Gas Detection GDA 4360 User manual

GDA 4360

Operating Manual

Carbon Dioxide Sensor

Hardware Version 11

© Copyright Gas Detection (Australia) Pty Ltd Sep 2015

Gas Detection (Australia) Pty Ltd Page 2 of 12 M-GDA-4360-V11-Rev 3

Precautions:

To avoid instrument damage and potential dangerous accident; do not use this product before reading

the manual.

Introduction:

The GDA 4360 is designed for use in safe area applications. It uses the latest laser semiconductor

technology for detection of carbon dioxide. The sensor and electronics are one homogenous unit and

must never be separated. It has an analog output which can be set to 4-20mA, 0-20mA, 0-10V or 0-5V.

Specifications:

Target Gas: Carbon Dioxide (CO2)

Range: 0-2000ppm; 0-10000ppm; 0-5% vol; 0-20% vol; 0-100% vol

Operating Voltage: 24 V DC

Output Type: 4-20mA (Standard), 0-20mA, 0-10V or 0-5V (User Specified)

Current Draw: 150mA peak @ 24V

Wiring: 3 core wire with overall screen with current carrying capability to suit cable

length of cable run, Screen must be connected to the Earth connection on the

connector P1.

Operating Temp Range: -20°C to +50° C

Humidity Range: 5-95%RH peak non condensing

Accuracy of Reading: +- 2% FSD +-0.5% reading @STP

Warm Up Time:< 4 min

Speed of Response: < 24 sec

Zero Drift: <0.5% FSD for 90days @STP

Calibration Drift: <0.5% FSD for 90 days @STP

Enclosure: Clipsal 2000 series 116 x 75 x 13 mm (L, W, D) in wall depth 40 mm

IP Rating of enclosure: IP50

Cable Entry: Rear

Operating Air Pressure: 950 to 1050 hPa

Gas Detection (Australia) Pty Ltd Page 3 of 12 M-GDA-4360-V11-Rev 3

Installation:

The sensor is rated IP50 and therefore suitable for indoor use only. If it is going to be used in external

environments seek specialist advice from GDA. The sensor should not be exposed to steam or saturated

water vapour.

Carbon Dioxide is heavier than air and therefore will (if there is no air movement) fall to lower levels. The

recommended minimum installation height above the floor is 300mm.

Mount the sensor as close as possible to where the leak of the gas being detecting may occur as the

distance from a potential leek effects the time taken to detect it. The further from the potential leeks the

more the gas will be diluted. Take into account drafts and air movements when mounting the sensor.

Fit using the four fixing holes in the corners of the box. When drilling avoid any vibration of the sensor

unit. The laser diode sensing unit is very sensitive. Do not expose the sensor to any mechanical shock.

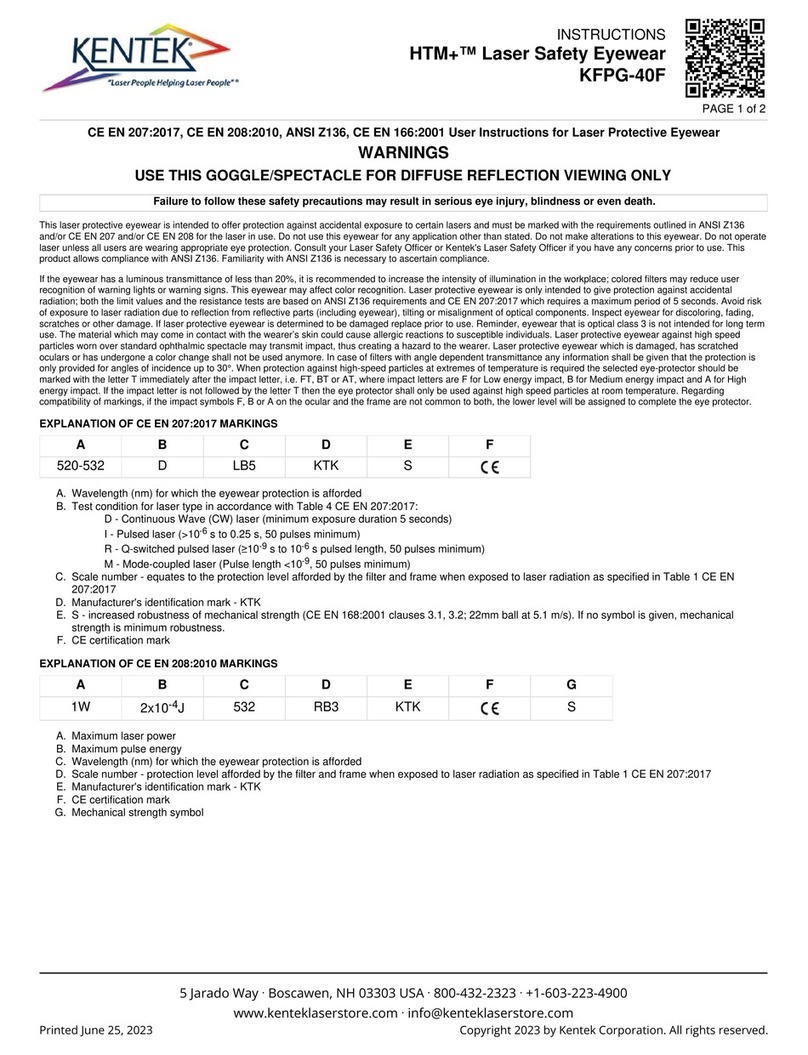

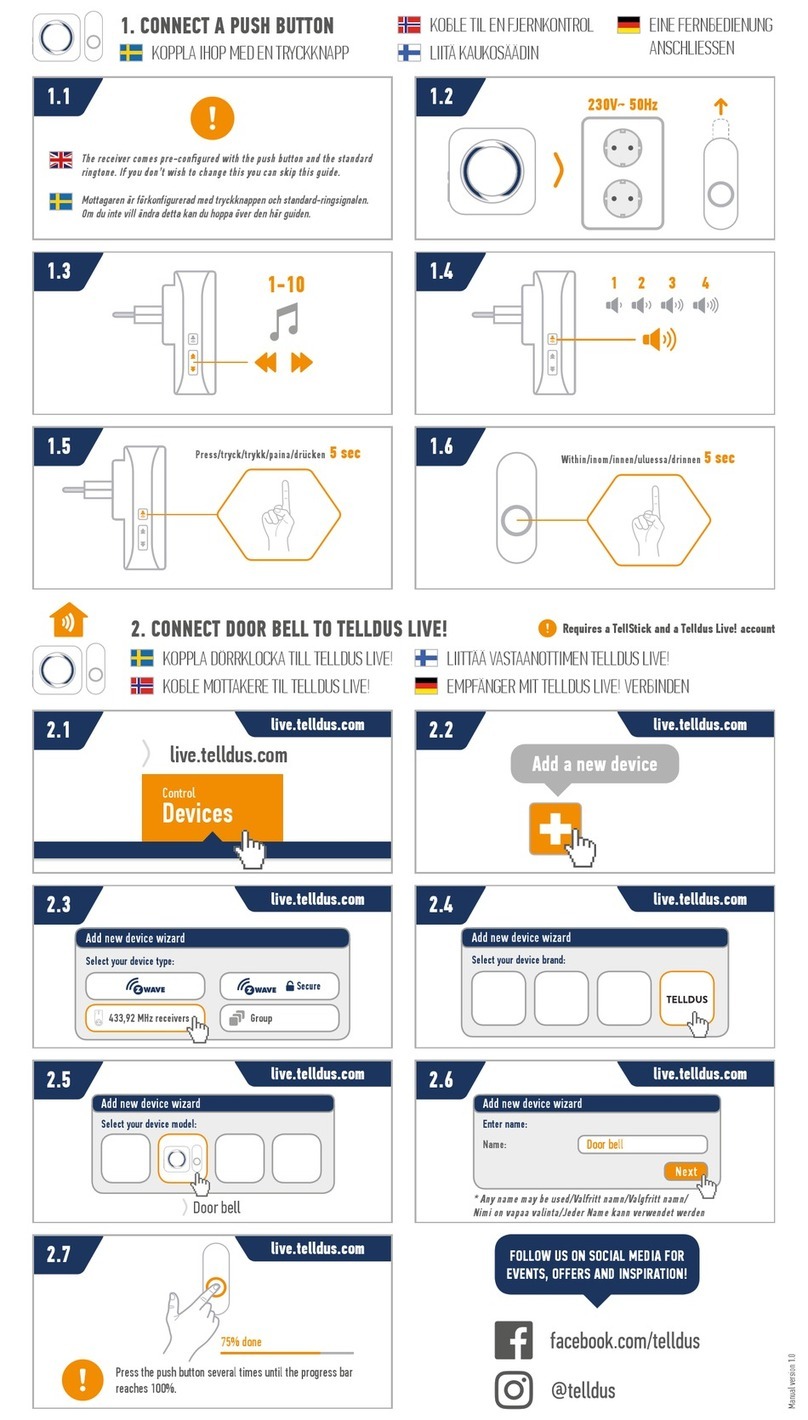

IT IS VERY IMPORTANT THAT THE GDA 4360 IS INSTALLED IN THE MOST UPRIGHT POSITION AGAINST A

VERTICAL STRUCTURE

DO NOT EXPOSE THE SENSOR FACE TO DIRECT WATER DROPLETS OR CONDENSING ATMOSPHERES

GDA 4360 SENSOR INSTALLATION POSITION

___________________________________________________________________________________

YES

NO

NO

Gas Detection (Australia) Pty Ltd Page 4 of 12 M-GDA-4360-V11-Rev 3

Operation:

When power is applied the sensor goes through a power up procedure as detailed below. Please note

that the current o/p is not valid for approximately 2-4 minutes from the power being applied.

During the 2-4 minute power up the current output of the GDA 4360 may reach the full scale of the set

output. Ensure that this does not affect external equipment.

LED

LED STATE

FUNTION

ON

Power is present

OFF

Power is not present

GREEN ON, BLUE

FLASHING

The sensor is in its warm up period (approx 2~4 mins)

during this period the sensor o/p is 0.45mA

GREEN ON, BLUE

FLASHING

Normal operation the sensor has stabilised and the 4-

20ma reflects the amount of gas present

GREEN & RED ON

This indicates a fault associated with the sensor. The o/p

current is reduced to 1.2ma

LED Indicator Location: Colours:

Gas Detection (Australia) Pty Ltd Page 5 of 12 M-GDA-4360-V11-Rev 3

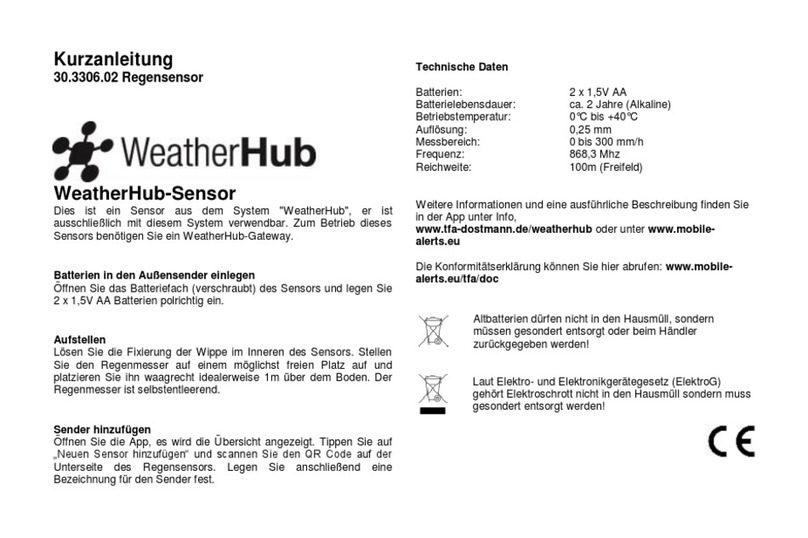

Electrical installation:

The sensor electrical connection is on the rear of the faceplate via a 4 pin polarised plug on the PCB.

The sensor is to be wired with a 3 core cable with an overall screen with current carrying capability to suit

cable length of cable run. Screen must be connected to the Earth connection on the connector P1. The

enclosure is platted with a layer of conductive chrome which is connected to the earth terminal on the

PCB.

The 4-20mA O/P is to be connected to the 4-20mA input of the control board.

4-20mA O/P

0V DC

+24V DC

EARTH

Protection

Cover Plate

Power and

Output

Connector

P1

Gas Detection (Australia) Pty Ltd Page 6 of 12 M-GDA-4360-V11-Rev 3

Output Operations:

Current or Voltage 0-20mA, 4-20mA, 0-5V, 0-10V Configuration:

This output will generate a current or voltage output reflecting the full scale of the sensor. This output is

factory set and calibrated to the user’s specified requirements at point of purchase.

If an output type was not specified by the user at time of purchase the default setup is set and calibrated

to 4-20mA. This is user adjustable out in field but will not be as accurate to what it was originally

calibrated to from factory.

The 4-20ma will drive into a maximum of 680Ω load impedance (line and input impedance) at 24V.

Be cautious when handling the GDA 4360 as there are delicate components that can easily be damaged

by static discharge. Always observe anti static precautions.

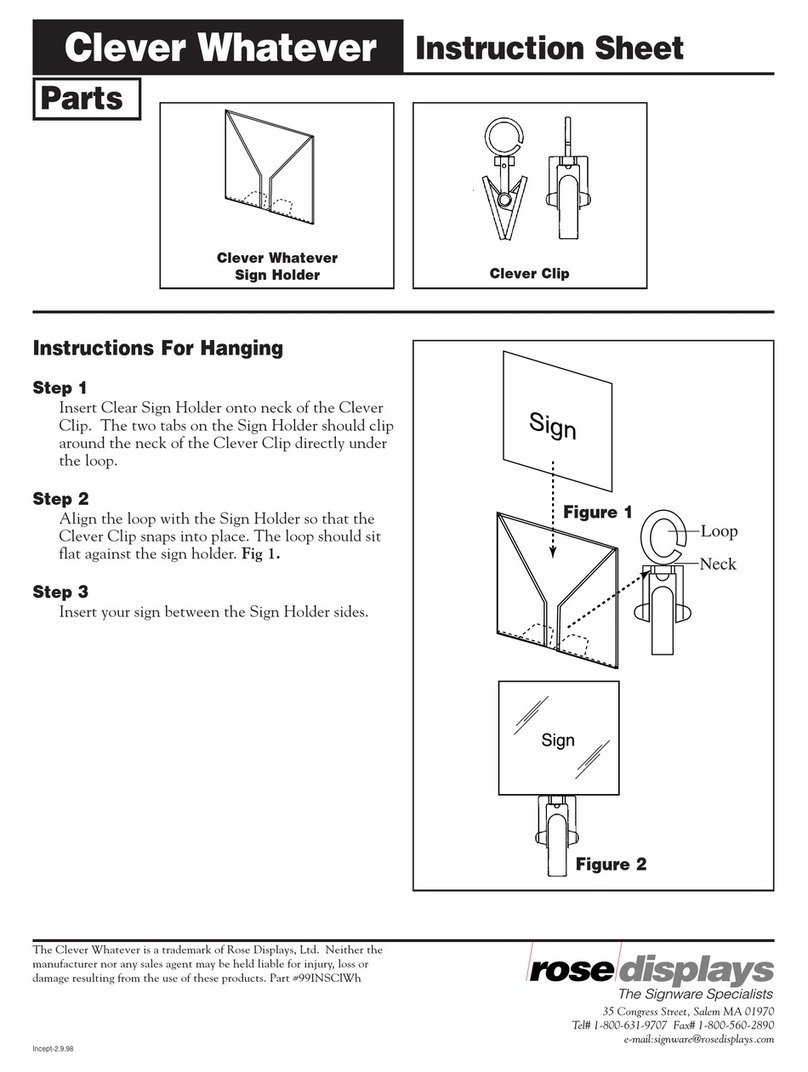

To change the output:

1. Isolate the GDA 4360 by removing the incoming power source connector (P1) from the rear of the

board

2. Adjust jumper pins to the desired output configuration (see Table below)

3. Ensure output is configured for the changed output option

4. Revert to normal operation

Output Type

P2 Jumper Configuration (IN or OUT)

P2 Jumper Location

1

Sen

Pwr

2

MCU

Pwr

3

HS/FS

4

0/4-

20mA

5

V Out

6

Reset

4 - 20 mA (Default as pictured)

IN

IN

IN

IN

OUT

OUT

0 - 20 mA

IN

IN

IN

OUT

OUT

OUT

0 - 5 V

IN

IN

OUT

OUT

IN

OUT

0 - 10 V

IN

IN

IN

OUT

IN

OUT

P2

P3

P2 Jumper

Description

P1

P2 Jumper Location No.:

1 2 3 4 5 6

Gas Detection (Australia) Pty Ltd Page 7 of 12 M-GDA-4360-V11-Rev 3

Calibration:

Sensors are issued tested & pre-calibrated under controlled lab conditions. Changes to humidity,

temperature, and other environmental factors affect the sensor accuracy and may need a re-set of the

fresh air zero point when introduced to new environments.

The GDA 4360 is an auto calibrating device and under most cases will auto calibrate to new environment

over time

Functional testing may be carried out with a suitable test gas to ensure that the 4-20ma o/p corresponds

with the gas level. This should be undertaken when the unit is fully assembled and using a flow rate of

~0.5L/min of the target gas. Test gas and equipment are available from Gas Detection Australia.

Fresh air Zero point Calibration:

A manual fresh air zeroing (span) of the sensor can be performed when the sensor has been powered for

a minimum of one hour. The fresh air zero can be performed when the sensor is in a known fresh air. The

sensor must be in the fresh air conditions for a minimum of five minutes or until the output has reached a

stable point.

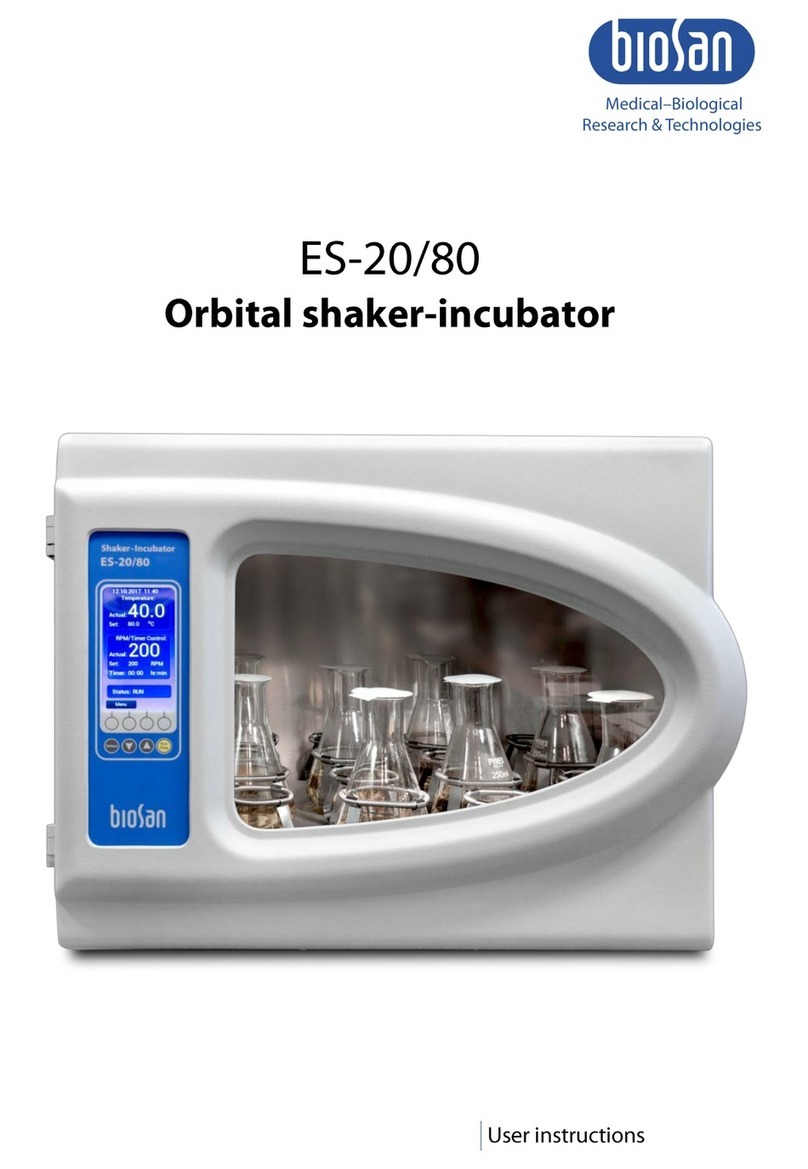

To perform a manual fresh air zero (span) point calibration:

1. Remove the GDA 4360 from the wall to access the back of the sensor unit;

2. Add a jumper to pins 1 and 3 of P3 see picture below, This enters Manual Calibration Mode (see table

for LED sequence);

3. Press and hold the SPAN/ Fresh Air Zero calibration button S1 for 1 to 2 seconds (see table for LED

sequence):

If the Fresh Air Zero was successful (see table for LED sequence)

If the Fresh Air Zero was NOT successful (see table for LED sequence). Repeat step 3

after ensuring that the sensor is in fresh air and stable.

Note: Do not press the ZERO button as it will perform a Nitrogen zero.

4. When successfully zeroed remove the Manual Calibration jumper from header P3 and return to normal

operation.

Mode

LED Light Sequence

Manual CAL Mode

0.5 sec

Alternate Blinking at once per

second

Performing Zero

0.5 sec

Alternate Blinking at once per

second for ~ 4 sec

Zero Successful

0.1 sec

Fast Blink for ~ 2 sec

Zero Failed

Solid for > 2 sec

Gas Detection (Australia) Pty Ltd Page 8 of 12 M-GDA-4360-V11-Rev 3

Contact Gas Detection Australia for more information if calibration of sensor is required

LED Colours:

SPAN/ Fresh Air Zero

calibration button S1

Manual Calibration

Mode: Add a jumper

to pins 1 and 3 of P3

1 3

Use supplied jumper

on pins 18 and 17 of

P3 for Manual

Calibration Mode,

return to this location

only.

Gas Detection (Australia) Pty Ltd Page 9 of 12 M-GDA-4360-V11-Rev 3

Notes

Gas Detection (Australia) Pty Ltd Page 10 of 12 M-GDA-4360-V11-Rev 3

Notes

Gas Detection (Australia) Pty Ltd Page 11 of 12 M-GDA-4360-V11-Rev 3

Notes

Thank You for Supporting

Australian Manufactured

Products

Gas Detection (Australia) Pty Ltd Page 12 of 12 M-GDA-4360-V11-Rev 3

Table of contents

Other Gas Detection Accessories manuals

Popular Accessories manuals by other brands

Eagle Tree Systems

Eagle Tree Systems Eagle Tree Microsensor V3 quick start guide

Multitech

Multitech Reveal user guide

Termozeta

Termozeta TZR60 instruction manual

Williams-Sonoma

Williams-Sonoma PATTERSON Assembly instructions

INNOBIZ

INNOBIZ 2141 Instructions for use

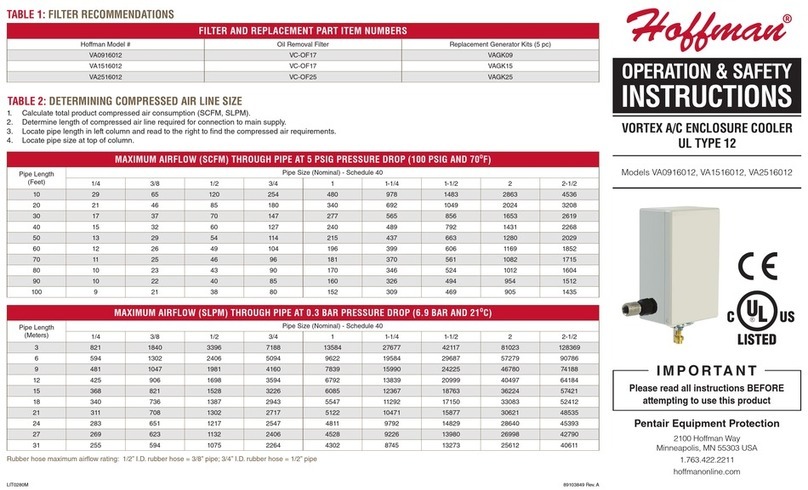

Hoffman

Hoffman VA0916012 Operation & Safety Instructions