INTRODUCTION..............................................1

TESTING AND MAINTENANCE......................2

1. COMPONENT

Component ................................................. 4

Optional Accessories .................................. 5

2. EQUIPMENT

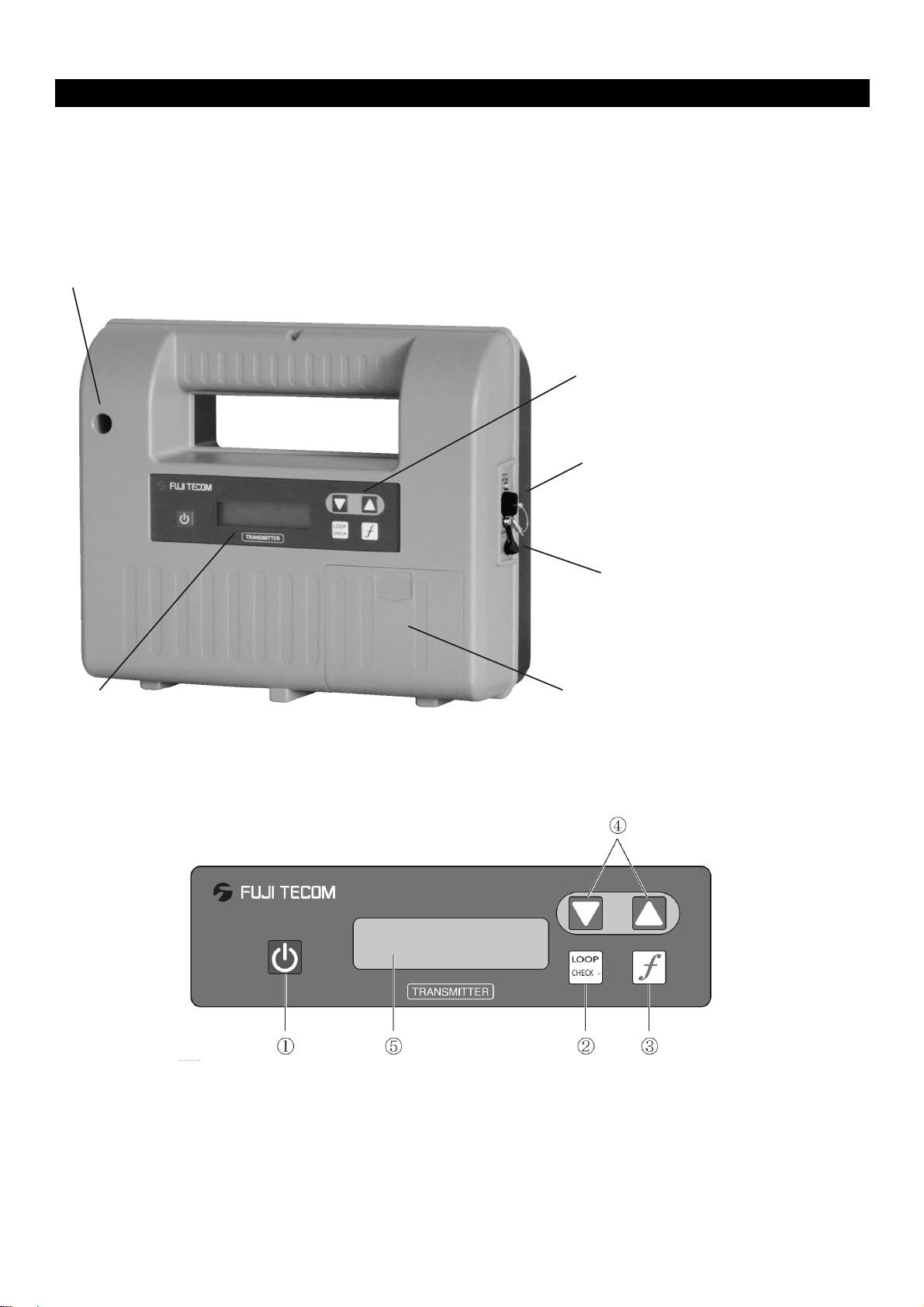

2-1 Transmitter

2-1-1 Main Unit ................................................ 6

2-1-2 Operation Panel ...................................... 6

2-1-3 Display Screen ........................................ 7

2-1-4 Replacement of Battery............................ 8

2-2 Receiver

2-2-1 Main Unit ................................................ 9

2-2-2 Operation Panel ...................................... 9

2-2-3 Display Screen ...................................... 10

2-2-4 Replacement of Battery ..........................13

3. PRINCIPLE AND USAGE

3-1 Principle of Operation .......................... 14

3-2 Proper use of Direct & Induction Mode ..... 15

3-3 Proper use of Frequency ..................... 16

3-4 How to cancel Auto Power OFF .......... 17

4. INSTALLATION OF TRANSMITTER

4-1 Direct Mode

4-1-1 Transmitter Main Unit ........................... 18

4-1-2 Installation in Loop Mode (option use).... 20

4-1-3 Detection by External Coil (option use) .. 21

4-2 Induction Mode.......................................... 22

5. OPERATION OF RECEIVER

5-1 Measurement mode & Operational procedure

5-1-1 Measurement Mode .............................. 23

5-1-2 Operational procedure of receiver.......... 23

5-2 Display screen & Measuring method of Receiver

5-2-1 Maximum & Bar & Sonde Mode............. 24

5-2-2 Pipe Axis Display.................................... 26

5-2-3 Continuous Depth Measurement............ 27

5-2-4 Pull up Measurement ............................ 28

Bluetooth Depth & Data Collection................ 29

5-2-5 Transverse Depth Measurement ............ 30

5-2-6 Detection by Sonde ............................... 31

5-2-7 Radio Mode ........................................... 32

5-2-8 AC/CP Mode ......................................... 33

6. OPERATION IN EACH SITE SITUATION

6-1 Detection by Induction Mode

6-1-1 With 2 surveyor ........................................ 34

6-1-2 With 1 surveyor ........................................ 36

6-2 Depth and current of close parallel pipes...... 37

6-3 Detection of parallel pipes in close proximity. 38

6-4 Measuring depth near end or bend of pipeline40

6-5 Confirmation of burial depth of pipeline......... 40

6-6 Detection of Elbow’s, T’s and bends in pipe.. 41

6-7 Detection of branch pipes.............................. 42

6-8 Crash barrier and curbstones are nearby...... 43

6-9 Congested pipes............................................ 44

6-10 Near electric power substation .................... 45

6-11 Near buildings ............................................ 45

6-12 Intersection ................................................ 46

6-13 Rail track side ............................................ 46

6-14 Subway passing under buried pipe.............. 47

6-15 Plumbing in factory .................................... 47

6-16 Reinforcement bars in pavement ............... 47

7. TROUBLESHOOTING ............................. 48

8. MESSAGES DISPLAY ON LCD.............. 49

9. DETECTION PERFORMANCE ............. 50

10. SPECIFICATIONS .................................... 51

11. WARRANTY ............................................... 53