Proper sensor type is also a very important factor to obtain precise

measurements. The sensor must have the correct temperature range to

meet the process requirements. In special processes the sensor might

need to have different requirements such as leak-proof, anti-vibration,

Standard thermocouple sensor limits of error are 4 degrees F

( 2 degrees C ) or 0.75% of sensed temperature plus drift caused by

improper protection or an over-temperature occurrence. This error is far

greater than controller error and cannot be corrected at the sensor except

by proper selection and replacement.

In order to connect the probe input device to the recorder, you must first

gain access to the microprocessor PC board that is mounted to the back

of the chart plate.

CAUTION! DO NOT TOUCH the terminals of the transformer

while the recorder is connected to the main AC power supply. To avoid the

risk of possible electric shock, unplug or disconnect the recorder from

the main power supply before attempting to open the recorder. If the

recorder is installed with the battery back-up option, disconnect the 9 Volt

battery to avoid damaging the recorder and draining the battery.

Your recorder will have a hinged chart plate held in place by two (2)

screws located on the right hand side of the chart plate. Remove these

two screws and open the hinged chart plate. If you are not sure how to

access the back of the chart plate, please contact FUTURE DESIGN

CONTROLS before continuing.

Proper sensor installation can eliminate many problems in a control system.

The probe should be placed so that it can detect any temperature change

with minimal thermal lag. In a process that requires fairly constant heat

output, the probe should be placed close to the heater. In a process where

the heat demand is variable, the probe should be close to the work area.

Some experiments with probe location are often required to find this

optimum position.

2-6 Sensor Installation

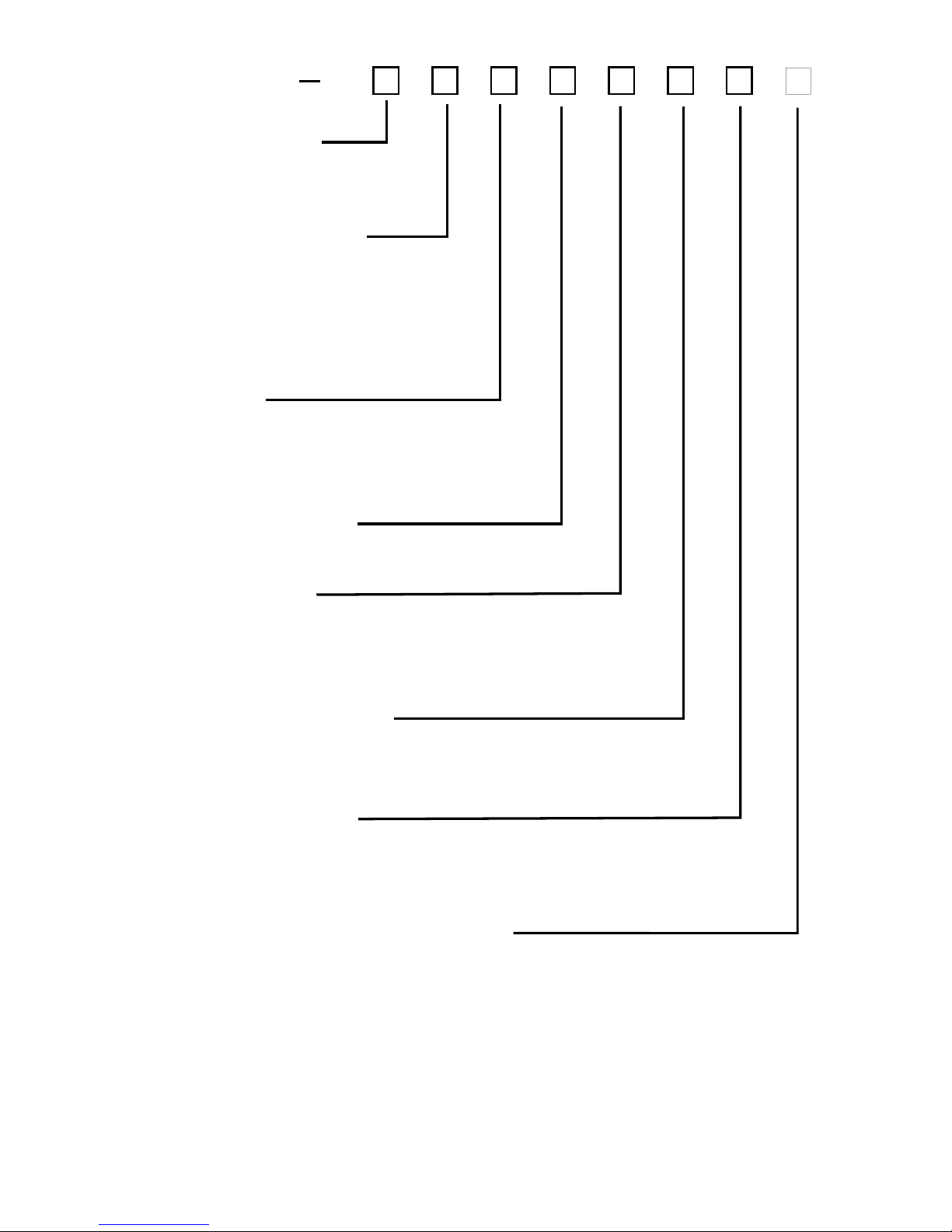

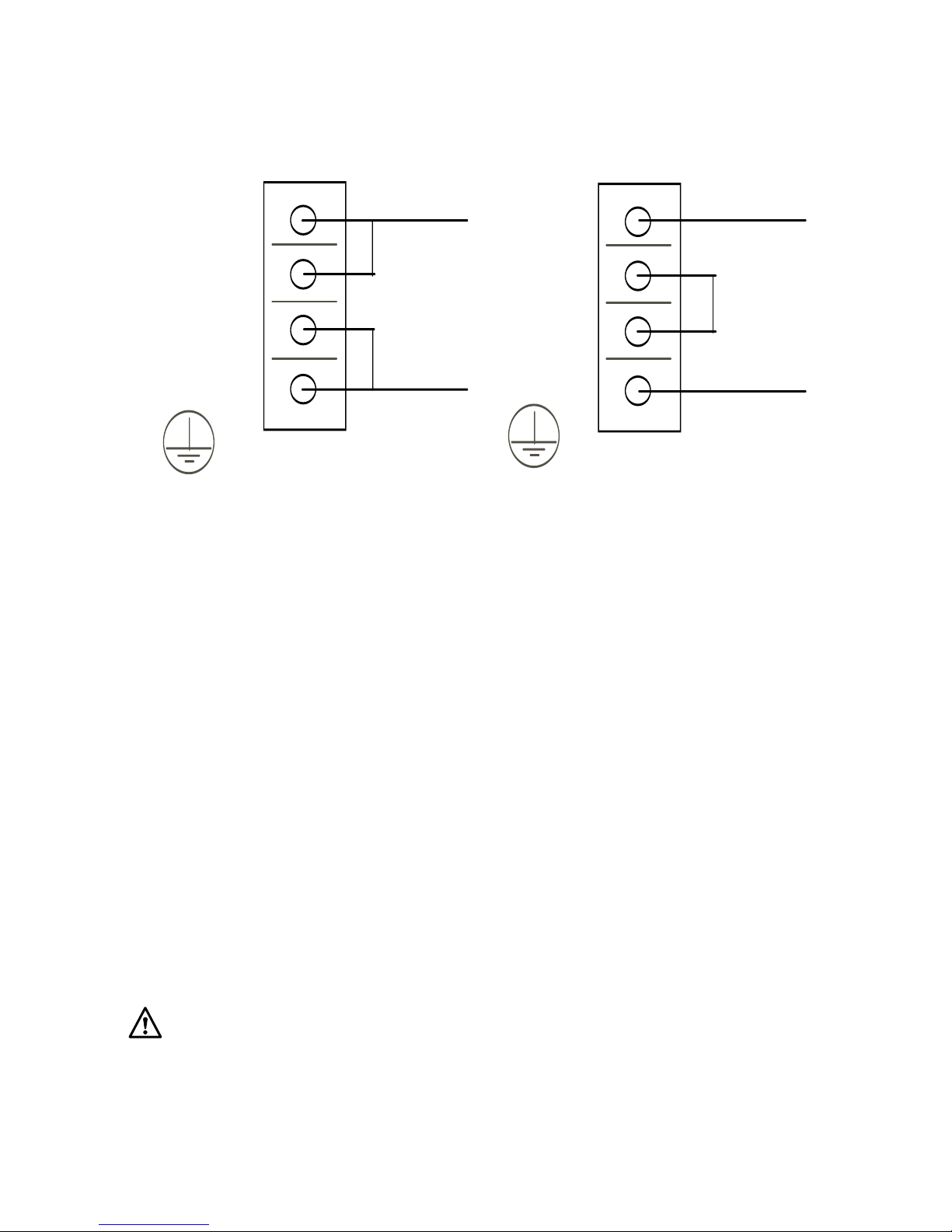

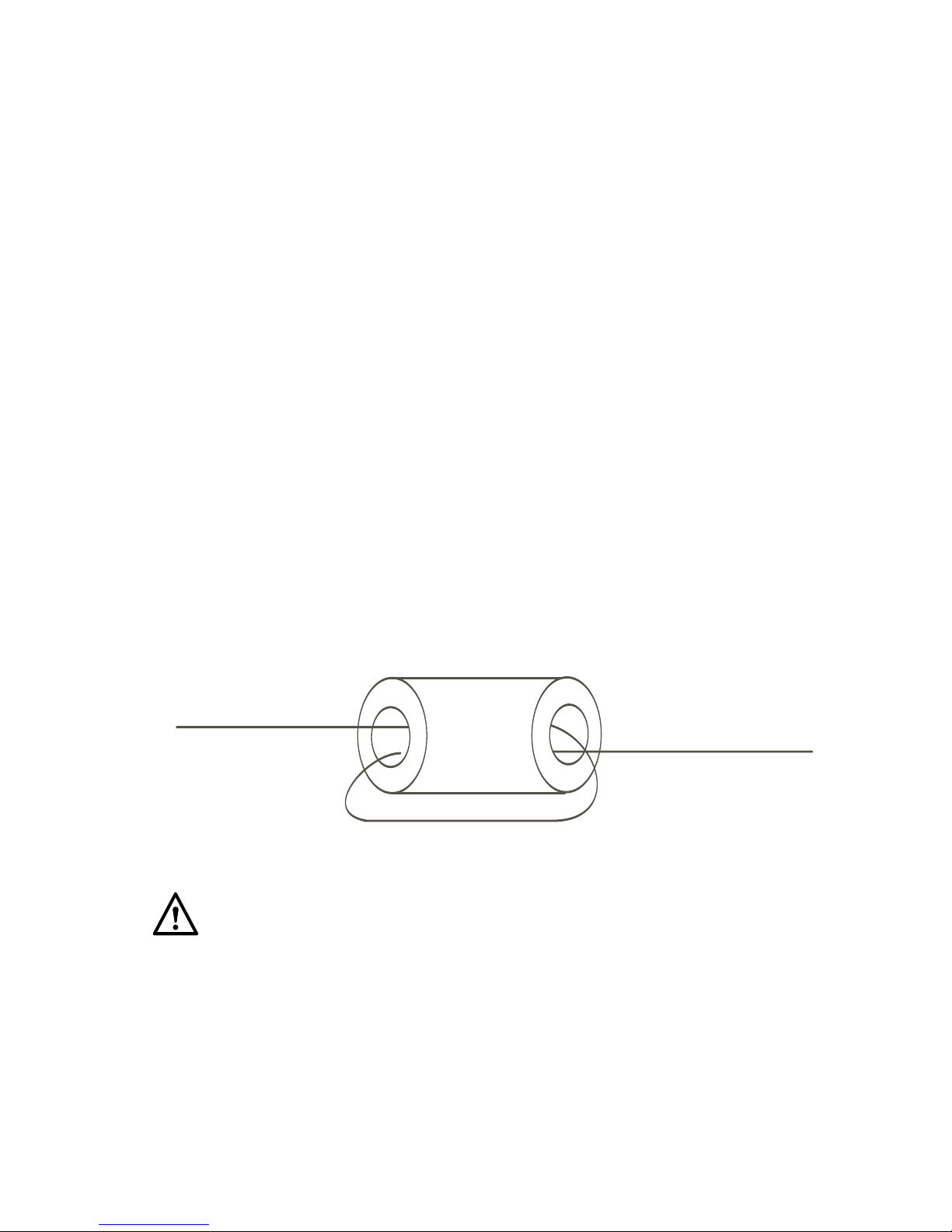

A ferrite bead has been included to provide additional protection for

electrical “Noise” sensor signal wires can pick up. See drawing below for

correct installation of this device. Figure 2.3

Ungrounded thermocouples recommended on 2 pen units.

Sensor wire in Sensor wire out

to Input terminal

Ferrite Bead

Figure 2.3

10