ARTU20

5 INSTALLATION

WARNING: unit installation and start-up must be entrusted

to competent personnel and performed in a workmanlike

manner, in accordance with current regulations.

For each unit an (IL) switch should be mounted on the power

supply, with opening contacts at a distance of at least 3 mm

and a suitable protection fuse (F) .

WARNING: Install the unit, circuit breaker (IL) and/or any re-

mote controls in a place out of reach of persons who may be

taking a bath or shower.

WARNING: the EMC lters connected to frequency con-

verters (inverters) can create leakage currents toward

ground (in order to make the unit EMC compliant, by re-

ducing conducted emissions on power supply line). De-

pending on installation site, this can force the cut out of the

dierential safety switch. It is recommended to install a sepa-

rate dierential safety switch, only for the BLDC unit, with an

adjustable threshold for the cut out current.

WARNING: base unit must be protect by original packaging

to avoid demage at the worksite, before cabinet installation.

WARNING: keep the cabinet inside the original packaging

until the nally installation

When choosing an installation site, you should observe the fol-

lowing rules:

The air conditioning unit should not be placed immediately

under a socket

Do not install the unit in places where inammable gases or

powders are present

Do not expose the unit to sprays of water

Install the unit on walls able to withstand its weight. Keep a

clear space all around the unit to assure the proper function-

ing and accessibility for routine and extraordinary mainte-

nance (see gure 11.4Dimensionp.62)

store the unit in its packing container until you are ready to

install it

INSTALLATION REQUIREMENTS

The fan coils should be installed in a position where the room

can be cooled or heated evenly, on walls able to withstand their

weight.

It is advisable to install any accessories on the standard unit pri-

or to positioning the latter.

For installation and use of accessories, please refer to the relative

technical sheets.

Install any remote control panel in an easily accessible position

allowing the user to set the functions while ensuring an accurate

reading of the ambient temperature, if provided.

Avoid therefore:

positions directly exposed to sunlight;

positions exposed to direct currents of warm or cold air

placing obstacles that impede an accurate temperature

reading

The water connections are on the left side, viewing the unit

from the front.

Hydraulic connections on the opposite side are available on-

ly on order

The water connection pipes must pass through the slots pro-

vided on the rear panel of the unit (depending on the L or R

version, use the appropriate slot)

NOTE: the electrical wiring must always be positioned on the

opposite side of the plumbing connections.

Make the plumbing connections to the heat exchanger and,

where the cooling function is to be used, to the condensate

drainage outlet.

It is recommended to connect the installation intake to the up-

per part of the heat exchanger and the return to the bottom part

of it.

Bleed air from the exchanger by means of the air vent valves

(hexagonal wrench type 10) situated beside the plumbing con-

nections of the exchanger. See gure p.63Air vent.

To favour the drainage of condensate, the drain hose should be

inclined downward, at least 3 cm/m; make sure that no loops or

bends form along its path.

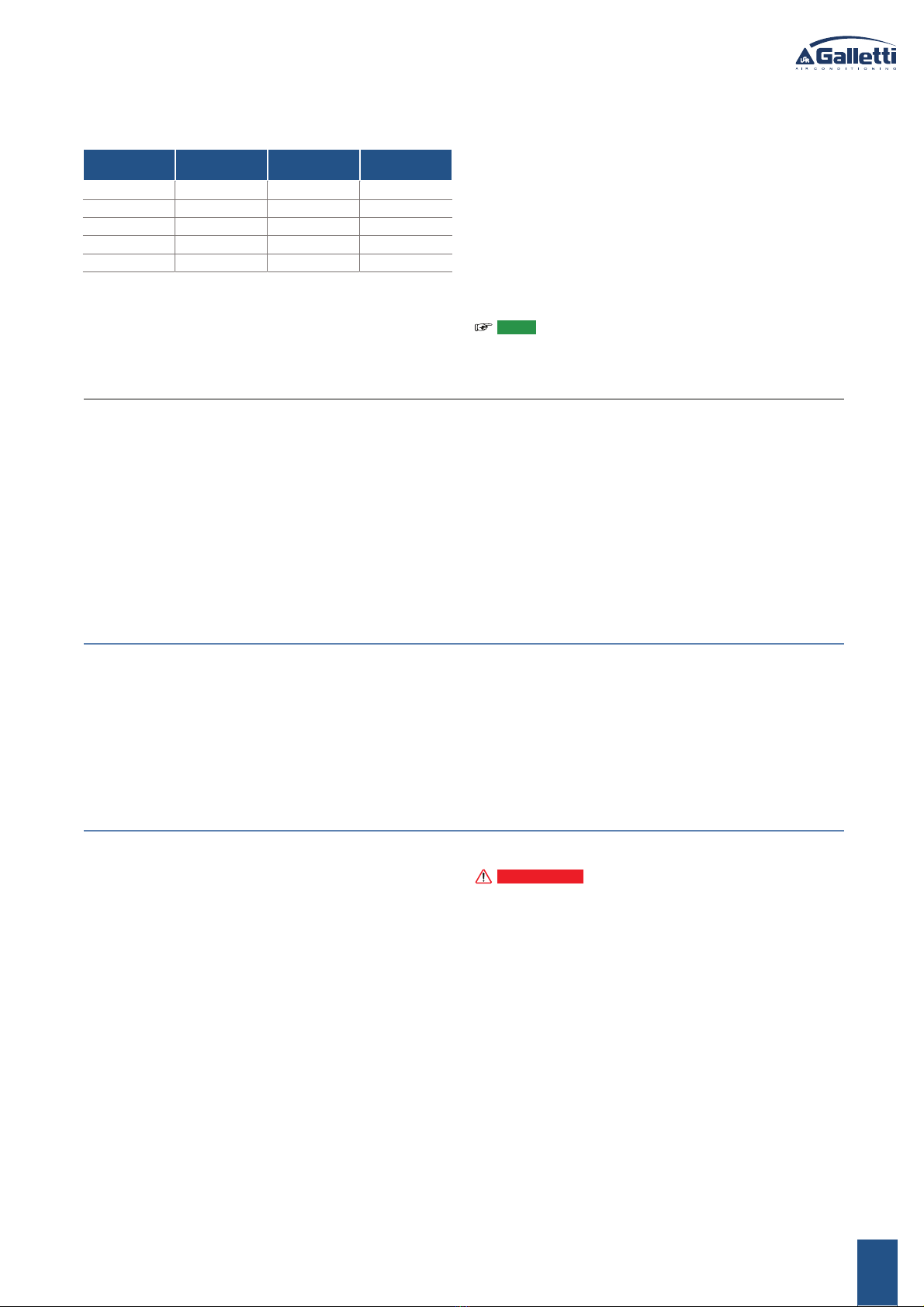

WARNING:

In normal operation, particularly with the fan at minimum

speed and ambient air with high relative humidity, conden-

sation may form on the air outlet and on some external parts

of the unit.

To avoid such issues while always remaining within the op-

erating limits envisaged for the unit, it is necessary to limit

the (average) temperature of the water inside the heat ex-

changer. In particular, the dierence between the air dew

point (TA,DP) and the average water temperature (TWM) must

NOT exceed 14 °C, according to the following relationship:

TW>TA,DP-14 °C

Example: in the case of ambient air at 25 ° C with 75% rel-

ative humidity, the dew point temperature is about 20 ° C

and therefore the average temperature of the water in the

battery must be greater then:

20-14 = 6 °C in order to avoid condensation on a fancoil

equipped with a valve.

20-12 = 8 °C If the valve kit accessory can not be installed.

Fan coil with valve

Air temperature dry bulb (°C)

Relative Humidity

%

21 23 25 27 29 31 33

405555555

505555568

6055557911

70556891113

80 5 6 8 10121416

90 6 8 10 12 14 16 18

Fan coil without valve

Air temperature dry bulb (°C)

Relative Humidity

%

21 23 25 27 29 31 33

406666666

5066666810

60666791113

70 6 6 8 10 11 13 15

80 6 8 10 12 12 16 18

90 8 101214141820

In the event the indoor unit is stopped for a prolonged peri-

od, with the fan stopped and circulation of cold water in the

heat exchanger, condensation may also form on the unit’s

exterior. In this case it is advisable to install the 3-way (or

2-way) valve accessory in order to stop the ow of water in

the coil when the fan is stopped.

During wintertime periods of quiescence, drain water from the