QUICK REFERENCE GUIDE

PI Rip sensor

Purpose

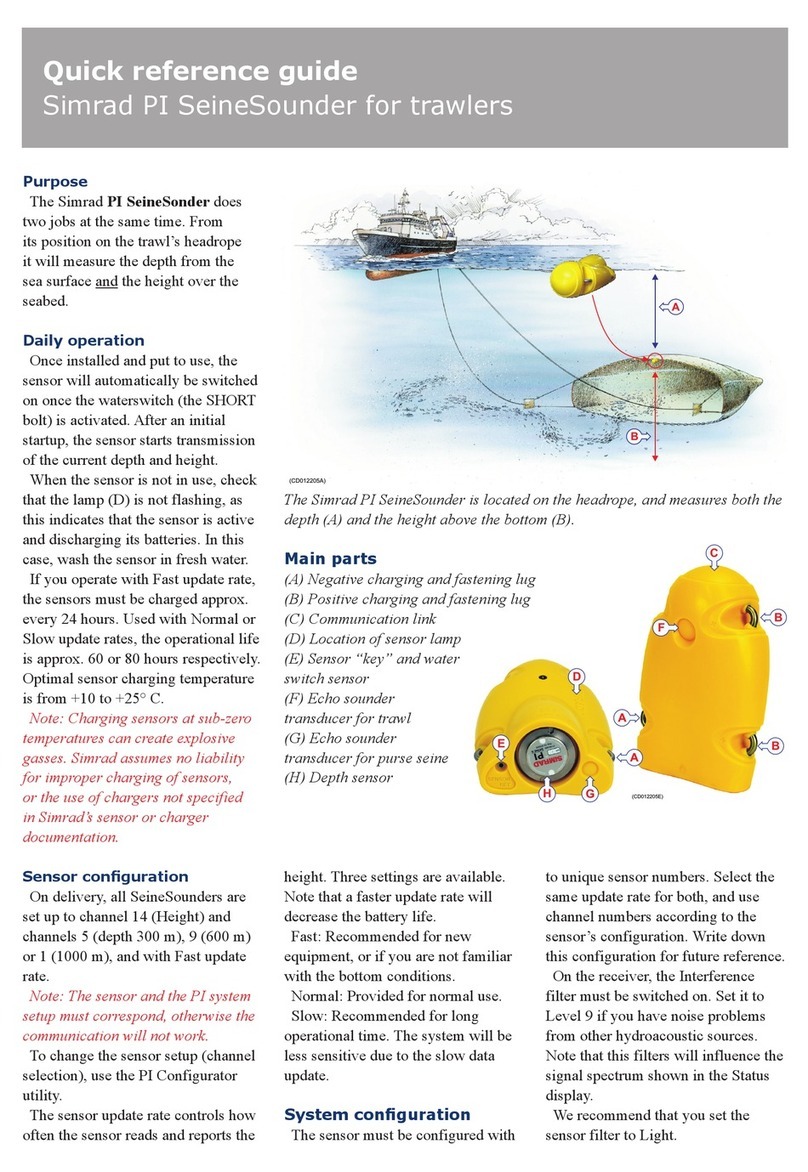

sensor is identical to the

, and it must be regarded as a

second application for the Catch sensor.

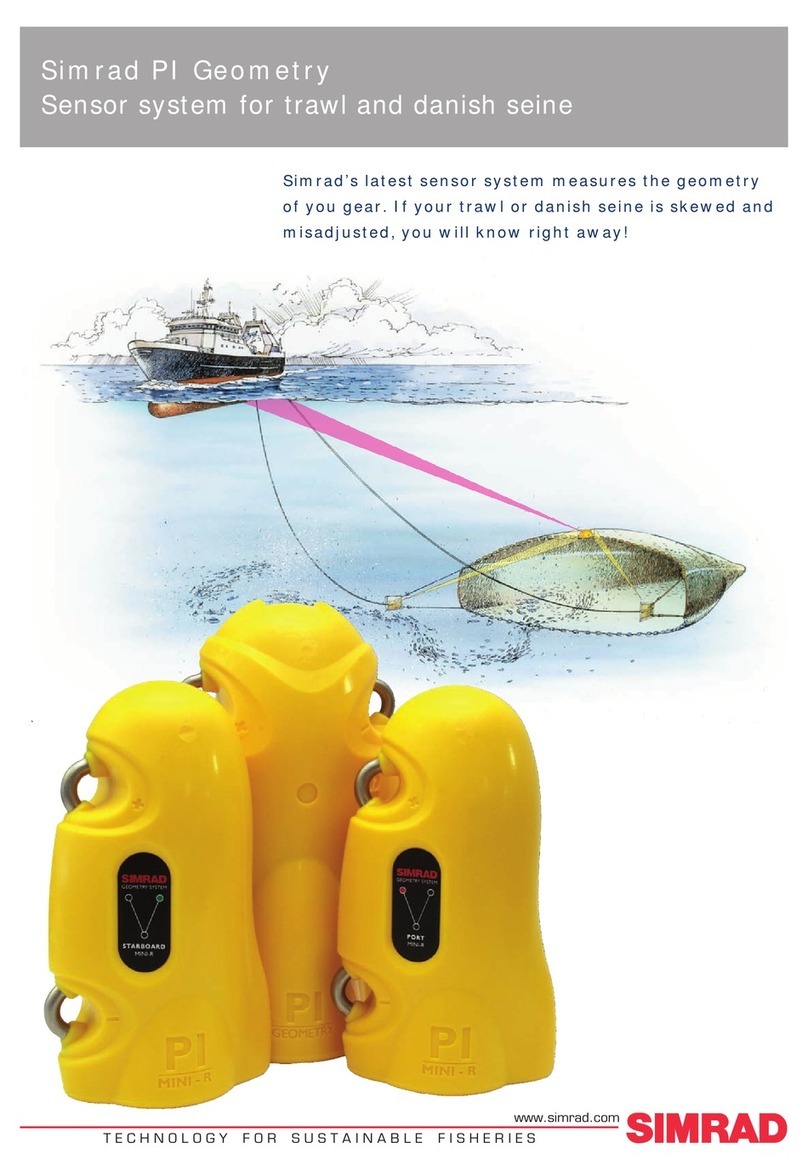

sensor will monitor if your

net is damaged and ripped apart due to

obstructions or foreign objects on the

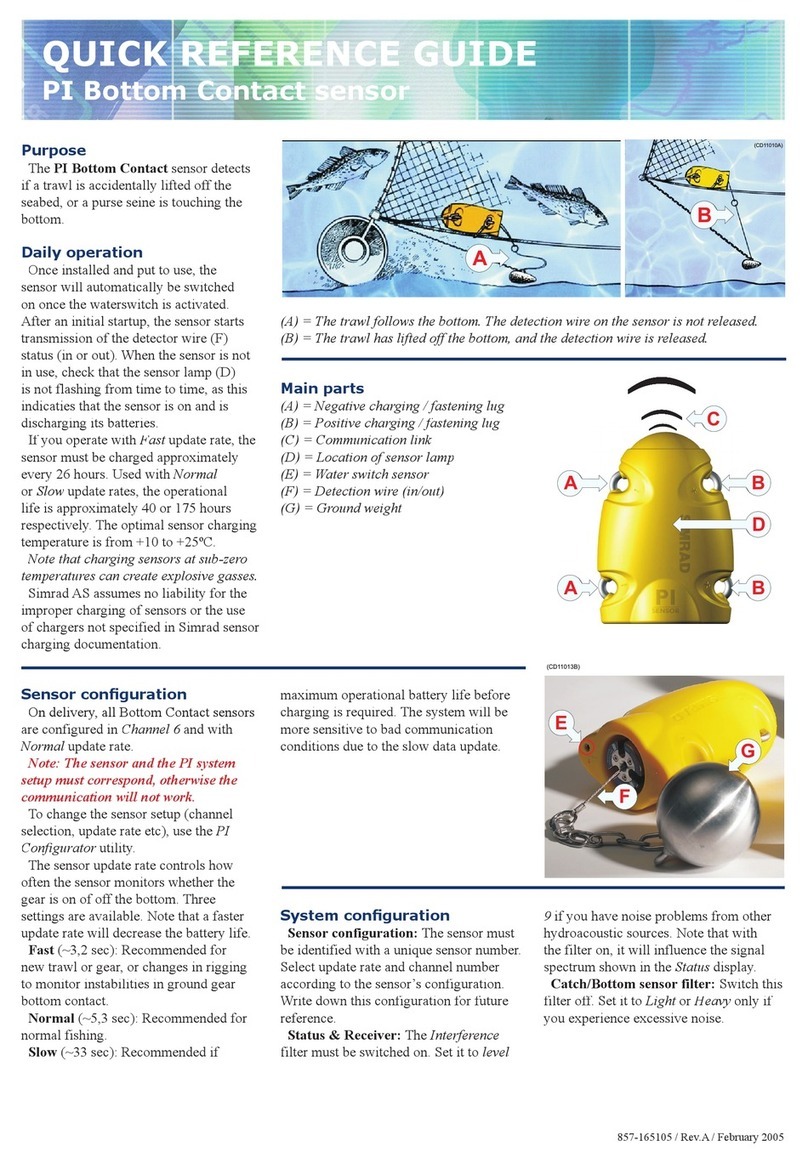

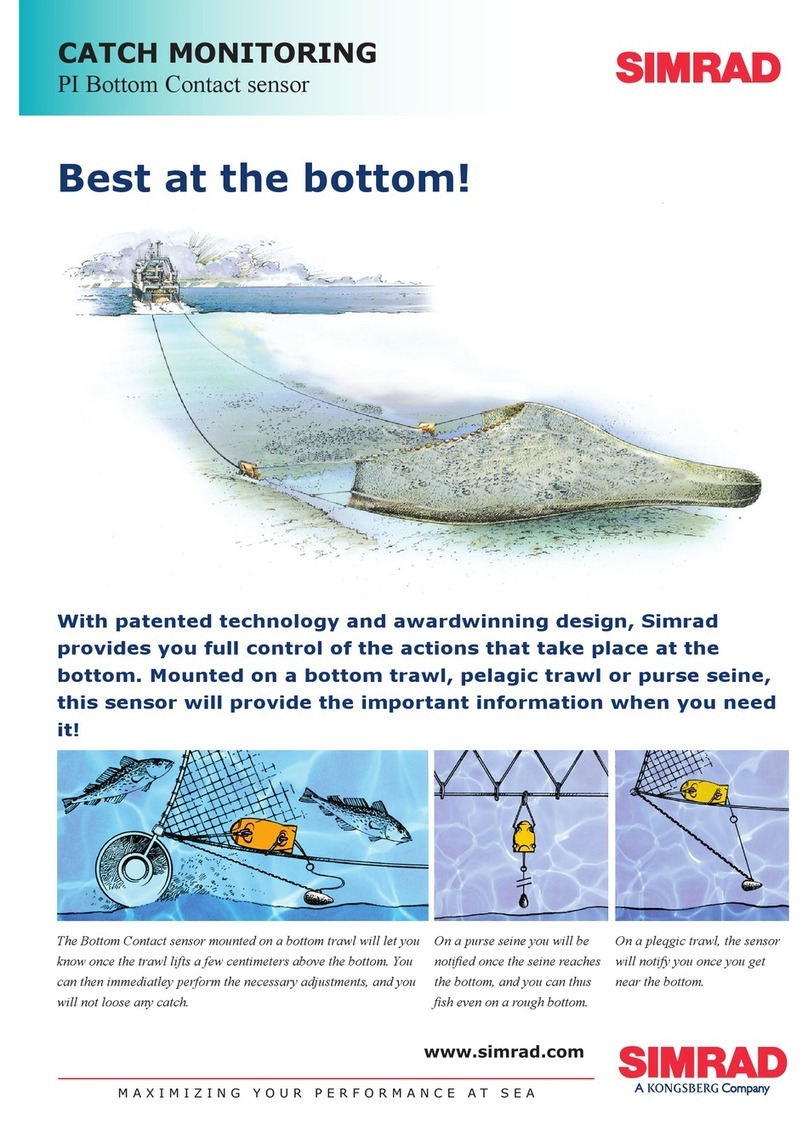

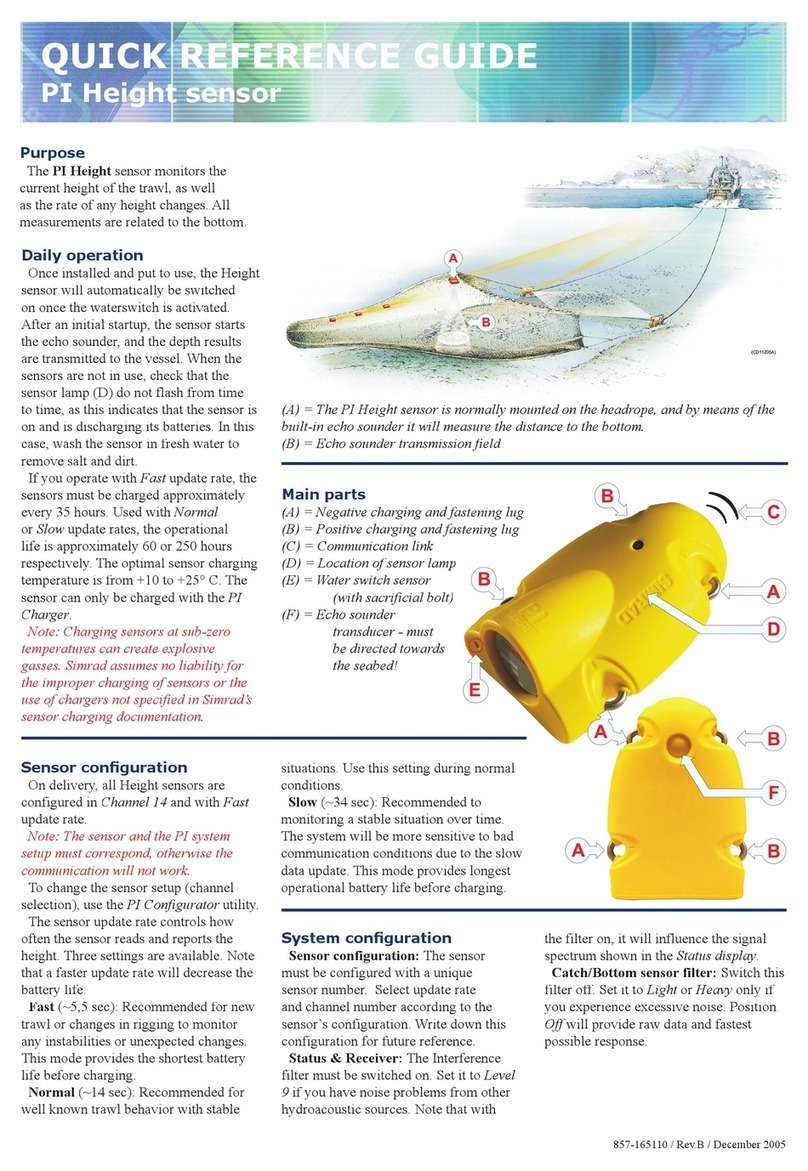

(A) = The PI Rip is mounted on the

footrope with the two sensor wires

stretched out and the wires engaged.

(B) = Two strong rubber bands

ensure that the sensor is activated.

If the net is torn, the slack in the net

will disengage the Rip sensor.

In most cases, one or two Rip sensors

mounted on the footrope will be

sufficient to monitor the condition of the

net. Once installed and put to use, the

sensor will automatically be switched on

once the waterswitch is activated. After

an initial startup, the sensor will detect

the status of the detection wires, and

transmit this information to the vessel.

When the sensor is not in use, check

that the sensor lamps (D) do not flash

from time to time, as this indicates that

the sensor is on and is discharging its

batteries. In this case, wash the sensor in

fresh water to remove salt and dirt.

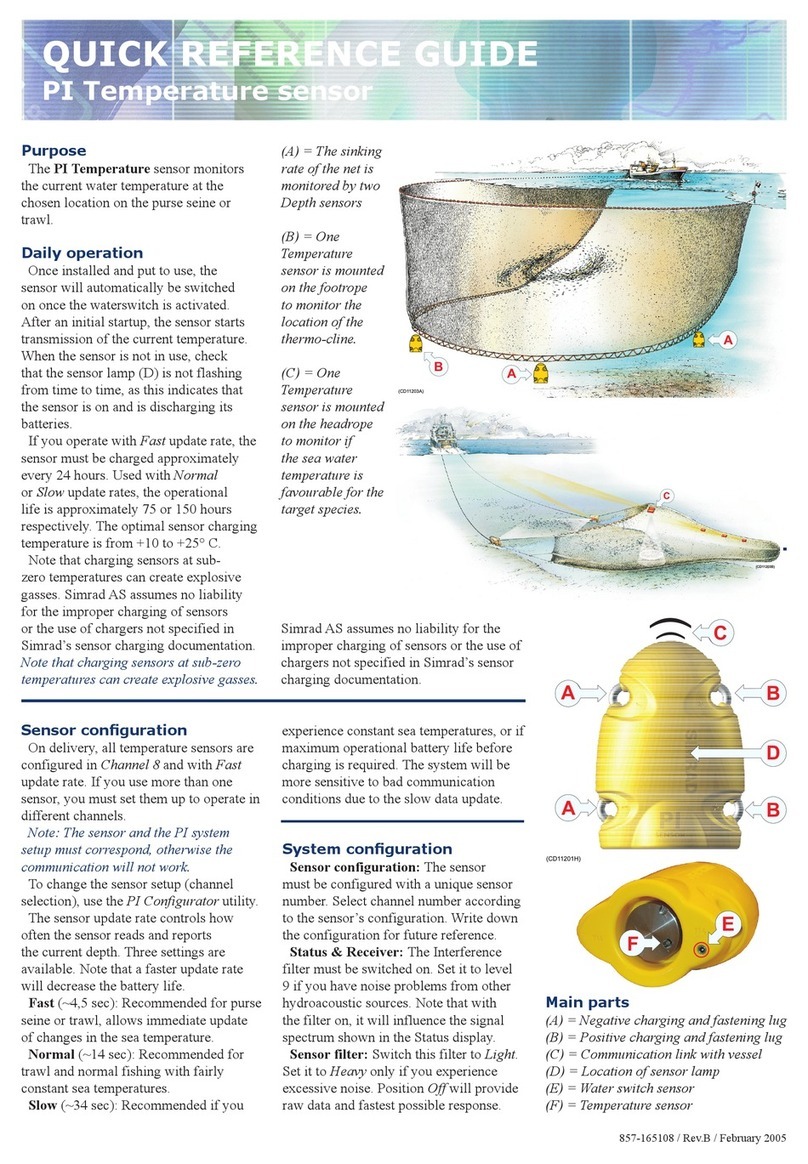

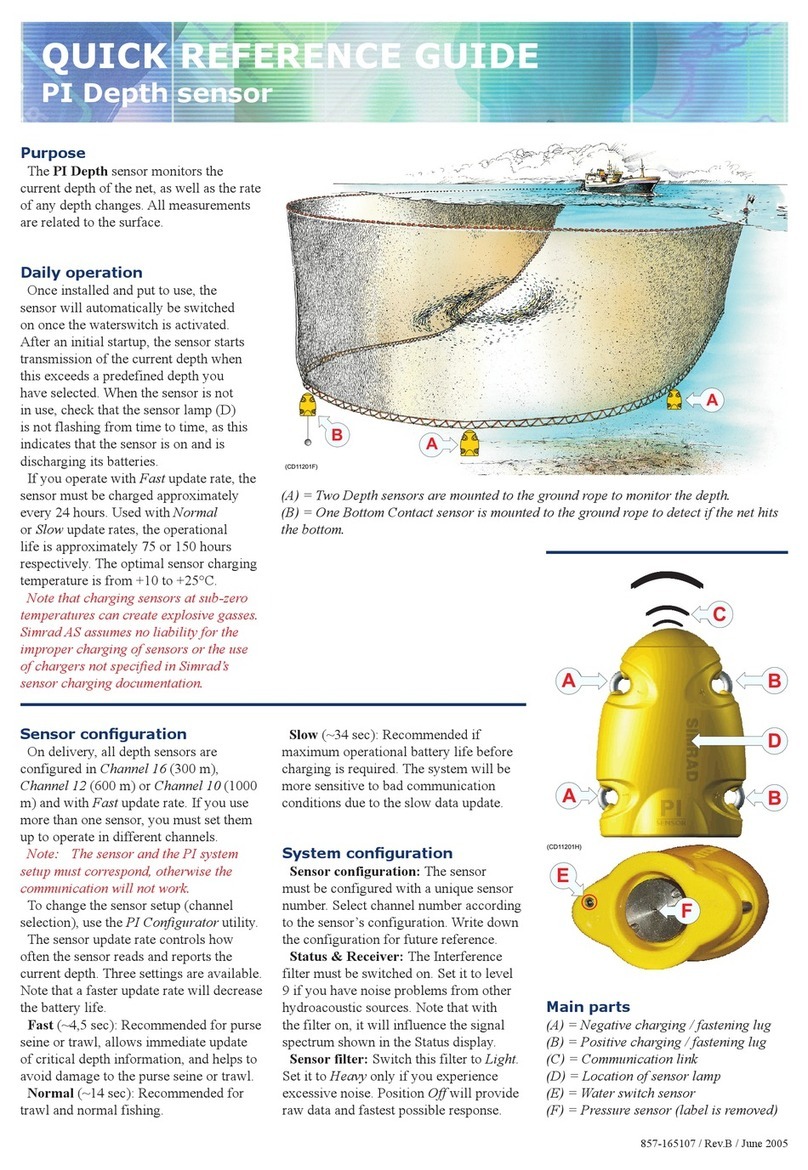

(A) = Negative charging / fastening lug

(B) = Positive charging / fastening lug

(D) = Location of sensor lamp

(E) = Water switch sensor

On delivery, all Rip sensors are

update rate. If you wish to use

sensors simultanously, one of them

must be set to a different communication

Note: The sensor and the PI system

setup must correspond, otherwise the

communication will not work.

To change the sensor setup (channel

selection), use the PI Configurator utility.

The sensor update rate controls how

often the sensor reads and reports the

door spread. Three settings are available.

Note that a faster update rate will

decrease the battery life.

(~5,3 sec): Recommended if you

suspect that the bottom conditions are

rough and unpredictable, and that damage

may be easily inflicted. This mode

provides the shortest battery life before

(~33 sec): Recommended for

normal bottom conditions.

(~125 sec): Recommended if the

bottom conditions are well known, and

you know that no obstructions exist.

This mode provides longest operational

battery life before charging.

857-165111 / Rev.B / December 2005

must be configured with a unique

sensor number. Select channel number

and update rate according to the

sensor’s configuration. Write down the

configuration for future reference.

filter must be switched on. Set it to

if you have noise problems from other

hydroacoustic sources. Note that with

the filter on, it will influence the signal

excessive noise. Position

raw data and fastest possible response.

rate, the sensor must be charged

approximately every 35 hours. Used

the operational life is approximately

150 or 300 hours respectively. The

optimal sensor charging temperature

Note: Charging sensors at sub-zero

temperatures can create explosive

gasses. Simrad assumes no liability

for the improper charging of

sensors or the use of chargers not

specified in Simrad sensor charging

documentation.