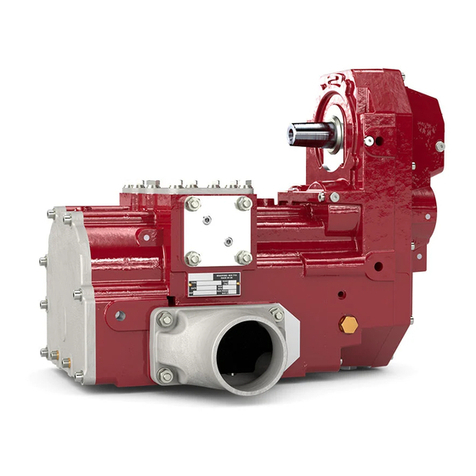

Compressor, Sectional View 10-3

Constant Speed Control System . . . . . . . . . . . . . . . . . . . . 4-8

Constant Speed (Duomatic) . . . . . . . . . . . . . . . . . . . . . . . 4-11

Control Piping ............. .... ................. 2-5

CONTROLS &INSTRUMENTS (SECTION 4) 4-1

Control System Automatic Start-Stop . . . . . . . . . . . . 4-9

Control System, Constant Speed... ............4-8

Control System Dual . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Control System Duomatic . . . . . . . . . . . . . . . . . . 4-11

Control Valve Oil Flow

(Duomatic Control Unit Only) . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Control Valve Thermal (Thermostatic Mixing) 5-3

Control Valve, Water Flow . . . . . . . . 5-5

Control Voltage ................... 4-1

COUPLING (SECTION 7) . . . . . . . . . . . 7-1

Daily Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Diagrams Wiring 4-2 thru 4-7

Differential Group Pressure ........................... 5-8

Differential\ Oil Cooler Oil Pressure

(Air-Cooled Radiatorj 5-8

Differential Oil Cooler Oil Pressure

(Water-Cooled Heat Exchanger 5-8

Differential\ Oil Cooler Temperature

(Air-Cooled Radiator 5-8

Differential!, Oil Cooler Temperature

(Water-Cooled Heat Exchanger 5-8

Differential Oil Cooler Water Pressure

(Water-Cooled Heat Exchanger) 5-8

Dimensions 10-10

Disassembly Instructions, ....... 10-1

Discharge Temperature Air &Oil 5-8

Discharge Pressure Valve Minimum 4-8

Discharge Service Line ................... ...... ..... 2-5

Drain Oil Reservoir ....................... ............ 2-2

Draining and Cleaning Oil System .5-2

Dual Control System .............. 4-10

Du,omatic Control System ..,..... 4-11

Dust Cup(Heavy-Duty Air filter) . . . . . . . . . . . . . . . . . . 6-1

Electrical ........................ 3-1

Electrical Wiring . . 4-9thru 4-12

Electrical Wiring Diagrams .4-2 thru 4-7

Electrical Wiring (Standard Units) 2-5

Element life, Filter (Heavy Duty). ..................... 6-2

Enclosure Acoustic ............................... 2-2, 3-1

Filling Oil Reservoir ... 5-3

Filter, Air ............................ 3-1, 6-1,8-1

Filter, Compressor Oil . . 5-3

Filter Element (Heavy Dutyj ........................... 6-1

Filter Element Life (Heavy Duty) . . . . . . . . . . . . . . . . . . . . . . 6-2

Filter, Heavy Duty Air ................... 6-1

FILTERS, AI R(SECTION6) . . . . . . . . . . . . . . . . . . . . . . . 6-1

Fits . .............. 1o-1o

Flow Control Valve Oil

(Duomatic Control Unit Only) ........................ 5-7

Flow Diagram —Air-Oil Systems. . . . . . . . . . . . . . . . . . . . . 5-1

Foundation . . 2-2

Gauge, Air Pressure .............. 4-8

Gauge, Oil Level ......................... ....... .... 5-2

Gauge, Oil Temperature ........... . . 4-8

Gauges& Instruments ................................. 4-8

General (Controls) .......................... .......... 4-1

GENERAL INFORMATION (SECTION 1) ... 1-1

General installation . . . . . . . . . . . . . . . . . . . 2-1

Grease Recommendations ........ 2-6

Grounding .................................... 2-6

Heat Exchanger, Water-Cooled Compressor

Oil Cooler ........... .. ................... . .. 5-4

Heat Exchanger Water Flow Control Valve 5-5

Heat Exchanger Water Shutoff Valve 5-5

Heavy Duty Air Filter ............. 6-1

High Air Temperature Shutdown 4-1

High Temperature Operation ............. . .......... 5-2

Hourmeter ........,..,.. 4-8

INFORMATION, GENERAL (SECTION 1) 1-1

Inlet Line, ...................... .... ..... ......... . 2-5

inlet Pressure Oil ................ 5-8

Inlet Screen &Tube (Heavy Duty Air Filter) 6-2

Inlet Temperature, Compressor Oil . . . . . . . . . . . . . . . . . . 5-8

Inlet Valve (Constant Speed Control 4-9

inlet Valve (Duomatic Control 4-12

Installation for Cold Weather Operation . . . . . . . . . . . . . 2-2

INSTALLATION (SECTION2) 2-1

INSTRUMENTS &CONTROLS

(sEcTloN 4) ........................................ 4-1

Instruments &Gauges ............ 4-8

Lifting Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Light test, Operating ............. 3-1

Location (installation) ............. 2-1

Lubricantq Compressor 5-1

Lubricants, Synthetic ........... .... ..... .... ..... 5-1

Lubrications, Cooling &Sealing 1-1

Lubrication Motor..,.. 2-6, 8-1

LUBRICATION, OIL COOLER, OIL FILTER &

SEPARATOR (SECTION5) .5-1

Maintenance of Air Filters ....... 6-1, 6-2

MAINTENANCE SCHEDULE (SECTION 8) 8-1

Minimum Discharge Pressure Valve 4-8

Mixing Valve, Thermostatic (Thermal Control) 5-3

Mode, Operating ................... ............... ... 3-1

Moisture Separator Trap .. ....................... ... 3-1

Motor &Compressor Alignment . . . 10-9

Motor Lubrication ......................... ....... 2-6, 8-1

Motor Protection Devices 4-1

Oil& Air Discharge Temperature. .5-8

OiF-Air Systems Flow Diagram ......................... 5-1

Oil Capacities .................................... . 5-2

Oil Change Interval .................................... 5-2

oil, Compressor .................................... 3-1

Oil Cooler, Compressor –Radiator Type 5-3

Oil Cooler, Water-Cooled Heat Exchanger 5-4

Oil Cooler Oil Pressure Differential

(Air-Cooled Radiatorj ................................ 5-8

Oil Cooler Oil Pressure Differential

(Water-Cooled Heat Exchanger . . 5-8

Oil Cooler Temperature Differential

(Air-Cooled radiator ................................ 5-8

Oil Cooler Temperature Differential

(Water-Cooled Heat Exchanger) 5-8

Oil Cooler Water Pressure Differential

(Water-Cooled Heat Exchanger) . . 5-8

Oil Filter, Compressor . . . . . 5-3

Oil Flow Control Valve

(Duomatic Control Unit Only) ........................ 5-7

Oil Inlet Pressure ...................................... 5-8

Oil Inlet Temperature Compressor .................... 5-8

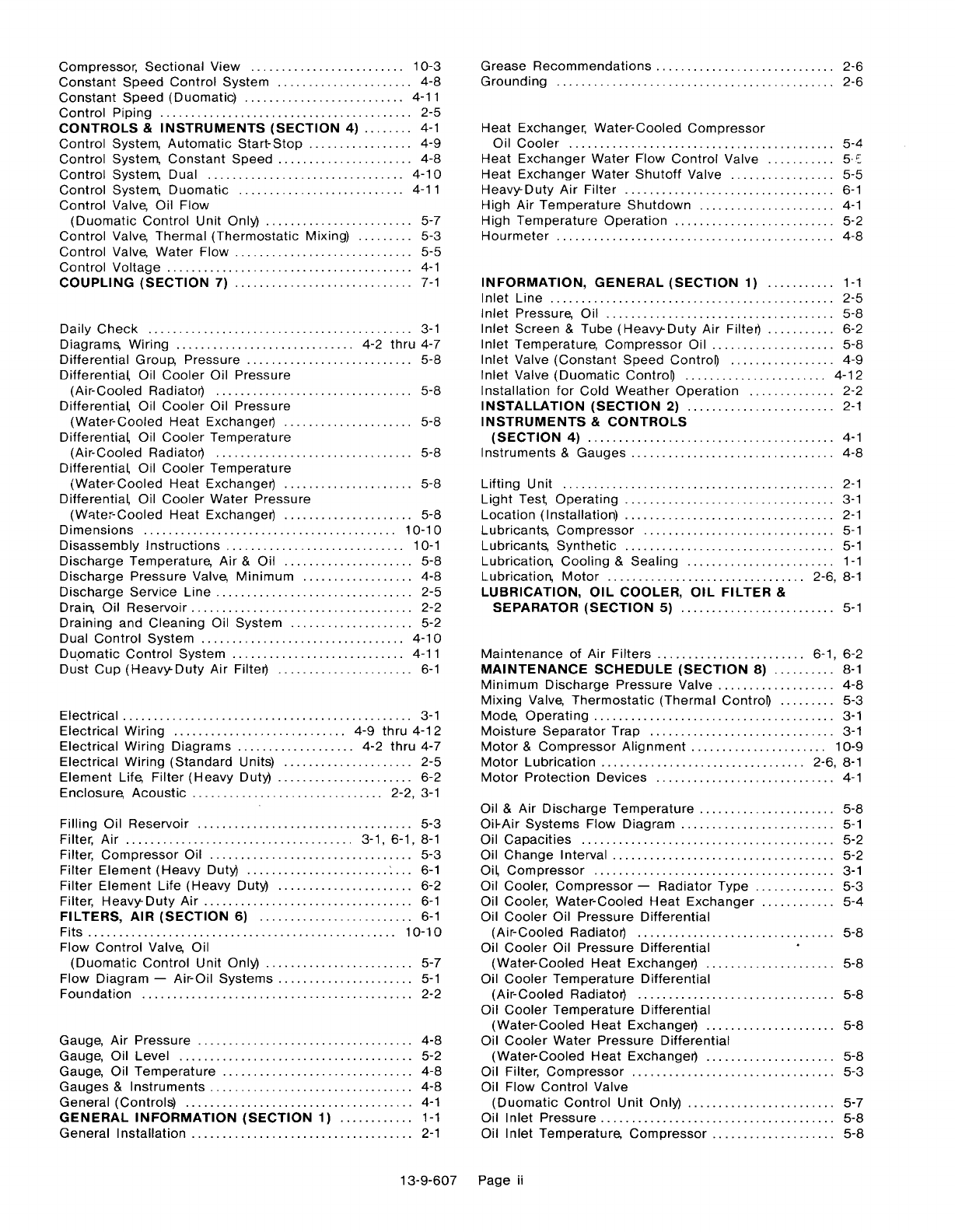

13-9-607 Page ii