68

MANUAL - QUARTOO

1. Introduction

Congratulations on purchasing your

Gardipool swimming pool. Your pool is

manufactured from quality North-Euro-

pean pressure impregnated pinewood.

This treatment offers protection against

rotting and keeps the wood mould-free.

The top border is either in North-Euro-

pean pine or in exotic hardwood, which is

by nature very resistant.

Enclosed, you will find the instructions

for the do-it-yourself assembly of your

Gardipool.

It is advisable that you read the complete

instructions before you start with the

assembly of the pool.

Always follow all safety regulations.

Should you encounter any problems du-

ring the construction, please contact your

Gardipool sales representative, who will

assist you with help and advice.

Without supervision,

your child is in danger.

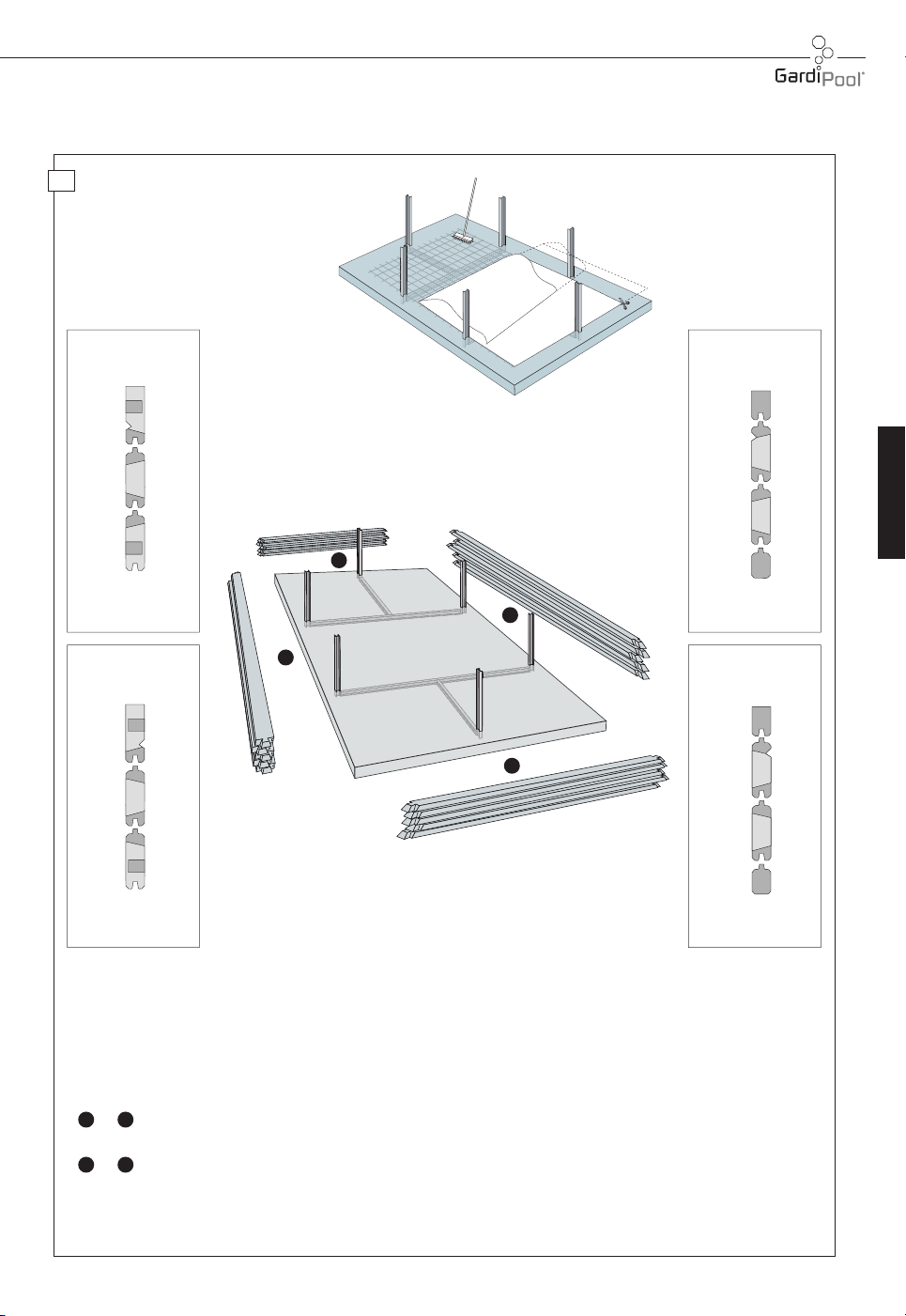

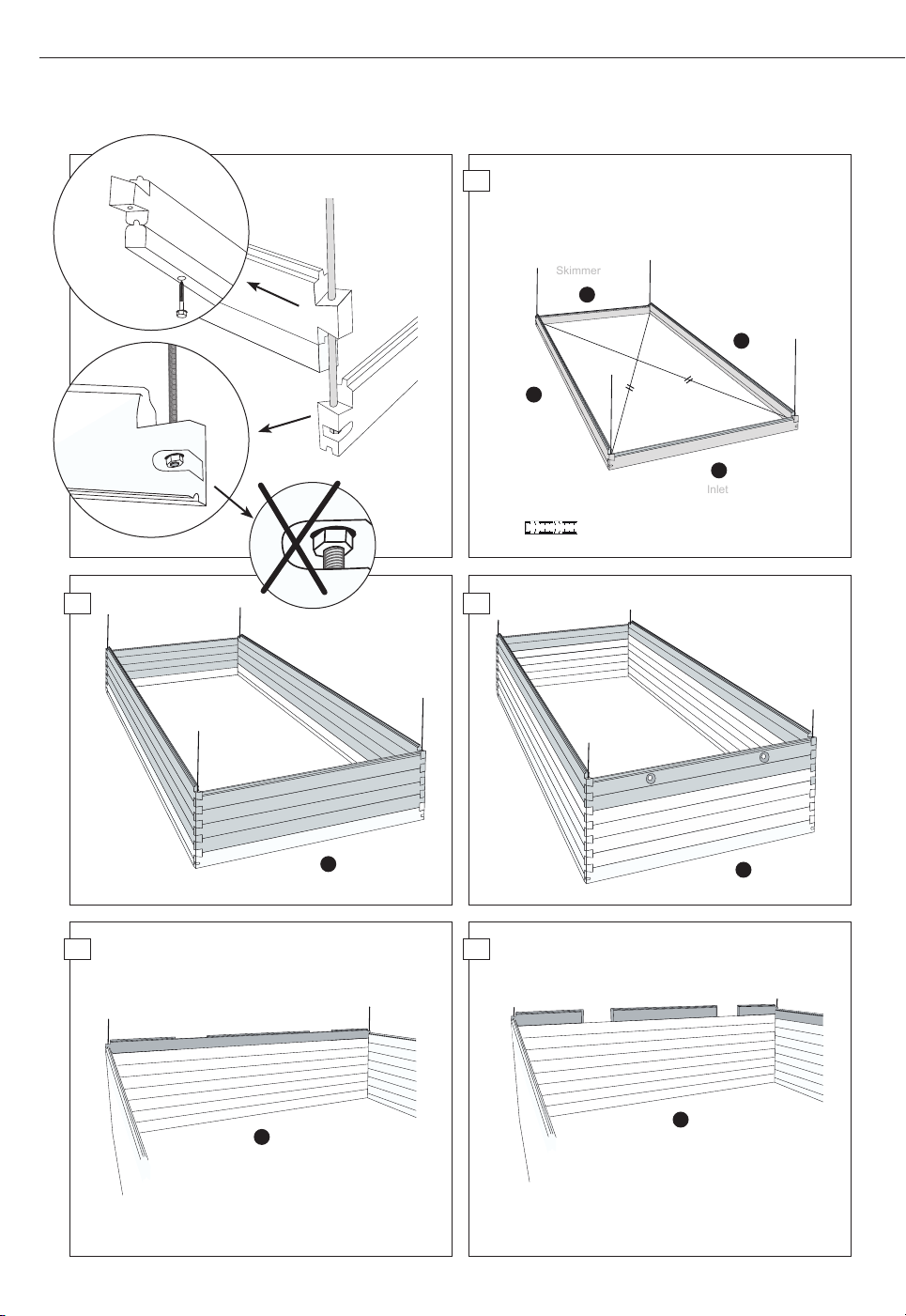

2. Assembly

2.1 Earth works

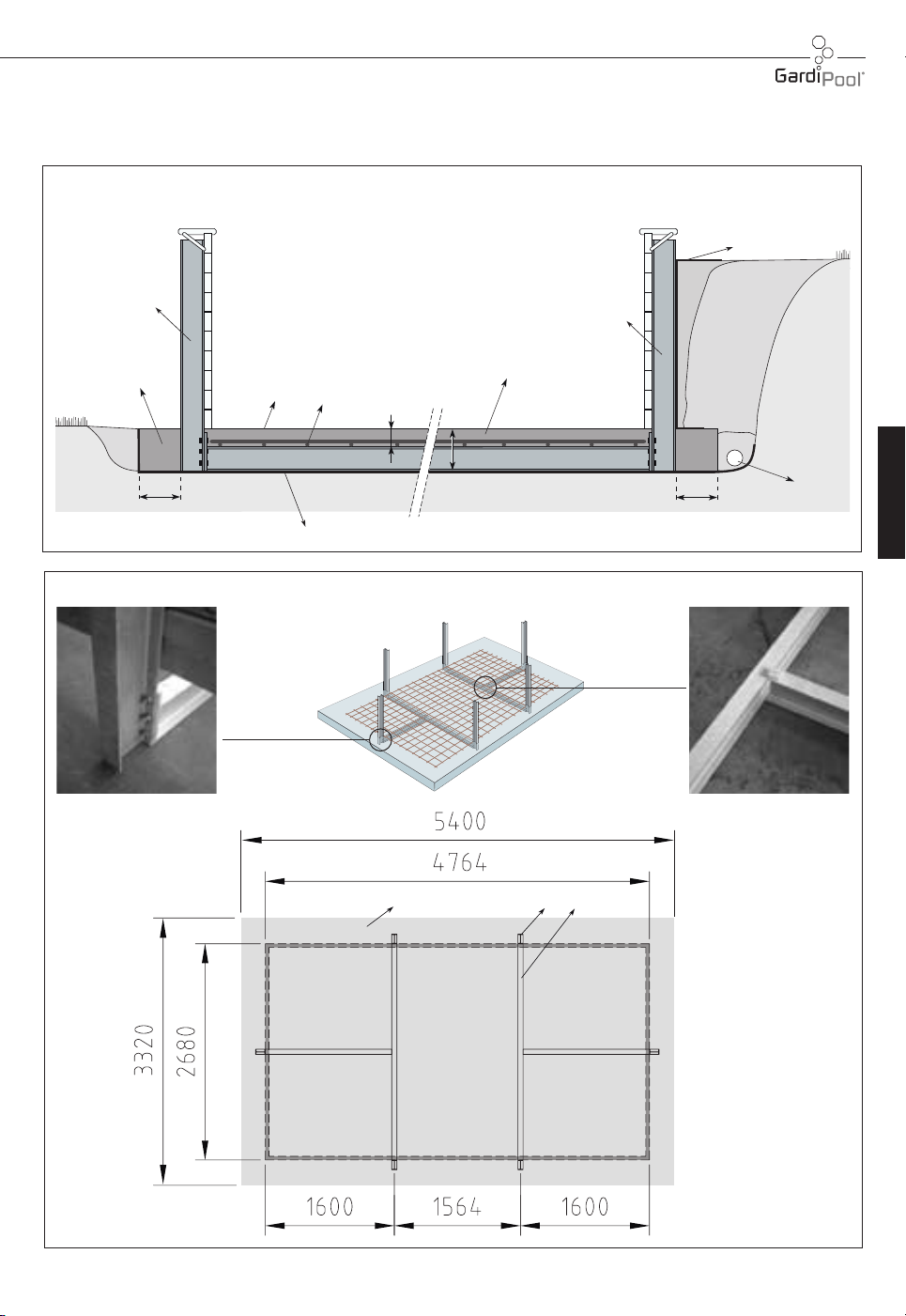

The pool should preferably be positioned

in a sunny place, away from any trees

whose leaves could fall into the pool.

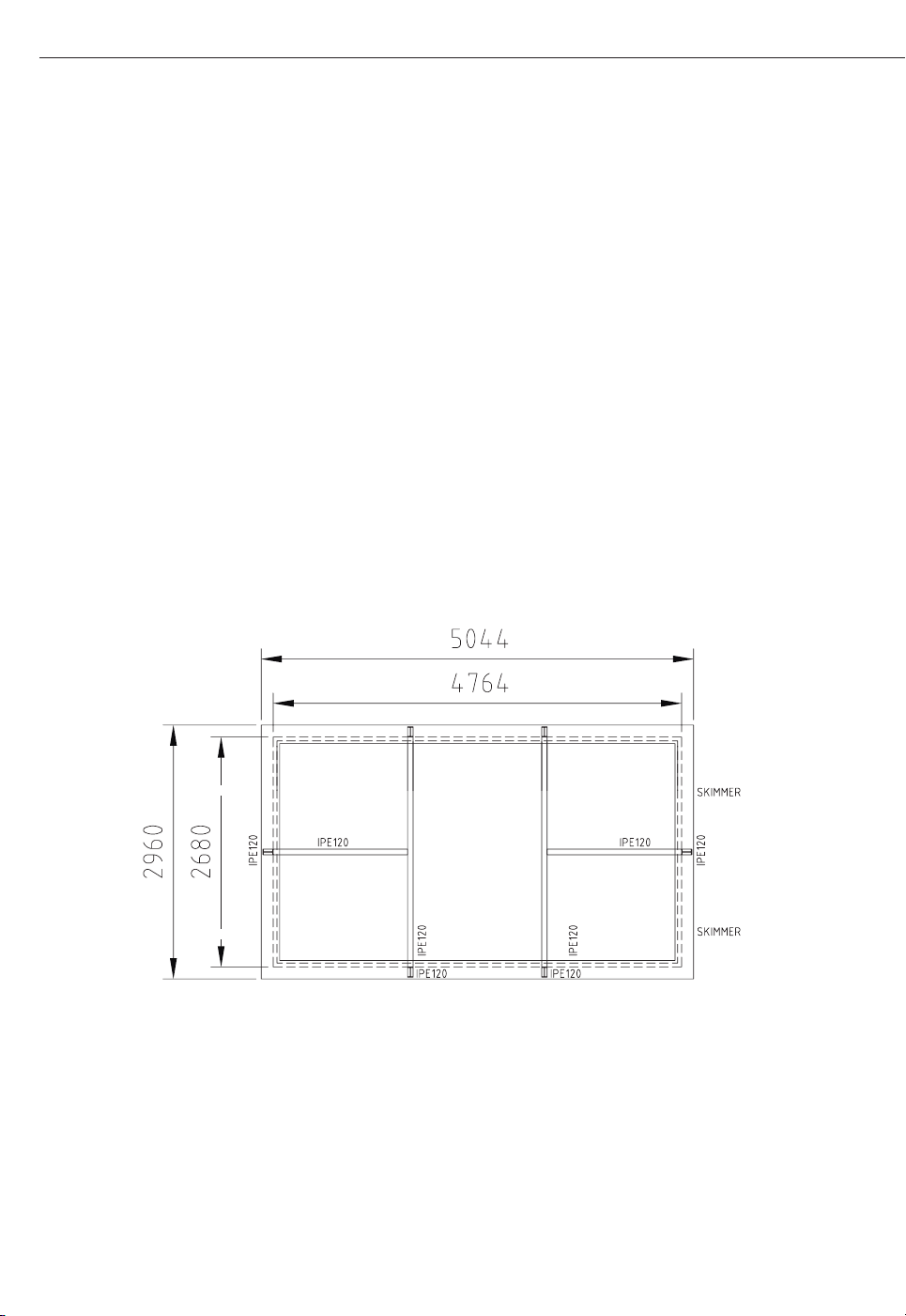

It is extremely important that your pool

be assembled on a stable foundation.

You need to construct a flat armed

uncracked concrete floor (C25/30) as

specified on the drawings herewith,

with integrated metal profiles and a

metal mesh 150x150x6x6 placed above

these metal profiles.

Apply a layer of plastic foil underneath

the concrete slab to obtain an optimal

drying.

In (half) sunken pools, allow an additional

border of ± 50 cm (20 in) around the

pool. In this case, you must cover the

underground wooden structure with a

protective felt layer to ensure that the

structure never touches the ground

directly. This forms the division between

the structure and the gravel with which

you filled the gap after the assembly of

the pool, to ensure adequate drainage

of the ground water and rainwater. You

must also ensure that the ground and

rain water around the pool is discharged

effectively by means of an adapted

drainage system.

Make sure that the ground or water

never touches the wooden structure

directly. Provide an adapted felt layer

around the pool as protection.

The finishing around the pool can be

chosen according to your personal taste:

wooden terrace, planks, paving stones,

tiles, or lawn (only a top layer of 10 cm

(4 inches).

Manual

CONTENT

1. Introduction

2. Assembly

2.1 Earth works

2.2 Wooden structure

2.2.1 General

2.2.2 Assembly

2.3 Interior finish

2.4 Technical installation

2.4.1 Parts

2.4.2 Monobloc

2.4.3 Connections

2.4.4 Functioning

2.4.5 Malfunctions

2.5 Finishing touches

3. Options

3.1 Summer tarpaulin

3.2 Winter tarpaulin

3.3 Technical housing

3.4 Electrical box

3.5 Lighting

3.6 Heating

3.7 Felt

3.8 Slide lock cover roller

4. Safety instructions

4.1 General

4.2 Technical installation

4.3 Electricity

5. Maintenance

5.1 Wooden structure

5.2 Water

5.3 Technical installation

5.4 Hibernation

6. Guarantee