Garford Robocrop Inrow Weeder Specifications

Operator Instructions

Contents

3. Overview

4. General Safety Instructions

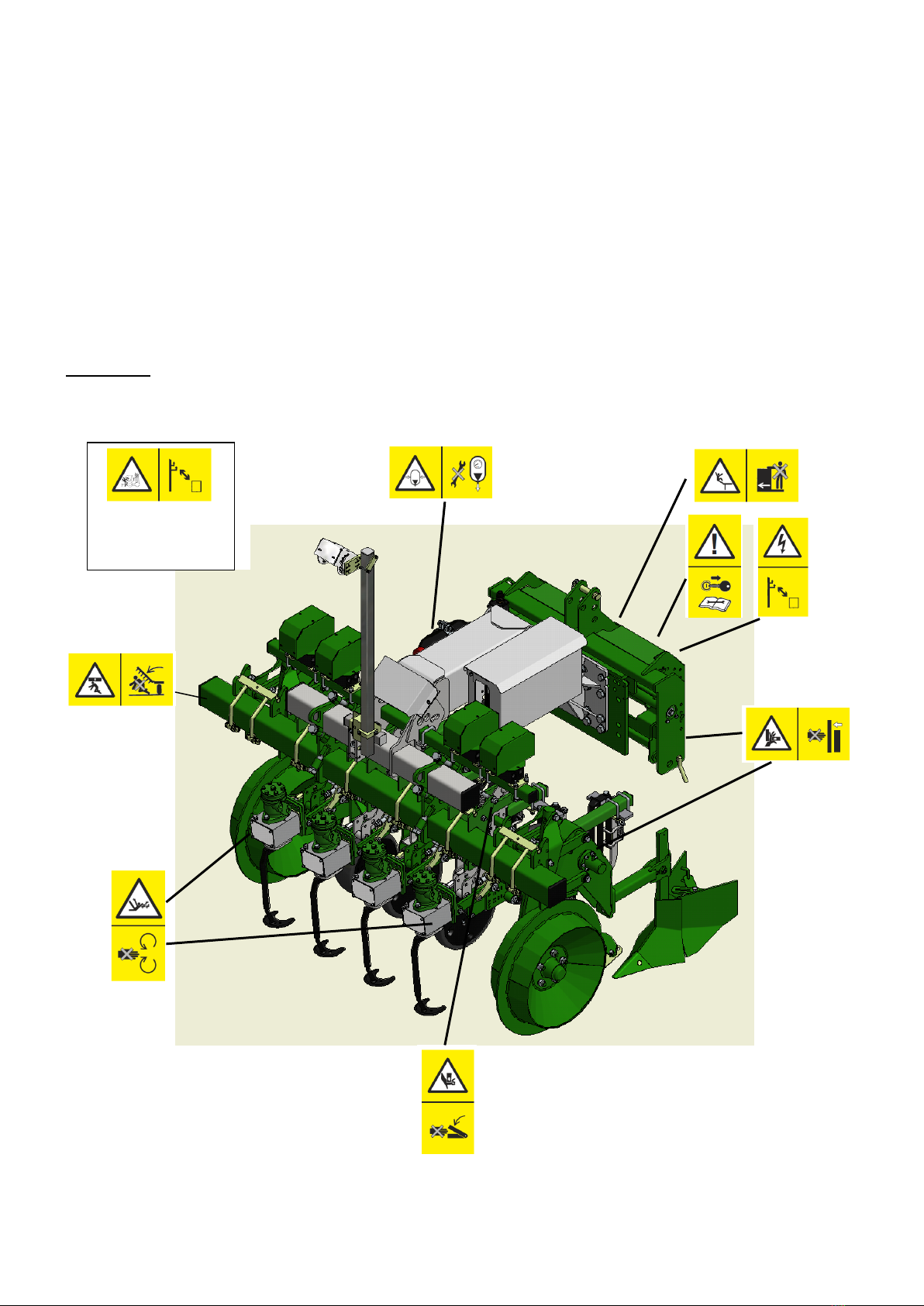

5. Safety Signs

6. Meaning of the safety signs

7. Operating Instructions

Mounting the Robocrop InRow Weeder to the Tractor

8. Robocrop Inrow Weeder Setup Guide

10. Tine and Disc Adjustments

CE Declaration of Conformity

Garford Farm Machinery Ltd

Frognall, Deeping St James,

Peterborough PE6 8RP. United Kingdom.

Declare that the product...

Product

Model

Serial number

Year

Complies with European Directive...

2006/42/CE and 2004/108/CE

The following standards are applied ...

ISO 4254-1:2013, ISO 4254-5:2010, ISO 3767-2:2008 and ISO 11684:1995.

Garford Farm Machinery Ltd. Deeping St James.

01.01.2014

Philip Garford

Managing Director

Overview

Garford Robocrop Inrow Weeders are designed for the purpose of weed destruction, using mechanical

means, inter-row and inter-plant in transplanted vegetable crops which are planted to a stand. It may

also be possible to operate in seeded crops so long as the plants are evenly spaced and the crop is the

more dominant feature rather than the weeds.

Weed destruction is achieved by cutting through the soil with a share the depth of which is controlled at

approximately 10-20mm depth by means of a parallel linkage gauge wheel unit.

The steering of the implement and the synchronisation of the inter-plant rotors is controlled by a

computer employing image analysis of the crop just ahead of the implement in real time.

The Robocrop InRow Weeders are supplied in a range of working width and crop row width

configurations to suit customers crop configurations.

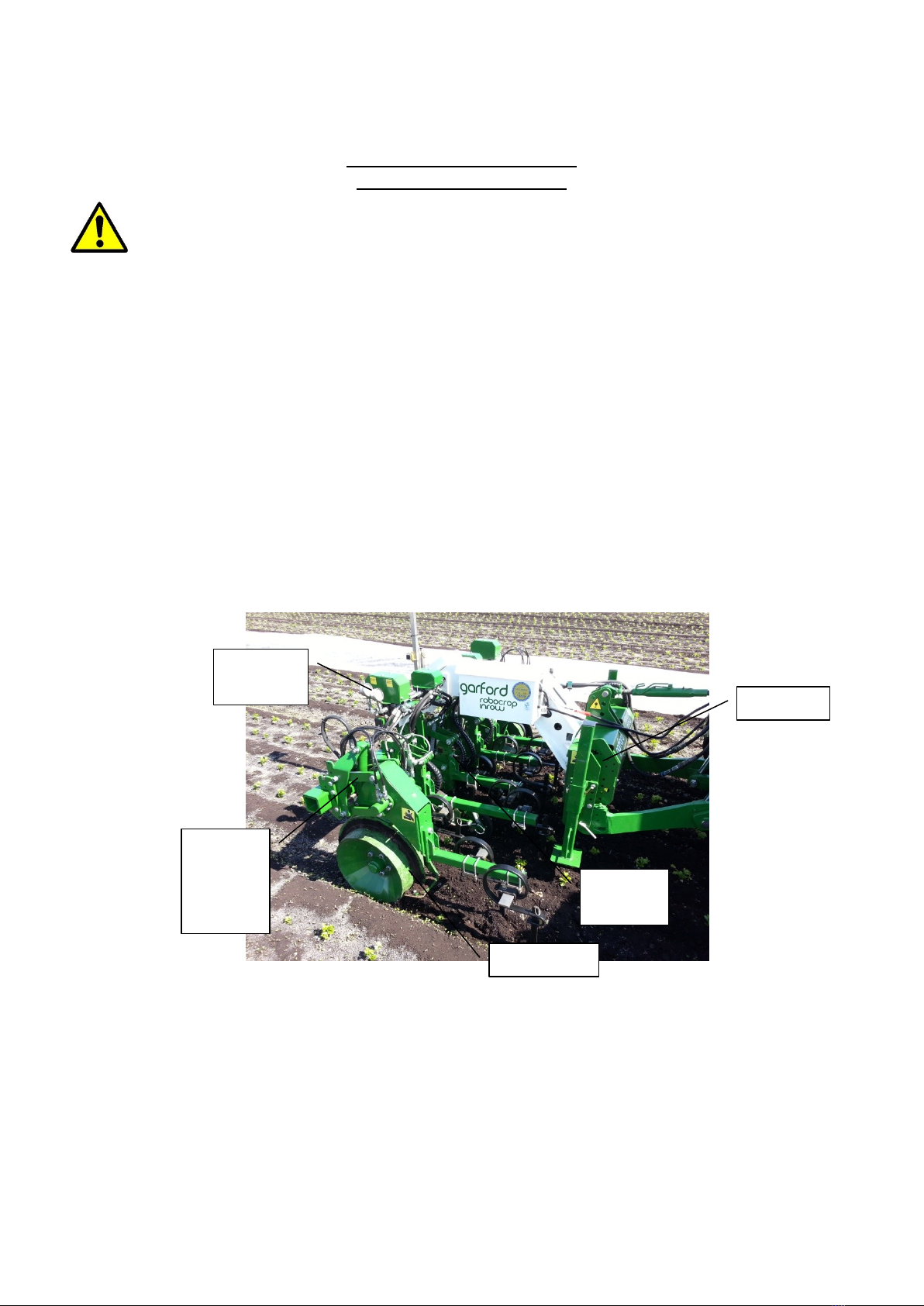

Typical employment of the Robocrop Inrow Weeder

Garford Weeding Implements

General Safety Instructions

Please read all of the safety instructions before commencing use of the implement.

Before carrying out mechanical repairs and adjustments

1. Stop the tractor engine and apply the handbrake

2. Turn off the hydraulic supply.

3. If carrying out mechanical repairs or adjustments of the implement, shut down the Robocrop computer

system and switch off the power via the rocker switch on the side of the console.

4. If the hydraulic system includes accumulators which store hydraulic pressure even when the tractor

supply is turned off, ensure the system is depressurised and allow oil to return to the tractor by

positioning the hydraulic lever in the float position. There are two pressure gauges on the hydraulic

system at the front of the implement, ensure they both read zero before carrying out repairs or

adjustments.

5. If the implement has an electric power pack, switch the isolator to the off position.

6. If possible lower the implement to the ground before working on it.

7. Never work under a raised implement unless it is supported by suitable jack stands.

8. Be aware of potential trap and shear points on the unit parallel linkages, the freeshift and the disc steer

units with self levelling, and do not put yourself at risk.

While changing settings on the computer the operator should ensure other persons do not try to make repairs

or adjustments to the implement and keep other persons well clear of the implement.

Never conduct maintenance work on the side shift or disk steering mechanisms while they are supporting the

weight of the implement.

Regularly check the condition of electric cables, hydraulic hoses and fittings and tightness of nuts and bolts etc.

If the hydraulic supply manifold is fitted with a hydraulic accumulator. Discharge the accumulator before

disconnecting the implement from the tractor.

Freeshift

Disc steer

Parallel

linkages

Pressure

gauges

Parallel

linkages

with self

levelling

It is the operator’s responsibility to ensure the safety of other persons and they must not be allowed to ride on

or work near the implement when it is in operation.

The 12V power supply cables have fuses fitted near to the power plug or battery terminals. This is for short

circuit protection and must not be omitted.

When routing the loom and power supply cables ensure that they do not cause a restriction or trip point in the

cab.

Due to the bespoke nature of the design some Garford Hoes, particularly the larger size hoes, may need special

measures when travelling on highways. Lighting equipment and marker boards are available as optional extra.

Garford lighting is designed to comply with the Revised Standard for agricultural Vehicles 1st January 2016.

Safety Signs

Folding Frame

models only

Meaning of the Safety Warning Signs

Read the operating instructions before carrying out adjustments or maintenance.

Electrical shock/Electrocution Risk. Keep sufficient distance away from electrical power lines.

Crushing risk. Keep clear of the sideshift and disc steer mechanism, folding frame points

and surrounding area during operation.

Never ride on machine during operation

Danger of crushing. Keep clear while machine is being unfolded or lowered.

Crushing risk. Keep clear of wheel unit parallel linkages during operation.

High pressure hydraulic system. Depressurise system before carrying out adjustments or

maintenance.

Powered Rotating Blade and Rotor. May rotate at anytime. Danger of entanglement

Mounting the Robocrop InRow Weeder

Never put yourself or others at risk between the tractor and implement while hitching the implement.

On a firm and level surface, hitch the implement to the tractors category 2 front 3 point linkage.

Check that the 3 point linkage has sufficient movement to raise the implement well clear of the crop when in

the field and that it will be possible to lower the implement to the soil and allow it to float on its own disc steer

support wheels.

Adjust the top link to be sure the implement is level when in the work position.

Connect the hydraulic supply lines to suitably located hydraulic supply couplings ensuring the correct direction

of flow. The supply hose is marked with a red marker and connects directly to the accumulator, the return line

is marked with a blue marker.

During work it will be necessary to lock the hydraulic supply valve of the tractor in a constant pumping position

but please ensure the supply can be stopped and pressure dumped immediately in an emergency.

It is preferable for the tractor to have a closed centre hydraulic system, however open centre systems can be

used but you may require the optional oil cooler and pressure reducer system.

Oil supply requirement is pressure of minimum of 175bar and flow of 10ltr/min + number of rows x 12ltr i.e. a 4

row machine requires 58 ltrs per minute.

Mount the console in the tractor cab in a convenient location, using the bracket supplied, where it can be easily

seen but does not obscure the operators view for safe driving. It is only necessary to glance at the console now

and again during work to reassure oneself that the system is working correctly and efficiently.

Robocrop Inrow Weeder requires 2 electrical power supply connections. The cab mounted console is fitted with

a D plug, common in most tractor cabs. The implement itself has a power cable which must be connected

directly to the tractor battery. Always take great care to observe the correct polarity - the fused side of the

supply Brown/Orange cable connects to positive, the blue cable connects to negative.

Ensure the hoses and cables are routed in such a way that they cannot chaff or become trapped or cut.

Robocrop InRow Weeder –Setup Guide

Setting up the Robocrop InRow Weeder consists of..

mechanical alignment of the weeding units

mechanical alignment of the cameras

configuration file settings

The inter relationship between all of these settings is critical; if one is wrong the weeder will not work

accurately. The accuracy of taking measurements and setting the weeder will be reflected in the accuracy of

work.

It is the operator’s responsibility to measure the crop and adjust the implement and computer settings to match

the crop.

1) The implement must be set up physically to suit the crop you are working on.

i) Set the disc steer wheel track width to suit the crop track width

ii) Set the weeder row units to suit the row widths to be worked (Always take these measurements from

the crop in the field to be worked).

iii) Ensure the rotor disc size fitted suits the crop to be worked and the setting shown on the setup

screen. The disc size should be equal to or smaller than the plant spacing to be worked. The physical

measurement across the wide part of the disc is approximately half the disc design size i.e 126mm

disc width = 25cm disc size.

Disc size designation is a special code

e.g. 16-4W6

1st part (16) is the crop spacing design size

2nd part (4) is the design offset between crop centre line and rotational axis of the disc

3rd part (W) specifies a Weeding disc, alternative =T, a Thinning disc

4th part (6) is the plant zone to be left by the disc

The numerical reference is in centimetres.

10005

8619

8614

8619

8614

8619

8614

8619

8614

8677 8677 8677 8719

8093

8091

130

8093

8091

130

8570r2

8673

8672

8673

8672

8673

8672

8673

8672

8673

8672

8673

8672

8673

8672

8673

8672

10007

9735 SL 50W

7749

7744

180

7749

7744

180

7749

7744

180

16-4W6

8543

Leg

18-4W6

8543

Leg

21-4W6

Leg

8495

25-4W7

Leg

8495

29-4W7

Leg

8495

33-4W7

Leg

8495

29-6W10

8684

Leg

33-6W10

8684

Leg

38-6W10

8684

Leg

45-6W10

8684

Leg

16-4W6 18-4W6 21-4W6 25-4W7 29-4W7 33-4W7 29-6W10 33-6W10 38-6W10 45-6W10

2) Switch on the hydraulic supply and console and allow the system to test and park the rotors.

i) Settle the weeder into the crop rows with all tractor wheels and the weeder well into the crop. You

should see the self levelling system adjust the steer discs in order to set the toolbar height. Put the 3

point linkage into the float position (never use pressure down). Adjust the top link so that the weeder

is level and the camera stem is vertical. The self levelling system monitors the position of the outside

most row unit parallel linkages to ensure the toolbar height stays a constant height above the soil

around the plants irrespective of wheeling depth or bed height. If the toolbar appears to be always

higher on one side than on the other consult your service agent.

3) Press “Setup” and check the basic settings.

i) Crop size - set to height of thickest part of foliage.

ii) Configuration –Check that the intended file is highlighted in white.

iii) Plant spacing - measure distance of 5 plant spaces and divide by 5 in at least 4 places and use the

average or set to a slightly smaller setting if it is found some plants do not get selected with a cross

while working.

iv) Clearance –start with the setting on Normal. This feature allows the non cultivated plant zone size to

be adjusted.

v) Crop Colour –set to suit the crop. If crop is a mix of red and green it may be necessary to work in

infra red mode (ask your service agent).

vi) Camera > Row quantity and width - It is the operator’s responsibility to measure the crop and adjust

the implement and computer settings to match the crop

vii) Camera > Height –settle the weeder onto the crop with all tractor wheels and the weeder well into

the crop so that everything is level. Measure the height from soil to camera lens. Check that the

height matches the setting in the configuration file. If not then adjust the camera on its bracket to the

setting shown on the console

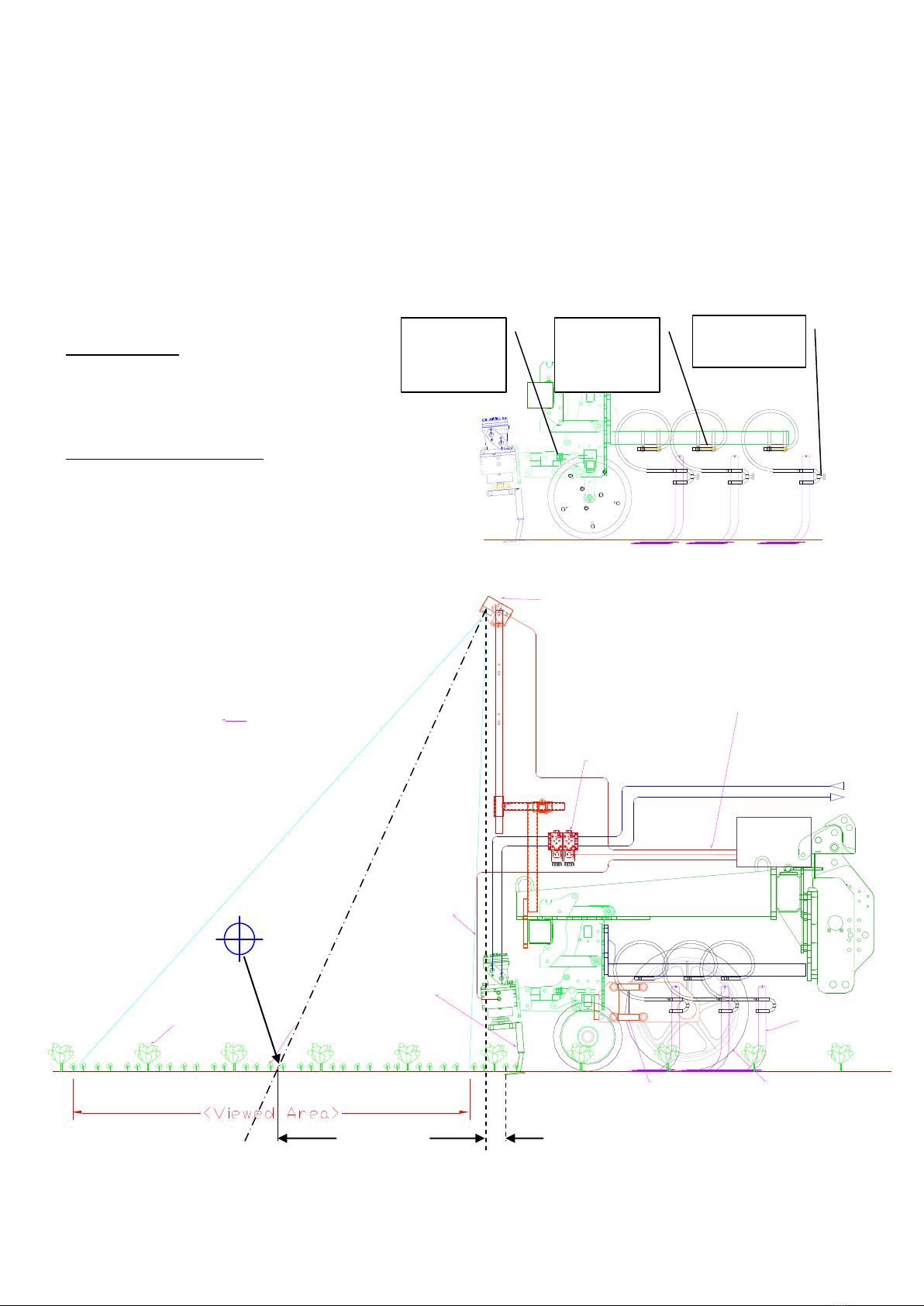

viii) Camera > Look ahead –check that the machine is level (camera stem vertical), if not adjust the top

link of the tractor 3 point linkage until it is. Ensure that every time you enter the crop, the implement

always settles to the same position by using the 3 point linkage in the float position (never impose

pressure down from the tractor via the tractor 3 point linkage!!). With the “manual” button pressed,

measure the distance along the soil from the point directly vertically below the camera lens to the

cross hairs on the camera image. This is the look ahead distance.

ix) Camera > Ahead of rotors –the distance back from the point below the camera lens to the rotational

centre of the rotor discs. If the discs are ahead of the camera lens filter then the distance is entered

as a negative.

x) Camera > Disc Size see section 1. iii above

4) Press the “Manual” button so that the grid lines appear. Go to setup>Advanced menu and set camera skew to

zero, then return to the working screen. If the grid, for each camera, does not exactly match the crop rows,

check the camera lateral adjustment, if necessary move the camera sideways until the grid is centred. If the

overall size of the grid looks wrong go to config editor and check the Camera > focal length setting. 2008

cameras should have a 4mm lens with focal length of 0.0185mm (0.7283”) and 2009 have a 2.9mm lens with

focal length of 0.0133mm (0.5253”).

5) Check that the in work sensor is set correctly and switches the grid on and off as the implement is lowered

and raised. Check that the odometer wheel is reliably in contact with the soil and soil flow is not impeded by

tines close to the wheel.

6) Check hydraulic oil supply pressure before commencing work and during working at full speed to be sure the

oil supply is sufficient. Oil pressure should be stable and not fall below 150bar (2100psi). The return line

pressure should be near to zero, please check it, if it is more than 20 bar refer to your service agent.

Fine offset- the two central buttons facilitate adjustment of the offset. Each press of

the button will move the cutting position by 1cm.

Start with the fine offset indicator dead centre. Right/left adjustment moves the

whole implement in relation to the crop position on the camera, forward/rearward

adjustment advances or retards the rotation of the rotor disc as the implement advances forwards.

On a 2 or 3 camera machine the offset forward and backwards will only adjust the rotors that each camera is

looking at. Use the select button to choose the camera section you want to alter, the cameras always read left to

right as do the thumbnail pictures on the console.

Once you are happy that the settings and adjustments are correct, slowly advance forward into the crop. Check

the path that the weeding disc passes to ensure it is accurately centreing on the gaps between the plants and

rotating around each plant. Use the fine offset to adjust it perfectly.

Likewise check that the implement is centred left/right on the crop rows and use the fine offset to adjust

perfectly.

Hydraulic drive machines have a capability to operate at a forward speed of up to 4 plants per second and electric

drive machines at up to 6 plants per second, however quality of work and soil throw should be monitored and

speed adjusted accordingly.

Tine adjustment

The tines are adjusted laterally by the clamp

on the 50x12mm brackets and vertically via

the clamp block.

Rotor disc depth adjustment

Use the rotor depth adjuster to adjust the

cutting depth of the disc

HAPPY HOEING.

Garford Farm Machinery Ltd, Frognall, Deeping St James, Peterborough PE6 8RP United Kingdom

8635

8605

8606

8323

7832

7831

8638

8645

8644

8643

8494

8570

4. Odemeter Wheel provides

accurate measure of forward

movement and speed

Lift sensor disables

the system when the

weeder is lifted

1. The camera views the

crop ahead of the weeder

8623

8540

7749

7750

180

7749

7750

180

7749

7750

180

8730

2. Computer analyses

images from camera

3. Computer monitors

rotor position and speed

Hydraulic supply

from tractor

Inter row tines

complete the

weeding operation

5. Computer adjusts

speed of rotor via

hydraulic valve

Computer

6. Weeding rotor destroys

weeds as it loops in and

out of the plant gaps

Direction of travel

Plants Weeds

Look Ahead

Distance ahead of Rotor

8719

8673

8672

7749

7750

180

9735SL 50W

8673

8672

7749

7750

180

8673

8672

7749

7750

180

Lateral

adjustment

clamp

Vertical tine

adjustment

Rotor

depth

adjuster

Table of contents

Other Garford Farm Equipment manuals