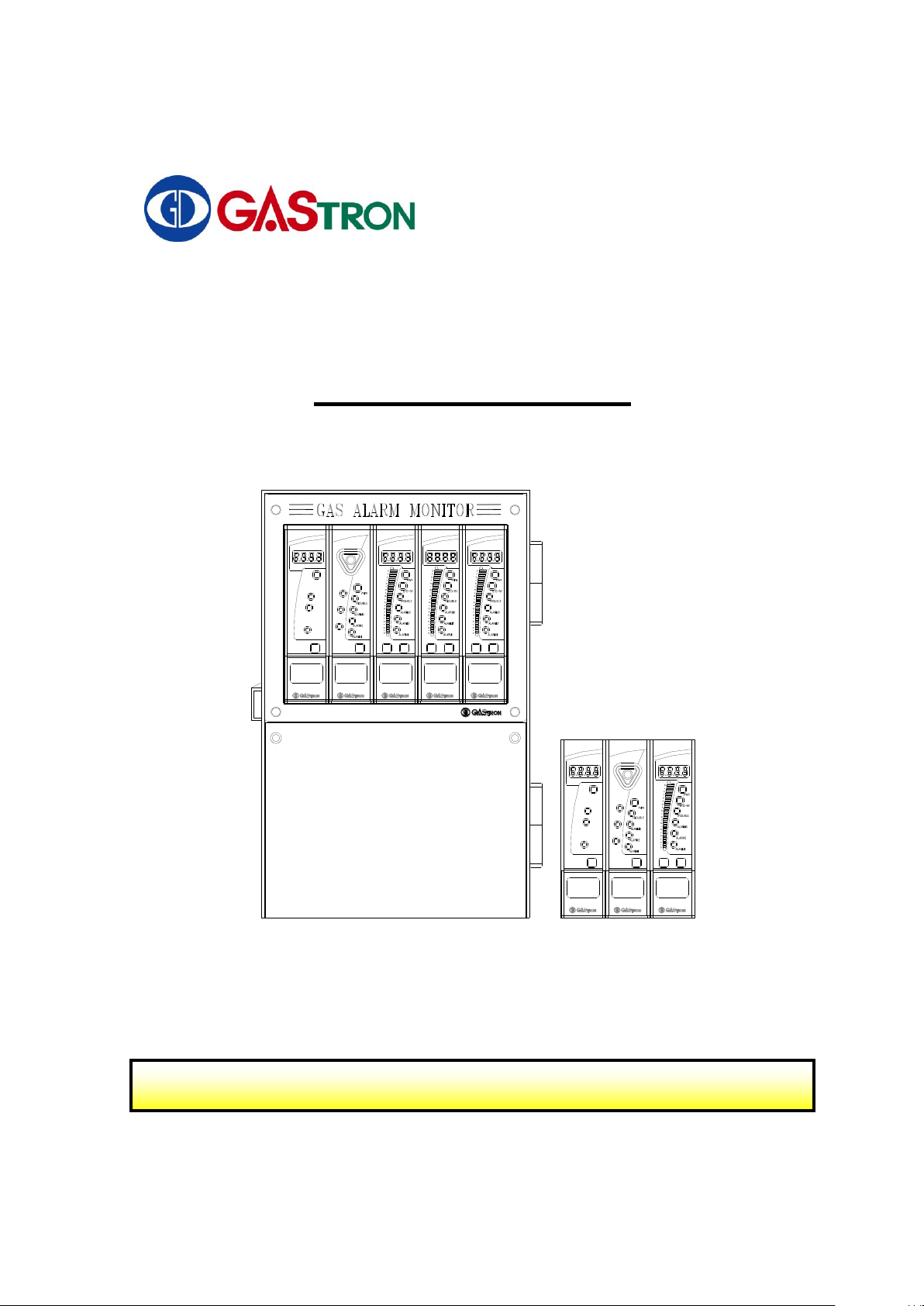

GASTRON GTC-200A User manual

Human Technology & Future

INSTRUCTION MANUAL

MODEL : GTC-200A

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

COM-PC

COM-CH

BZ. STOP

GTC200A COMMON

RESET

BZ. STOP

GTC200A

BATT TROUBLE

BATT GOOD

BATT POWER

MAIN POWER

BATT TEST

VOLT

GTC200A POWER

GTC200A

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

COM-PC

COM-CH

BZ. STOP

GTC200A COMMON

RESET

BZ. STOP

GTC200A

BATT TROUBLE

BATT GOOD

BATT POWER

MAIN POWER

BATT TEST

VOLT

GTC200A POWER

GTC200A

For proper use, please read this manual carefully!

GTC-200A

2

We much appreciate your wise purchase of GASTRON products

Gastron, a world-renowned company for manufacturing gas detectors and gas monitoring devices

exclusively, has enjoyed a great reputation from numerous consumers and customers in and out of

Korea for its superb quality and convenience in use. We, at Gastron, have always strived and will

further endeavor to let our consumers gain an easy access to our products at all times. Furthermore,

we are proud to let you know that Gastron has exerted ourselves to ceaselessly develop and

research for gas detectors catering to customers' satisfaction. Our customers are now invited to

solve all the problems and dissatisfaction related to gas detectors by using our Gastron products.

Our customers are warranted to receive contentment with our Gastron gas detectors at all times and

at any place.

The following operating manual serves to explain an installation method, an operating method, a

simple maintenance method and other useful guidelines regarding the toxic gas leakage detector

"GTC-200A" . We trust that this manual will be of good use whenever there are any questions or

inquiries during usage of the detector. You are encouraged to carefully read and make good use

of the operating manual by safekeeping and referring to the same at your every need.

As always, we once again appreciate your patronage of our products and should you have any

inconveniences or problems on our products, kindly contact us at the following address during

use to receive prompt attention and necessary measures.

Note

• You are kindly requested to get your gas detector inspected and calibrated at

least once within a three-month period using calibration gas according to the

type of gas in order to ensure an exact operation of the gas alarm, and to

receive a periodic inspection including one or more calibration inspections for

each six-month period under the provision of relevant Industrial Safety and

Sanitary Act promulgated by the Korea Labor Ministry.

• No periodic inspections and calibrations may be a cause of erroneous operation

of the gas detector due to aged sensor unit.

• The disintegration or disassembly of the gas detector needs a person who has a

technical expertise on the gas alarm.

• You are kindly invited to call our technical department or write to our e-mail

address or web site for inspection and calibration of gas detectors or alarms.

GTC-200A

3

C o n t e n t s

1. Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

2. Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

3. Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

4. Part’s name and major functions - - - - - - - - - - - - - - - - - 7

5. Terminal wiring diagram - - - - - - - - - - - - - - - - - - - - - - 14

6. How to use - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

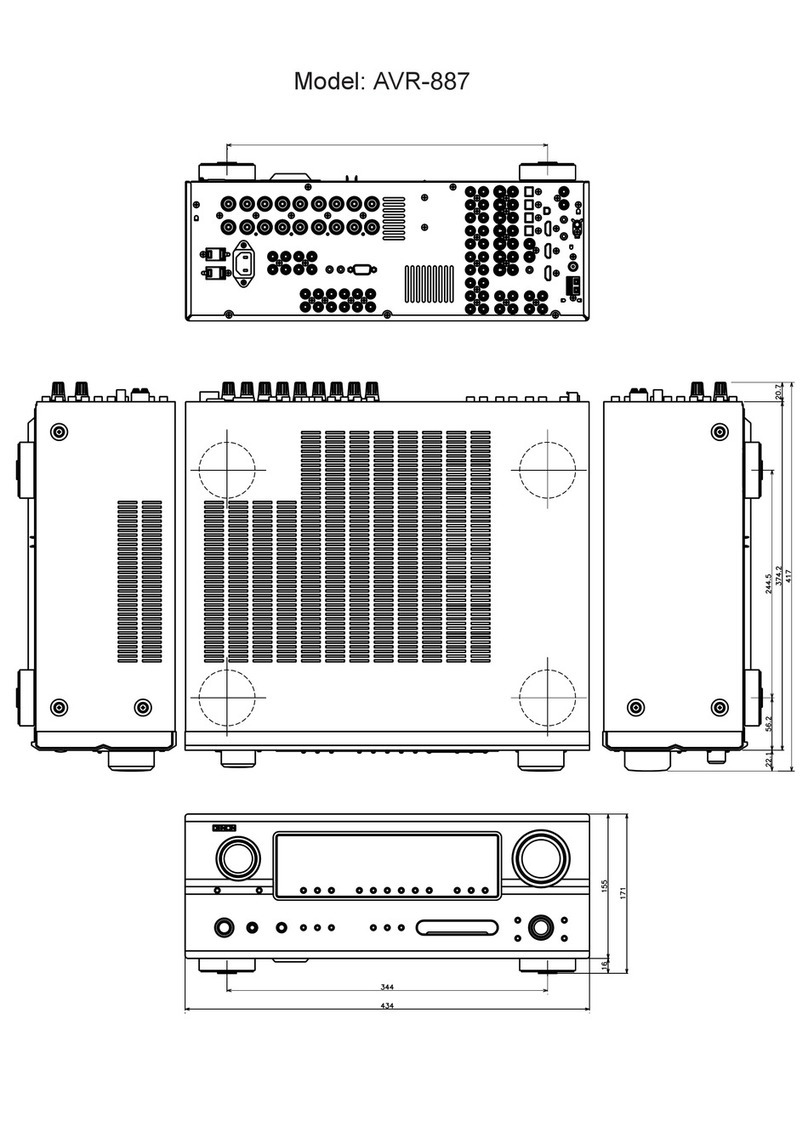

7. External Drawings and Dimensions - - - - - - - - - - - - - - - 26

GTC-200A

4

1. Introduction

GTC-200A Series has a high performance A/D converter and micro-processor so that it

has various functions built-in. GTC-200A Series is centralized, that is, composed of one

common alarm unit and several multi-channel control units. Each multi-channel control

unit is connected to its sensing part.

GTC-200A is encapsulated in DIN type case. There are two product types - Panel mount

type and Wall mount type.

GTC-200A has FND digital display (PV value) function and 3 colors LED bar graphic

display (PV & alarm set value) function, it also has three instant alarm (1st H/L, 2nd H/L,

and 3rd H/L) and trouble alarm.

2. Features

GTC-200A Series produces audible (buzzer) and visual (alarm LED and bar graphic LED

flashing) warnings in case of instant alarm and trouble alarm. If an alarm occurs, this

product can hold a Max. PV value holding.

GTC-200A series enables remote control for alarm cancellation. Our product can carry

out synchronous control functions because it has an output signal of the alarm (SPDT

contact).

GTC-200A series offers two outputs; Isolation type RS-485 signal (Option) is provided

for a monitoring system from common unit, the other is a measurement output (4-20mA,

DC) from channel control unit.

Since GTC-200A series is composed of the state of art parts, it has stability and

credibility. It can be expanded as large as its maximum (up to 64 channels)

GTC-200A

5

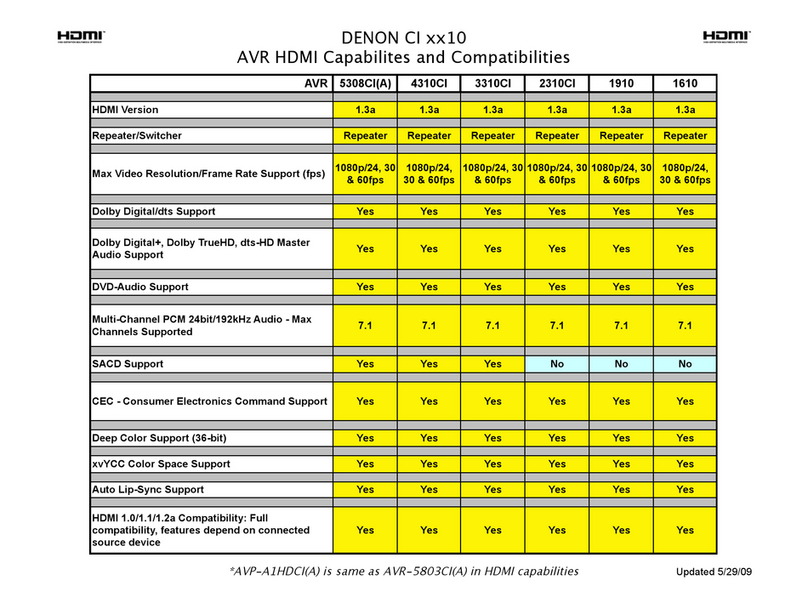

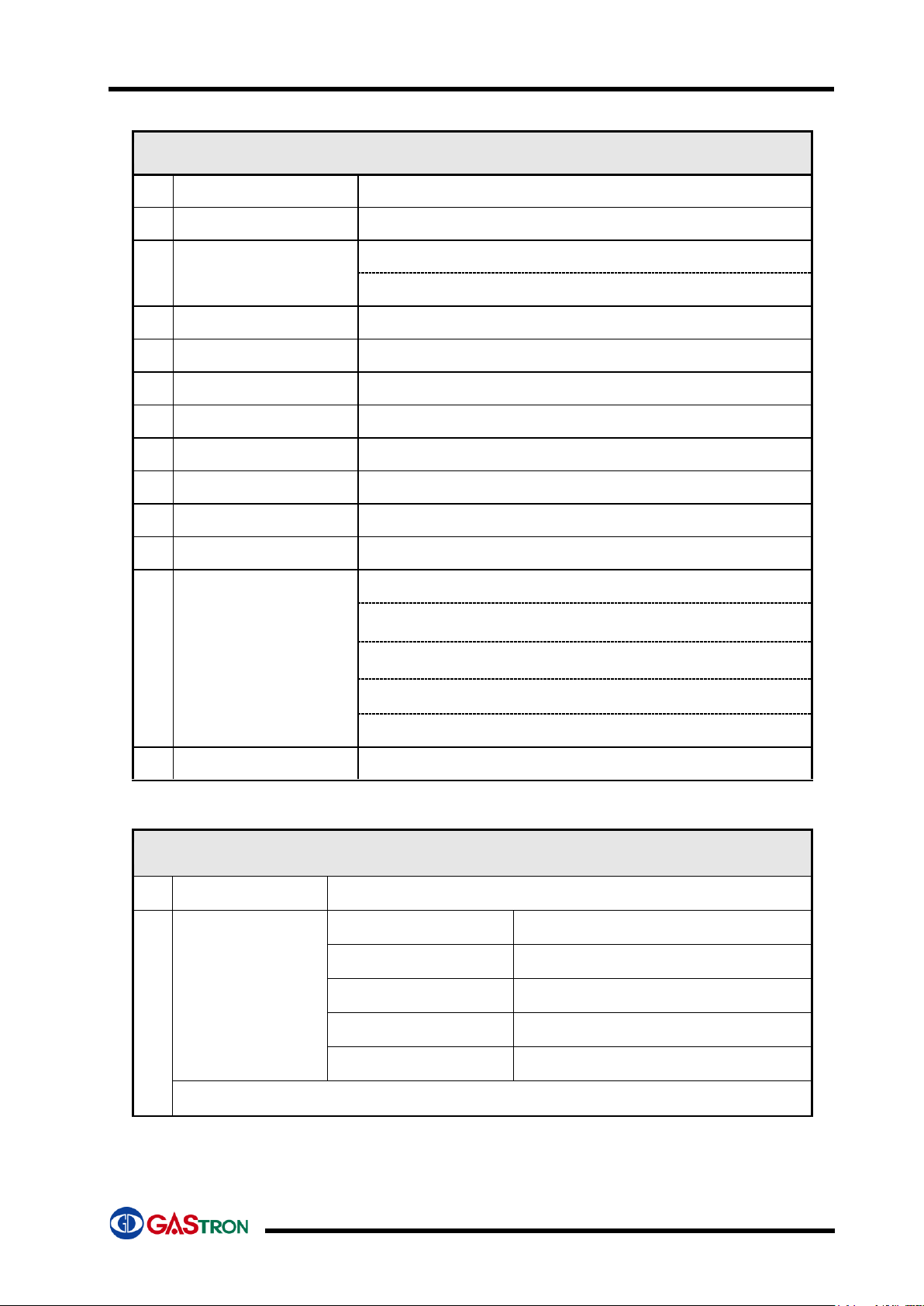

3. Specifications

3-1. Power Unit (Option)

Power Unit

1

Input power

DC. 24V

2

Output power

DC. 24V (Aux. power : DC. 27V / 300mA)

3

Output power display

FND Digital Display

4

Main power display

Green LED

5

Aux. power display

Green LED

6

Aux. power monitoring

Red LED

7

Aux. power test

Aux. power test S/W

8

Aux. power

Ni-Cd Battery 24V / 600mA(under 6 channels)

3-2. Common Unit

Common Alarm Unit

1

Input type

RS-485

2

Input check interval

100ms

3

Alarm type

Audible(Buzzer) & Visible (LED)

4

Alarm reset

Manual (Reset Switch)

5

Control input

Remote Reset–Buzzer stop/reset

6

Measuring output

Isolation RS-485 (Option)

7

Alarm output

Buzzer - STDT Relay Dry contact Signal Output

Fault Alarm- STDT Relay Dry contact Signal Output

1st Alarm - STDT Relay Dry contact Signal Output

2nd Alarm - STDT Relay Dry contact Signal Output

3rd Alarm - STDT Relay Dry contact Signal Output

* Relay Dry contact capacity : AC125V 10A

8

Operating Power

DC 24V

GTC-200A

6

3-3. Channel Unit

Channel Control Unit

1

Input type

4-20mA.DC / Full Scale

2

Measurement display

0.000 to 9999 Digital (settable by user)

3

Measurement

Accuracy

FND Digital –bigger one between ±1% Full Scale or 1 Digit

LED Bar --- bigger one between ±1% Full Scale or 1 Digit

4

Input check interval

100 ms

5

Alarm setting

3 stage Alarm (settable by user)

6

Alarm setting display

3 Color Bar Graphic (Green/Red/Yellow LED)

7

Alarm display

LED Bar Graphic

8

Alarm reset

Manual (Common Unit)

9

Self diagnosis

Test Switch & Reset Switch

10

Control In/out

RS-485

11

Measurement Output

4-20mA.DC / Full Scale

12

Alarm Output

Fault Alarm - STDT Relay Dry contact Signal Output

Alarm 1 STDT Relay Dry contact Signal Output

Alarm 2 STDT Relay Dry contact Signal Output

Alarm 3 STDT Relay Dry contact Signal Output

* Relay Dry contact capacity : AC125V 10A

13

Operating Power

DC 24V

3-4. Wall Mount Type

Wall Mount Type

1

Input Power

AC 110V/220V 50/60Hz (default: AC220V 50/60Hz)

2

Applicable SMPS

capacity by

Channel quantities

Channel

Capacity

3(4) Channel

24V 1.5A (24V 1.5A)

5(6) Channel

24V 2.1A (24V 2.1A)

7(8) Channel

24V 2.1A (24V 3.5A)

9(10) Channel

24V 3.5A (24V 3.5A)

**( ): quantities and capacity when there is no Power Unit

GTC-200A

7

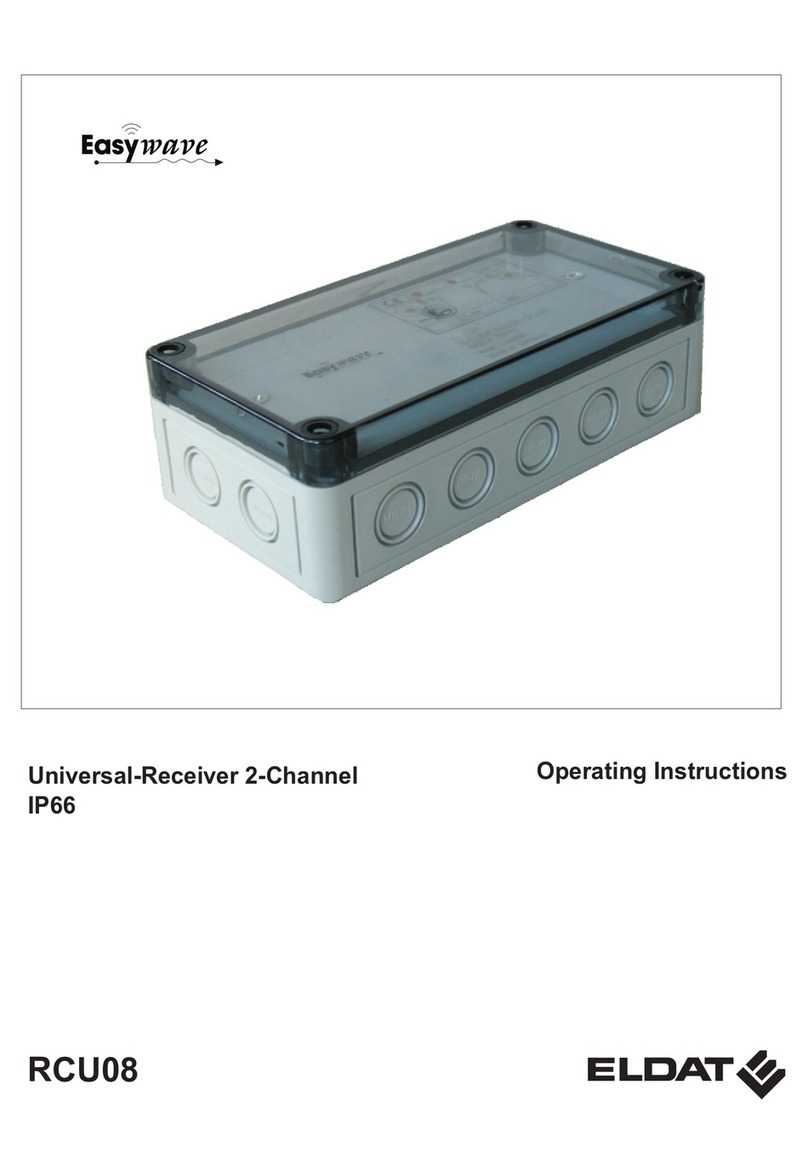

4. Part’s names and major functions

4-1. Configuration of Power unit

1 1 2

3

4

6 5

7

8

9

10

11

12

13

14

15

16

17

18

BATT TROUBLE

BATT GOOD

BATT POWER

MAIN POWER

BATT TEST

VOLT

GTC200A POWER

ON OFF POWER

No.

DESCRIPTION

No.

DESCRIPTION

1

FRONT COVER CASE

10

BAT. POWER TROUBLE LED

2

MAIN BODY CASE

11

BAT. POWER TEST KEY

3

ACRYLIC

12

BAT. POWER ON/OFF SWITCH

4

FRONT SUB COVER

13

FRONT COVER SCREW

5

MAIN BODY FIXED BRACKET

14

TERMINAL PCB

6

MAIN/BAT. POWER DISPLAY

15

TERMINAL PCB SCREW

7

MAIN POWER LED

16

DC INPUT CONNECTOR

8

BAT. POWER LED

17

BATTERY CONNECTOT

9

BAT. POWER GOOD LED

18

DC OUTPUT CONNECTOR

4-1-1. MAIN/BAT. POWER DISPLAY

Display voltage of main and Aux. power.

This is also one for Common Unit and Channel Unit.

4-1-2. MAIN POWER LED

This LED is turned on when using AC Power, and turned off in case of using Battery

4-1-3. BAT. POWER LED

This LED is turned on when using batterypower

GTC-200A

8

4-1-4. BAT. POWER GOOD LED

If battery voltage is above 18V when connecting with battery, this LED is turned on.

4-1-5. BAT. POWER TROUBLE LED

If battery voltage is below 18V when connecting with battery, this LED is turned on. This LED is

flickering if there is no connection with Battery.

4-1-6. BAT. POWER TEST KEY

This S/W is for testing operation of Battery. When pressing this S/W, battery power is

applied and operates gas detection system. Also voltage of battery is displayed on FND.

4-1-7. BAT POWER ON/OFF SWITCH

This is battery power on/off S/W.

Note)When the products is released the batter switch should be off. After turning

on main power the battery power should be turned on.

GTC-200A

9

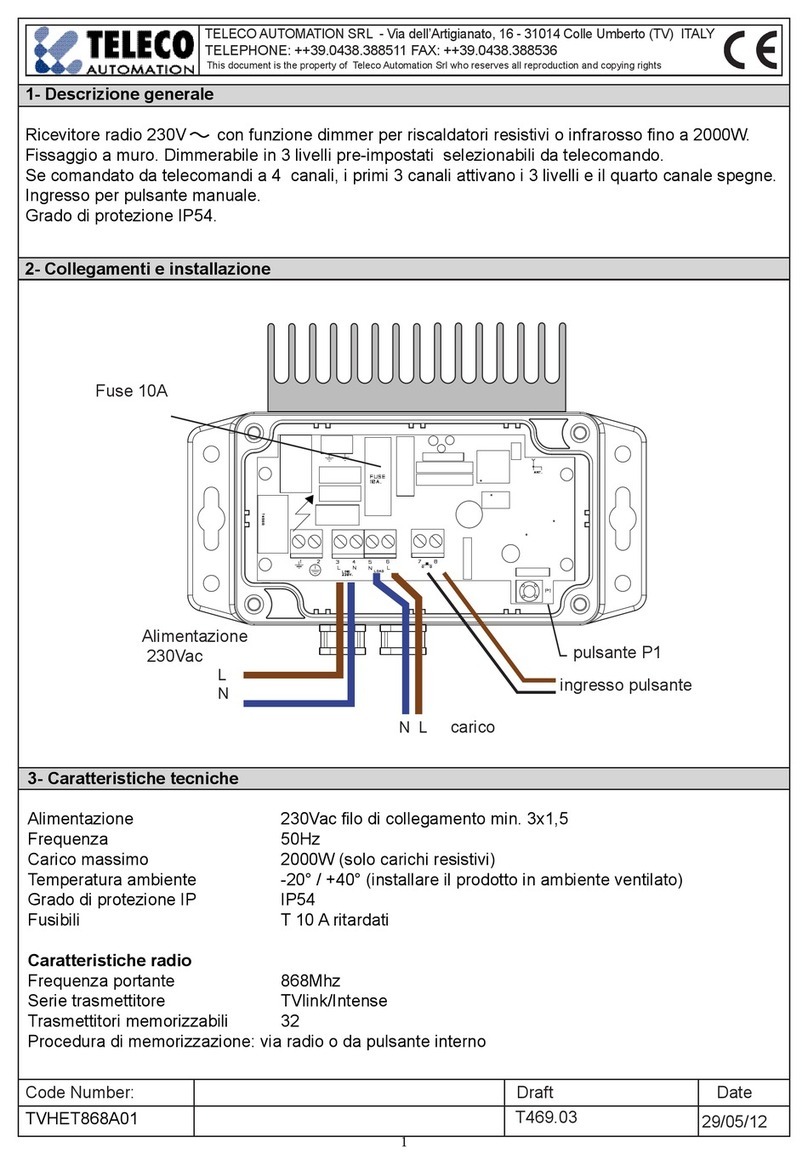

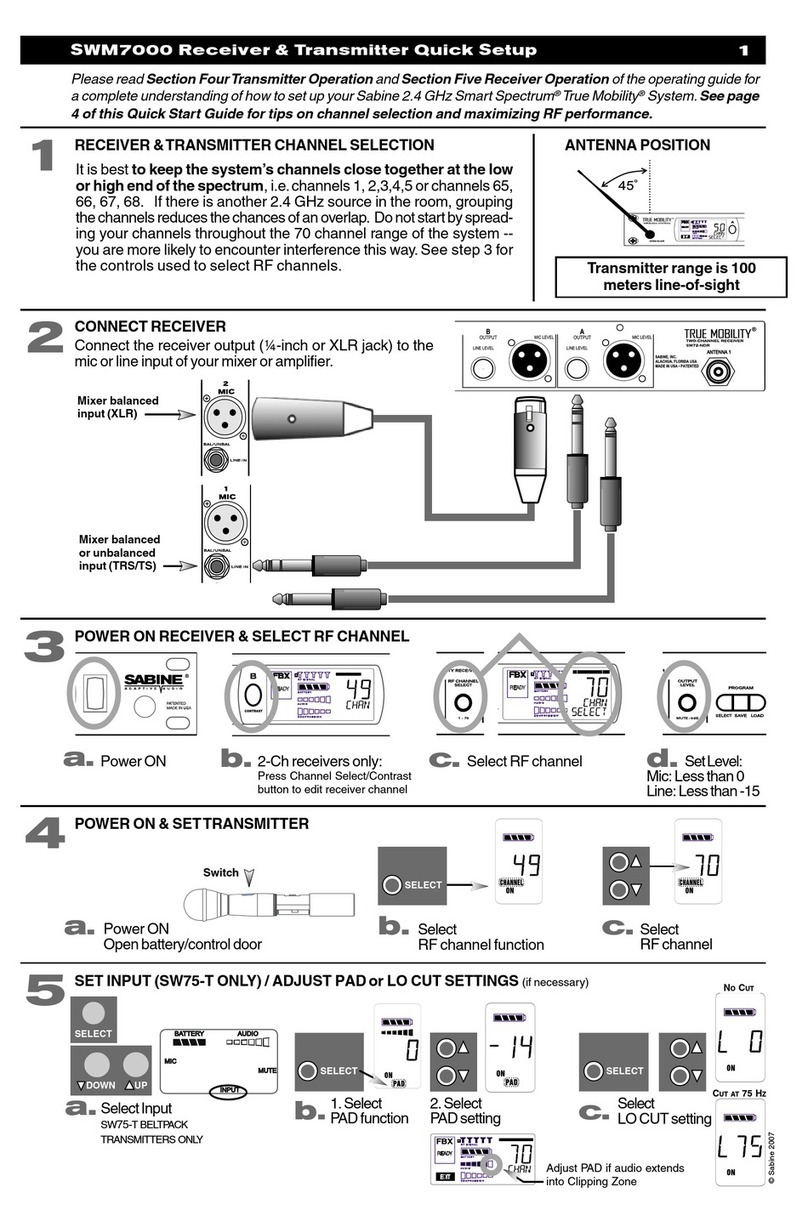

4-2. Configuration of Common unit

11 2

3

4

65

7

8

9

10

15

16

17

18

20

11

12

13

14

COM-PC

COM-CH

BZ. STOP

GTC200A COMMON

RESET

BZ. STOP

ON OFF POWER

NC NOCOM NC NOCOM NC NOCOM NC NOCOM AB AB

ALARM1 ALARM2 ALARM3 TROUBLE BUZZER RESET

19 1918

Panel Mount Type Wall Mount Type

No.

DESCRIPTION

No.

DESCRIPTION

1

FRONT COVER CASE

11

ALARM-1 LED

2

MAIN BODY CASE

12

COMMUNICATION LED (CHANNEL)

3

ACRYLIC

13

COMMUNICATION LED (PC)

4

FRONT SUB COVER

14

BUZZER STOP LED

5

MAIN BODY FIXED BRACKET

15

BUZZER STOP/RESET KEY

6

BUZZER

16

POWER ON/OFF SWITCH

7

POWER LED

17

FRONT COVER SCREW

8

TROUBLE LED

18

TERMINAL PCB

9

ALARM-3 LED

19

TERMINAL PCB SCREW

10

ALARM-2 LED

20

CONNECTOR

4-2-1. Buzzer

Buzzer sounds when trouble or alarm occurs from each channel unit.

4-2-2. Power LED

When power is applied from Common Unit, power LED turns on.

4-2-3. Trouble LED

If trouble occurs from each channel unit, Trouble LED turns on.

Ex) In case of bad wiring with gas detector or other trouble

GTC-200A

10

4-2-4. 1st Alarm LED (Alarm 1 LED)

Alarm 1 LED is on when first alarm occurs on each channel unit.

If the value reaches at 1st alarm value during test of each channel unit, Alarm 1 LED

is on.

4-2-5. 2nd Alarm LED (Alarm 2 LED)

Alarm 2 LED is on when second alarm occurs on each channel unit. If the value

reaches at 2nd alarm value during test of each channel unit, Alarm 2 LED is on.

4-3-6. 3rd Alarm LED (Alarm 3 LED)

Alarm 3 LED is on when third alarm occurs on each channel unit. If the value

reaches at 3rd alarm value during test of each channel unit, Alarm 3 LED is on.

4-2-7. Channel communication LED (COM-CH LED)

If Common Unit normally communicates with whole Channel Units set on common

unit, this COM-CH LED is turning on continuously. If there is some channel units

having no communication with common unit, this COM-CH LED is flickering.

(If number of channel unit is set as under 1 on Common Unit, the LED is flickering

with 0.5 second interval)

4-2-8. PC communication LED (COM-PC LED) (Option)

If Common Unit normally receives communication data from PC, this COM-PC LED

is off after turned on once.

(If number of common unit address is set as under 1 on Common Unit, the LED is

flickering with 0.5 second interval.)

4-2-9. Buzzer Stop LED (BZ-STOP LED)

Buzzer stop s/w is used for stopping buzzer sound in case of alarm at each channel

unit and buzzer stop LED is also on. In case of pushing buzzer stop s/w again on

common or channel unit, buzzer stop LED is off. (This LED is activated only when

set alarm type as “Hold” on Channel Unit)

4-2-10. Buzzer Stop & Reset Key

This key is used for stop & reset of buzzer on alarm at each Channel Unit.

- Push once .... Buzzer sound stops and BZ-STOP LED is on.

- Push twice .... BZ-STOP LED is off and performs Reset function.

4-2-11. Main Power ON / OFF Switch

This is Power On/Off switch of Common Unit.

GTC-200A

11

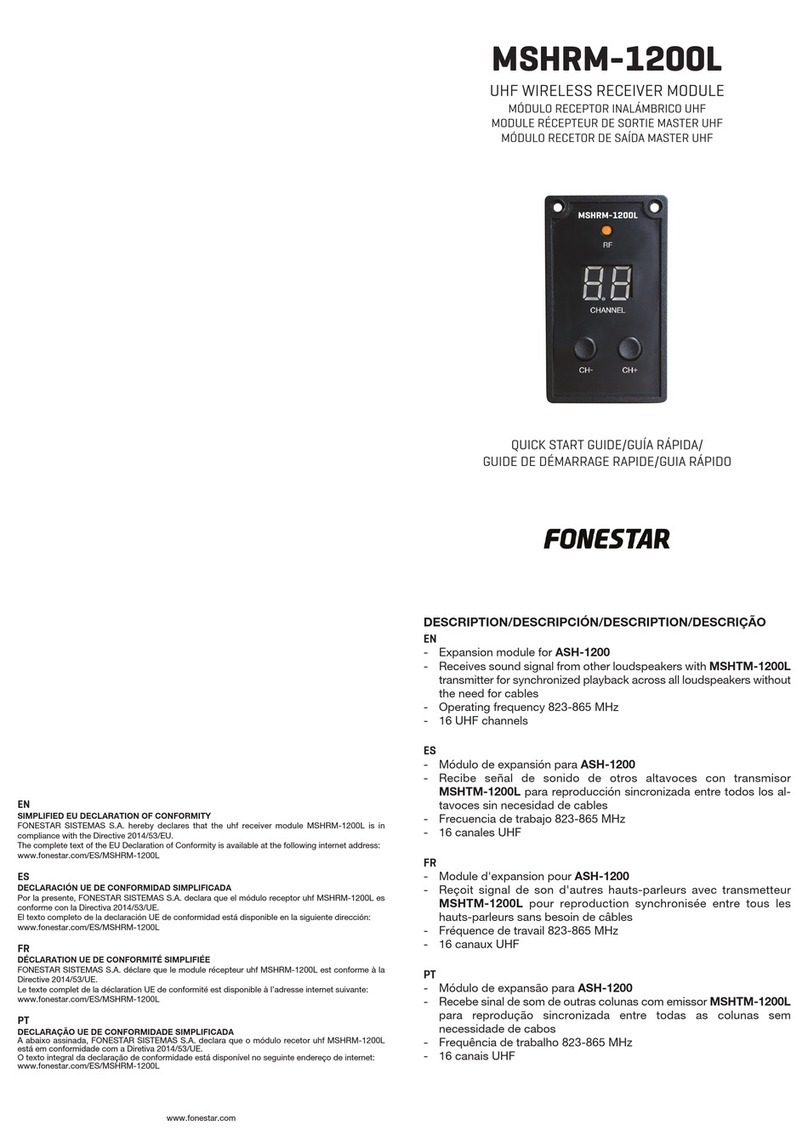

4-3. Configuration of Channel unit

1 1 2

3

4

6 5

7

9

10

12

14

19

20

21

23

8

11

16

15

17

18

13

mA +- SENSOR NC NOCOM NC NOCOM NC NOCOM NC NOCOM

ALARM1 ALARM2 ALARM3 TROUBLE +-

OUTPUT

4-20mA

21

Panel Mount Type Wall Mount Type

22 22

0

10

20

30

40

50

60

70

80

90

100

%LEL

ON OFF 전원

기능

경보1

경보2

전원

점검

고장

경보3

복귀시험

GTC210A CHANNEL

No.

DESCRIPTION

No.

DESCRIPTION

1

FRONT COVER CASE

13

3 COLOR BAR GRAPHIC LED

2

MAIN BODY CASE

14

RESET KEY

3

ACRYLIC

15

DOWN KEY

4

FRONT SUB COVER

16

TEST KEY

5

MAIN BODY FIXED BRACKET

17

FUNCTION KEY

6

FND DISPLAY

18

UP KEY

7

POWER LED

19

POWER ON/OFF SWITCH

8

STANDBY LED

20

FRONT COVER SCREW

9

TROUBLE LED

21

TERMINAL PCB

10

ALARM-3 LED

22

TERMINAL PCB SCREW

11

ALARM-2 LED

23

CONNECTOR

12

ALARM-1 LED

4-3-1. Measurement density display (FND Digital Display)

Continuously displays measurement value of corresponding detector connected

with each channel unit, and displays user setting value with flickering when doing

Test function.

4-3-2. Power LED

This Power LED is on when power is applied to channel unit.

4-3-3. Stand-by LED

This STD-BY LED is flickering when checking gas detector.

4-3-4. Trouble LED

This trouble LED is flickering in case of trouble on Channel Unit and/or gas detector.

Ex) * bad connection with gas detector or other trouble

GTC-200A

12

4-3-5. 1st Alarm LED (Alarm 1 LED)

Alarm 1 LED is on when first alarm occurs on channel unit. If the value reaches

at1st alarm value during test of channel unit, Alarm 1 LED is on

4-3-6. 2nd Alarm LED (Alarm 2 LED)

Alarm 2 LED is on when second alarm occurs on channel unit. If the value reaches

at 2nd alarm value during test of channel unit, Alarm 2 LED is on

4-3-7. 3rd Alarm LED (Alarm 3 LED)

Alarm 3 LED is on when third alarm occurs on channel unit. If the value reaches

at 3rd alarm value during test of channel unit, Alarm 3 LED is on.

4-3-8. 3 Color Bar Graphic LED

3 Color Bar Graphic LED displays the measured value and alarm setting value continuously

like FND display

- When the measured value is lower than 1st alarm, the LED color is green.

- When the measured value is lower than 2nd alarm, the LED color is orange

- When the measured value is lower than 3rd alarm, the LED color is red.

If measured value is higher than alarm setting value, bar graphic is being held at the

maximum value and is flickering with the alarm

4-3-9. Test Key

If pressing Test Switch, channel unit goes into self- diagnosis mode.

- Measurement display FND is flickering and user can check alarm function on channel unit

and common unit by changing flickering measurement value with ▲or ▼key

- By pressing reset key on each channel unit once, self diagnosis mode is cancelled.

4-3-10. Reset Key

This key is used for canceling of alarm, self test and/or program setting of Channel Unit.

4-3-11. Func. Key

Function Key is used for switching or selecting mode when setting of alarm value, alarm

type, alarm dead band and/or alarm delay time.

4-3-12. ▲ ▼ Key (UP/DOWN KEY)

After selecting each mode by Func Key, desired value will be chosen by “▲”, “▼” Key.

Furthermore, the value change will be accelerated by keeping “▲”, “▼” Key press if user

need to change a lot of numbers at one time.

GTC-200A

13

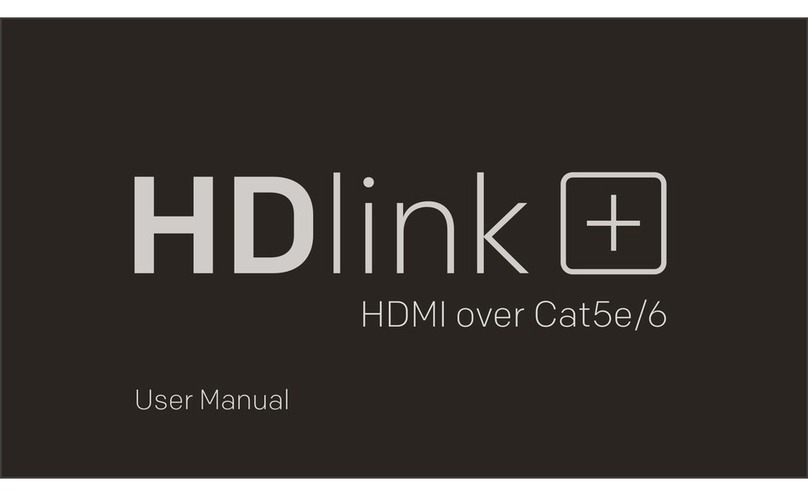

4-4. Configuration of Wall Mount Type panel

1

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

COM-PC

COM-CH

BZ. STOP

GTC200A COMMON

RESET

BZ. STOP

GTC200A

BATT TROUBLE

BATT GOOD

BATT POWER

MAIN POWER

BATT TEST

VOLT

GTC200A POWER

GTC200A

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

11 2141310654

7 8 9 123InnerSIDEFRONT 15 16 17 18

No.

DESCRIPTION

No.

DESCRIPTION

1

WALL MOUNT CASE FRONT

10

NAME PLATE

2

WALL MOUNT CASE REAR

11

DIN CASE FIXED BRACKET

3

WALL MOUNT CASE COVER

12

CASE COVER SCREW

4

POWER UNIT (Option)

13

FRONT CASE FIXED HOOK

5

COMMON UNIT

14

WALL MOUNT FIXED HOLE

6

CHANNEL UNIT

15

MCCB (Molded Case Circuit breaket)

7

MOTHER BOARD FILTER PCB

(Option)

16

POWER SUPPLY

8

MOTHER BOARD COMMON PCB

17

BATTERY (Option)

9

MOTHER BOARD CHANNEL PCB

18

BATTERY COVER (Option)

4-4-1. Power Unit (Option)

This unit is only for Battery and supplied as Option item.

4-4-2. Mother Board Filter PCB (Option)

This PCB is supplied when using Power Unit and protects circuit from electromagnetic wave,

Noise and Surge.

4-4-3. Mother Board Common PCB

Provides relay contact output terminals for buzzer, trouble and alarms.

4-4-4. Mother Board Channel PCB

Provides terminals for relay contact output, 4~20mA output and connection with gas detector.

GTC-200A

14

5. Terminal wiring diagram

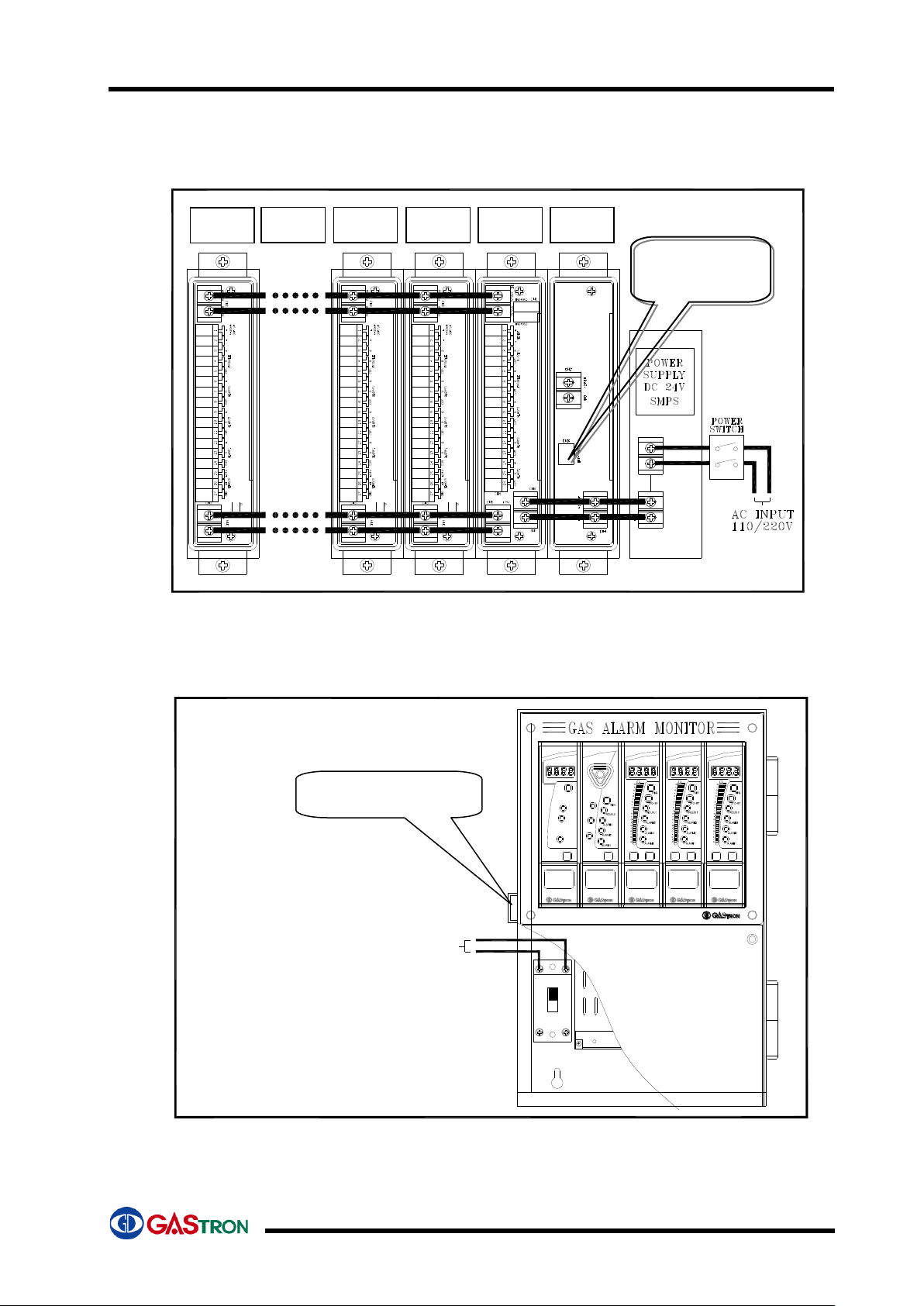

5-1. POWER CONNECTION

5-1-1. Panel Mount Type

0V 24V

AC 110/220V

*. Power Unit is supplied only when using Battery. In case of no Power Unit, DC power (24V)

is directly connected from Power Supply to connector (CN6) of common unit. (Power Unit

is an option item.)

5-1-2. Wall Mount Type

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

COM-PC

COM-CH

BZ. STOP

GTC200A COMMON

RESET

BZ. STOP

GTC200A

BATT TROUBLE

BATT GOOD

BATT POWER

MAIN POWER

BATT TEST

VOLT

GTC200A POWER

GTC200A

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

RESETTEST

0

10

20

30

40

50

60

70

80

90

100

GTC200A CHANNEL

%LEL

GTC200A

Channel

Unit-#64

Channel

Unit-…

Channel

Unit-#2

Channel

Unit-#1

Common

Unit

Power

Unit

Release the fixing ring and open

front case. And then connect

electrical power to NFB, located at

left side in case

Operating voltage is AC110V or

220V and user can select voltage on

order. (Default voltage is AC220V)

Wall Mount Front Case

fixing ring

Back-up battery

(battery connection)

GTC-200A

15

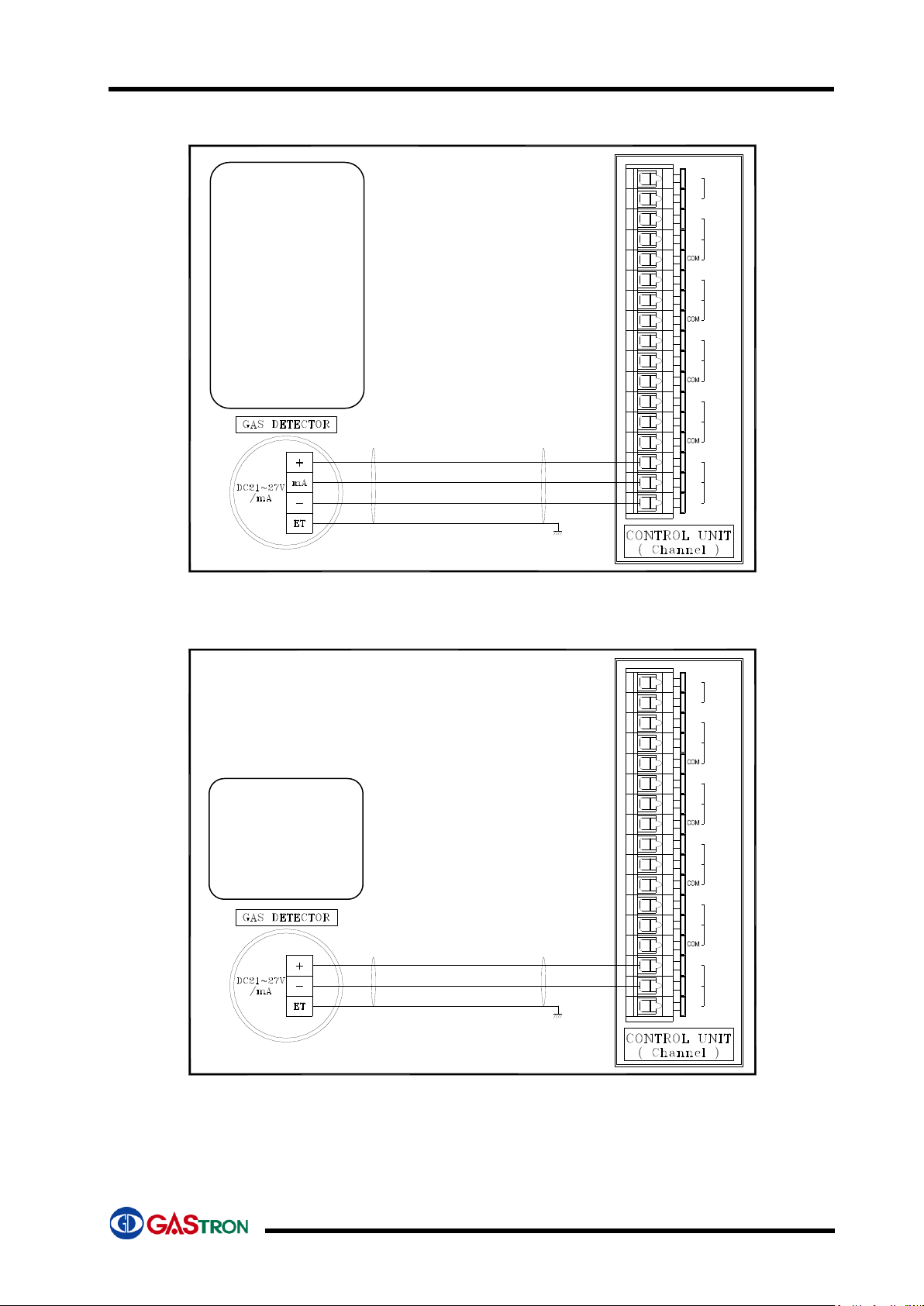

5-2. Gas Detector connection diagram (3Wire type)

11

10

8

9

7

-

mA

6

4

5

3

1

2

OUTPUT

4-20mA

-

+

SHILD

EARTH

ALARM3

( 경보3 )

ALARM2

( 경보2 )

SENSOR

(탐지기)

14

13

12

17

16

15

ALARM1

( 경보1 )

+

NO

TROUBLE

( 고 장 )

NC

NO

NC

NO

NC

NO

NC

Note) Please use CVVS or CVVSB 1.5sq↑ Shield Cable!

5-3. Gas Detector connection diagram (2Wire type)

11

10

8

9

7

-

mA

6

4

5

3

1

2

OUTPUT

4-20mA

-

+

SHILD

EARTH

ALARM3

( 경보3 )

ALARM2

( 경보2 )

SENSOR

(탐지기)

14

13

12

17

16

15

ALARM1

( 경보1 )

+

NO

TROUBLE

( 고 장 )

NC

NO

NC

NO

NC

NO

NC

Note) Please use CVVS or CVVSB 1.5sq↑ Shield Cable!

( Gas detector )

TS-1100Ex

TS-2000Ex

TS-2100 Series

TS-4000 Series

TS-4100 Series

TS-5100 Series

GTD-1000 Series

GTD-2000 Series

GTD-3000 Series

GIR-3000 Series

( Gas detector )

TS-1100Tx

TS-2000Tx

TS-3000 Series

TS-3100 Series

GTC-200A

16

6. How to use

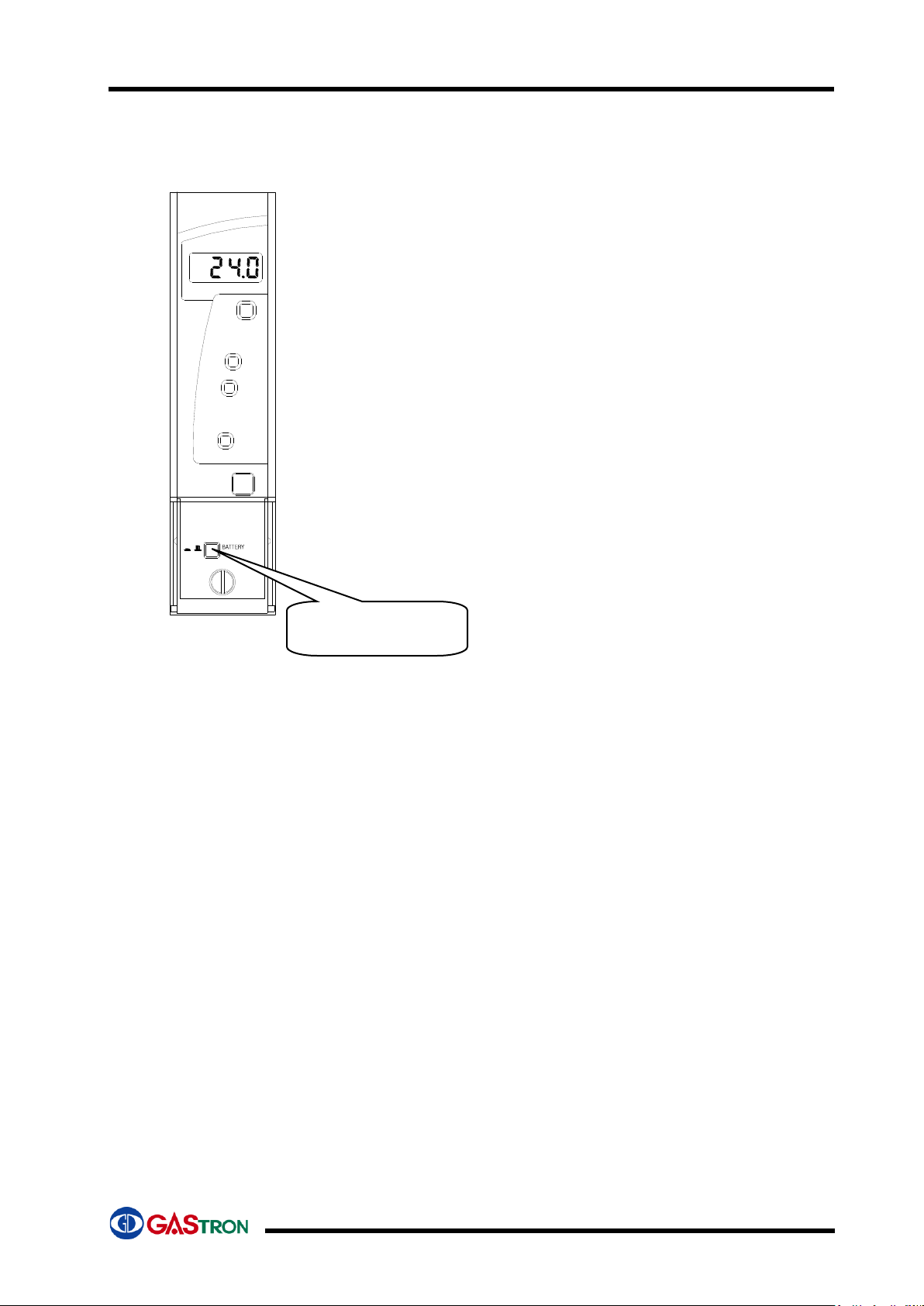

6-1. How to operate Power Unit

-. Voltage of main power is displayed on FND Digital Display.

-. If battery test key was pressed, the power is changed to Aux.

power (battery) and voltage of battery is displayed on FND

Digital Display.

-. If a back-up battery is not connected, battery trouble LED is

blinking (0.5 second interval).

-. If a back-up battery voltage is above 18V,the back-up battery

power is normal LED is on. Otherwise, battery trouble LED

is on.

Note) this unit is off when shipment.

Please turn on Aux. power switch after turned on main

power.

6-2. How to operate Common Unit

6-2-1. Buzzer alarm

-. gives short intermittent sound when receiving trouble signal from Channel Unit

-. gives long intermittent sound when receiving alarm signal from Channel Unit.

6-2-2. Trouble/alarm LED

-.These LEDs are turned on when receiving trouble or alarm signal from Channel

Unit

Alarm LED is flickering during alarm time.

6-2-3. Communication LED

-.COM-CH LED represents communication status between Common Unit and

Channel Unit. This LED is turned on at first communication (0.1 sec) with each

channel unit and turned off. If Common Unit can normally communicate with whole

pre-set channel units, this LED is continuously turning on. (Channel Unit Access

time: 0.1)

-.COM-PC LED is turned on once and immediately turned off when Common Unit

receives normally communication data from PC.

-. If SW1 (channel unit number) and SW2 (common unit address) are set under 1 in

common unit, COM-CH and COM-PC LEDs are flickering (0.5sec interval)

BATT TROUBLE

BATT GOOD

BATT POWER

MAIN POWER

BATT TEST

VOLT

GTC200A POWER

ON OFF POWER

Back-up battery

switch

GTC-200A

17

6-2-4. Buzzer Stop LED (BZ-STOP LED )

-. This LED is on when buzzer stops by pressing buzzer stop key in case of alarm

from Channel Unit (This LED is activated only when alarm type is set as Hold in

Channel Unit)

-. This LED is off when pressing buzzer stop key once again in Common or Channel

Unit.

6-2-5. Buzzer Stop & Reset Key

- In case of trouble or alarm on each channel unit, this key is used for stopping buzzer and

resetting

- Push once .... Buzzer sound stops and BZ-STOP LED is on.

- Push twice .... BZ-STOP LED is off and performs Reset function.

6-2-6. RS485 MODBUS communication Data

6-2-6-1. RS-485 communication Format

- Baudrate : 9600BPS

- Stop bit : 1 Stop

- Parity : Even parity

6-2-6-2. Gas density value (Analog input)

No

Function name

Address

Other

1

Channel-1 unit gas density value

30001

Channel address is

increased by 1 for

each channel unit.

2

Channel-2 unit gas density value

30002

3

Channel-3 unit gas density value

30xxx

6-2-6-3. Channel unit status Bit Data(Digital input contact reading Data)

Channel Unit

No

Function name

Address

Other

Channel-1

Unit

Alarm1 status Data

10001

8Bit is assigned

for each channel

unit

Alarm2 status Data

10002

Alarm3 status Data

10003

Trouble status Data

10004

Test status Data

10005

Spare Data

10006~10008

Channel-2

Unit

Alarm1 status Data

10009

8Bit is assigned

for each channel

unit

Alarm2 status Data

10010

Alarm3 status Data

10011

Trouble status Data

10012

Test status Data

10013

Spare Data

10014~10016

Channel-n

Unit

Status Data

10001+((n-1)*8) ~

10001+(((n-1)*8)+8)

GTC-200A

18

6-3. How to operate channel unit

6-3-1. Check of wiring

- Check wirings to operation power, gas detector, common unit and channel unit with

reference to Terminal wiring diagram (Section 5).

* Power supply is AC110/220V, 50/60Hz. (Please make sure to check power type before

turning on power)

6-3-2. Power ON

-.Turn power on after checking voltage of power supply.

-.Check power LED turned on at common unit and channel units.

-.Check “SELF” on FND at channel units.

6-3-3. Display of gas density

-.After power on of Channel Unit, “SELF” on FND at channel unit is flickering

about 15 seconds and the channel unit goes into measurement mode. If

the unit or gas detector has trouble, trouble signal occurs at this time.

-.Channel unit displays gas density received from gas detector as number

type on FND digital display.

-.Gas density is also displayed with 3 Color Bar Graphic LED

Under 1st Alarm density: Green color

Above 1st Alarm and under 2nd Alarm density: Orange color

Above 2nd Alarm density: Red color.

-. If there is no connection with gas detector or trouble at gas detector,

channel unit displays “Undr” with flickering (0.5 sec interval).

-. Trouble LED Lamp is also turned on.

-. Lowest round LED at 3 Color Bar Graphic LED is turned on with Red color.

-. If current value received from gas detector is 10% higher than

predetermined High scale value, “OuEr” is displayed with flickering (0.5

sec interval).

-. Highest round LED at 3 Color Bar Graphic LED is turned on with Redcolor.

-.If gas density is higher than alarm setting value, corresponding alarm is

activated after Alarm holding time.

-.Alarm LED Lamp is flickering (0.5 sec interval) during alarm holding time

and turned on after Alarm holding time.

-.Alarm Relay is ON after Alarm holding time.

-.If Alarm Latch Type is “on” mode, Alarm status and gas density value is

held at maximum value when alarm is activated. Gas density value held is

not automatically reset when real gas density is decreased below alarm

setting value and only can be reset by “Reset” key.

-.If Alarm Latch Type is “off” mode, Alarm is reset according to change of

measured gas density.

6-3-4. Program Data setting

-. Push “▲”, “▼” at the same time for over 2 seconds in gas density display

mode and goes into program data setting mode.

(During program setting mode, automatically return to density display

mode if there is no key input for 10 seconds.)

-. Firstly, “dP-S” (decimal point setting) is displayed.

-. Press “Func” key to go into decimal point setting mode.

-. If pressing “RESET” key, returns to density display mode.

GTC-200A

19

-. By pressing “▲” or “▼”, decimal point can be changed in 3 types.

-. Press “FUNC” key when desired decimal point is displayed to set the point

and go to next item

-. If pressing “RESET” key, returns to density display mode.

-. High Scale (Maximum display value of gas density) is displayed as “H-SL”

-. Press “Func” key to go into High scale setting mode

-. If pressing “RESET” key, returns to density display mode.

-. High Scale value was set when shipping from factory according to

domestic law

-.High Scale value can be changed according to measuring range with “▲”

or “▼”(increase or decrease).

-.If desired High scale value is displayed, press “FUNC” key to set the value

as High Scale and go to next item.

-. If pressing “RESET” key, returns to density display mode

-. This scale is set as same as detection range of gas detector at the factory.

Ex) when set Range as 100

4 mA.DC input ................... 0 Display

20 mA.DC input ................... 100 Display

-.SAD (compensating error from gas detector) setting message is displayed

as “SAd ”.

-. Press “Func” key to go into SAD value setting mode.

-. If pressing “RESET” key, returns to density display mode

-.When pressing “▲” or “▼” key, SAD value is increased or decreased (in

case of negative number, “-“ sign is added and displayed.

-.If desired SAD value is displayed, press “FUNC” key to set the value as

SAD and go to next item.

-.If pressing “RESET” key, returns to density display mode

ex) In case of setting SAD as 2 : if output error from gas detector is -2, the

display will be -2. In this case, User should compensate 2 (SAD setting

value) to display 0 on FND.

-. Channel Number setting message (setting recognition number of each

channel unit) is displayed as “CHno ”.

-. Press “Func” key to go into Channel Number setting mode..

-. If pressing “RESET” key, returns to density display mode

-.Common unit can check operation status of each channel unit with channel

number and this mode is to input each number (address) of channel unit.

When pressing “▲” or “▼” key, address no. of channel unit will be

increased or decreased.

-.If desired address number is displayed, press “FUNC” key to set the value

as Address NO. and go to next item (Alarm Reset Type function).

-.If pressing “RESET” key, returns to density display mode

-. If Channel No. was not inputted, Channel Unit and Common Unit can

not communicate with each other.

-. Please make sure to assign different number to Channel units.

6-3-5. Alarm Data setting

-.Push “Func” for over 2 seconds in gas density display mode and go into

alarm data setting mode.

-.(During alarm data setting mode, automatically return to density display

GTC-200A

20

mode if there is no key input for 10 seconds.)

-.Function to set Alarm Latch Type “LACH” is displayed.

-.Press “Func” to go into Alarm Latch Type setting mode.

-.If pressing “RESET” key, returns to density display mode

-.This step is for changing Alarm Reset Type. “ on” and “ oFF” are changed in

turns when pressing “▲”or “▼” key.

-.If desired Alarm Latch Type is displayed, press “FUNC” key to set the value

as Alarm Latch Type and go to next item.

- .If pressing “RESET” key, returns to density display mode

-. There are two kinds of Alarm Latch Type (“ on” and “ oFF”)

OFF mode is to automatically reset Alarm and ON mode is to reset alarm

manually.

-. Alarm1 value setting function (“AL-1”) is displayed.

-. Press “Func” key to go into Alarm1 value setting mode.

-.If pressing “RESET” key, returns to density display mode

-.This mode is to change Alarm1 setting value (up to High Scale value)

Alarm 1 value is increased or decreased by pressing “▲” or “▼” key.

-. If desired Alarm1 value is displayed, press “FUNC” to set the value as

Alarm1 and go to next item.

-.If pressing “RESET” key, returns to density display mode

-.Alarm Level was set when shipment according to density designated on

domestic law.

-. This mode is to set moving direction of Alarm1

“1H ” or “1L ” is displayed in turns when pressing “▲” or ▼” key.

-.“1H ” mode is to activate alarm when value is equal and bigger than alarm 1

setting value and “1L ” mode is to activate alarm when value is equal and

smaller than alarm 1 setting value.

-. If desired mode is displayed, press “FUNC” to set mode and go to next

item.

-.If pressing “RESET” key, returns to density display mode

-.Alarm Type was set at shipment (combustible: 1H & 2H & 3H / Oxygen: 3H

& 2H & 1L / Toxic: 1H & 2H & 3H Type).

-.This mode is to set alarm 1 dead band value and the value is increased or

decreased by pressing “▲” or ▼” key.

-. When Alarm1 is in “1H ”, alarm 1 is activated above the value (Alarm value

plus Dead band value) and is deactivated below the value ( Alarm value

minus Dead band value).

-. When Alarm1 is in “1L ”, alarm 1 is activated below the value (Alarm value

minus Dead band value) and is deactivated above the value ( Alarm value

plus Dead band value)

-. If desired alarm1 dead band value is displayed, press “FUNC” to set the

value and go to next item.

-.If pressing “RESET” key, returns to density display mode

-.This function is to give hysteresis value to removefrequent alarm on/off

around alarm setting value (this value is zero when shipment).

Ex) If alarm setting value is 20%LEL and Dead Band is 2%LEL, alarm is

activated at 22%LEL and deactivated at 18%LEL.

-.Alarm1 delay time setting function (“AL1t”) is displayed.

-.Press ”Func” key to go into alarm1 delay time setting mode.

-.If pressing “RESET” key, returns to density display mode

-. This function is to prevent malfunction by external shock or noise and

change of alarm1 delay time is increased or decreased by pressing “▲” or

“▼” key

-. If desired alarm1 delay time is displayed, press “FUNC” key to set alarm1

Other manuals for GTC-200A

1

Table of contents

Other GASTRON Receiver manuals