REPAIR AND ADJUSTMENT

3.5/28 mm LENS ST801

1.

III. REPAIR AND ADJUSTMENT TEISFEHFfF

II. REPAIR AND ADJUSTMENT

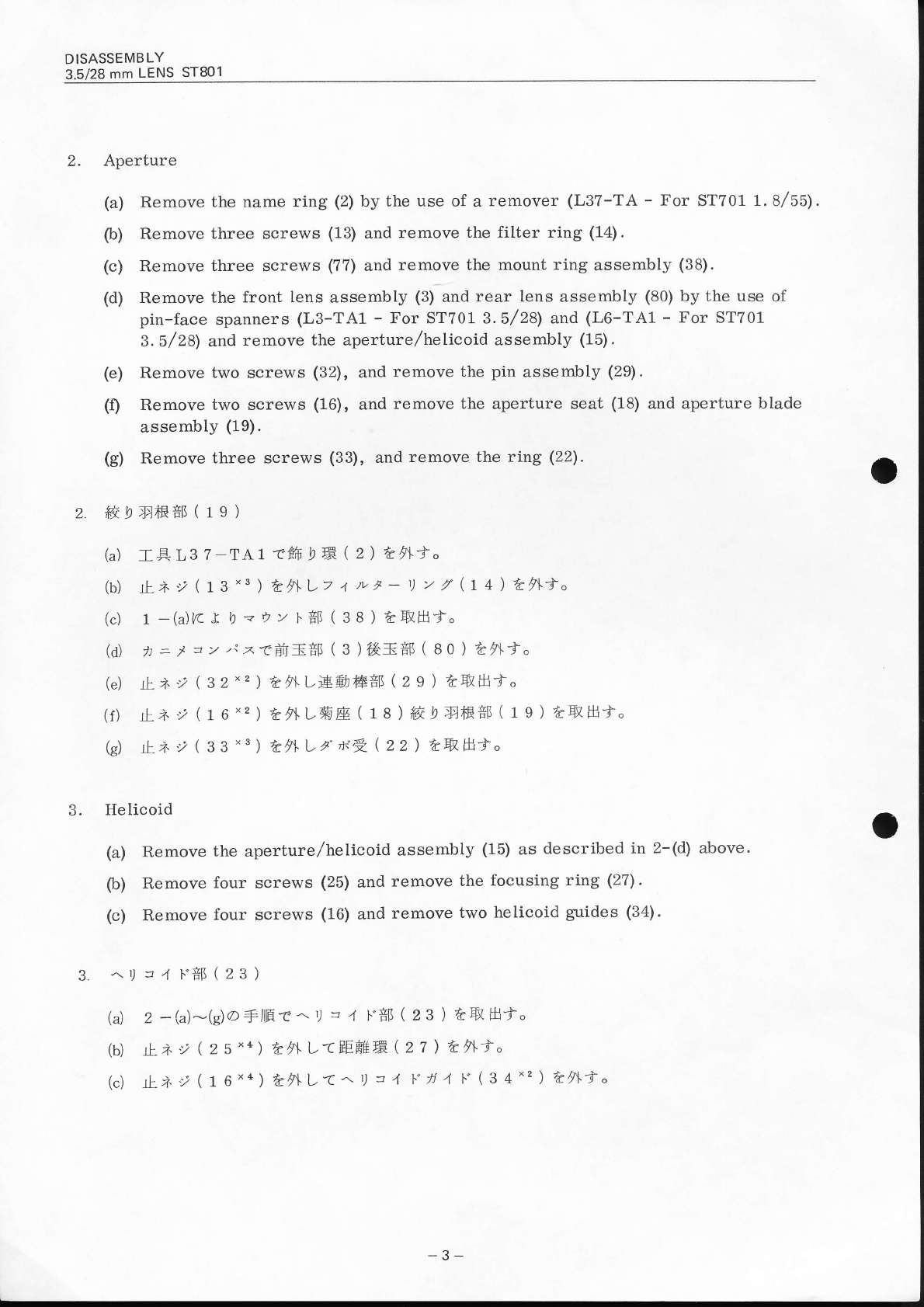

Focusing

(a) Remove the name ring (2) by the use of a pin-face spanner (L37-TA1 - For ST701

1.8/551

(b) Remove three screws (1'3) and remove the filter ring (14).

(c) Select a camera body having correct flangeback, and set shutter speed to I'B'r by

the use of a cable release.

Mount the lens on the camera bodY.

place a base plate (KL35A-AOGA1-) on the base of a collimator, and install the

camera on the base Plate.

(d) Loosen four screws (25) and watching focus in the collimator, properly turn the

male helicoid (28) to adjust flangeback.

(e) Retighten the four screws (25) and lock the screws with screw locking agent.

CAUTION: Be careful not to put the screw locking agent to the thread on the

helicoid (28).

(0 Reinstall. the filter ring (1-4) with three screws (13) and lock these screws with

screw locking agent.

(g) Reinstall the name ring (2) by the use of a pin-face spanner (L37-TA1 - For

sr?01 1,. B/55).

Ibw-åBW.*fiE

t y | -iffiM.

(a) rF-L3 7 -rA1 "effi 9W ( 2)kt\J"

(n) rL^t (13,')b^l-z.r )v2- \ / r" (t+) äryHf.

G) 7, v9,i v tafr'Cvtbh / rrr:f 4 [affiEfrkw.b2tr]bo Laffi'Z'J-)r ] t'Ff 't4FlJ

Iåv t) - Åv 4 + -blfr-ffi\-<, 'v+ 11 4 -7' C- l" * B" l[c(å- ( ' å"

6.trc=, / - raäffi.aE-Hsffi. (KL35A-AOGA1) äEå fi t 7k+v l'f å"

(d vyÅt^ 4 -oc y lif_nftrt\b, it (25)*4 fuz*v>'ct ffi^ tJ :r 4 l'. (28) ä18

l-'C z, :z')'\ > 2 k=6HM.-f b"

4t (25)"n kffik\4ttd' å rE[rc^tu'> 2-f b"

--. U = 4 l.';?{ -tVc^ ) p v t ?_ftAår'&feiIHf ba L"

7 4 )v, - t) v / (14) hit (13)*3 'citrJ:k5-f b" l')a t t Ifrffia'Lo

ffi bW (2) kIF-L 3 7-T Ar t{frffi1-{ + tilt-r"

u.

1.

(e)

(f)

G)