Via Centallo, 136 - Centallo (CN) – ITALY

Tel 0171.718005 Fax 0171.71800

TABLE OF CONTENT

1 INTRODUCTION---------------------------------------------------------------- 4

2 GENERAL INFORMATION------------------------------------------------------ 5

.1 INFORMATION ON THE MANUAL----------------------------------------------------------------------5

. INFORMATION ON THE MACHINE--------------------------------------------------------------------- 6

2.2.1 Identification of the machine------------------------------------------------------------------------------------------ 7

2.2.2 Conforming use--------------------------------------------------------------------------------------------------------- 8

2.2.3 Adverse field conditions------------------------------------------------------------------------------------------------ 9

.3 FEATURES OF THE MACHINE----------------------------------------------------------------------- 10

2.3.1.Identification of the models-------------------------------------------------------------------------------------------- 10

2.3.2 Main com onents ------------------------------------------------------------------------------------------------------ 11

.4OPERATION AND TECHNICAL FEATURES---------------------------------------------------------1

.5 NOISE LEVEL------------------------------------------------------------------------------------ 15

.6PACKING, TRANSPORT AND LIFTING------------------------------------------------------------------- 16

.7STORAGE---------------------------------------------------------------------------------------- 18

.8DISPOSAL AND SCRAPPING-------------------------------------------------------------------------- 18

3.SAFETY RULES------------------------------------------------------------------- 19

3.1SAFETY AND ACCIDENT PREVENTION RULES ------------------------------------------------------------- 0

ATTENTION!.................................................................................................................. 23

ATTENTION!.................................................................................................................. 23

3. SAFETY SIGNS WITH WARNING SYMBOLS------------------------------------------------ 5

3.3LOCATION OF SAFETY SIGNS ON THE MACHINE---------------------------------------------------------- 8

4 INSTALLATION AND OPERATION-------------------------------------------- 29

4.1 SAFETY RULES FOR ATTACHING TO THE TRACTOR ------------------------------------------------------- 9

4. CHECK LIFTING AND STABLE OPERATION OF THE TRACTOR------------------------------------------------- 30

4.3TRANSPORT ON PUBLIC ROADS---------------------------------------------------------------------- 31

4.4 ATTACHING TO THE THREE POINT LINKAGE OF THE MACHINE --------------------------------------------- 34

4.4.1Assembly of the drive shaft--------------------------------------------------------------------------------------------- 36

Overrunning clutch drive shaft --------------------------------------------------------------------------------------------- 37

4.4.2 Hydraulic system------------------------------------------------------------------------------------------------------- 38

4.5ADJUSTEMENTS----------------------------------------------------------------------------------- 39

5OPERATING INSTRUCTIONS---------------------------------------------------- 41

5.1SAFETY RELEASE DEVICE--------------------------------------------------------------------------- 44

6MAINTENANCE------------------------------------------------------------------- 45

6.1LUBRICATION OF MECHANICAL COMPONENTS------------------------------------------------------------ 46

6. LUBRICATION--------------------------------------------------------------------------------47

6.2.1Lubrication of the centre gearbox------------------------------------------------------------------------------------- 47

6.2.2 Lubrication of overgear unit------------------------------------------------------------------------------------------ 48

6.2.3 Lubrication of conditioner reduction gearbox--------------------------------------------------------------------- 48

6.3KNIVES----------------------------------------------------------------------------------------- 49

6.4CURTAIN REPLACEMENT-------------------------------------------------------------------- 50

6.5FURTHER TROUBLESHOOTING-------------------------------------------------------------------------51

7GUARANTEE----------------------------------------------------------------------- 52

8SPARE PARTS--------------------------------------------------------------------- 54

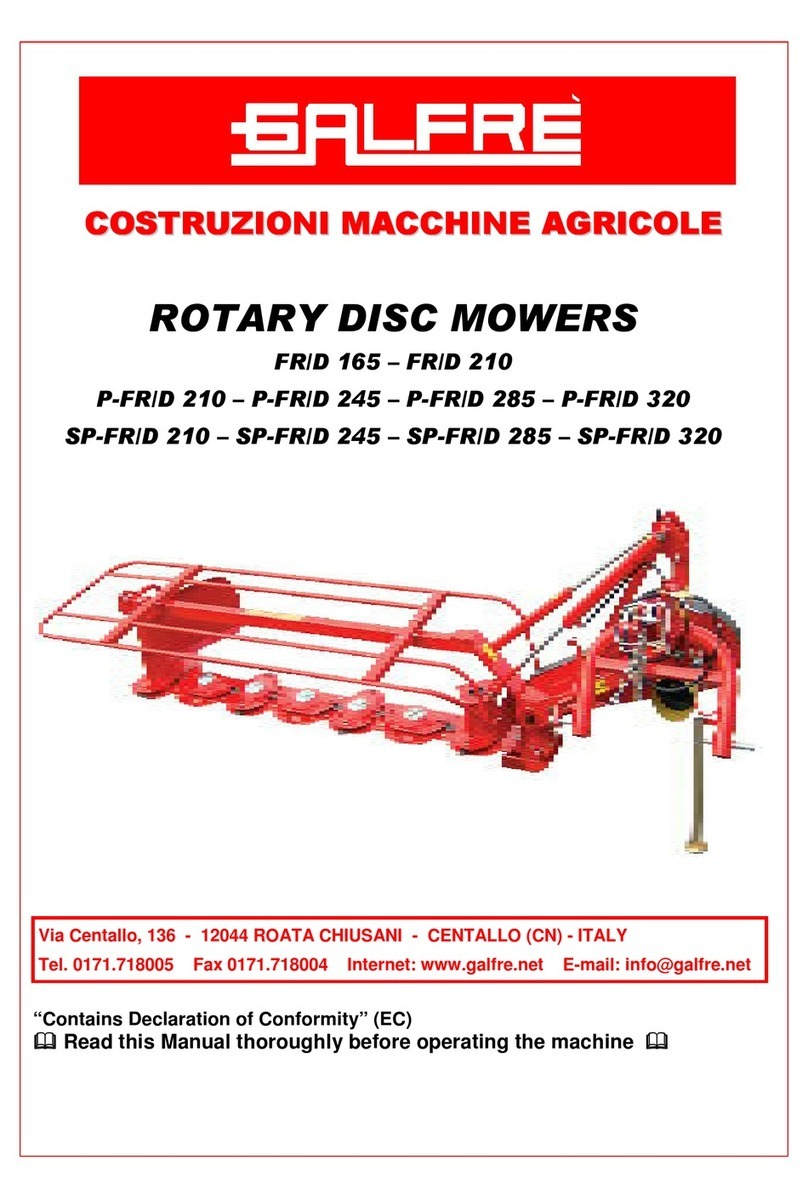

Operator’s and Maintenance Manual – Rotary Drum Mowers and Conditioners