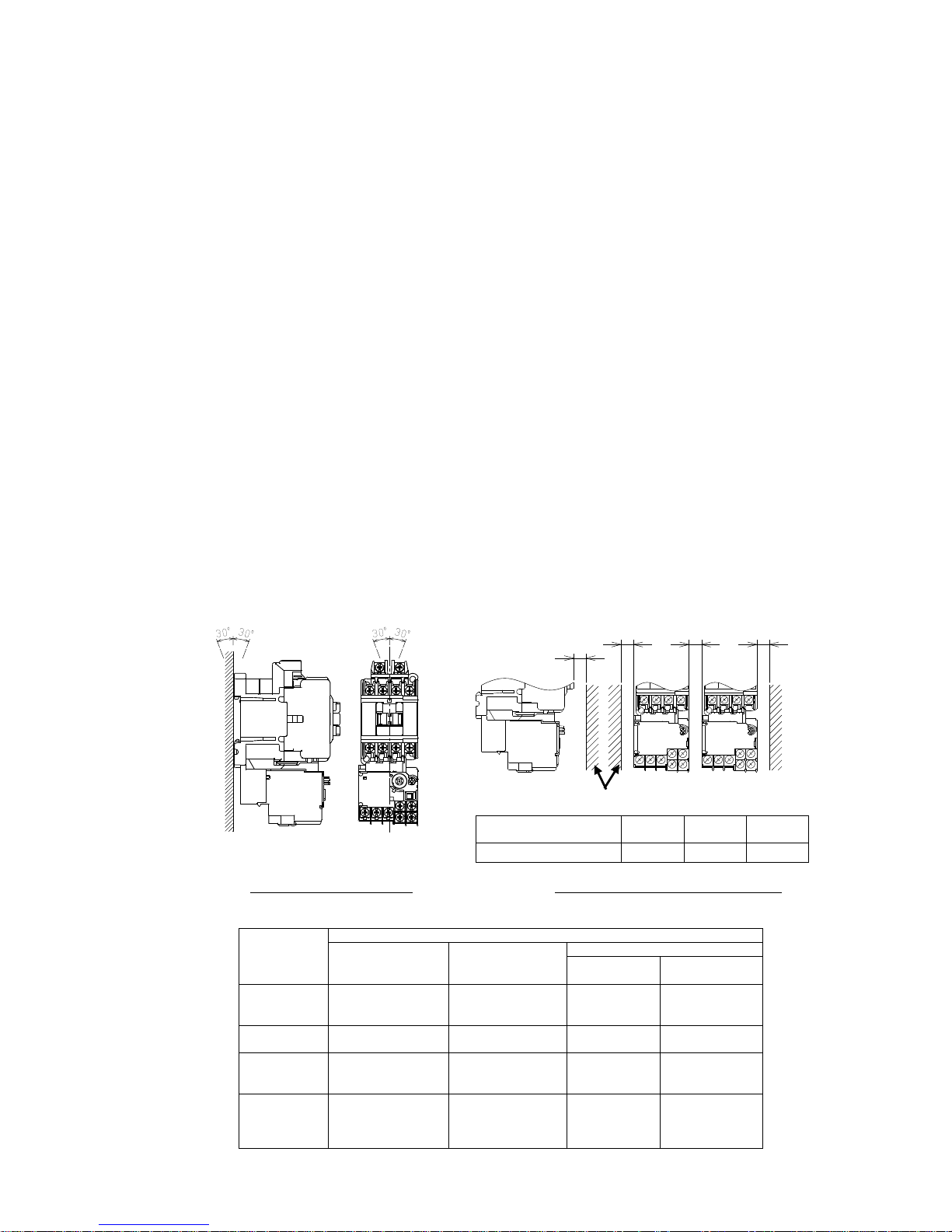

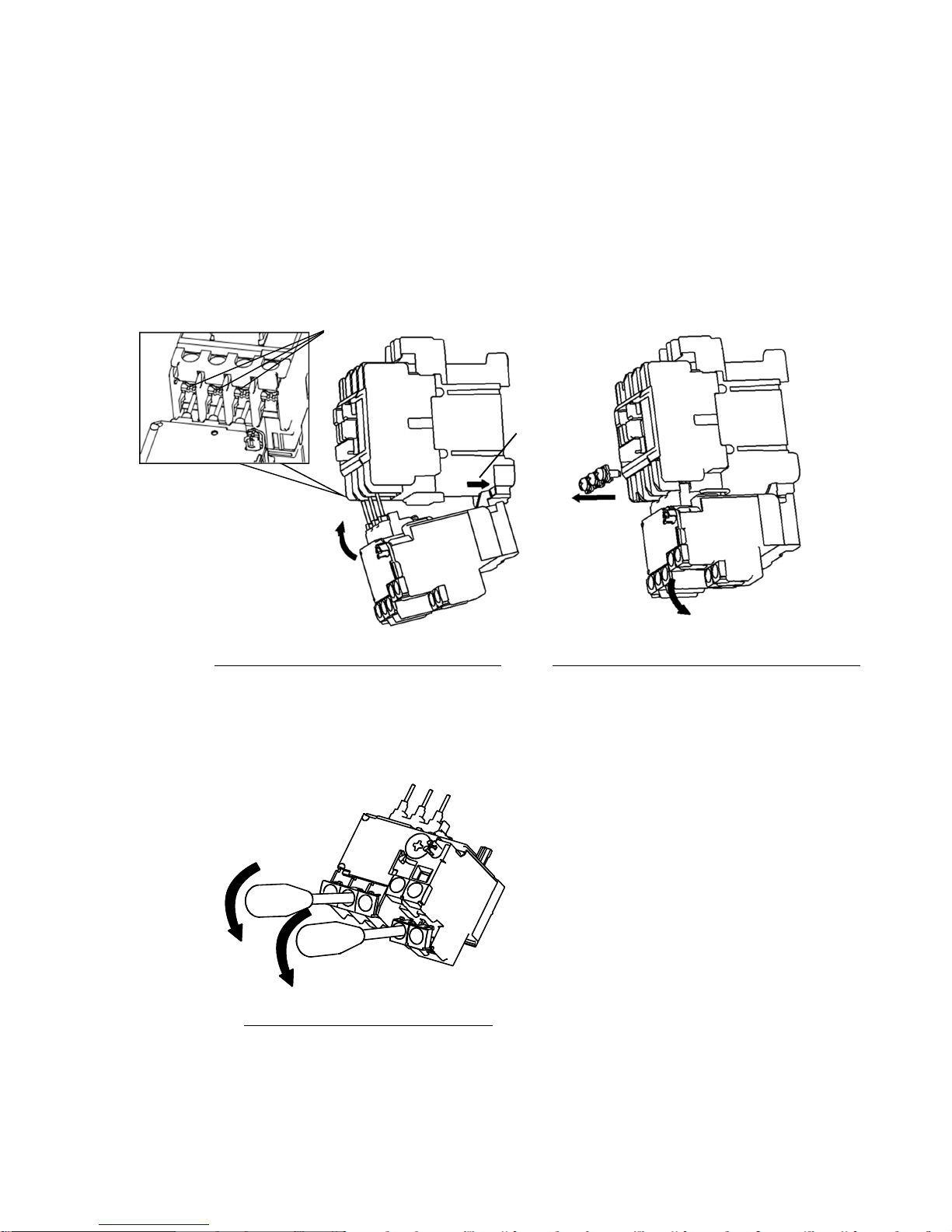

(7) Changing from manual reset to automatic reset (Figure 8.5)

Change from the manual reset to the automatic reset according to the following procedure.

Or, change from the automatic reset to the manual reset according to the reverse procedure.

(a) Open the front cover.

(b) Using a screwdriver or a similar tool, press the reset bar and turn it clockwise by 90 degrees.

(c) Confirm that the reset bar is held pushed in.

(d) Close the front cover.

Note) Attention must be paid to the fact that, in case of a two-wire control circuit, the motor is automatically

started when the thermal overload relay is automatically reset.

Figure 8.4 Current Setting, Operating Indicator, Sequence Checking, and

Resetting Figure 8.5 Changing to Automatic

Reset

リセット棒

調整ダイヤル

動作表示窓

▼マーク

リセット状態 トリップ状態

トリップ表示:白

(説明のため黒色で表記)

シーケンスチェック

④

②

③

①

リセット棒

A: Automatic reset (Automatic)

M: Manual reset (Manual)

A