Garford Robocrop User manual

Manual

Version 6.4 (Draft)

Disclaimer

Considerable effort has gone into making Robocrop reliable under

normal commercial conditions. However, it is possible that under some

adverse circumstances the guidance system will be unable to operate

reliably. It is the operator’s responsibility at all times to ensure that the

machine is operating in a satisfactory manner. Should excessive crop

damage occur operation should cease and if necessary, your Garford

dealer should be contacted for advice.

2

Contents

1. Preface.......................................................................................... 3

2. Safety............................................................................................ 4

3. Assembly....................................................................................... 5

Step 1 –Mounting the console.................................................... 5

Step 2 –Setting up the linkage arms........................................... 5

Step 3 –Reducing lateral movement...........................................5

Step 4 –Levelling the implement.................................................5

Step 5 –Connecting the hydraulic hoses.....................................5

Step 6 –Connecting implement loom to the console...................5

Step 7 –Connecting the power supply........................................ 5

Step 8 –Starting the tractor and console.....................................6

Step 9 –Checking hydraulic operation........................................ 6

4. Start up and working screen……………......................................... 7

5. Getting to work in the field.............................................................. 9

Step 1 –Selecting configuration file and crop size…………....... 9

Step 2 –Checking camera height and inclination in the field...... 9

Step 3 –Initial running and adjusting camera lateral position….. 11

6. Notes on operation with a correctly set up machine………………..12

7. Information screens and menus……………………………………… 13

Setup menu…………………………………………………………. 14

Advanced set up & diagnostics menu………………………........ 15

Configuration file editor……………………………………………. 17

8. Maintenance and storage.............................................................. 24

9. Service menu…………………………………………………………… 24

10. Troubleshooting............................................................................. 25

LED Blink codes………………………………………………….. 25

Console fault codes………………………………………………… 26

Flow Charts…………………………………………………………... 27

Copyright notice

The computer vision guidance and control software and the associated

configuration tool on all Robocrop systems are copyright Tillett and Hague

Technology Ltd.

This product also makes use of public domain operating system code. Under

the terms of the GNU general public licence and/or the University of

California, Berkeley (UCB) license copies of the public domain software are

available on request.

3

1. Preface

Congratulations on purchasing a Robocrop precision guided implement.

Robocrop precision guided implements are guided by a computer controlled steering system.

There are 3 main components to the system.

1. A digital camera or cameras mounted on the implement looking ahead at a wide area of

crop normally taking in several rows.

2. A cab mounted console containing a computer to analyses camera images and find exact

row centres.

3. A hydraulic side shift (or steered discs) controlled by the computer to keep the camera

centrally over crop rows and the implement precisely on track.

Schematic of Robocrop on a rear mounted inter-row cultivator with side shift

Robocrop uses a colour camera to pick out green crop and weed from backgrounds containing

soil, stones and trash. (Consult your Garford dealer for systems to work in red crops.) Robocrop

locates crop rows within a scene by matching a template corresponding to the known planting

pattern with crop rows as they appear in the camera image. That image is displayed live on the

console with the template overlaid as green lines.

Matching a template to a broad area of crop rather than locating individual rows improves reliability

especially when parts of those rows are not present or obscured by weeds. Template shape is

determined by a configuration file pre-programmed to suit a particular crop planting geometry and

implement configuration. Different configuration files can be created for different crops and

implements.

A good match between the template and crop rows is very important for accurate row following.

Console working screen showing a typical live video image with the template superimposed as

green lines over crop rows.

Camera

Micro

controller

and valves

for hydraulic

side shift

Console

4

2. Safety

1. When carrying out repairs or adjustments to a side shift, steering discs or

implement, ensure that the Robocrop system is switched off and also that the

hydraulic supply is off.

Be aware that spurious speed signals can be generated potentially causing

the side shift/steering discs to move unexpectedly. This is most likely if

odometry is generated via GPS, which is inclined to drift, or via computer

vision, particularly if people are moving in the camera field of view.

2. Never conduct maintenance work on the side shift mechanism while it is

supporting the implement.

3. The side shift and steered disc mechanisms forms pinch, trap and shear

points. Be aware of these when carrying out maintenance.

4. Regularly check the condition of hydraulic hoses and fittings.

5. Do not allow other persons to ride on or work near the implement when it is in

operation.

6. The power supply cable has a 20Amp fuse fitted near to the battery terminals.

This is for short circuit protection and must not be omitted.

7. When routing the loom and power supply cables ensure that they do not

cause a restriction or trip point in the cab.

5

3. Assembly

The following steps outline how the Robocrop precision guided implement should be set up.

Step 1 - Mounting the console

Mount the console in the tractor cab in a position where it can be clearly seen, but does not

obscure operator's visibility. Four M6 tapped holes at a square 100mm pitch in the rear of the

console facilitate mounting to a bracket. A number of alternative mounting arrangements are

possible, but it is recommended that the chosen method should provide some vibration isolation.

Caution

•The console should be protected from severe vibration.

•Do not use longer screws than those supplied otherwise damage to the console may result!

Step 2 –Hitching to the tractor

Position the tractor and implement on a level surface. Check that the tractor’s lower link arms are

evenly adjusted and hitch the tractor to the 3-point linkage points on the side shift frame.

Caution

•The side shift 3-point linkage points are to standard category 2 dimensions and so must be

attached to a similar tractor linkage.

•Once the 3-point linkage is correctly fitted stop the tractor and apply the handbrake.

Step 3 –Reducing lateral movement

Adjust the stabiliser links to prevent lateral movement of the lower link arms.

Caution

•For side shifting front mounted systems it is particularly important that there is no lateral

movement in the linkage.

Step 4 –Levelling the implement

With the cultivator on the ground, adjust the top link so that the cultivator is level, front to rear

(camera pole(s) should be vertical).

The control system loom and hydraulic hoses can now be routed from the implement to the tractor.

Caution

•Clipping the loom and hoses to the top link should keep them clear of catch points.

•Make sure that the linkage can be operated over its full range without stretching or chaffing

the loom conduit or hoses.

Step 5 –Connecting the hydraulic hoses

Plug the hoses into a suitable double acting valve connection on the tractor. Markers on the hoses

indicate the following:

Supply –RED Return - BLUE.

Step 6 –Connecting the implement to the console

The cable/conduit from the implement module should be routed into the tractor cab and through to

the console.

Caution

•Do not to allow the loom to restrict access to or exit from the cab or act as a trip point.

Plug the multi pin plug into the socket in the bottom of the console.

Caution

•Note the correct alignment of the tabs in the plug and socket and avoid excessive force in

pushing the connector together. If you have any problems with this connector consult

your dealer as incorrect assembly may seriously damage the computer.

6

Step 7 –Connecting the power supply

The 12V power supply cable running from the implement module should be connected directly to

the tractor battery or via purpose designed power sockets. Cigarette lighter sockets are not

suitable.

Caution

•Route the cable carefully ensuring that it cannot become trapped or chaffed.

•The 20amp fuse at the battery terminal end of the cable is for short circuit protection and

must not be removed.

•The polarity is denoted by + and –marker rings on the cables. The fuse is on the + cable.

Step 8 –Start the tractor and console

With the implement still on the ground check that the spool valve is in neutral and all persons are

well clear. Start the tractor then press the console power button which will remain illuminated. Wait

for the system to "boot up" with a few text screens then a graphics start up screen with touch

screen buttons should appear. Press the touch screen button labelled Inter-Row. A new screen

with a live video image will appear, this is referred to as the working screen.

Step 9 –Checking hydraulic operation

Set the tractors hydraulic control to provide a constant flow to the implement with the facility to

disengage the supply immediately should a fault occur.

Once the system has booted up and the working screen is displayed, lift the implement clear of the

ground and engage the hydraulic supply. The side shift or steered discs should centralise.

If the side shift or discs were already central and you wish to test them press the second touch

screen button from the bottom on the right labelled “manual”. The hydraulic side shift/steering is

now in manual mode and can be operated via the touch screen buttons labelled with left and right

arrows. Each button press steps side shift/steering by 7% of its stroke. Repeated pressing (but

not holding your finger down) will result in continuous travel up to the end of the stroke. This

procedure can be used to check that hydraulic flow is in the correct direction and that the side shift

rate is correct. A normal side shift rate would be 0.1m/s (e.g. 3s to travel a 0.3m stroke). To return

to normal automatic mode press the same button again. The side shift/disc will stay in the position

until the implement is lowered and raised again, or the machine starts to travel forward.

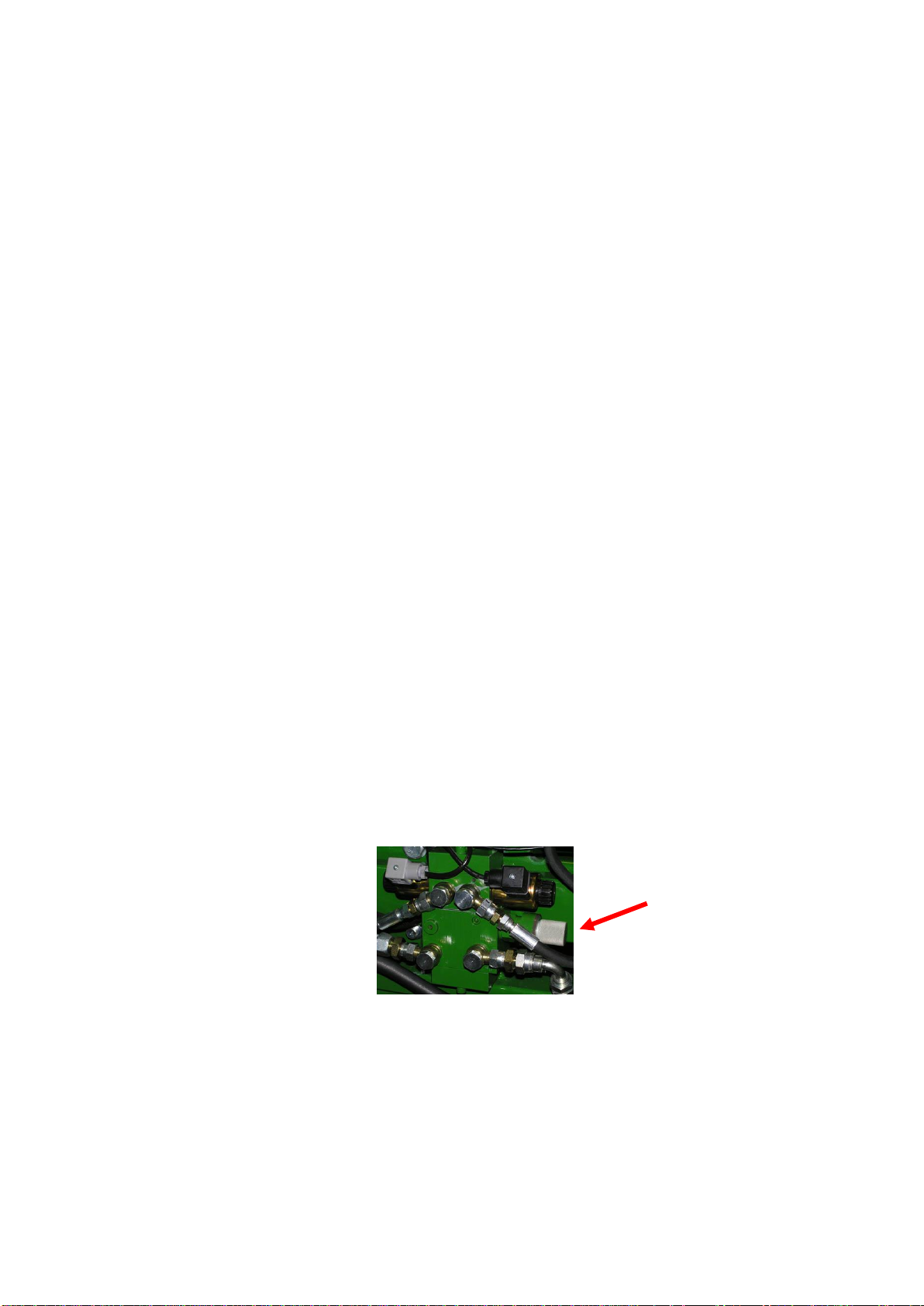

Caution

•Side shift/disc travel all the way to one side on lifting the implement may indicate that the

hydraulic supply is connected the wrong way.

•Rapid side shift/disc oscillations back and forth about the central position indicate that the

hydraulic flow rate is too high. The tractor flow control should be turned down. Alternatively,

the hydraulic flow control valve on the implement may be adjusted, see picture.

•Only adjust the flow control valve with the implement on the ground and the tractor engine

switched off.

The machine is now ready for work, though before proceeding to the operational phase it is worth

familiarising yourself with the working screen.

7

4. Start up and working screen

Turn the system on by pressing the console button for about a second until the button is

illuminated. After some PC start up text the user is presented with a start-up screen offering the

choice between starting the guidance system, going directly to the set up screen, opening the

service menu or shutting down.

To get to the working screen press touch screen button with the crop row symbol. When a press

has been detected the touch screen button will become darker, though the function is only

activated when your finger is released.

The working screen as illustrated below has the following features:

•A live camera video image over which are superimposed two sets of markings. The first are

green lines representing the template to which crop rows are matched. The second are a

series of eight crosses arranged from the top to the bottom of the image. These represent how

well the template lines up at different levels up the image. Blue crosses indicate a good

match. Yellow and red crosses indicate a poor match.

•Systems with multiple cameras display live thumbnail videos along the top of the display.

•An image quality gauge to the left of the screen giving relative indication of likely

tracking performance. The higher the green bar the better. A low bar indicates

either a poor template match or poorly defined crop rows. Guidance will, under

most circumstances, operate down to an indication of approximately 20% albeit at

reduced accuracy.

•Information symbols at the bottom left of the display:

oA warning triangle indicating poor tracking is displayed if estimated

error in lateral position exceeds 25mm. The number between the

arrows is the section to which the warning applies. On seeing this

warning users should check performance on the ground. If enabled

the warning triangle will be accompanied by an audible warning.

oAn implement lift symbol is displayed if the lift sensor detects the

implement is lifted.

oA circular red braked symbol is displayed if the implement is down but

not moving.

•A speed gauge on the right shows forward speed which should match tractor

speed. The speed bar is green up to 11kph and red over 15kph, which is

normally a sensible operating limit, though guidance is good to 20kph where

soil/crop conditions permit.

8

•A green dot and red/green chevrons below the image indicate side shift

position. A red chevron with a vertical bar indicates the limit of travel has been reached.

This should not be allowed to occur for extended periods.

•The fine offset gauge shows the amount of left or right bias set by the user. This is used to

compensate for minor lateral camera misalignment, but can also be useful on side slopes.

By default, fine offset has six 1cm steps in either direction, though the number and size of

steps is configurable.

The function of touch screen buttons located along the right of the screen are given below:

•Spanner symbol, this button accesses the setup menu (section 9).

•“Select” on multi camera systems and blank for single camera systems. This touch screen

button toggles between cameras affecting the main image displayed and fine offset context.

Alternatively, pressing on a thumbnail image will also select it for full size display.

•←moves fine offset left 1cm, or when in manual mode, side shifts/steers 7% left.

•→moves fine offset right 1cm, or when in manual mode, side shifts/steers 7% right

•Touch screen button labelled “Manual” disables vision steering and allows the user to move

left or right manually in steps of 7% of potentiometer stroke for each press of the arrow

buttons. For disk steered machines this is achieved by automatically steering the discs to

maintain the desired slide position. To prevent mechanical damage these functions only

operate when lifted or moving.

In manual mode green lines representing the template and purple cross hairs are locked on

the screen whilst retaining a live video image. These are useful when adjusting cameras.

Return to vision guidance by pressing same button, now labelled “Camera”, again. By

default the side shift/discs remain in the position they were placed manually until forward

movement under vision guidance is commenced, or an implement lift is detected. The later

will centralise the side shift/discs. Alternatively, systems can be configured such that side

shift/discs centralise on entry into manual mode (section 9.3).

For single section side shift machines manual control is retained with a normal tracking

screen when moving forward so operators can see if vision guidance is likely to succeed.

For machines with mechanical guidance feelers the “Manual” button cycles between

manual mode, feeler and vision guidance. In manual or feeler guidance mode the fine

offset slide bar is replaced by Text in red capitals indicating the mode in use. For machines

fitted with a remote override manual control box the text would say “REMOTE MANUAL”

when the box was switched on.

•Pressing the touch screen button with the power switch logo enters a shutdown screen from

which you can confirm shutdown.

9

5. Getting to work in the field

The most important procedure to ensure good guidance is to match the template, as illustrated by

the green lines, to crop rows as they appear in the live video image. The following steps outline

how to get the best match and hence achieve good guidance.

Tip

For the first few hundred meters of running after commissioning Robocrop learns a term known as

camera skew (see section 7.3) Camera skew compensates for minor errors in camera orientation

in the horizontal plane. Wherever possible we recommend that set up runs (step 4) are conducted

in crop showing the clearest rows available so that camera skew is learned as quickly and

accurately as possible. High visibility rows also help manual alignment checks (step 3). We also

recommend that side slopes and intense partial shadows are avoided during initial running. Once

set up is complete more challenging situations can be tackled. It is also possible to view the

current value of camera skew and reset it manually (see section 7.3).

Step 1 –Selecting configuration file and crop size

From the working screen press button labelled with a spanner symbol to reach the setup screen.

The top line of this screen indicates crop size (height) settings under categories of small (<5cm)

medium (5-15cm) and large (>15cm). The second line lists the available configuration files. Use

the buttons labelled with arrows to ensure that the highlighted options correspond to the crop and

crop size being used for setup and initial running.

Check details at the bottom of the screen to ensure selected configuration file settings match crop

and camera geometry.

If either crop geometry or configuration settings are not correct refer to section 7 for instructions on

making the necessary changes.

To return to the working screen by pressing the button labelled “OK”.

Step 2 –Checking camera height and inclination angle in the field

Draw into the crop and set the cultivator down onto a typical section of crop row. The cultivator

should be level and set onto the rows as accurately, and as straight as possible with the camera at

its normal operating height (displayed in the “set up” screen).

Press button labelled “Manual”, The overlaid green lines representing the template should lock in

the centre of the screen.

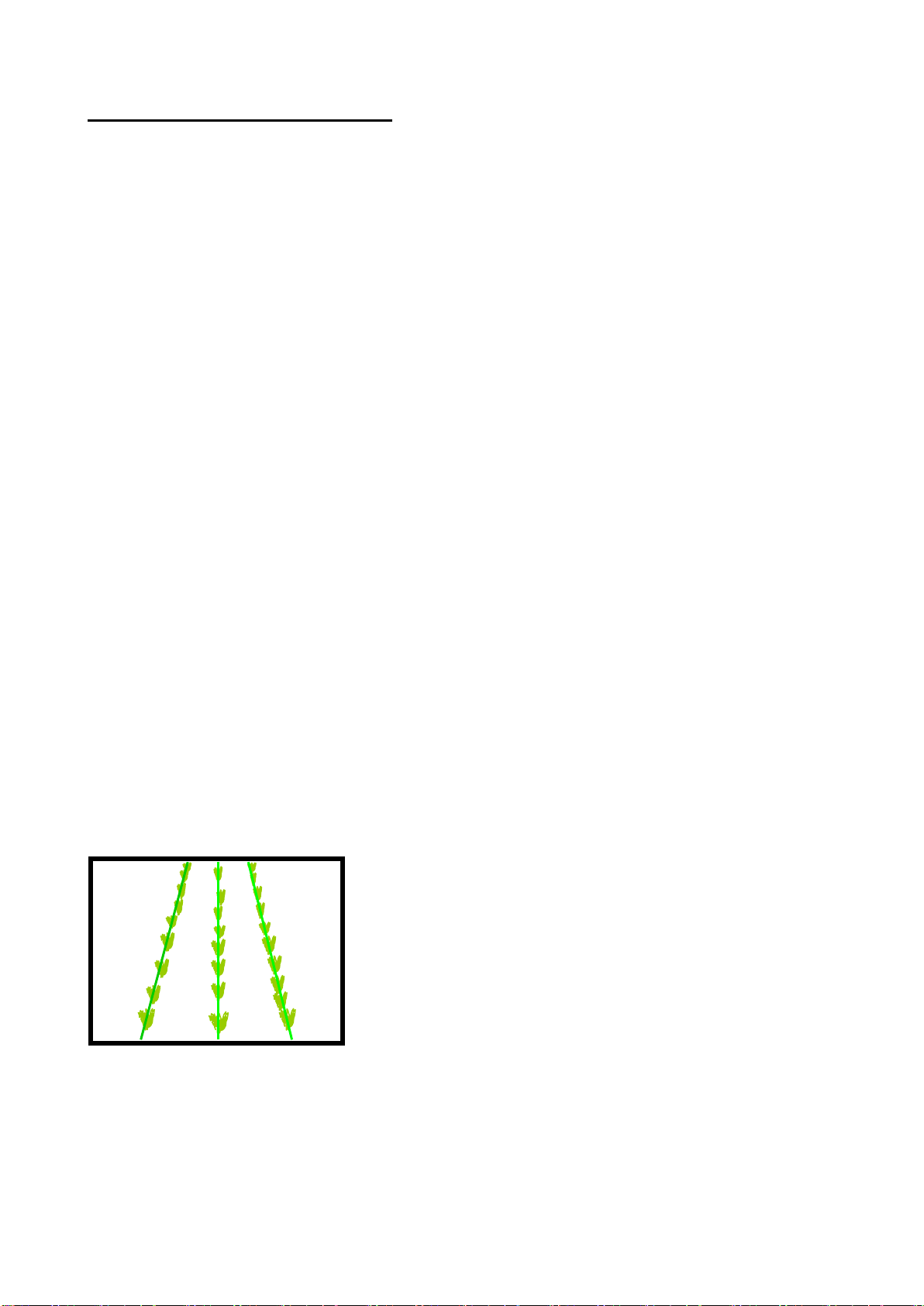

Green lines superimposed over the live image should align with crop rows as illustrated below.

Tip

If crop rows are difficult to see in the live video image you can enhance them by placing high

visibility objects such as a strip of wood exactly over the row centre line.

Caution

If the overlaid green lines are not symmetrical on the screen (by more than 4 degrees) the camera

skew value may need resetting. Refer to the advanced set up & diagnostics menu in section 7.3.

✓

10

However, if the green lines appear narrower or wider than the real crop rows check the “crop

size”selected in the “set up”screen and change if appropriate. If this does not resolve the

problem, it may be that the camera height (measured from centre of lens to ground level) does not

match the figure displayed in the “set up” screen. The best solution is to measure the correct

position and move the camera accordingly. A less accurate, but sometimes satisfactory

alternative, is to adjust camera height until the “picture” looks correct as illustrated below.

If the camera is too low, then the template will appear narrower

than crop rows. In this case raise the camera.

If the camera is too high, then the template will appear wider

than crop rows. In this case lower the camera.

If the template matches mid screen, but not at the top or bottom, check that the implement is level.

If it is camera inclination angle may need adjusting. Again the best solution is to make careful

measurements and adjust accordingly. This may be done as follows. Go into the “set up” screen

and make a note of a distance called “look ahead”. Return to the working screen and press Sk5

labelled “manual”. Purple cross hairs will appear in the image. Now mark a point on the ground

directly below the camera lens (ideally using a plumb bob). From that point measure forward along

the ground and place an object at the “look ahead” distance. When viewed on the screen the

object should now coincide with the cross hairs intersection in the image centre. If it does not

camera inclination should be adjusted until it does.

Again a less accurate, but sometimes satisfactory alternative is to adjust camera inclination until

the “picture” looks correct as illustrated below.

If template lines appear narrower than crop rows at the top of

the image but wider at the bottom, then the camera is inclined

down too far. In this case rotate the camera up so it views

further ahead.

If template lines appear wider than crop rows at the top of the

image but narrower at the bottom, then the camera is

inclined up too far. In this case rotate the camera down so it

views less far ahead.

Good tracking will only be achieved if template lines are centred on all of the rows being tracked.

Note Remember to tighten any bolts loosened in the process of adjustment.

11

Step 3 –Initial running and adjusting camera lateral position

When you are happy you have a good template match press the button labelled “Manual” again to

return to the normal working screen ready for tracking. You can be sure that the machine is ready

for tracking if a line of blue crosses has appeared down the centre of the display.

Note

For initial set up runs almost all the crosses should be coloured blue and form a relatively straight

vertical line. If this is not the case, or a triangular tracking warning symbol is displayed, either the

machine is not correctly set up, or crop rows are not sufficiently well defined for initial running.

If tracking appears good set off slowly into the crop. The implement should quickly align with crop

rows. It is likely that after a short distance it will have settled at a small lateral offset. Small offsets

can be corrected using the fine offset facility available from the working screen. Buttons labelled

with left and right arrows adjust fine offset whose current position is displayed centrally below the

live video image. Each press of an arrow key biases the side shift in steps of 1cm (3/8”). Continue

down the field stopping occasionally to check lateral position. If the required fine offset exceeds

the available number of steps the camera should be physically moved as described below and step

3 repeated.

It is the operator's responsibility to decide at which point the vision guidance system

becomes 'lost'. If the system losses track of crop rows the operator should carefully guide

the implement through to the next good reference.

Garford accept no responsibility for damage to or loss of crop whatsoever.

After approximately 200m of running Robocrop should have learnt camera alignment (“camera

skew”) and lateral bias should therefore have stabilised. If fine offset is set to greater than two

steps, we recommend physically moving the camera along the toolframe by the equivalent

distance and resetting fine offset to zero.

Tip

If fine offset is set to the left, then the camera should be moved right as viewed from behind looking

forward.

Once you are confident that Robocrop is tracking accurately and reliably forward speed can be

increased. Working speeds up to 12 kph can be accommodated with Robocrop, however the

mechanical interaction of shares and shields on the soil and its effect upon plants will determine if

this is achievable.

“Camera

height”(m)

“Look ahead” distance (m)

12

6. Notes on daily operation with a correctly set up machine

•Before operation check that electrical and hydraulic connections are secure and that there are

no obstructions to side shift/disc movement.

•On first setting the implement down in the field check that the green overlaid lines representing

the template line up with crop rows and that overlaid blue crosses have appeared

approximately central in the image.

•Proceed with caution for first few meters checking that Robocrop’s speed gauge matches the

tractors and that implement alignment is good. If performance is satisfactory speed can be

increased. Robocrop’s tracking should be satisfactory up to 12kph, though soil movement

considerations may dictate a lower operating speed.

•Robocrop remembers fine offset settings from previous sessions and so there should not

normally be any need to adjust this unless changes have been made to camera position.

•Operating on side slopes will result in some lateral error due to the tractor “crabbing” across

the slope. Normally this is not significant, but in extreme cases it may be necessary to use the

fine offset function to compensate. If operating in this way remember to reverse the bias when

heading in the opposite direction and to return to a neutral setting when stopping work or

moving to a flat area. A similar technique can be used to compensate for crop bent laterally by

a cross wind.

•Each time the implement is lifted at row ends it will centralise ready for the next run.

•At the end of the day shut down by pressing the bottom right touch screen button labelled with

the power symbol and confirm with the “exit” button. This will shut down power to the entire

system though the console power button will briefly flash every 5 seconds to indicate that the

12V supply is connected. In this state the current draw is negligible.

If in doubt about any machine settings or operating procedures, please contact Garford Farm

Machinery on +44 (0)1778 342642.

13

7. Information screens and menus

Robocrop has a graphical working screen that conveys all the information necessary for normal

operation. A description of this screen is given in section 4.

A series of six touch screen buttons along the right of the display allow operators to access user

controls such as fine offset and manual control of side shift/steered discs. Their function is

described by labels superimposed on each button.

Set up procedures and more advanced information can be accessed via additional screens that

can be navigated to via the working screen. The function of the touch screen buttons changes with

each screen, but is always described by its label.

7.1 The Setup Menu

The setup screen can be reached by pressing the spanner button from the working screen. Three

settings “Crop size” and “Configuration” and “Crop Colour” (optional facility) can be altered in this

screen.

Navigation within the set up screen is achieved by moving the cursor over options using buttons

labelled with arrows. When the cursor is over an appropriate setting it can be selected by pressing

the button labelled “OK”.

“Crop size” increases template size to compensate for the crop canopy getting closer to

the camera as it grows. This avoids the need to physically adjust camera height when

moving between crops of different heights. Robocrop has settings for small, medium and

large crops. As a guide, crops up to approximately 5cm (2”) high are regarded as small,

5cm (2”) to 15cm (6”), medium and greater than 15cm (6”) high, large. On initial set up the

default will be medium, though Robocrop remembers crop size from the previous session

regardless of which configuration file was used.

“Configuration” allows users to select between alternative pre-programmed configuration

files for different crop planting geometries requiring different templates.

The main parameters of the chosen configuration file are displayed at the bottom of the

setup screen, they are:

Camera number

Viewing - Number of rows being used for tracking.

Spacing - The row spacing between the rows being viewed.

Camera height - Distance vertically from lens to ground when in work

Camera look ahead –Horizontal distance along the ground from a point vertically below

the lens to the centreline of sight (marked by cross hairs in “Manual” mode).

14

“Crop colour” (optional facility) –For green crops select “Green”. Selecting

“Red” inverts colour segmentation so that plants that are completely red are tracked.

Where crops have red outer leaves and a green centre, users should select “R & G”. It is

also possible to select “Custom” colour which can bias the colour used by the system to

search for foliage. This can be advantageous on crops such as brassicas or alliums with a

blue/green colour (a value of about 50 has often be found to be satisfactory).

For plants with particularly unusual colours that cannot be tracked using any of the normal

colour options an Infra-Red camera can be fitted. This will be automatically detected and

is recognisable by monochrome video images.

If a suitable configuration is not available, it can be created. We recommend customers

ask their Garford distributor for an appropriate configuration file. However, experienced

users can use the configuration file editor (section 7.4) to create their own.

7.2 Advanced set up & diagnostics menu

This screen is reached from the set up screen by pressing the top right button labelled with a

spanner ++ symbol. Navigation within this screen is similar to the set up screen.

The first three items on this screen are for information only and cannot be changed by the user.

Area worked is based on distance x width.

The remaining items on this screen are as follows:

Current job

Provides resettable counters for elapsed time and area treated.

Units

Selecting toggles between metric and imperial units. This change affects all user screens and the

configuration file editor.

Camera skew

Camera skew is a measure of camera angular misalignment in the horizontal plane. This angle is

estimated by Robocrop’s computer programme during field operations. Rate of change is highest

during initial runs and after resetting to zero. It stabilizes after approximately 100m of running.

During this initial learning phase, it is sometimes necessary to readjust the fine offset (section 7.1).

The purpose of estimating angular misalignment and automatically compensating is to avoid the

need for very accurate mechanical setting up.

15

As camera skew relates to a particular camera poise it is necessary to reset it to zero manually

and allow it to estimate a new value each time the camera is moved either deliberately or by

accident. Small lateral camera adjustments by sliding within the stroke of the supplied camera

bracket should not however require a reset, as camera poise should not be significantly affected.

A reset to zero is achieved by using arrow buttons to highlight reset and pressing the return button.

Caution

After resetting camera skew it will probably be necessary to adjust fine offset.

Camera skews in excess of 3 degrees indicate poor camera alignment requiring improvement.

Camera Offset (only present with multiple cameras on the same section)

Camera offset is the lateral error between two or more cameras fitted to the same section. Like

skew it is estimated by Robocrop’s computer programme during field operations. Rate of change

of this estimated displacement is highest during initial runs and after resetting to zero. It stabilizes

after running approximately 100m. There are as many offsets as there are cameras on a section.

The first camera is master from which offsets are derived and so it always has zero offset.

The purpose of estimating lateral misalignment and automatically compensating is to avoid the

need for very accurate mechanical setting up.

Camera skew relates to camera offset so that resetting skew resets both figures for all cameras

fitted. However, resetting offset does not automatically reset skew.

Custom colour (only present if enabled and custom colour selected)

Selecting “adjust” provides a tool allowing users to bias the colour used for detecting plants. For

example, a small deviation from the standard green (0 on this scale) towards blue (e.g. 30) can

improve detection of some brassicas and alliums. Arrow keys shift the current selected colour

value which is reflected in plant icon colour. Large arrows move in steps of 10. Small arrows in

steps of 1.

Enabling custom colour is discouraged unless it is absolutely necessary as it adds complexity and

can, if not set correctly, dramatically reduce performance.

Test steering

This test function checks a number of components and settings relating to side shift or steering

angle movement. Included are micro-controller communication with the main computer, direction

of hydraulic flow, rate of flow (too fast or too slow), correct side shift/disc potentiometer connection

polarity and continuity over the stroke. It also detects mechanical obstructions preventing full

travel. This is achieved by exercising the hydraulic cylinder and recording the response. It is

therefore necessary to turn the hydraulic supply on. For multi section machines you are prompted

to select which section to test.

Caution

Ensure the side shift/disc steering mechanism is clear of obstructions and people before running.

16

Audible Warnings

When selected “Yes” a buzzer inside the console sound when warning symbols such as the poor

tracking symbol appear on the working screen. The default is “Yes”.

Auto select feelers (only shown with mechanical crop guidance feelers fitted)

When selected “Yes” automatically drops from vision guidance to feeler guidance when one of the

feelers is deflected by the crop. The default is “No”.

Leave manual on moving

When selected “Yes” automatic camera control takes over when motion is detected. The default is

“No”.

Go to manual if lost

When selected “Yes” control will be switched to manual if the system is unsure of row position and

the buzzer will sound for four seconds. If “No” is selected it will attempt to relocate the rows and

continue vision guidance. The default is “No”.

Centre when entering manual

When selected “Yes” the side shift or steering discs will centralise whenever manual is selected. If

“No” is selected the side shift or discs will stay in their current position until a manual steering input

is made. The default is “No”.

Error log

This is a log of automatically generated error messages (e.g. camera connections, microcontroller

connections and excessive camera skew). Selecting “view log” displays single line messages that

can be helpful with diagnostics. Not all messages indicate serious faults. On exit you have the

option to select “clear” which erases messages or close which returns to the advanced set up &

diagnostics menu without erasing. These messages are saved between sessions.

Tip When seeking advice over the telephone it is very useful to have an exact word for word record

of any error messages and to make a note of numeric error codes.

μC version

Displays the version numbers of any microcontroller boards fitted.

To exit the advanced set up and diagnostics screen press the bottom right button labelled “OK”.

17

7.3Configuration file editor

Configuration files store information relating to a specific crop planting pattern and

implement/tractor geometry that is necessary for row tracking. Each combination of a different

crop pattern or implement geometry requires its own configuration file.

The configuration file editor allows experienced users to create and edit configuration files, but also

provides a method of changing general machine settings such as language and units. It is reached

from the advanced set up and diagnostics menu by pressing the top right button labelled with a

pen and file editing graphic. Users are required to enter a PIN to prevent accidental entry to the

editor. The default is 1,2,3,4.

Less experienced users are advised to contact their Garford dealer who can supply them with

customised configuration files.

The editor is available in English language only though use of graphical symbols makes many

functions independent of language.

The editor uses the touchscreen for navigation and data entry.

Configuration file editor screen

Overview of screen display and how to edit files

On entry to the configuration editor users are presented with a list of available pre-entered

configuration files in blue text. Touching on a file name selects that file, highlights it in white and

prefixes it with a “>” character.

Buttons on the right-hand side of the screen perform actions on the selected file, create new files,

or change language settings.

•The top right button with a drawing of a single file and a “+” symbol creates a new file. If

pressed users are presented with a series of choices regarding the type of machine that

they want to create a file for. Following these choices will eventually lead to a default

configuration that offers the best starting point for a new configuration. The newly created

file will be added to the list, given the name “new” and selected ready for editing.

NB It is very rarely advisable for users to create a new configuration from defaults in this

way. It is usually easier and safer to use the copy function (see below) to create a new file

based on one that was factory installed and is already known to work.

•The second button down depicting two files copies the selected file and adds that copy to

the list with the name “new”. It is selected and ready for editing. This is the preferred

method for creating new files on a working machine.

•The third button down depicting a file and a pen starts the editing process on the selected

file, presenting a list of configuration file parameters that are available for editing. Touching

18

on one of the list either pops up an appropriate keyboard (Letters for editing

name, numeric for entering numbers) or presents another lower level list of parameters to

select from. To remove the keyboard from the screen, press it’s return key.

In editing mode three buttons are present at the bottom right of the screen:

-The top button marked with a spanner and two “+” symbols selects the advanced

version of the editor. This offers a wider range of settings, but is rarely necessary

under normal circumstances and should only be used by experts, and even then

with caution. See below for the additional functions offered in the advanced editor.

-The second button from the bottom switches between metric and imperial units.

-The bottom button labelled with a loop back arrow returns users to the next level up.

•The fourth button down on the top configuration editor page depicting a bin deletes the

selected file.

•The next button depicts the flag of the country whose language is currently selected for

working screens. On pressing users are presented with a choice of flags, which if pressed,

will change the language used.

•The bottom button labelled with a loop back arrow returns to the start menu.

Note: When you next run the system you need to select the appropriate configuration file as

editing a file does not automatically select it.

Settings available from the standard editor

General settings

The first provides an opportunity to change the configuration file name. Touching on this will pop

up a touch keyboard.

The remaining categories of settings relate to machine sub components. It is possible to have

more than one of these sub components on a single machine. For example, a machine may have

two or more cameras so there will be the option to edit settings for each of these cameras

independently. For reasons relating to internal computing conventions numbering of these sub

components always starts at zero, e.g. the first camera has index number 0 and the second 1.

To edit settings for any of these subcomponents touch on the blue index number in “[ ] for the sub

component that you wish to edit. This will get you into the edit page for that particular component.

Once you have completed editing that sub component you can return to the previous page by

pressing the button with a loop back arrow.

Configuration file editor screen with standard settings selected

19

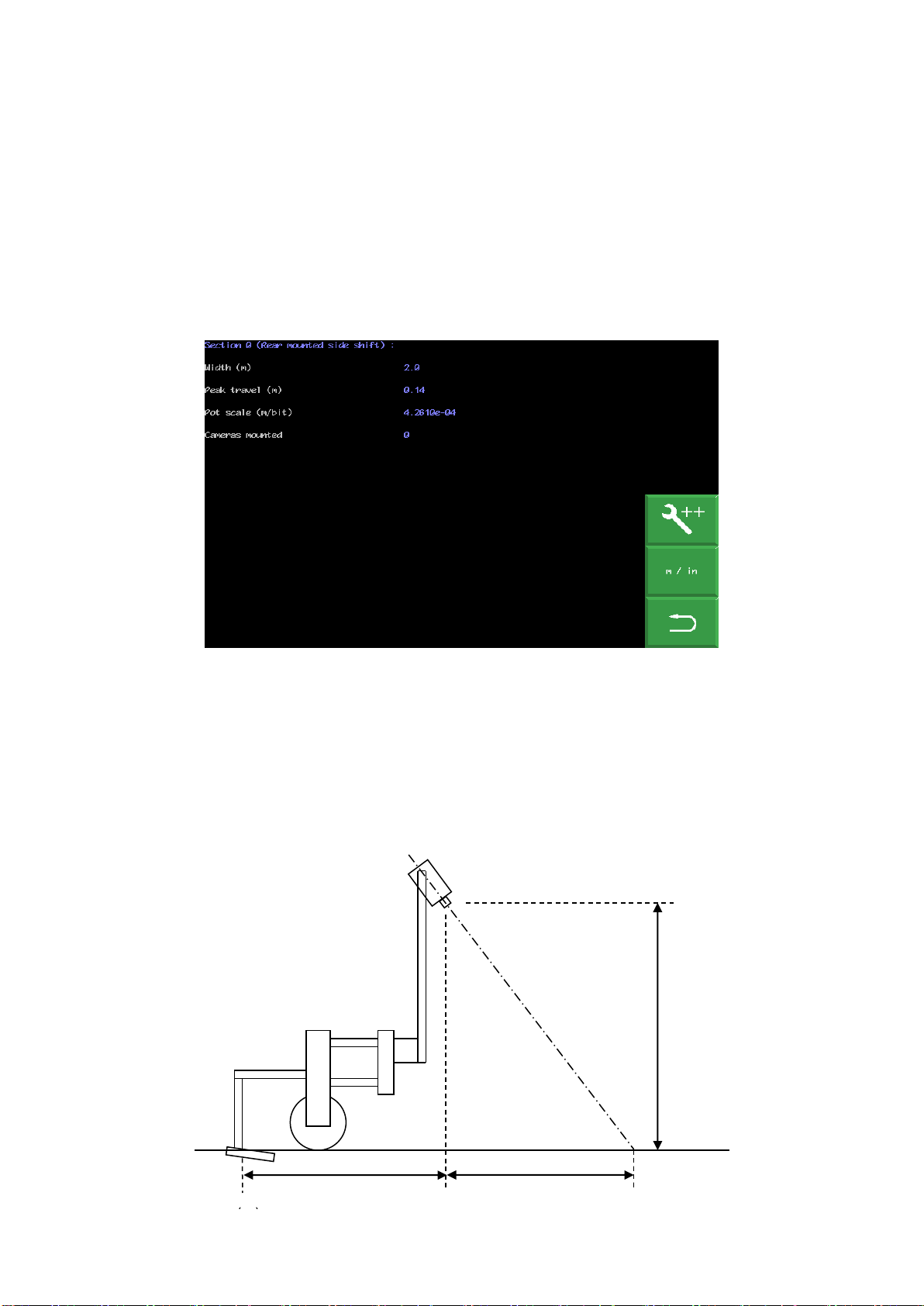

Section settings

A section is defined as a frame that has independent steering. Most implements will have only one

section. However, it is possible to have an implement with multiple independently steered

sections. This is useful when it is required to span multiple drill/transplanter bouts.

The settings are; “Width” is the width of that section and is only used to calculate area worked,

“Peak travel” which is stoke of the side shift mechanism, “Pot scale” refers to calibration of the

linear potentiometer that measures side shift position and the final setting allocates which cameras

are fitted to that section.

It is also possible to have settings (if appropriate defaults are installed) for disc steered machines.

For disc steer machines the second, third and fourth settings relate to; maximum angular deflection

from the central position, distance between the steering disc pivot axis and disc ground contact

point, and calibration of the rotary potentiometer that measures steer angle.

Configuration file “Section”standard editor screen

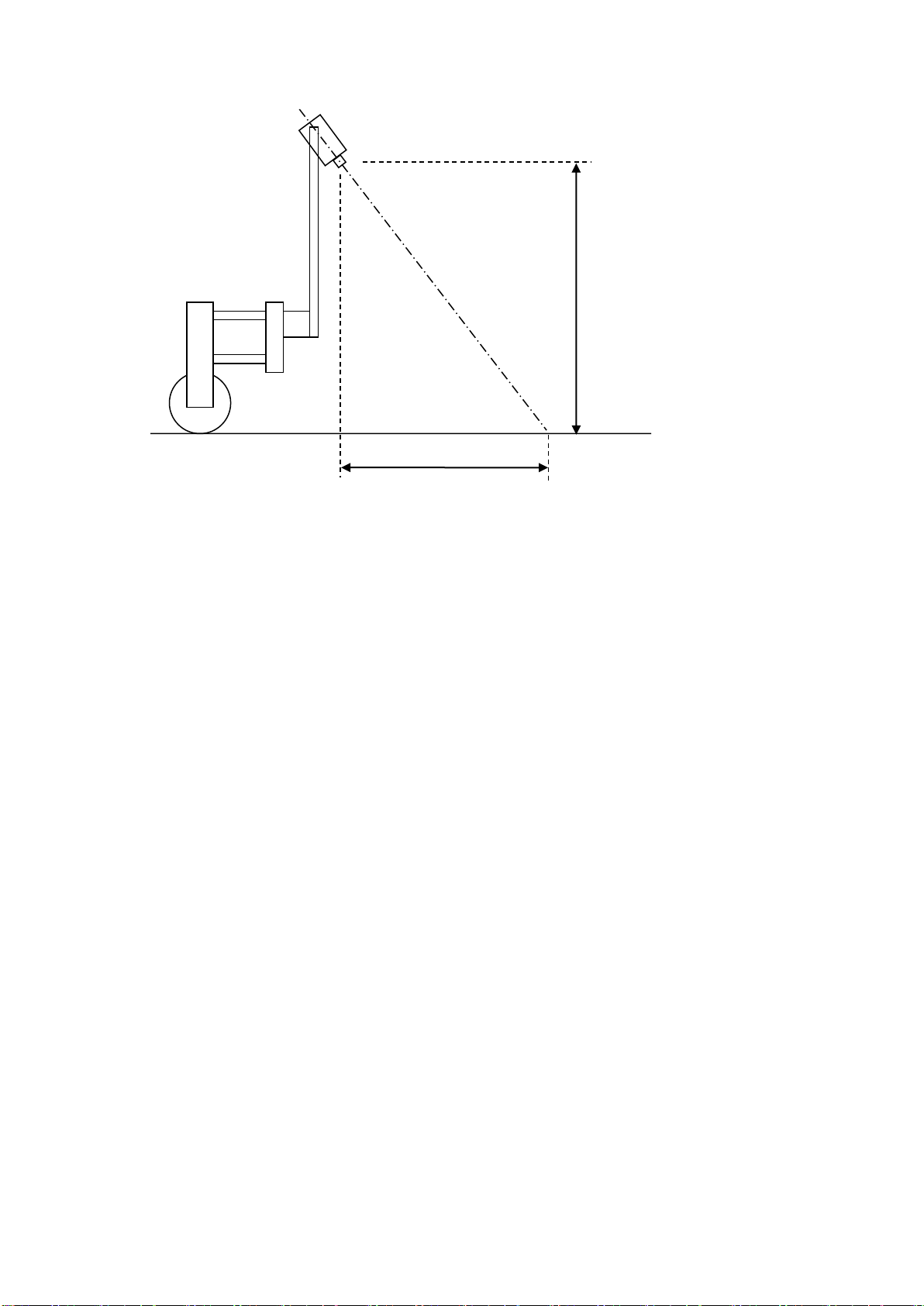

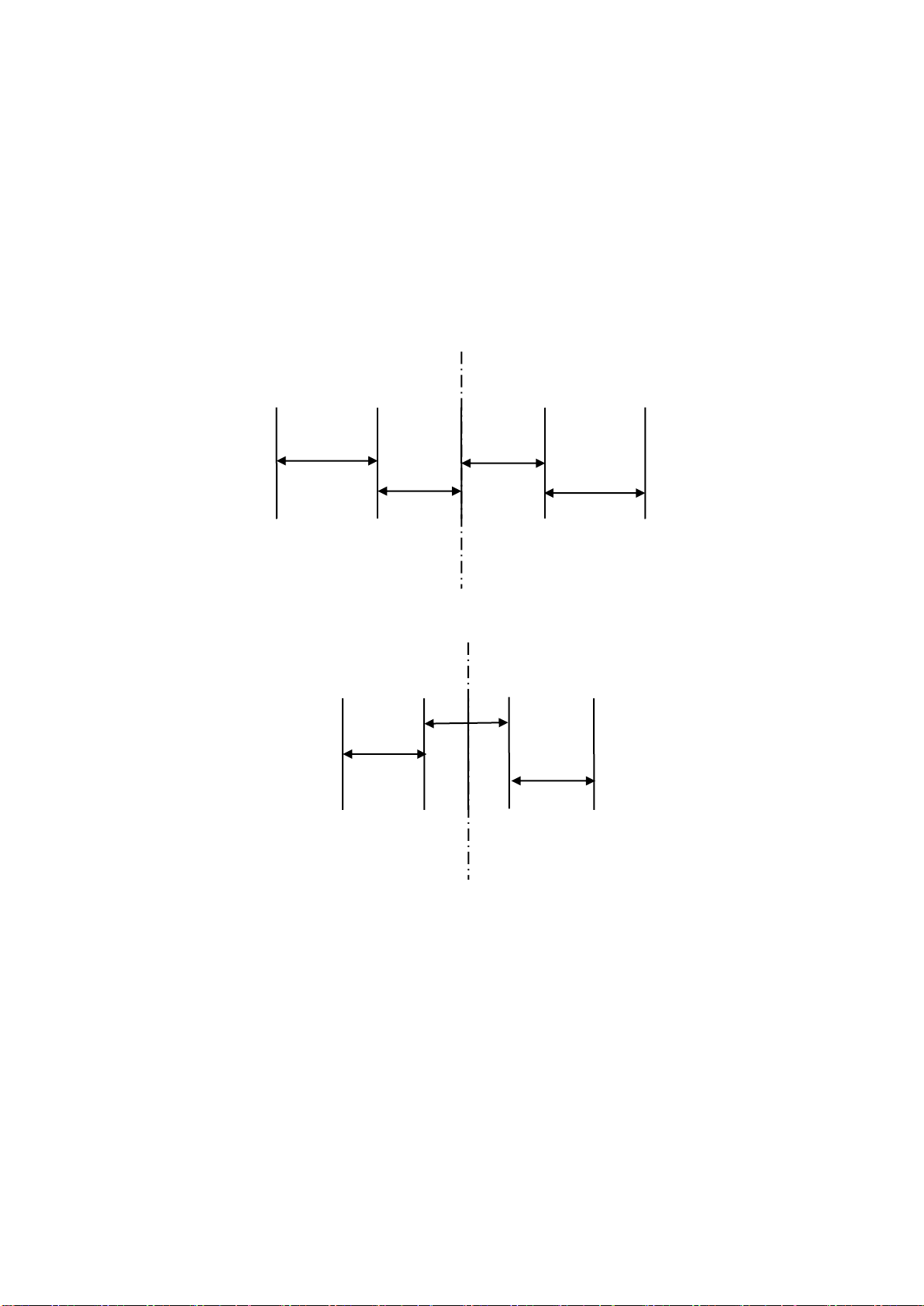

Camera settings

The first three settings relate to camera mounting geometry as illustrated below. Camera height is

the vertical distance in m (or inches with imperial units set) from ground level to the camera lens

when the implement is at its normal working height. Look ahead is the horizontal distance from a

point directly below the centre of the camera lens the centre of the image in the ground plane

(depicted by cross hairs in “manual” mode). “Distance ahead of cultivators”is the horizontal

distance in m (or inches with imperial units set) from a point vertically below the camera lens back

to the cultivator blades. (If In-row software is installed this distance is referred to as “Distance

ahead of rotors/nozzles” even if operating in inter-row mode)

“Look ahead” (m)

Height (m)

“Distance ahead of cultivators”

(m)

20

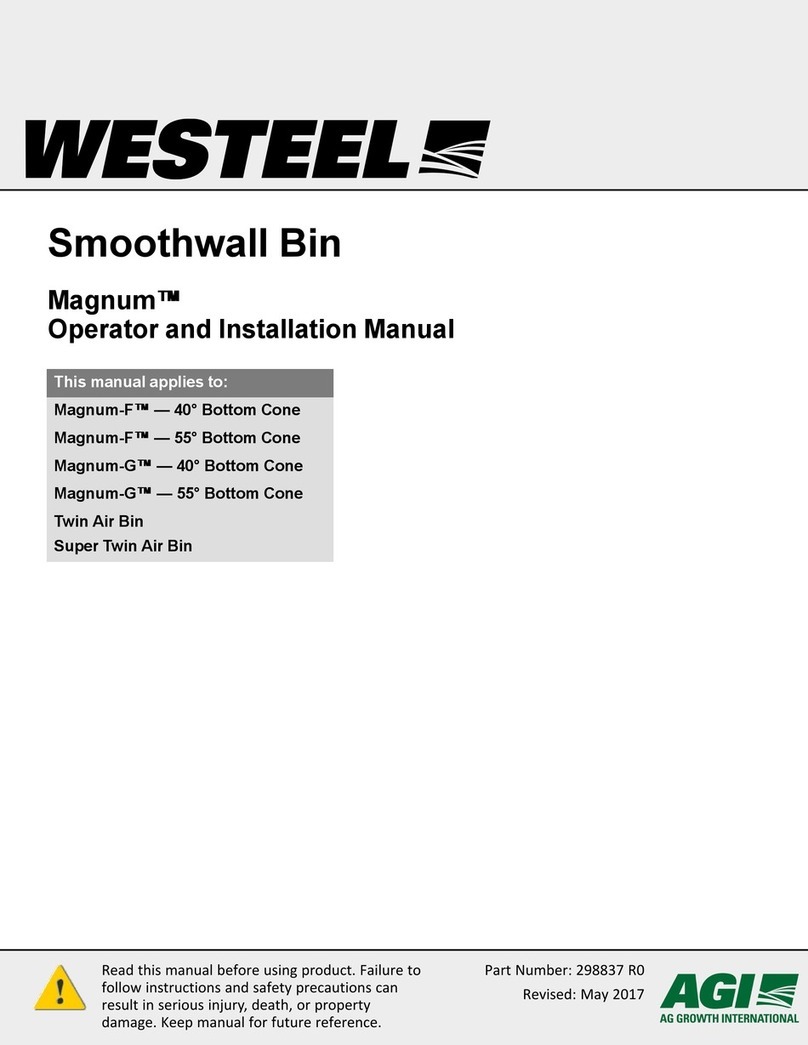

The next settings relate to what is seen in the image. The number of, and spacing between rows.

The number of rows entered here determines how many rows are used to construct the template.

Spacing between rows is normally uniform across the field of view and is therefore a single figure.

However, some crop geometries with a number of different row spacings in the same scene

require a more complex arrangement. Syntax for this is based on the assumption that the pattern

is symmetrical about the centre line and starts with the central row spacing working out to the

edge. Figures are comma delimited. In the case of an even number of rows the first figure is

always the whole row spacing, not the distance from the centre line to the next row. The following

examples cover likely configurations.

Odd no of rows irregular spacing example

Rows 5 Spacing 0.4,0.5

Even no of rows regular spacing example

Rows 4 Spacing 0.4

In the special case of following only one row the most accurate tracking will be achieved with row

spacing set to between two and three times crop foliage width with an absolute minimum of 20cm.

0.5m

0.4m

0.4m

0.5m

0.4m

0.4m

0.4m

Table of contents

Other Garford Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Buhler

Buhler Round Bale Carrier 1500 Operator and parts manual

Westeel

Westeel Magnum Series Operator and installation manual

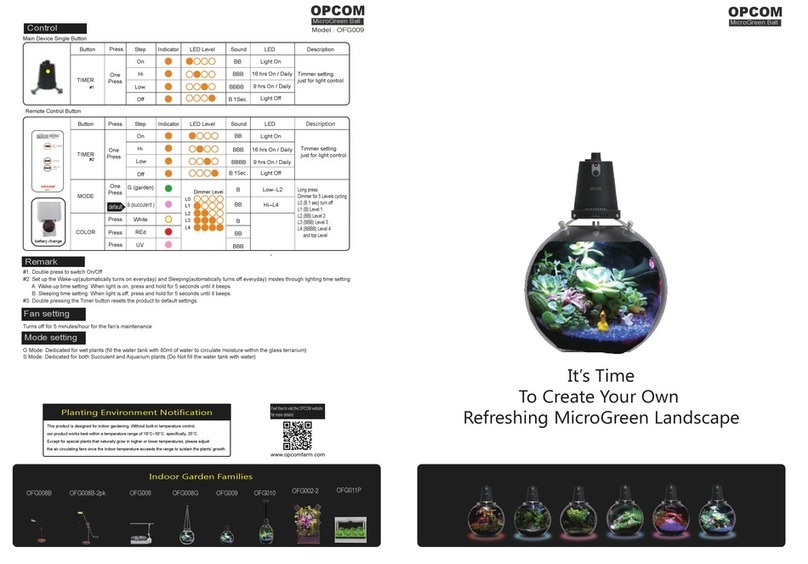

OPCOM

OPCOM OFG009 quick start guide

GREAT PLAINS

GREAT PLAINS Turbo Max 1800TM Operator's manual

GREAT PLAINS

GREAT PLAINS PL5200 Operator's manual

HMF

HMF LEOFANT 24 ABB2471 instruction manual