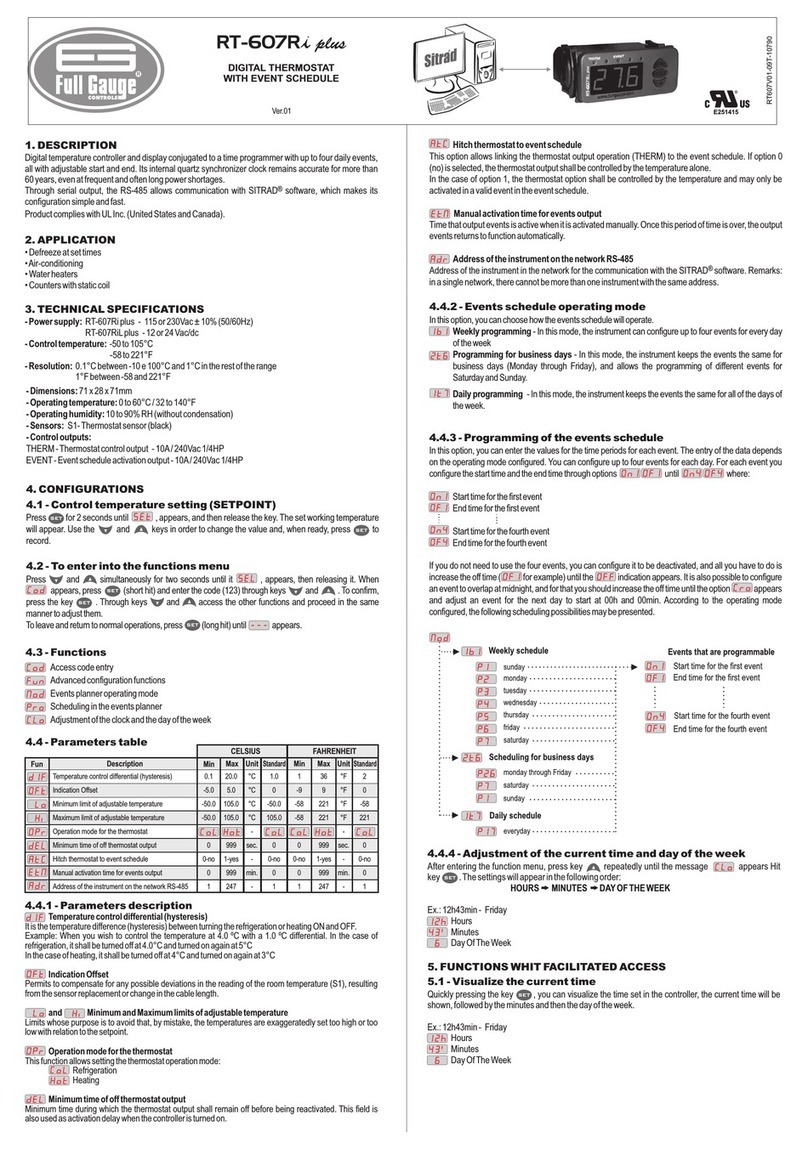

8.3.8. Event schedule programming

This option allows entering the values of the time intervals for each event. Data input depends on the

configured operation mode. Up to eight events may be configured for each day. The start time and end

time of each event is set using options[,OnI]to [,On8][Off8], where:

[,On1] - Start time of the 1st event.

[OFF1] - End time of the 1st event.

.

.

.

[,On8] - Start time of the 8th event.

[OFF8] - End time of the 8th event.

NOTE: To program the event schedule outside the facilitated menu, it is necessary to enter the access

code 123. From the menu, press the key ; (quick touck) until you teach the [Prog] menu, skip steps a

and b and then press / (quick touch).

a)Press<and>(quick touch) simultaneously, the option[Code], will be displayed to request the

access code.

b)Press/and enter the access code 123 using the <or>key,confirming with/.The

option[Code]will appear again.

c)Browse the menu using the<or>key until the option[Prog]appears, and then press /. The

following programming options may be displayed depending on the operation mode:

[IbI,]- Weekly Programming

[mode]

[,,p1]- Sunday

[,,p2]- Monday

[,,p3]- Tuesday

[,,p4]- Wednesday

[,,p5]- Thursday

[,,p6]- Friday

[,,p7]- Saturday

[2t6,]- Weekdays Programming

[,p26]- Monday to Friday

[,,p7]- Saturday

[,,p1]- Sunday

[It7,]- Daily Programming

[,p17]- Every day

Events programmable by day

[,0n1]- Start time of the

1st event

[0ff1]- End time of the

1st event

[,0n8]- Start time of the

8th event

[0ff8]- End time of the

8th event

.

.

.

If it is not necessary to use all the eight events then they may be configured in the disabled mode by

increasing the switch off time ([Off1] for instance) until [Off,]is displayed. It is also possible to

configure an event to cross midnight by incrementing the switch off time until the option [Cro,] is

displayed and adjusting an event for the following day starting at 12:00 AM.

d)The time configured for the chosen event will be displayed. Use the<or>key to change the time

and press / again to return to the event programming menu.

e)To leave the event programming menu and return to the home screen, press/until the message

[----]is displayed.

Temperature control differential (hysteresis)

Sensor indication offset

Minimum setpoint allowed to the end user

Maximum setpoint allowed to the end user

Operation mode

Minimum thermostat output off time

Link the thermostat to the event schedule

Event schedule link mode

Time for manual activation of the event output

Preferred measurement view

Recirculation - Scan time

Interval between scans

Maximum time the thermostat output remains on

without reaching the setpoint

Thermostat output off time in state of alarm for not

reaching the setpoint

Digital input operation mode

Digital filter intensity applied to the sensor

Function lock mode

Time for functions lock

Control functions shutdown

Address of the instrument in the RS-485 network

[,f01]

[,f02]

[,f03]

[,f04]

[,f05]

[,f06]

[,f07]

[,f08]

[,f09]

[,f10]

[,f11]

[,f12]

[,f13]

[,f14]

[,f15]

[,f16]

[,f17]

[,f18]

[,f19]

[,f20]

Description

Fun Min Max Unit

CELSIUS FAHRENHEIT

Min Max Unit

StandardStandard

0.1

-5.1(off)

-50

-50

0(cool.)

0(no)

no

0

0(no)

temp.

0(no)

0(no)

0(no)

1

0(off)

0(no)

0

15

0(no)

1

8.5. Parameters table

20.0

5.0

200

200

1(heat.)

999

yes

7

999

all

999

999

999

999

2

9

2

60

4

247

°C

°C

°C

°C

-

sec.

-

-

min.

-

min.

min.

min.

min.

-

-

-

sec.

-

-

1.0

0.0

-50.0

105.0

1(heat.)

0(no)

yes

0

120

temp.

0(no)

0(no)

0(no)

1

0(off)

0(no)

0

15

0(no)

1

°F

°F

°F

°F

-

sec.

-

-

min.

-

min.

min.

min.

min.

-

-

-

sec.

-

-

1

-10(off)

-58

-58

0(cool.)

0(no)

no

0

0(no)

temp.

0(no)

0(no)

0(no)

1

0(off)

0(no)

0

15

0(no)

1

36

9

392

392

1(heat.)

999

yes

7

999

all

999

999

999

999

2

9

2

60

4

247

2

0

-58

221

1(heat.)

0(no)

yes

0

120

temp.

0(no)

0(no)

0(no)

1

0(off)

0(no)

0

15

0(no)

1

F01- Temperature control differential (Hysteresis):

It is the difference in temperature (hysteresis) between TURNING ON and OFF the cooling (or heating).

Example: One wants to control the temperature at 4.0 °C with a differential of 1.0 °C. Therefore, the

cooling is switched off at 4.0 °C and switched back on at 5.0 °C (4.0 + 1.0), in the heating mode the

output is switched off at 4° C and is switched on again at 3° (4.0 - 1.0), as per the charts below:

8.5.1. Description of parameters

Temperature [°C]

Cooling

Setpoint

Setpoint + Hysteresis

Time [S]

Relay Off

Relay On

4°C

5°C

Temperature [°C]

Heating

Setpoint

Setpoint - Hysteresis

Time [S]

3°C

4°C

Relay Off

Relay On

F02 - Sensor indication offset:

It allows compensating possible deviations in the temperature reading caused by the replacement of the

sensor or changes in the cable length. The temperature sensor can be switched off by adjusting this

function to the minimum value until the message[,OFF]is displayed. Under these conditions the

thermostat is disabled and the THERM output changes to the same state as the EVENT output.

F03 - Minimum setpoint allowed to the end user:

Avoids regulation of excessively low setpoint temperatures by mistake.

F04 - Maximum setpoint allowed to the end user:

Avoids regulation of excessively high setpoint temperatures by mistake.

F05 - Operation mode:

Allows selecting the controller operation mode.

[,,,0]- Refrigeration

[,,,1]- Heating

F06 - Minimum thermostat output off time:

It is the minimum time the thermostat output will remain off, i.e. the length of time between the last stop

and the next start up. It is used to relieve the discharge pressure and increase the service life of

compressor. This time is also used as an activation delay when the controller is switched on. This

function can be switched off by setting it at the minimum value 0 [No,,].

F07 - Link the thermostat to the event schedule:

This option allows linking the operation of the thermostat output to the event schedule. If the option 0

(no) is selected, the thermostat output will be controlled by the temperature only. In the case of option 1,

the thermostat output will be controlled by the temperature and will only be activated with a valid event in

the schedule.

F08- Event Schedule link mode:

This function allows the user to define whether the thermostat will work together with the event output or

not. Case the thermostat is linked to the event calendar (F07 = On), this function will inform which events

(times) the THERM and EVENT outputs will work. Otherwise, only EVENT events will be selected.

[,,,0] THERM linked to events 1,2,3,4,5,6,7 and 8.

EVENT linked to events 1,2,3,4,5,6,7 and 8.

[,,,1] THERM linked to event 1.

EVENT linked to events 2,3,4,5,6,7 and 8.

[,,,2] THERM linked to events 1,2.

EVENT linked to events 3,4,5,6,7e 8.

[,,,3] THERM linked to events 1,2,3.

EVENT linked to events 4,5,6,7e and 8.

[,,,4] THERM linked to events 1,2,3,4.

EVENT linked to events 5,6,7e 8.

[,,,5] THERM linked to events 1,2,3,4,5.

EVENT linked to events 6,7 and 8.

[,,,6] THERM linked to events 1,2,3,4,5,6.

EVENT linked to events 7 and 8.

[,,,7] THERM linked to events 1,2,3,4,5,6,7.

EVENT linked to event 8.

NOTE: By default, the event schedule leaves the factory with the same events for every day of the week,

and the schedules defined as fallows:

[,On1] - Opening time of 1st event: 04:00

[Off1] - End time of 1st event: 08:00

[,On2] - Start time of the 2nd event: 17:00

[Off2] - End time of the 2nd event: 21:00

Other events are disabled.

NOTE 2: When the event schedule operation mode is changed all events return to the default.

8.3.9. Unit Selection

To select the units that the system will use to operate, press<and>simultaneously as the

temperature is being displayed, enter the option[Code] using the access code [,231]and then

press/. Then select the desired unit[,=C,]or[,=F,]using the<>keys, and press/to

confirm.

NOTE: Whenever the units are changed, the functions’ configuration assumes the factory default, so

they need to be configured again.

8.4. Advanced operations

8.4.1. Adjustment of the parameters

Parameter adjustment can be done through the quick access menu (;) by accessing the option

[Func], or by pressing <and>simultaneously when the temperature/time is being displayed.

The following options will be displayed:

[Code]Entry to the access code

[Func]Change the advanced parameters

[Mode]Event schedule operation mode

[ProG]Event schedule programming

[ClO,]Adjustment or visualization of the date and time

8.4.2. Access code

To change the parameters or adjust the clock, select the[Code]option by pressing / (quick touch)

and entering the access code 123 (one hundred and twenty-three) using the<or>key, and confirm

with/.

Select the desired function using the<and>keys. Press/ (quick touch) after selecting the function

to view its value. Use<or>to change the value and press/when ready to save the configured

value and return to the functions menu. To leave the menu and return to the normal operating mode

(temperature indication), hold down/ (long touch) until[----]appears.

Note: If the function lock is active, the controller will show the message [LOC,]in the display upon

pressing <or> and will not allow the adjustment of the parameters.

8.4.3. Event schedule operation mode

In the main menu (after entering the code 123) select the option [Mode] and then the desired function

using the<or>keys. The factory default for the controller is [It7,]- Daily Programming.

To leave the menu and return to the normal operating mode (temperature indication), hold

down/(long touch) until [----]appears.

[IbI,]- Weekly Programming: In this mode the instrument can configure up to 8 events for each day

of the week.

[2t6,]- Weekdays Programming: In this mode, the instrument keeps the same events from

weekdays (Monday to Friday) and allows you to program different events for Saturday and Sunday.

[It7,]- Daily Programming: In this mode, the instrument keeps the same events for all days of the

week.