5 Cod. 80000080c – 17.07.2018

GENERAL RECOMMENDATIONS

It is hardly necessary to pay attention to the following instructions and guidelines, as well as to the

pictograms and their meanings. The topics included in this section of the manual have been categorized

and grouped according the following criteria:

NOTIC : information for a correct and effective use of the equipment.

DANG R: topics related to potential risks for users and third persons.

WARNING: topics related to potential risks for things and/or for the equipment itself.

Placement of the cabinet

For unloading and handling of the counter by means of a forklift make reference to the handling lifting

points described in this manual. The use of forklifts is exclusively allowed to skilled and authorized

personnel who has been certified as “forklift operator”. During unloading, placement and installation of the

cabinets the use of proper protective equipment is required (e.g. protective gloves and eyeware).

The cabinet cannot be used in open spaces. Verify the environment conditions in which the unit is

going to be installed (temperature and relative humidity) and make sure they are not higher than those of

the climate class indicated in the identification plate (e.g. climate class 3, max. temp. 25°C, R.H. 60%).

Higher levels of temperature and or relative humidity can possibly cause a higher energy consumption and

poorer performances of the cabinet. Such possible conditions are therefore likely to cause a shortening of

the shelf-life and a rapid deterioration of the displayed products.

Avoid the exposure of the cabinet to direct sun ight, or a placement of the unit in proximity of hot

sources like cooking ovens, heating radiators, high-intensity lighting systems and any other possible heating

source.

It is hardly recommended to place the unit away from doors, windows, AC air-grills. In any case, it

must be avoided that air drafts with speed higher than 0.2 m/sec may hit the cabinet.

Cabinets with built-in condensing unit (plug-in): assure a frequent change of air in the environment in

which the cabinet is operating, also during closing time closing holidays of the P.o.S.

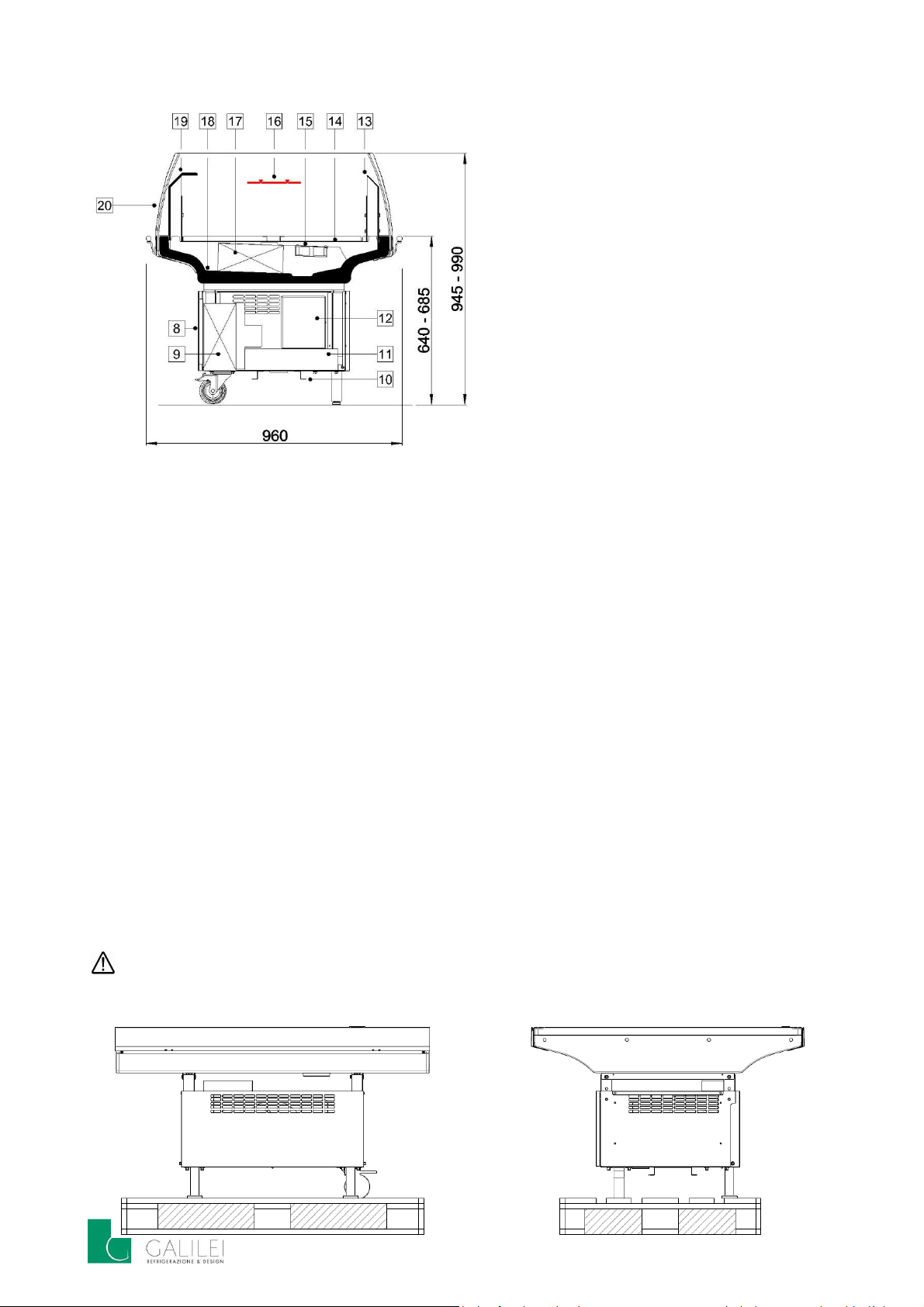

Cabinets with built-in condensing unit (plug-in): the basement of the cabinet has been engineered to

guarantee a proper ventilation of the condensing unit, it is therefore recommended not to obstruct the air-

intake gri s by p acing materia s, of whatever nature, a ong its externa perimeter.

Warning: insta ation of further covers or customized c adding systems of the basement is not a owed.

Cabinets with built-in condensing unit (plug-in): some plug-in units (e.g. promotional stand-alone

units) can be multiplexed side-by-side and or back-to-back, to form larger shop-around-islands. In this case

it is recommended to observe the instructions and the arrangement drawings included in this manual, and

not to exceed the indicated number of multiplexed units. The failure to observe these requirements lead to

a higher energy consumption and, as result of an insufficient ventilation, also to possible damages of the

condensing unit itself.

Cabinets with built-in condensing unit (plug-in): In case the cabinet is placed with its backside to a wall,

make sure to leave at least 5cm between the wall and the backside of the unit.

Once the cabinet is placed in the final point of installation, remove the packaging and the possible

protecting film. For remote counters, remove the handling bars (if present) fixed to the levelling feet.