GasTech IQ Express User manual

R eferenc e M a nua l

IQ E xpres s

D oc king S ta tion

for

ToxiP ro, Tox iLtd

& Toxi3Ltd

Gastech

24 Baretta Rd

Wangara Western Australia 6065

Tel 1800 999 902

Fax 1800 999 903

http://www.gastech.com

1

THE IQ EXPRESS IS DESIGNED TO INTERFACE WITH SPERIAN

INSTRUMENTATION GAS DETECTORS.

SPERIAN INSTRUMENTATION GAS DETECTORS HAVE BEEN

DESIGNED FOR THE DETECTION OF DEFICIENCIES OF OXYGEN,

ACCUMULATIONS OF FLAMMABLE GASES AND VAPORS AND

ACCUMULATIONS OF TOXIC VAPORS.

IN ORDER TO ENSURE THAT THE USER IS PROPERLY WARNED OF

POTENTIALLY DANGEROUS ATMOSPHERIC CONDITIONS, IT IS

ESSENTIAL THAT THE INSTRUCTIONS IN THIS MANUAL AND THE

OPERATIONS AND/OR REFERENCE MANUAL(S) FOR THE GAS

DETECTOR(S) BE READ, FULLY UNDERSTOOD, AND FOLLOWED.

THIS MANUAL IS NOT INTENDED TO REPLACE THE OPERATIONS

AND/OR REFERENCE MANUALS FOR THE GAS DETECTOR. THIS

MANUAL IS ONLY DESIGNED TO AID IN THE INSTALLATION AND

OPERATION OF THE IQ EXPRESS SYSTEM AND SHOULD BE USED IN

CONJUNCTION WITH THE INSTRUMENT REFERENCE OR

OPERATIONS MANUAL AT ALL TIMES.

IQ Express Reference Manual

Sperian Instrumentation Part Number 13-275

Version 4.02

Copyright 2008

by

Sperian Instrumentation, LLC

Middletown, Connecticut 06457

All rights reserved.

No page or part of this operation manual may be reproduced in

any form without written permission of the copyright owner

shown above.

Sperian Instrumentation reserves the right to correct typographical errors.

2

Table of Contents

Warnings and Cautions ........................................................................................ 3

A. Signal Words...................................................................................................................3

1. Overview ........................................................................................................ 4

1.1 Tests and record keeping ...........................................................................................4

1.2 PC Connection ............................................................................................................4

1.2.1 USB Connection..........................................................................................................4

1.2.2 Ethernet Connection and E-mail.................................................................................4

1.3 PC Requirements........................................................................................................5

1.3.1 Ethernet Requirements........................................................................................5

1.4 Instrument Firmware Requirements ...........................................................................5

1.5 Power Requirements...................................................................................................5

1.5.1 Dock with direct USB Connection to PC .............................................................5

1.5.2 Multi-Dock Setup with USB Connection..............................................................5

1.6 Sensor compatibility....................................................................................................5

1.7 Default Calibration Gas Settings and Dock Compatibility ..........................................6

1.8 Calibration Gas Cylinder Regulator Requirements.....................................................6

1.9 Delivery .......................................................................................................................6

2. Installation ..................................................................................................... 6

2.1 Installation Overview...................................................................................................6

2.2 IQ Administrator Pro and PostgreSQL Database Server Installation.........................6

2.3 IQ Database Manager Software Installation...............................................................7

2.4 IQ Express PC Software Installation...........................................................................7

2.5 Install IQ Administrator Pro and PostgreSQL database. ............................................8

2.6 Power and Connectivity ..............................................................................................8

2.6.1 PC – Single Dock via USB ..................................................................................8

2.6.2 PC – Multi Dock via USB.....................................................................................8

2.7 Connecting the Calibration Gas Cylinder(s) to the Dock(s)........................................9

2.7.1 Single Cylinder to Single IQ Express Dock .........................................................9

2.7.2 Single Cylinder to Multiple Docks......................................................................10

2.7.3 Fresh Air Port Instructions .................................................................................11

Fresh Air Filter...............................................................................................................11

Providing Fresh Air in a Contaminated Environment ...................................................11

Option 1: Using a Gas Cylinder to Provide Fresh Air to the Dock...........................12

Option 2: Using a Sealed Conduit to Provide Fresh Air to the Dock.......................12

Multi-Dock Setups with Fresh Air Manifold...............................................................12

2.8 Dock Setup................................................................................................................13

3. Software ....................................................................................................... 13

3.1 Dock Status ...............................................................................................................14

3.1.1 Dock status LED ................................................................................................14

3.1.2 Instrument status LEDs .....................................................................................14

3.2 Dock Controls and Instrument Status .......................................................................15

3.2.1 Dock Configuration ............................................................................................15

Hardware Configuration................................................................................................15

AC Power ......................................................................................................................15

3

LCD Contrast Control....................................................................................................15

Battery...........................................................................................................................16

Pump Diagnostics .........................................................................................................16

Audible Alarm Sensitivity Controls................................................................................16

Calibration Interval ........................................................................................................16

Gas Configuration .........................................................................................................16

Special Instructions: Gas Configuration, Oxygen Detectors .......................................17

Saving new settings ......................................................................................................18

Dock LCD Display.........................................................................................................18

Ethernet Controls ..........................................................................................................18

3.2.2 Instrument Tab...................................................................................................18

3.3 Advanced Settings / Passcode .................................................................................19

4. Dock Use...................................................................................................... 20

4.1 Test Sequence ..........................................................................................................21

4.2 Loss of IrDA Connection ...........................................................................................22

4.3 Test Failures .............................................................................................................22

4.3.1 No gas detected ................................................................................................22

4.3.2 Span calibration failure......................................................................................22

4.3.3 Wrong Gas Type ...............................................................................................22

4.3.4 Alarm test failure................................................................................................22

4.3.5 PC Aborted Test ................................................................................................22

5. Tools............................................................................................................. 22

5.1 Dock ..........................................................................................................................23

5.2 ToxiPro ......................................................................................................................23

5.3 Certificates ................................................................................................................24

5.4 Session Downloading ...............................................................................................24

6. Software Revisions ..................................................................................... 24

Appendix A: USB Architecture with Network Access..................................... 25

Appendix B: Calibration Frequency ................................................................. 26

Sperian Instrumentation Warranty Gas Detection Products........................... 27

Warnings and Cautions

A. Signal Words

The following signal words, as defined by ANSI Z535.4-1998, are used in the IQ Express

Reference Manual.

indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

indicates a potentially hazardous situation, which if not avoided,

may result in moderate or minor injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

4

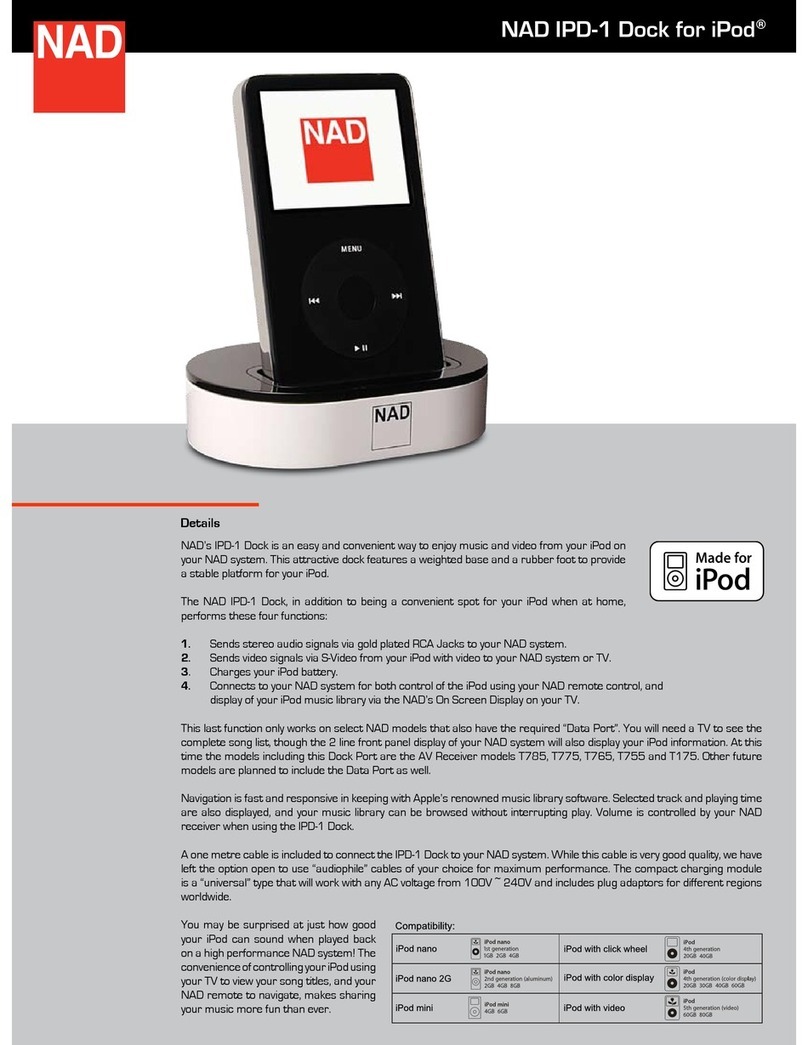

1. Overview

The IQ Express is an automatic calibration

station for use with the ToxiPro, OxyPro,

ToxiLtd and OxyLtd Gas Detectors. The IQ

Express automatically performs up to eight

critical tests including sensor identification,

instrument performance, bump and alarm

tests and necessary record-keeping

procedures. The station retains a historical

record of instrument testing in the system's

onboard memory.

The IQ Express Dock is available in two

versions. The standard version is able to

process instruments containing O2, CO and

H2S sensors. The enhanced version adds

the ability to process ToxiPro instruments

for SO2, Cl2, NO2, NH3, HCN and PH3.

Either type of dock may be operated as a

stand-alone calibration station, or may be

connected to a PC via USB or Ethernet for

increased control over system operations.

When the IQ Express is operated without a

PC interface, it will operate with the last set

of calibration gas settings that were

uploaded into the instrument and will

automatically store data until its memory is

full.

Unless specified at the time of purchase, all

IQ Express Docks are shipped from Sperian

Instrumentation configured for CO/H2S

instruments with standard calibration gas

settings. In the event that the dock is to be

used as a stand-alone calibration station for

an instrument with a gas other than CO or

H2S, or requires a non-standard calibration

gas setting, the dock must be

reprogrammed with the IQ Express PC

Software.

The IQ Express PC Software must be

loaded onto the PC prior to completing the

physical connection to the PC. When

connected to the PC, the IQ Express will

automatically upload all instrument data into

the PC whenever the instrument is placed in

the dock.

Note: Do not connect the IQ Express to

the PC until the software has been

installed and the PC has been restarted.

1.1 Tests and record keeping

The IQ Express Station automatically

performs the following eight procedures

whenever an instrument is placed in the

dock.

•Instrument identification

•Battery test

•Audible alarm test

•Visual alarm test

•Vibrating alarm test (if applicable)

•Fresh air calibration

•Bump test

•Record-keeping

•Datalogger and Eventlogger download

(IQ Express must be connected to PC to

extract the information from the dock)

In the event that an instrument fails the

bump test, or if the instrument’s calibration

due date has passed, the IQ Express will

automatically proceed to a full calibration

without further intervention from the user.

If the instrument fails any of the tests listed

above, the IQ Express will notify the user

through the display on the dock, and

through the PC if the dock is connected to

the PC and the software is running.

Results of tests and calibration attempts are

stored in the dock and uploaded to the PC if

the software has been loaded and the USB

or Ethernet connection is active.

IQ Express software versions greater than

3.0 will have the ability to download the

contents of the instrument’s datalogger and

eventlogger into a file on the PC that may

be opened with BioTrak software. The IQ

Express must be connected to the PC for

the download to occur.

IQ Express software versions greater than

6.20 have the ability to update the ToxiPro’s

firmware/flash file.

1.2 PC Connection

1.2.1 USB Connection

To enable the interface from the IQ Express

to the PC, first install the IQ Express

Configuration Software and IQ Database

Manager Software. Then connect the PC to

the IQ Express Dock with the USB cable

that is included at the time of purchase.

See section 2 for more detailed setup

instructions.

1.2.2 Ethernet Connection and

E-mail

IQ Express Docks with the Ethernet

upgrade may be connected to the PC via

USB or via a network. To connect via

Ethernet, follow the directions given in the

IQ Express Ethernet Instructions booklet.

5

Docks that are connected by Ethernet have

additional controls at the PC to ping the

dock, to view the Ethernet settings and to

view and test the e-mail system.

E-mail may be sent by the dock to a single

e-mail address when a fault is detected at

the dock, but for no other reason. The dock

must be connected to a network via

Ethernet for the e-mail function to work. E-

mail capability is controlled entirely through

the IQ Database Manager Pro program. For

more information on the e-mail function see

Ethernet Controls in section 3.2.1 below or

the IQ Database Manager Pro manual.

1.3 PC Requirements

•Pentium Processor 1.0GHz or better or

equivalent.

•256MB RAM.

•Windows 2000 Pro / XP / Server 2003

•50MB hard drive disk space.

1.3.1 Ethernet Requirements

To be Ethernet compatible, the IQ Express

Dock must have Flash version 4.00 or

higher and must be equipped with an

Ethernet port.

PC Software must be version 4.00 or higher

to support Ethernet connections.

1.4 Instrument Firmware

Requirements

Instrument firmware version 4.3 or higher is

required in the ToxiPro, OxyPro, ToxiLtd or

OxyLtd for compatibility with the IQ Express.

Firmware upgrades to the ToxiPro and

OxyPro may be made with a PC through the

IrDA port. Instrument firmware upgrades

are available free of charge through Sperian

Instrumentation’s download website:

http://www.biodownloads.com

ToxiLtd and OxyLtd instruments must be

returned to Sperian Instrumentation for

firmware upgrades. Call Sperian

Instrumentation for a Return Authorization

number (RA#) before shipping.

1.5 Power Requirements

Power requirements for IQ Express Docks

vary with the number of docks and the type

of connection.

If the dock is to operate as a stand-alone

calibration station, or if the dock is to be

connected via Ethernet, the IQ Express

must be plugged in to an appropriate

electrical outlet using the power supply /

wall cube that was included with the dock at

the time of purchase.

If multiple IQ Express docks are purchased

with the IQ Express Mounting Bracket, an

optional power supply is available that is

capable of running up to four IQ Express

Docks from a single electrical outlet.

For docks that will remain connected to the

PC via USB Port, follow the relevant

instructions below in section 1.5.1 or 1.5.2.

The IQ Express Dock is delivered with an

appropriate power supply, which should be

specified at the time of purchase.

•100-120 VAC, 60Hz, 9A

•200-240 VAC, 50Hz, 4.5A

If the power supply includes a voltage input

selector switch, be sure to set the switch to

the appropriate voltage for your electrical

supply.

Note: If the IQ Express Dock(s) is to be

installed on the IQ Express Mounting

Bracket, follow the instructions that were

sent with the bracket.

1.5.1 Dock with direct USB

Connection to PC

If each IQ Express Dock can be given its

own USB port and connected directly to the

PC via USB cable, then the PC will provide

enough power to run the dock(s).

1.5.2 Multi-Dock Setup with USB

Connection

For multi-dock configurations, Sperian

Instrumentation recommends the use of a

powered USB hub, which is able to power

multiple USB devices directly through their

USB cables.

Under no circumstances can multiple IQ

Express Docks be run from a single USB

port without supplemental power.

Power and Connectivity are discussed in

greater detail in section 2.6.

1.6 Sensor compatibility

Standard versions of the IQ Express Dock

are capable of processing instruments

containing the following sensor types: O2,

CO and H2S.

Enhanced versions of the IQ Express Dock

are capable of processing instruments with

all of the sensors listed above plus ToxiPro

instruments for SO2, Cl2, NO2, NH3, HCN

and PH3.

6

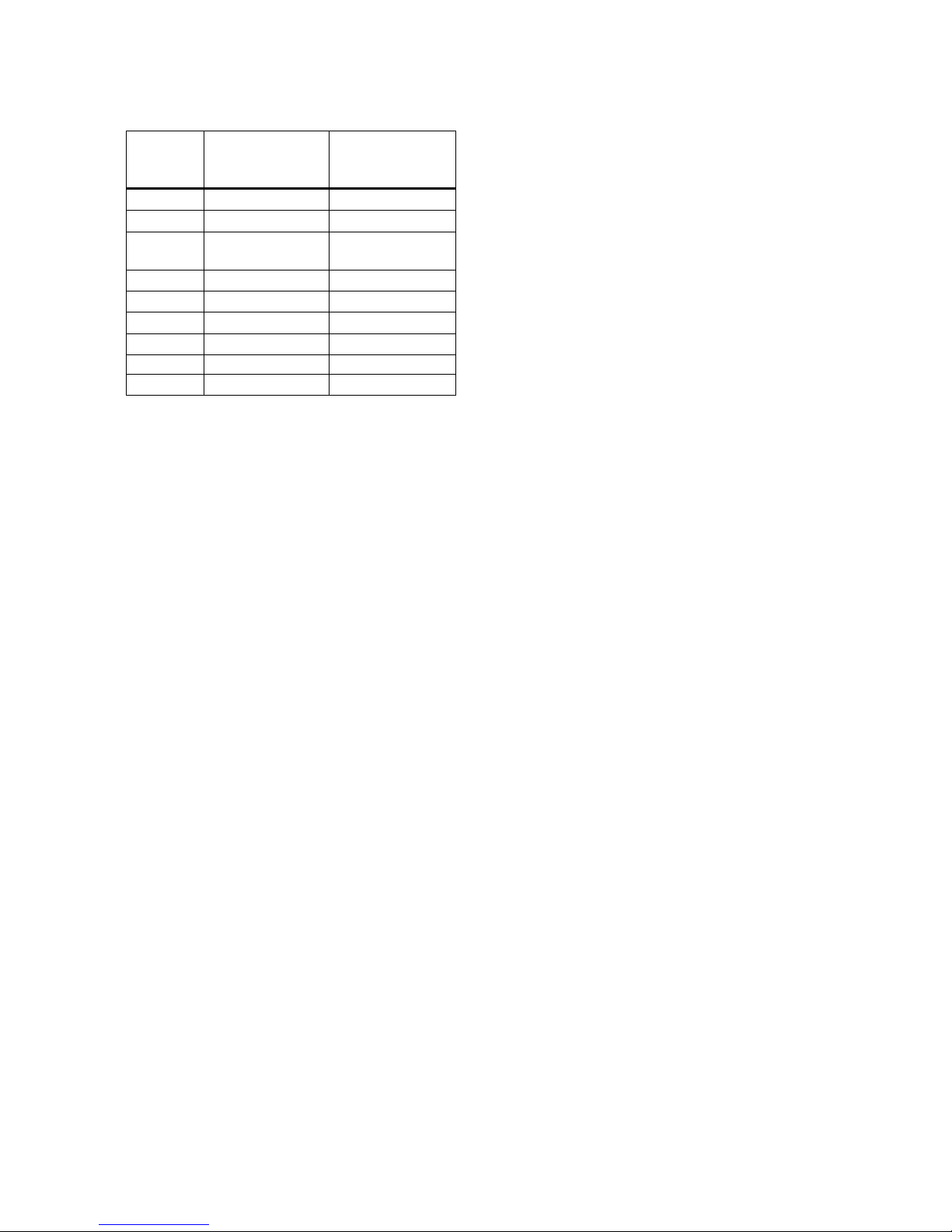

1.7 Default Calibration Gas

Settings and Dock

Compatibility

Dock

Setting

Default Cal Gas

Setting

Dock Type

S=Standard

E=Enhanced

CO 50 PPM S,E

H2S 25 PPM S,E

CO / H2S 50 PPM CO /

25 PPM H2S

S,E

SO210 PPM E

Cl210.0 PPM E

NO25.0 PPM E

NH350.0 PPM E

HCN 10.0 PPM E

PH35.0 PPM E

Default Calibration Gas Settings and

Dock Requirements

1.8 Calibration Gas Cylinder

Regulator Requirements

A demand-flow regulator must be used with

the IQ Express.

1.9 Delivery

Each IQ Express Calibration Station is

delivered with the following items:

•IQ Express

•IQ Express Configuration Software

•IQ Database Manager Software

•USB Cable

•Power Supply

•Standard versions are delivered with a

2’ piece of calibration gas tubing with

pre-installed white quick disconnect

fitting.

•Enhanced versions are delivered with a

calibration gas tubing assembly

comprising a 1” piece of standard tubing

connected to a black elbow fitting, which

is then connected to a 2’ long piece of

smaller diameter tubing with pre-

installed white quick disconnect fitting.

2. Installation

The IQ Express must be configured with a

PC prior to use. Once the dock has been

configured, it may be used as a stand-alone

calibration station without a PC connection,

or connected to a PC via USB cable or

Ethernet for increased control over system

operations.

Note: If the dock is configured for an

Ethernet connection, specific

instructions for Ethernet are included

with the dock.

Unless otherwise specified at the time of

purchase, all IQ Express Docks are shipped

from Sperian Instrumentation configured for

CO/H2S instruments with the standard

calibration gas settings.

If the user chooses to activate the IQ

Express without a PC connection, or if the

PC connection has been lost, the dock will

operate with the last set of calibration gas

settings that were uploaded into the

instrument and will automatically store

calibration data until the onboard memory is

full.

Note: Do not connect the IQ Express

Dock to the PC until the IQ Express and

IQ Database Manager Software have

been installed and the PC has been

restarted.

2.1 Installation Overview

1. Install the PostGreSQL Database and

the IQ Administrator Pro program. See

section 2.2 below.

2. Install the IQ Database Manager

program as described in section 2.3.

3. Install the IQ Express PC Software as

described below in section 2.4.

4. Use Administrator Pro to create a

default PostgreSQL database as

described below in section 2.5.

5. Follow the instructions in section 2.6 for

connecting the IQ Express Dock(s) to

the PC via USB. Follow the Ethernet

Instructions booklet if connecting by

Ethernet.

6. Follow the instructions in section 2.7 for

connecting the calibration gas cylinders.

7. For docks that will be connected

permanently by USB port, configure the

docks by connecting them to the PC’s

USB port. For an Ethernet connection,

follow the Ethernet Instructions that

came with the dock.

See Appendix A for the USB Connection

Diagram.

2.2 IQ Administrator Pro and

PostgreSQL Database

Server Installation

The IQ Administrator Pro Program is

contained on the IQ Express Installation

Disk. Place the disk in your PC’s CD tray

and follow the installation instructions given

7

in the IQ Administrator Pro Reference

Manual that is included with the IQ Express

Dock.

2.3 IQ Database Manager

Software Installation

The Database Manager Pro Program is

contained on the IQ Express Installation

Disk. Place the disk in your PC’s CD tray

and follow the installation instructions given

in the IQ Database Manager Software

manual that is included with the IQ Express.

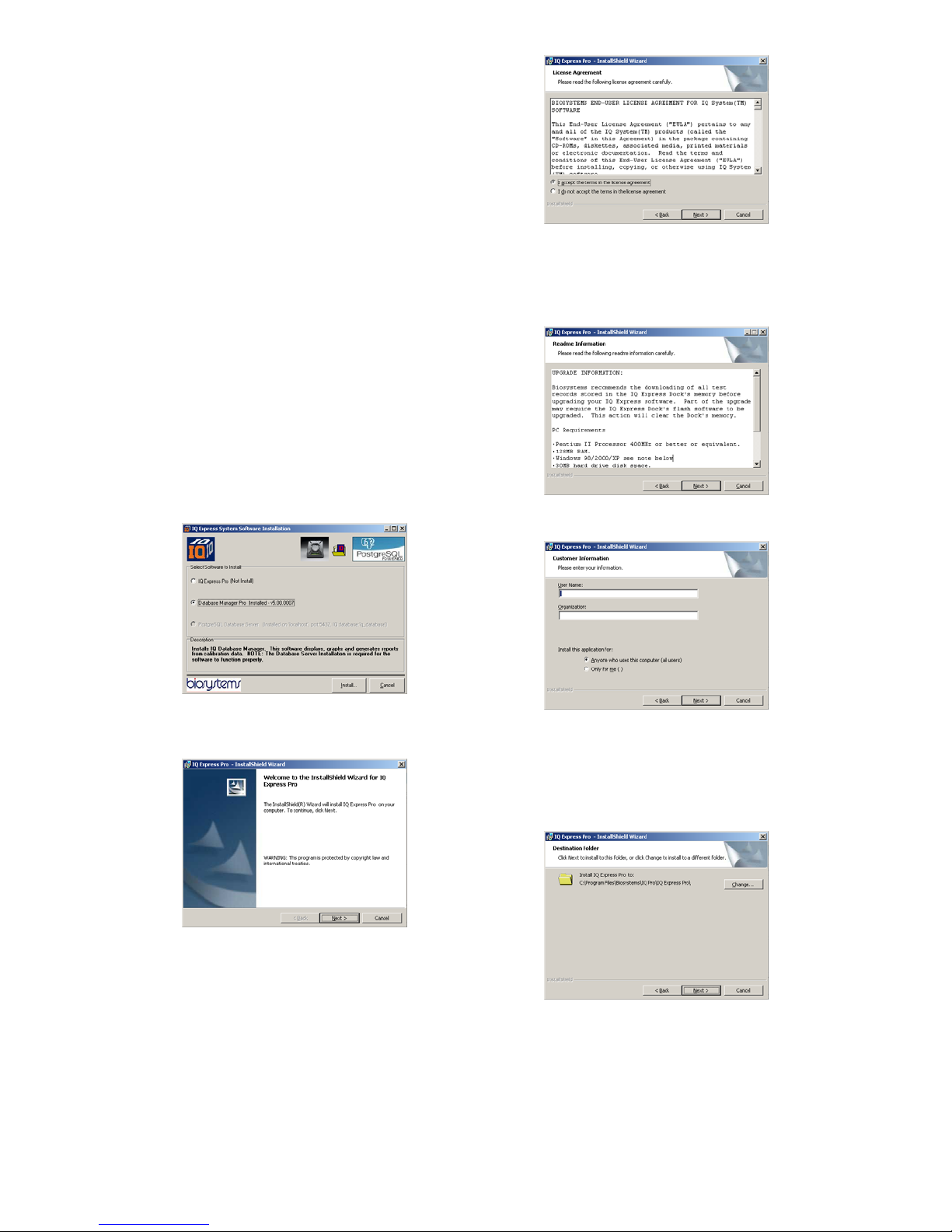

2.4 IQ Express PC Software

Installation

Note: Screens shown below may be

slightly different depending on your PC’s

operating system.

1. The Software Installation screen should

come up automatically once the

installation of Database Manager is

complete. If this screen does not come

up, access the CD drive using Windows

Explorer.

2. Select IQ Express Pro and click “Install”.

The InstallShield Wizard will begin the

installation.

3. Click “Next” to continue with the

installation. The Licensing Agreement

screen will be shown.

4. If you accept the terms of the License

Agreement, click “I accept.....” and then

click “Next” to continue. The upgrade

information and PC requirements will be

shown.

5. Click “Next” to continue. The Customer

Information screen will be shown.

6. Enter the name of the user and the

name of the organization. Then select

whether this application may be used by

“Anyone who uses this computer” or

“Only for me”. Then click “Next. The

destination folder screen will be shown.

7. To install IQ Express in the default

directory at “C:\Program Files \

Biosystems \ IQ Express”, simply click

“Next”. To install the files to another

directory, click “Browse” and use

Windows Explorer to specify the new

location. Click “Next” once this is

8

accomplished. The following screen will

then be shown.

8. Click “Next” to continue. The status of

the file decompression will be shown.

Once the installation is complete, the

following screen will be shown:

9. Click Finish to conclude the installation.

The IQ Express logo will appear on your

desktop.

Note: Do not launch the IQ Express

Software again until the instructions in

sections 2.5 – 2.8 below have been

completed.

2.5 Install IQ Administrator Pro

and PostgreSQL database.

Proceed to the IQ Administrator Pro

Reference Manual section 6 and follow the

instructions to create and specify the

PostgreSQL database.

2.6 Power and Connectivity

This section covers providing power to the

IQ Express Docks and connecting them to

your PC. The instructions given below

pertain to standard connections via the PC’s

USB port.

Note: Disregard this section if you are

planning to connect the docks via

Ethernet or if you have purchased the IQ

Express Mounting Bracket.

IQ Express Docks that are Ethernet-ready

are shipped with an Ethernet Instructions

booklet. Proceed to the Ethernet

Instructions booklet if you are planning to

connect the dock to the PC via Ethernet.

Once the instructions in the booklet have

been followed and the IQ Express Dock is

connected, return to section 2.7 for

calibration gas cylinder connection

instructions.

If you have purchased the IQ Express

Mounting Bracket, proceed to the Assembly

Instructions for IQ Express Mounting

Bracket. Once the docks are correctly

installed on the mounting bracket, proceed

to section 2.7.3 for instructions concerning

the Fresh Air Port(s).

2.6.1 PC – Single Dock via USB

For single dock setups, the power from the

PC via the USB cable is sufficient to power

the dock. Connect the dock to the PC with

the USB cable that was included with the

dock and proceed to section 2.7 for

instructions on connecting calibration gas

cylinders.

2.6.2 PC – Multi Dock via USB

For multi-dock configurations, Sperian

recommends the use of a powered USB

hub, which is able to provide power to

multiple USB devices directly through the

USB cable. With a powered USB hub, it is

not necessary to use the wall cube power

supplies that are included with the IQ

Express Docks.

If you prefer to not use a powered USB hub,

the following other options are available:

1. If you have enough open USB ports on

your PC to connect each of the docks

directly to its own USB Port, you may

connect each dock directly to the PC.

Most users decide against this option

either because their PC doesn’t have

enough USB ports, or because it is an

inappropriate use of their PC’s system

resources.

2. Use a non-powered USB hub to connect

the PC to the docks by USB cable.

Although the PC has enough power to

run one dock from one USB port, it will

9

be unable to power the 2nd, 3rd and 4th

docks in the series. There are two

options in this case. The first option is

to connect each dock to a suitable

power source using the wall cube power

supply that was included with the IQ

Express Dock. A suitable, grounded

power strip may be used. The second

option is to purchase the optional power

supply that is capable of running up to

four IQ Express Docks from a single

electrical outlet.

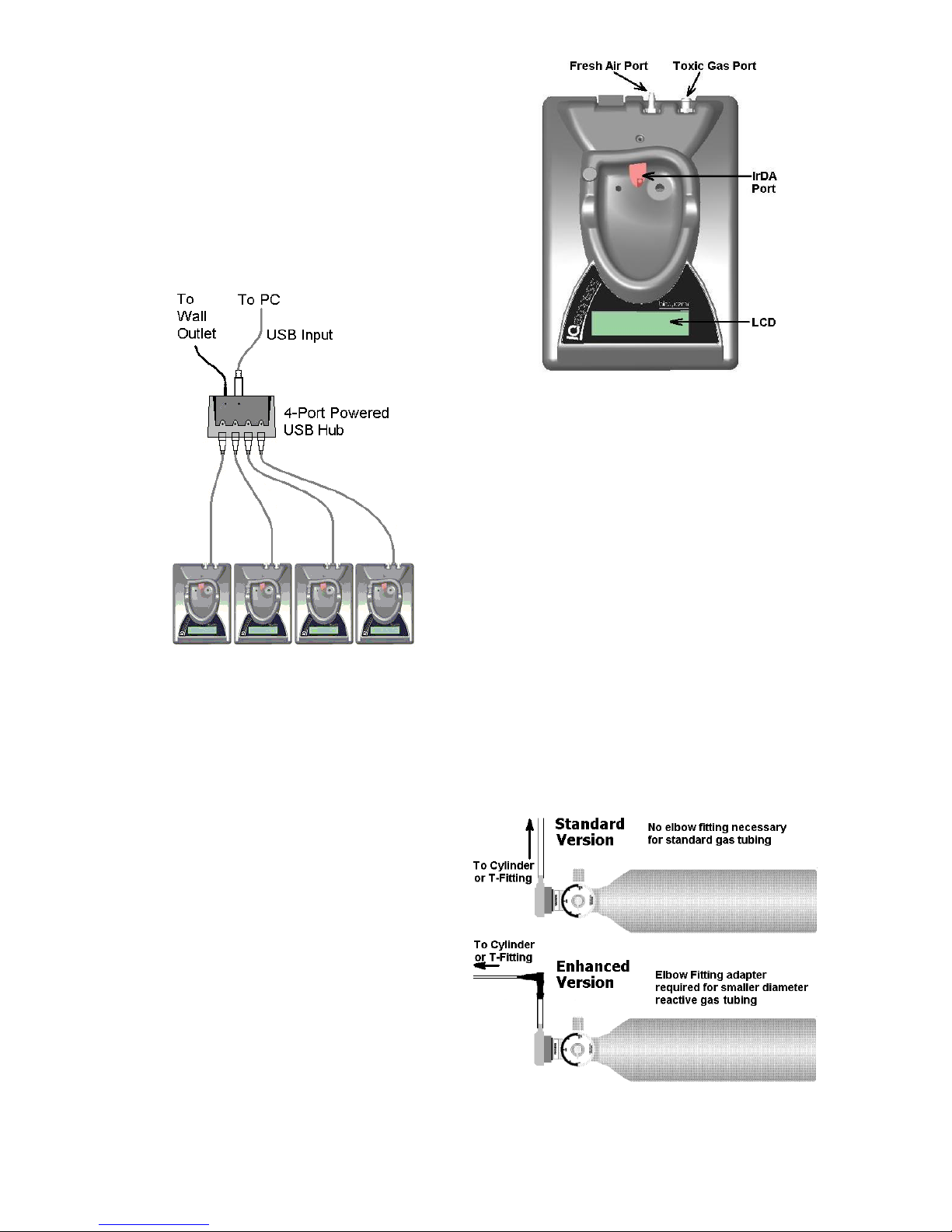

Figure 2.6.2 Preferred Method for USB

Connection and Powering Multiple IQ

Express Docks.

Under no circumstances can multiple IQ

Express Docks be run from a single USB

port without supplemental power.

2.7 Connecting the Calibration

Gas Cylinder(s) to the

Dock(s)

Connection requirements for calibration gas

cylinders vary with how many docks will be

connected to the cylinder and whether the

calibration gas is considered reactive.

Enhanced versions of the IQ Express

include a tubing assembly that is suitable for

use with reactive gases.

Figure 2.7. IQ Express Gas Ports

For instructions on connecting the gas

cylinder to a single IQ Express dock

proceed to section 2.7.1.

For instructions on connecting the gas

cylinder to multiple IQ Express docks

proceed to section 2.7.2.

2.7.1 Single Cylinder to Single IQ

Express Dock

1. Insert the demand flow regulator into the

calibration gas cylinder.

2. Standard docks are delivered with a 24”

piece of tubing with a white quick

disconnect on one end. Enhanced

docks are delivered with a 24” piece of

tubing that meets a black elbow fitting

followed by a 1” piece of standard

tubing. Slide the open end of the tubing

assembly over the regulator. For

enhanced docks, slide the open end of

the 1” piece of tubing over the regulator.

Figure 2.7.1 Standard versus Enhanced

Setup for Regulator and Tubing

10

Note that the tubing assemblies for the

standard and the enhanced versions of

the IQ Express Docks are different. The

tubing assembly for the enhanced

versions includes a black elbow fitting

that should be located just above the

regulator.

3. Connect the end of the tubing with the

white quick disconnect fitting to the toxic

GAS port on the IQ Express Dock (see

figure 2.7 above for location of the GAS

port).

4. Proceed to section 2.7.3 for further

instructions concerning the fresh AIR

port.

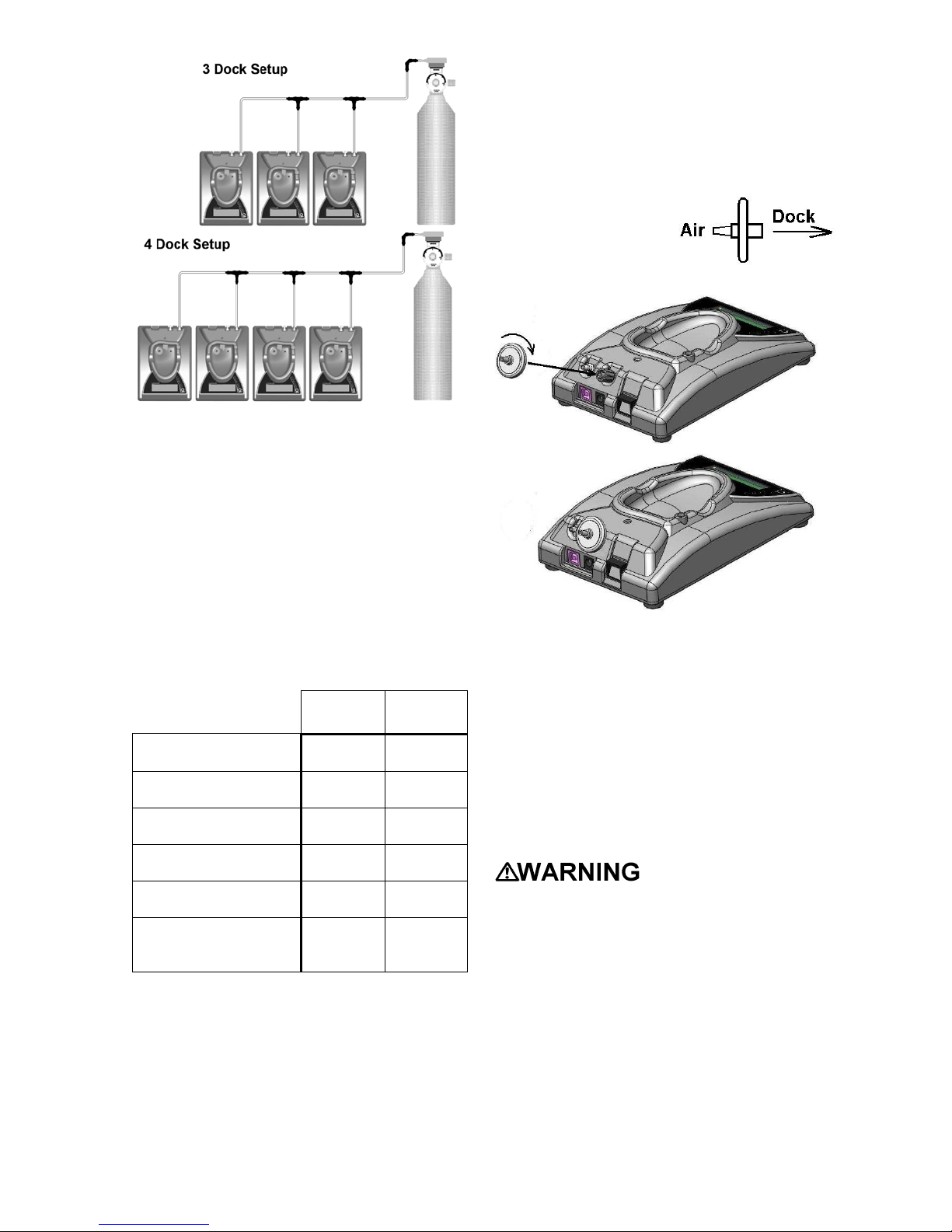

2.7.2 Single Cylinder to Multiple

Docks

When a series of IQ docks is connected to a

single cylinder of calibration gas, a manifold

is used to disperse the calibration gas from

the cylinder to the docks.

The manifold is part number 54-46-115 and

includes a detailed instruction sheet for its

use. The manifold comes with tubing and

fittings necessary for connecting up to 4

Express Docks to a single cylinder of

calibration gas.

Note: Do not exceed the output capacity

of your demand flow regulator. Each IQ

Express dock is able to draw calibration

gas at a maximum rate of 0.75

liters/minute. The demand flow regulator

supplied by Sperian Instrumentation

(part number 12-039) has a maximum

output capacity of 3 liters per minute, so

it can be used to calibrate up to 4 docks

simultaneously. Do not connect more

than 4 docks to a single cylinder of

calibration gas while using the 12-039

demand flow regulator.

The 54-46-115 manifold is comprised of:

(1) small black elbow fitting

(3) small black T-fittings

(2) pieces of gas tubing 5” long

(1) piece of gas tubing 10” long

(1) piece of gas tubing 1” long

54-46-0115 Manifold

1. Insert the Demand Flow Regulator into

the calibration gas cylinder.

2. Modify the tubing assembly as follows

depending on how many docks will be

connected. If 4 docks will be used, no

modifications are necessary. For 2 or 3

docks, begin by separating the tubing at

the location described below.

Once this is accomplished, set the two

parts aside. The section that will be

used is shown in the following images

(depending on the number of docks).

Manifold for two docks

Manifold for three docks

Manifold for four docks

3. Each dock is delivered with a 24” piece

of tubing with a white quick disconnect

fitting, which is normally used to connect

a single gas cylinder directly to a single

dock. Connect the white quick

disconnect fittings to the GAS ports on

the docks and connect the open ends to

the manifold’s open t-fittings. For

enhanced docks, remove the black

elbow fitting entirely from the 24” piece

of tubing and run the smaller diameter

tubing directly from the docks to the

open T-fittings.

At this point, tubing should run from each

dock’s GAS port to the t-fittings. There

should be no open T-fittings at this point in

the procedure, but there should be one

piece of open tubing on the elbow fitting.

4. Connect the open piece of tubing on the

elbow fitting to the Demand Flow

Regulator.

Final Appearance

11

Note: Tubing lengths in these images

are not to scale.

2.7.3 Fresh Air Port Instructions

The Fresh Air Port is used to draw the fresh

air sample into the dock for instrument

processing. Check valves and/or fresh air

filters are required depending on how fresh

air is delivered to the dock. See the chart

below for specific requirements for your

setup. The fresh air filter is placed on the

Air Port at the dock to protect the dock from

contaminants. Check valves are used to

ensure the purity of external fresh air

sources when more than one dock is used.

Air Filter

at Dock

Check

Valve(s)

Single Dock in Fresh

Air Yes N/A

Multiple Docks in

Fresh Air Yes N/A

Single Dock w/Zero

Air Cylinder No No

Multiple Docks

w/Zero Air Cylinder No Yes

Single Dock w/Sealed

Fresh Air Conduit Yes No

Multiple Docks w/

Sealed Fresh Air

Conduit

Yes Yes

Air Filter / Check Valve

Requirements Chart

Fresh Air Filter

Under normal circumstances, the IQ

Express Dock is located in a fresh air

environment and fresh air is drawn in from

the local environment. A filter is included

with the dock that is used to protect the

dock from contaminants that may

inadvertently enter the dock. The air filter

should be installed if the dock is drawing

fresh air from the immediate surroundings or

if it is drawing fresh air from an external

source via a sealed conduit. The fresh air

filter can be left off if the fresh air source is a

calibration cylinder.

Only one side of the

filter will screw into the

Air Port on the dock.

Providing Fresh Air in a

Contaminated Environment

If the IQ Express is to be located in a

potentially contaminated environment, fresh

air must be delivered to the Air Port on the

dock for use during instrument processing.

This can be accomplished either by using a

cylinder of “zero air” with a demand flow

regulator (option 1 below) or by plumbing

fresh air into the dock in a sealed conduit

from an outside location that has known

fresh air (option 2 below).

Performing the fresh

air calibration in a contaminated

atmosphere will lead to inaccurate and

potentially dangerous readings. Fresh

air containing 20.9% oxygen and no

contaminants must be provided to the IQ

Express Dock for instrument processing.

If fresh air is unavailable in the

immediate area, steps must be taken to

provide fresh air to the dock.

When a secondary fresh air source (either

gas cylinder or sealed conduit) is used with

two or more IQ Express Docks, a one-way

check valve must be placed in line between

the common section of the fresh air manifold

12

and each of the docks to ensure the purity

of the fresh air source. See the section

below titled “Fresh Air Manifold” for further

instructions.

Option 1: Using a Gas Cylinder to

Provide Fresh Air to the Dock

A calibration cylinder containing “zero air”,

which contains 20.9% oxygen and no

contaminants may be connected to the gas

port labeled “AIR” to provide fresh air to the

dock for calibration. The cylinder must be

equipped with a demand flow regulator.

The connection from the cylinder and

regulator to the dock may be made with

standard gas tubing.

For single docks, simply connect the “zero

air” cylinder and demand flow regulator to

the dock’s AIR port using standard gas

tubing. A check valve is not necessary

when a cylinder is used to provide fresh air

to a single dock. The fresh air filter is also

not required in this configuration.

For multiple dock setups (up to 4), a one-

way check valve must be placed in the line

between each T-fitting and dock to ensure

the purity of the fresh air source. See

“Multi-Dock Setups with Fresh Air Manifold”

below for further instructions. The fresh air

filter is not necessary when a gas cylinder is

used to provide fresh air to the dock(s).

Option 2: Using a Sealed Conduit to

Provide Fresh Air to the Dock

Fresh air may also be delivered to the dock

from a known fresh air source via a sealed

conduit that feeds directly from the source

into the AIR port on the dock.

For single docks, install the fresh air filter as

discussed above and simply plumb the fresh

air source directly into the dock’s AIR port.

For multiple dock setups in which fresh air is

provided to the dock via sealed conduit,

begin by installing the fresh air filter on each

dock. A one-way check valve must be

placed in the line between the t-fitting in the

fresh air manifold and each dock to ensure

the purity of the fresh air source. See

“Multi-Dock Setups with Fresh Air Manifold”

below for further instructions.

Multi-Dock Setups with Fresh Air

Manifold

For more information on this, see

Applications Note # AN20050722, which is

available at http://www.biosystems.com.

The 54-46-116 manifold is necessary for

use when more than one dock is to be used

with an external fresh air source, whether is

be a cylinder of “zero air” or a sealed

conduit to a fresh air source.

The 54-46-116 manifold is comprised of:

(3) small black T-fittings

(4) clear one-way check valves

(10) pieces of gas tubing 5” long

(1) piece of gas tubing 10” long

54-46-115 Tubing Assembly

1a. If the fresh air source is a calibration gas

cylinder, insert the Demand Flow

Regulator into the calibration gas

cylinder and proceed to step 2.

1b. If the fresh air source is a sealed conduit

from an external fresh air source, install

the fresh filter on each dock as

described above and proceed to step 2.

2. Modify the tubing assembly as follows

depending on how many docks will be

connected. If 4 docks will be used, no

modifications are necessary. For 2 or 3

docks, begin by separating the tubing at

the location described below.

Once this is accomplished, set the two

parts aside. The section that will be

used is shown in the following images

(depending on the number of docks).

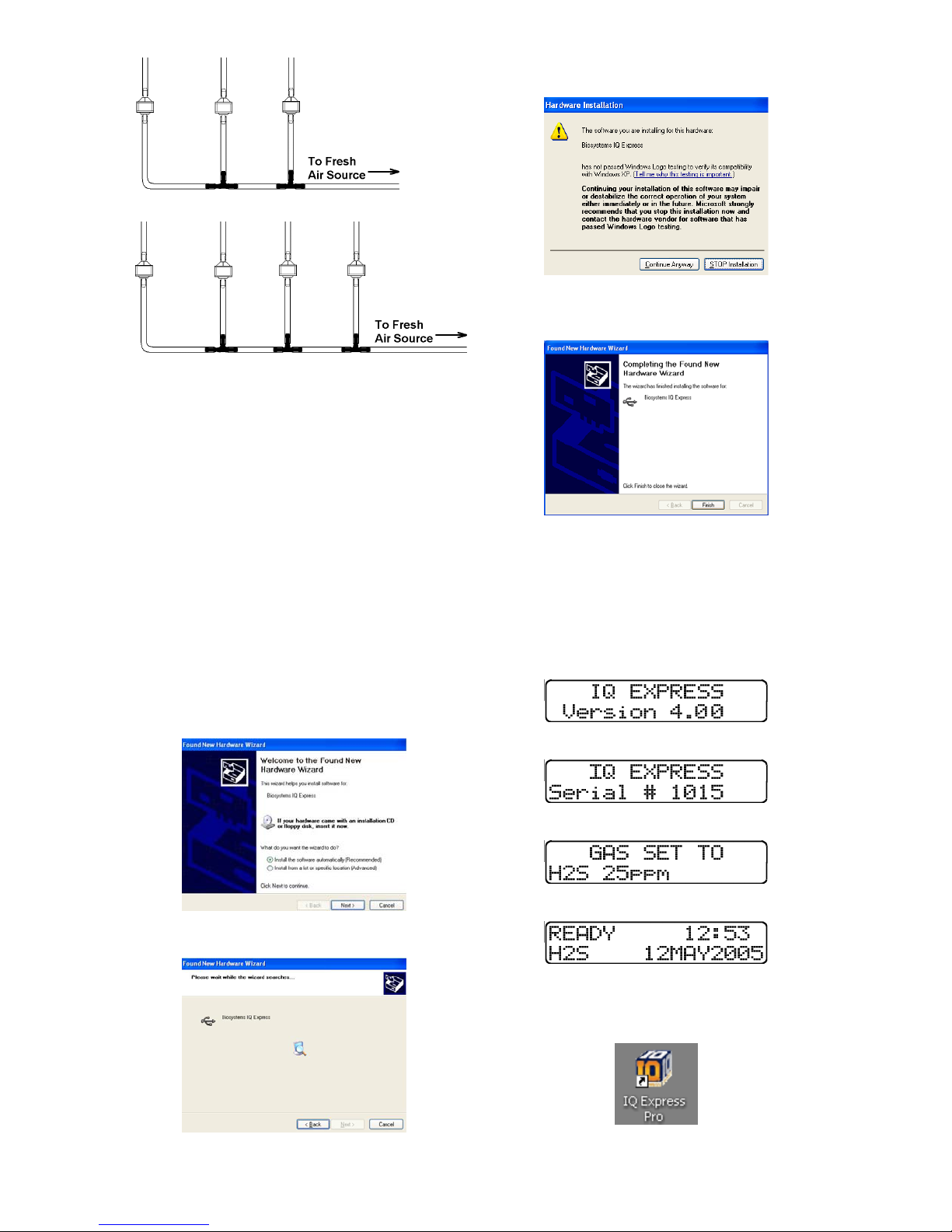

Fresh Air Tubing for 2 Docks

13

Fresh Air Tubing for 3 Docks

Fresh Air Tubing for 4 Docks

3. Connect the pieces of tubing above the

check valves to filter that was installed

on the dock in step 2.

At this point, the tubing assembly should be

connected to each dock’s AIR port.

4. Connect the only open piece of tubing

(below the black t-fittings) to the

demand flow regulator on the gas

cylinder or to the conduit for the external

source of fresh air.

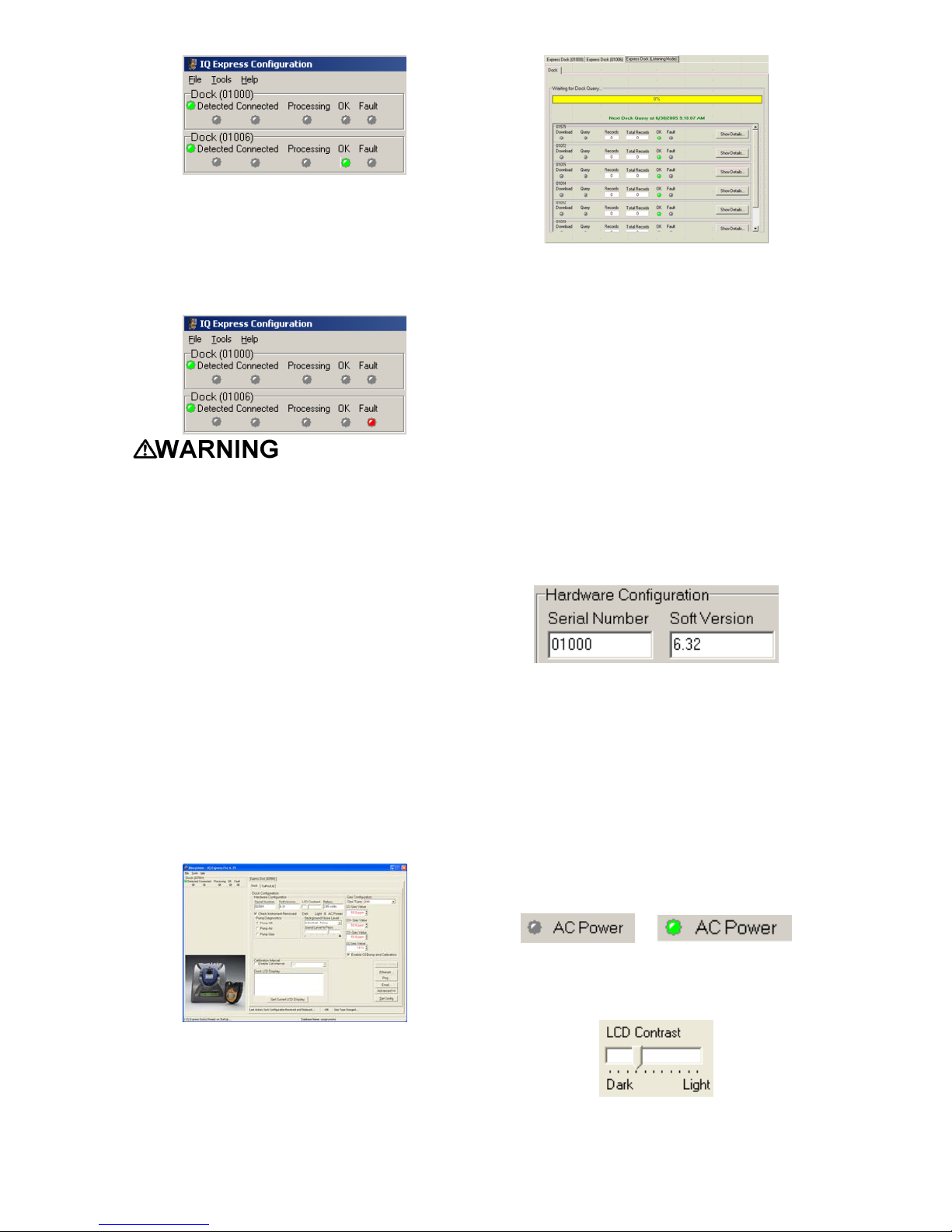

2.8 Dock Setup

Once the software has been installed, and

the USB wire(s) is/are plugged into the PC,

the Found New Hardware Wizard screen

will be shown on the PC.

NOTE: These screens vary depending

on your PC’s operating system.

Click Next to continue. The Wizard will

proceed to search for the USB drivers.

If installing to XP, the following screen will

be shown and should be disregarded.

Click “Continue Anyway” (XP Only). The

software will notify you when the process is

complete.

Click “Finish”.

The IQ Express Dock will display its

software version number, serial number,

and the calibration gas type and expected

calibration gas concentration whenever it is

plugged in. The IQ Express is ready to go

once it displays “READY” with the gas type,

time and date.

↓

↓

↓

3. Software

To launch the IQ Express Software, click on

the IQ Express icon on your PC’s desktop.

14

Note: Do not launch the software until

the installation instructions in section 2.1

– 2.8 have been completed.

The software may also be launched by

accessing the program through the start

button and selecting Programs / Biosystems

/ IQ Express / IQ Express (unless another

location was specified during the

installation).

Once the IQ Express Software is launched,

the following screen will be shown.

The screen is divided into right and left

sides. The left side gives the status of the

docks that are currently installed and

recognized. At the top of the right side of

the screen there is a tab for each dock that

is currently installed and recognized. Within

each dock tab are two sub-tabs: one for

dock controls and one that shows the

calibration status and details for the

instrument that is currently in the dock.

3.1 Dock Status

3.1.1 Dock status LED

The status bars at the far left show the

status of the docks that are currently

registered on the PC.

Each dock that is currently connected to the

PC by either USB or by a “Live” Ethernet

connection will have a distinct status bar.

The green LED at the far left shows the

general status of the dock.

All docks that are connected via Ethernet

and are currently in “Listening Mode” are

given a single status bar.

For docks in Listening Mode, if a single fault

is detected on any of the docks, the dock

LED will turn grey and the Fault LED will

turn red.

Specific information for individual docks in

“Listening Mode” can be accessed via the

“Express Dock (Listening Mode) tab on the

right side on the screen. See section 3.2 for

more information.

3.1.2 Instrument status LEDs

When a detector is placed in the dock, the

indicator will change to reflect the new

status. Status changes are also be shown

on the dock’s LCD.

↓

Processing is shown in yellow.

If the dock is able to successfully complete

processing, OK will be shown in green.

15

If a fault is detected and the IQ Express

Dock is unable to complete the tests, the

red fault light will be lit on the screen.

Details of the fault will be listed in the input

box on the right side of the screen under the

instrument tab. See section 3.2.2 for

details.

Do not reinsert the

ToxiPro or ToxiLtd back into an IQ

Express Dock for at least 5 minutes after

it has been removed. Immediate

reinsertion of the ToxiPro or ToxiLtd into

an IQ Express Dock may lead to

inaccurate and potentially dangerous

readings.

3.2 Dock Controls and

Instrument Status

The right side of the screen contains

individual controls for each IQ Express Dock

that is connected by USB or by a “Live”

Ethernet connection. Each dock has its own

page, which can be accessed by clicking on

the appropriate tab at the top of the page.

Within each dock’s page are two sub-tabs.

One contains specific information on the

dock itself. The other displays information

on any instruments that are currently

recognized in the dock.

The last tab on the left accesses all of the

IQ Express Docks that are connected by

Ethernet and in “Listening Mode”.

3.2.1 Dock Configuration

Click on the Dock tab to access the dock

settings.

To change the configuration of the IQ

Express Dock that is currently connected to

the PC, click on the “Change Config” button

at the lower right of the screen. Once the

dock configuration is uploaded, the “Set

Config” button will be enabled. Once

changes are made, click on the “Set Config”

button to save the new settings.

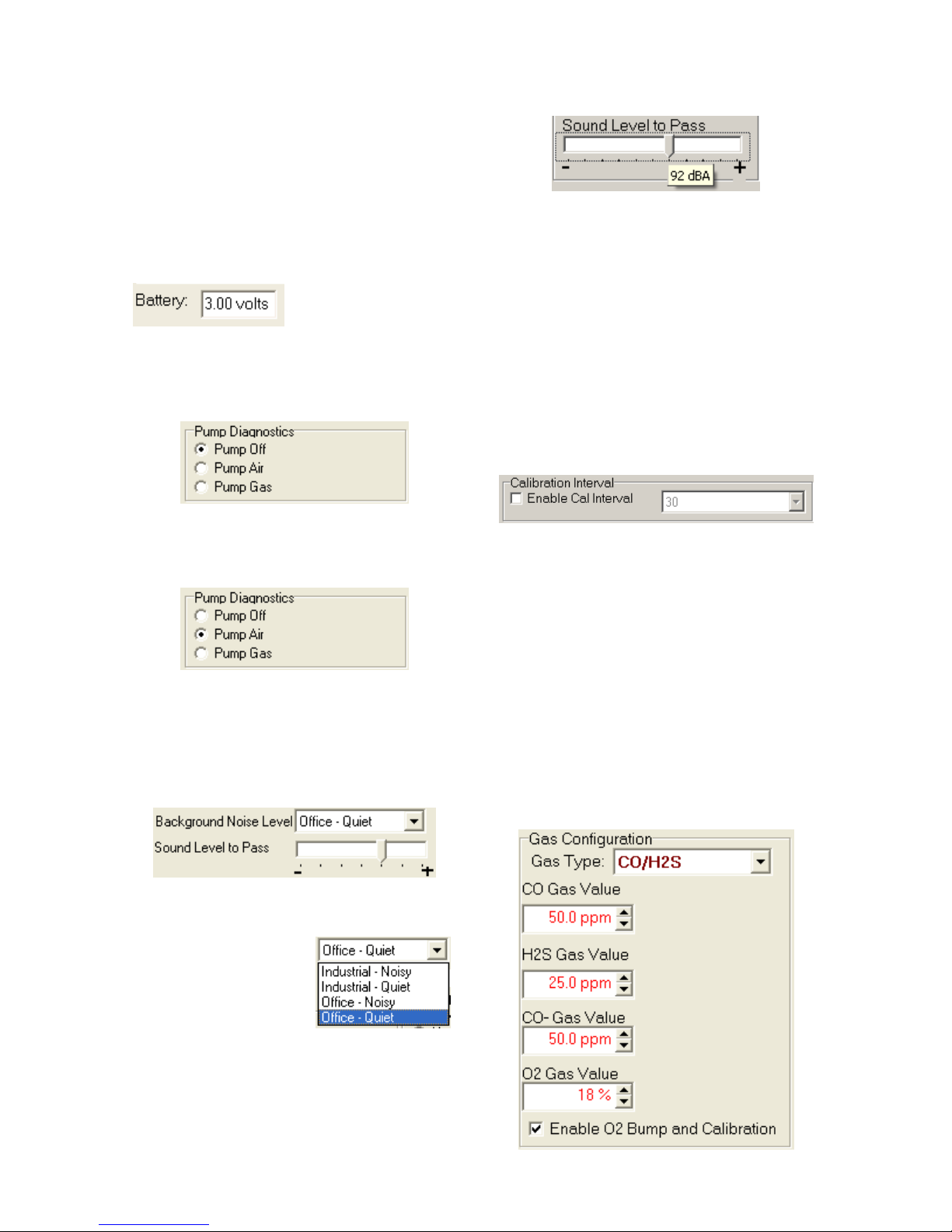

Hardware Configuration

The hardware configuration section contains

the serial number and software version

number of the IQ Express Dock at the upper

left corner.

This information may not be arbitrarily

changed with the software. Software

updates will cause the software version to

change.

AC Power

The AC Power indicator is located directly

beneath the connection speed setting. If the

dock is being powered by the USB cable,

the AC Power will appear grey. When the

dock is being powered by an AC power

source, the AC Power indicator will appear

green.

or

LCD Contrast Control

At the right side of the Dock Configuration

box is the LCD Contast.

16

To darken or lighten the LCD on the IQ

Express Dock, move the slider as

appropriate.

Battery

The battery level shown on the dock tab is

for the internal battery in the IQ Express

Dock. This battery serves to keep the real

time clock accurate while the dock is

unplugged and should not be a concern to

the user unless the battery level drops

below 2.50 Volts.

Pump Diagnostics

Pump diagnostics are controlled through the

Pump Control section on the Dock Settings

page.

Click “Pump Gas” to draw span calibration

gas through the right gas port at the back of

the dock. Click “Pump Air” to draw the fresh

air sample through the left gas input port.

Either pump will run until “Pump Off” is

selected.

Audible Alarm Sensitivity Controls

The audible alarm sensitivity controls allow

the user to customize the audible alarm test

criteria.

The Background Noise Level adjustment

offers four levels of background noise

levels. For the best

results, select the one

that most closely

approximates the

background noise

level expected during

testing.

The Minimum Sound Level setting

determines the minimum amount of sound

required to pass the alarm test. The setting

is controlled by a slider. The higher the

setting, the louder the alarm will need to be

to pass the test. The sound level is given in

decibels when the cursor is placed over the

slider.

Calibration Interval

The Dock’s calibration interval settings are

controlled from the Dock Tab and are

located below the battery level and above

the LCD Display box. The dock’s calibration

interval is the maximum number of days that

the dock will allow to pass between

calibrations for any instrument that is placed

in the dock. If an instrument is placed in the

dock and the interval has been exceeded,

the dock will automatically initiate a full span

calibration of the instrument regardless of

the results of the bump test or the

instrument’s own calibration status.

To use the setting, click on Enable Cal

Interval and set the interval to the number of

days between calibrations. Note that this

setting overrides the instrument’s own

calibration due reminder and may cause

the instrument to undergo a full

calibration even when the instrument

itself is not due for calibration.

Gas Configuration

The calibration gas configuration settings

are located at the right side of the dock tab.

The Gas Type and Gas Value should be set

to exactly match the type and amount of

each component of the gas cylinder that is

connected to the inlet port on the dock.

17

To change the gas type, click on the down

arrow to the right of the gas setting and

select the new gas type.

Once the gas type is chosen, enter the

calibration gas composition, including the

values for any toxic gases in the cylinder in

terms of parts-per-million (ppm) and the

oxygen level in terms of percent volume

(%). To change a gas value use the arrows

to the right of the gas value input box to

increase or decrease the value until it

matches the value given on the gas

cylinder.

Since a common calibration gas mixture

includes CO and H2S, a CO/H2S option is

available that offers distinct settings for CO

and H2S. This allows the dock to process

CO, CO- and H2S units without changing the

gas setting.

Note: Due to cross-sensitivity issues,

CO+ detectors must be calibrated with

CO calibration gas only. A CO+ detector

placed in a dock that is configured for

CO/H2S will automatically fail to process.

The IQ System will automatically fail any

detector that is processed when the

calibration gas type fails to match the

sensor type.

Calibration values

shown in the Gas Value column must

match those appearing on the calibration

gas cylinder(s) that will be used to

calibrate the detector. Non-matching

calibration gas and calibration gas value

settings will lead to inaccurate and

potentially dangerous readings.

Special Instructions: Gas

Configuration, Oxygen Detectors

An oxygen detector can be processed by

the IQ Express in a fresh air atmosphere

without the use of calibration gas, but an

optional bump test is available to verify

oxygen sensor response. The O2 Bump

and Calibration is automatically enabled at

the factory. If the user wishes to bypass the

oxygen bump test, the O2 Bump and

Calibration option can be disabled by

deselecting the “Enable….: check box at the

bottom of the Gas Configuration settings. .

Each calibration gas type includes an

oxygen setting that should reflect the

amount of oxygen in the calibration gas

cylinder (typically 18%).

With the O2 Bump and Calibration option

enabled, when an oxygen detector is placed

in the dock, the system will proceed with an

oxygen bump test based on the O2gas

value that has been entered. If the bump

test fails, the dock will show a warning on

the screen that the instrument has failed the

test.

A special case exists when a cylinder of

0.0% oxygen calibration gas is connected to

the dock. If the O2 Gas Value is set to 0.0%

oxygen and the instrument fails the bump

test, it will automatically attempt a full zero

calibration at 0.0% oxygen.

For all other levels of calibration gas

(>0.0%), the oxygen bump test is the only

test available. The zero calibration of the

oxygen sensor is only available with

calibration gas containing 0.0% O2.

To disable the O2 Bump and Calibration

deselect the option.

18

Saving new settings

When all necessary changes have been

made, press the “Set Configuration” button

(in the lower right corner of the screen) to

upload the new settings to the IQ Express

Dock.

The software will notify you once the dock

configuration has been updated.

Dock LCD Display

At the lower left corner of the Dock status

tab is Dock LCD Display window. This is

most often used when a dock is controlled

remotely via Ethernet where the PC user is

unable to physically see the dock.

To view the dock’s Display, click on “Get

Current LCD Display”.

Ethernet Controls

For docks that are

connected by

Ethernet, there are

three additional

controls on the lower

right corner of the

display: Ethernet,

Ping and E-mail.

To view the Ethernet

settings, click on the

Ethernet button

To test the dock connection, press the Ping

button. A status window will be shown to

indicate whether the ping was successful or

not.

The dock’s e-mail settings are controlled

through the Database Manager Pro

program, but can be viewed by clicking on

the e-mail button. The e-mail status, IP

Address of the dock, recipient e-mail

address and text of the e-mail message are

shown.

To test the e-mail ability of the dock, press

the Test E-mail button at the lower left. An

e-mail will be generated and sent to the

recipient e-mail address that is listed.

Press OK to close the Email Setup window.

3.2.2 Instrument Tab

The ToxiPro/Ltd tab shows instrument

information for the detector that is currently

in the IQ Express Dock. The right side of

the tab is identical to the Dock Status tab

section discussed above. The blank space

at right shows is an output box that shows

detailed instrument information as it is

processed.

19

The output box is updated as the instrument

is processed. If any faults occur, the details

of the fault will be shown and a red fault light

will be shown. In the image below, a span

calibration failure is the cause of the fault.

If the datalogger has been downloaded, the

“View Session Data” control will appear on

the right. Click on “View Session Data” to

directly access individual session files for

the instrument. The session files can be

accessed using the BioTrak Program.

If the dock is currently empty, none of the

status indicators will be lit and the output

box will be blank.

3.3 Advanced Settings /

Passcode

The IQ Express Dock may be set to verify a

specific 4-digit passcode (PIN) in any

instrument that interfaces with the dock. If

the dock detects a PIN in the instrument that

matches its own PIN, it will process the

instrument. If the dock fails to detect a PIN,

or recognizes a non-matching PIN, it will not

process the instrument.

To use the passcode feature a PIN must be

entered into the IQ Express Software and

then uploaded to every instrument that will

interface with the dock. Each dock must

then be programmed with the same PIN and

set to check for the code in the instruments.

1. Verify that the ToxiPro and ToxiLtd

instruments have firmware version 6.3

or higher. Instrument firmware version

is shown in the start up screens for the

instrument.

If needed, new ToxiPro Firmware can

be downloaded at no charge from

Sperian Instrumentation’s download

website at

http://www.biodownloads.com. The

ToxiLtd will need to be returned to

Sperian Instrumentation for firmware

updates.

2. Verify that the IQ Express Dock contains

firmware version 4.23 or higher. New

dock firmware can also be downloaded

at no charge from Sperian

Instrumentation’s download website at

http://www.biodownloads.com.

3. Select the dock that will be used to write

the PIN (Personal Identification Number)

to the instrument. Connect the dock to

the PC either by USB port or by

Ethernet port. If using an Ethernet

connection, the Ethernet setting must be

configured to “Live”. If more than one

dock will be used to update the

instruments, perform steps 4-10 for

each dock.

4. Open the IQ Express software.

5. Click “Advanced” in the row of buttons

on the lower right. The software will

automatically show the Security Login

screen and prompt you for your user

name and password. If the “Advanced”

button is not shown, click on “Change

Config” first to access it.

6. Enter a valid User ID and Password.

The Access PIN settings will be shown:

Table of contents

Other GasTech Docking Station manuals