GASTRON GTL-200 User manual

GTL-200

Instruction Manual

Headquarters / Engineering research laboratory :

23 Gunpo Advance d Industry 1-ro(Bugok-dong), Gunpo-si, Gyeonggi-do

Tel +82-31-490-0800 Fax +82-31-490-0801

Yeongnam business office / Plant :

55 Gonghangap-gil 85beon-gil, Gangseogu, Busan Metropolitan City

Tel +51-973-8518 Fax +51-973-8519

E-mail : [email protected]

www.gastron.com

Read in detail for correct use.

Gas & Flame

Detection System

GTL-200

Instruction Manual

www.gastron.com

02_03

When abnormalities occur after purchasing the product,

please contact the following address.

·Address : 23 Gunpo Advanced Industry 1-ro,

Gunpo-si, Gyeonggi-do

·Tel : 031-490-0800

·Fax : 031-490-0801

·URL : www.gastron.com

·e-mail : [email protected]

Thank you very much for purchasing a product from Gastron Co. Ltd.

Our Gastron Co.Ltd. is a company specialized in Gas Detector & Gas Monitoring System and have been

recognized by many customers for the best quality and use convenience. We always seek to help our

customers to find the product they need and we continuously research to develop gas detectors that

satisfies our customers. From now on, you can solve all problems related to gas detectors with the

products of Gastron. We Gastron will be responsible for your satisfaction.

This user manual describes operation and simple maintenance methods etc. for the gas detector.

Please read carefully and store it in a safe place. Using it as a reference will help a lot when you have a

question during use.

The product and manual are subject to change without a notice for the product's functional improvement and ease

of use.

■ Only an individual specialized in explosion-proof devices and warning lights may disassemble

the device.

■ Please contact our company's technical support, e-mail, or website for inquiries related to

inspection and calibration of the explosion-proof warning light.

Greetings

6. Drawings and Dimensions ········································································· 18

6.1. Combination Type ·············································································· 18

6.2. Sounder Type ·················································································· 19

6.3. Beacon Type ··················································································· 20

7. Precautions during Installation ····································································· 21

Appendix A. Sound Tone Table ······································································ 22

Appendix B Method to Set Tone ······································································ 24

8. Revision History ··················································································· 26

www.gastron.com

04_05

ContentsContents

1. Overview ·························································································· 6

2. Specification ······················································································· 6

2.1. Basic Specifications ··········································································· 6

2.2. Mechanical Specifications ····································································· 7

2.3. Electrical Specifications(DC Type) ······························································ 7

2.4. Electrical Specifications (AC Type) ······························································ 8

2.5. Environmental Specifications··································································· 8

3. Name and description of each part ································································ 9

3.1. Combination Type Components ································································ 10

3.2. Sounder Type Components ···································································· 11

3.3. Beacon Type Components ···································································· 12

4. Installation ························································································· 14

4.1. Detachment of Cover ········································································· 14

4.2. Combination & Sounder Type Terminal Configuration ············································ 15

4.2.1. AC Type Terminal Description ··························································· 15

4.2.1. DC Type Terminal Description ··························································· 15

4.3. Beacon Type Terminal Configuration ··························································· 15

4.3.1. AC Type Terminal Description ··························································· 15

4.3.2. DC Type Terminal Description ··························································· 15

5. Operation Method ················································································· 16

5.1. Operation Status Setting ······································································· 16

5.2. External Contact Point Control ································································· 16

5.2.1. Dry Contact Configuration ······························································· 17

5.2.2. Wet Contact Configuration ······························································ 17

GTL-200

Instruction Manual

www.gastron.com

06_07

2. Specication

GTL-200 explosion-proof warning light uses semi-permanent LED light source and has aluminum housing. It is an

explosion-proof product with excellent durability and safety.

With Gastron's unique lens-type lighting system, it has high emission effect of optical signal. Using built-in switches,

sound type, speaker volume, and rotation speed of reflector can be adjusted, thus they can be changed in

accordance to installation condition.

LED has 4 colors; Red, Yellow, Green, and Blue and the max. volume of the speaker is 120 dB. 64 different sound

tones can be selected and external contact is operated by Dry & Wet Contact Method.

3 types of product are available; combination type with speaker and LED combined together, sounder type with

speaker operation only, and beacon type with LED operation only.

GTL-200 explosion-proof warning light has explosion-proof enclosure and is a product that can be used in

combination of stand-alone beacon, speaker, and combination types, etc.

2.2. Mechanical Specifications

ITEMS SPECIFICATION

Explosion-Proof Type Explosion-Proof Enclosure

Cable Inlet 3/4" PF ( 1/2" or 3/4" NPT )

Mounting Holes Ø 7 ±0.1

Size (Dimension) (mm)

Sounder 164(W) * 139(H) * 322(177)(D)

Beacon 164(W) X 278.5(H) X177(D)

Combination 164(W) * 278.5(H) * 322(177)(D)

Weight

Sounder App. 5.0kg

Beacon App. 5.0kg

Combination App. 6.2kg

Body Material Lamp Cover Explosion-Proof Tempered Glass

Body ALDC12

2.3. Electrical Specifications(DC Type)

ITEMS SPECIFICATION

Input Voltage

※ Customer supplied PSU must meet requirements

IEC1010-1 and CE Marking requirements.

Absolute min:

Nominal:

Absolute max:

Ripple maximum allowed:

18V

24V

30V

0.1V pk-pk

Sounder Wattage Max. wattage:

Max. current:

24W @+24 VDC

1A @+24 VDC

Beacon Wattage Max. wattage:

Max. current:

12W @+24 VDC

0.5A @+24 VDC

Combination Wattage Max. wattage:

Max. current:

36W @+24 VDC

1.5A @+24 VDC

EMC Protection: CE

2. Specication

1. Overview

GTL-200

Instruction Manual

2.1. Basic Specifications

ITEMS SPECIFICATION

Display Method LED light source with a rotating reflector

Display Color Option Red, Yellow, Green, Blue

Sound Maximum output Normal 110dB@1meter(1.2KHz)

Max 120dB@1meter(1.2KHz)

Tone Selection 64 user selectable tones

Approvals Classification Ex dⅡC T4~T6

EN 61000-6-2 , EN 61000-6-4

Ingress Protection IP66

Product Type

Sounder

Beacon

Combination

Warranty 2Year

www.gastron.com

08_09

3. Name and Description of Each Part

3.1. Combination Type Components

[Figure 1. Combination Type Configuration]

2. Specication

GTL-200

Instruction Manual

2.4. Electrical Specifications (AC Type)

ITEMS SPECIFICATION

Input Voltage

※ Customer supplied PSU must meet requirements

IEC1010-1 and CE Marking requirements.

Absolute min:

Nominal:

Absolute max:

Ripple maximum allowed:

210V

220V

230V

0.1V pk-pk

Sounder Wattage Max. wattage:

Max. current:

36W @ AC220 VDC

0.11A @ AC220 VDC

Beacon Wattage Max. wattage:

Max. current:

36W @ AC220 VDC

0.06A @ AC220 VDC

Combination Wattage Max. wattage:

Max. current:

36W @ AC220 VDC

0.17A @ AC220 VDC

EMC Protection: CE

2.5. Environmental Specifications

ITEMS SPECIFICATION

Operation Temperature T5 -40 to 70 ℃

T6 -40 to 60 ℃

Storage Temperature -40 to 70 ℃

Operation Humidity 5 to 99% RH (Non-condensing)

No ITEMS SPECIFICATION

1Case Body Protects internal PCB and other parts by body.

2Case cover Protects internal parts by body.

3Case Glass Cover Protects internal glass and other parts by body.

4Explosion Light Glass It is an explosion-proof case made of glass material and disperse light to outside.

5Case Glass Ring Prevents diversion during explosion light glass fastening.

6Gasket Prevents diversion during explosion light glass fastening.

7O-Ring/1 Inhibits inlet of dust, particles, water, gas

8Reflector Diffracts LED light to emit.

9Reflector troll plate Works as rotating plate that rotates reflector.

10 Motor troll plate Works to deliver rotating speed of motor.

11 Motor Works to rotate reflector.

www.gastron.com

10_11

3.1. Combination Type Components

No NAME DESCRIPTIONS

12 Led assy plate(bracket) Fastens LED Assy to the body.

13 lens Lens for light source that emits LED light.

14 Heat sinking plane Heat-proof body that decreases LED temperature and increases lifetime.

15 Bearing washer Washer for bearing that operates rotating plate to decrease friction.

16 Heat sinking plane-Net Net that fastens heat-proof plate to LED assy plate (bracket)

17 Speaker Cover Protects internal Driver unit and other parts by body

18 Flame Arrester ∮25x2 Prevents entrance of debris and delivers buzzer sound to outside.

19 Driver unit Speaker that emits PCB signal sound.

20 Horn set Horn that enhances output of driver unit and prevents water from entering.

21 Cage Protective mesh for explosion light glass

22 Terminal PCB AC/DC Power Supply

23 Main PCB Operates by receiving signal upon an error in LED/speaker/motor

24 Led PCB PCB with LED

No NAME DESCRIPTIONS

1Case Body Protects internal PCB and other parts by body

2Case cover Protects internal parts by body

3O-Ring/1 Inhibits inlet of dust, particles, water, gas

4Speaker Cover Protects internal Driver unit and other parts by body

5Flame Arrester ∮25x2 Prevents entrance of debris and delivers buzzer sound to outside.

6Driver unit Speaker that emits PCB signal sound.

7Horn set Horn that enhances output of driver unit and prevents water from entering.

8Terminal pcb AC/DC Power Supply

9Main pcb Operates by receiving signal upon an error in LED/speaker/motor

10 Name plate lavel Label for Authentication

[Table 1. Combination Type Configuration Description]

GTL-200

Instruction Manual

3.2. Sounder Type Configuration

[Figure 2. Sounder Type Configuration]

[Table 2. Sounder Type Configuration Description]

3. Name and Description of Each Part3. Name and Description of Each Part

www.gastron.com

12_13

GTL-200

Instruction Manual

[Table 4. Beacon Type Configuration Description]

No NAME DESCRIPTIONS

1Case Body Protects internal PCB and other parts by body

2Case cover Protects internal parts by body

3Case Glass Cover Protects internal Glass and other parts by body

4Explosion Light Glass It is an explosion-proof case made of glass material and disperse light to outside.

5Case Glass Ring Prevents diversion during explosion light glass fastening.

6Gasket Prevents diversion during explosion light glass fastening.

7O-Ring/1 Inhibits inlet of dust, particles, water, gas

8Reflector Diffracts LED light to emit.

9Reflector troll plate Works as rotating plate that rotates reflector.

10 Motor troll plate Works to deliver rotating speed of motor.

11 Motor Works to rotate reflector.

12 Led assy plate(bracket) Fastens LED Assy to the body.

13 lens Lens for light source that emits LED light.

14 Heat sinking plane Heat-proof body that decreases LED temperature and increases lifetime.

15 Bearing washer Washer for bearing that operates rotating plate to decrease friction.

16 Heat sinking plane-Net Net that fastens heat-proof plate to LED assy plate (bracket)

17 Cage Protective mesh for Explosion Light Glass

18 Terminal pcb AC/DC Power Supply

19 Main pcb Operates by receiving signal upon an error in LED/Speaker/Motor

20 Led pcb set PCB with LED

3.3. Beacon Type Components

[Table 3. Beacon Type Configuration]

3. Name and Description of Each Part3. Name and Description of Each Part

www.gastron.com

14_15

4. Install4. Install

GTL-200

Instruction Manual

■

It is prohibited for an individual, other than an approved user or a technician responsible for installation and repair

from the head office, to install an explosion-proof warning light on site or open the cover of the installed warning

light and manipulate it. This may cause serious loss of life and property from fire, explosion, and etc.

■ In addition, please check whether there is any remaining explosive gas or combustible material in the

surroundings. Power must be turned off before performing work.

4.1. Detachment of Cover

■ Turn the slotted set screw (M4) fixing the cover part of main body 3~4 turns counter clockwise (ccw) using a hex

wrench (M2) then turn the cover of gas leak detector ccw to detach the cover.

■ When the bottom cover is detached, terminal board for external wiring appears. Perform cable wiring as shown

in the terminal configuration below.

[Figure 3. Slotted Set Screw Configuration]

No PCB SILK DESCRIPTION NOTE

1L1 AC Power (Live)

2L2 AC Power (Natural)

3S1 External Signal Line 1

Operates upon connecting "COM" terminal to

a desired signal line.

(Only supports Dry Contact Operation)

4S2 External Signal Line 2

5S3 External Signal Line 3

6COM Digital Ground

4.2.1. AC Type Terminal Description

4.2. Combination & Sounder Type Terminal Configuration

No PCB SILK DESCRIPTION NOTE

1 + DC + Power

2 - DC - Power

3S1 External Signal Line 1 For Dry Contact Operation, connect to "DC -"

power to run. For Wet Contact Operation, run

"S1~S3" and "DC-"

4S2 External Signal Line 2

5S3 External Signal Line 3

4.2.2. DC Type Terminal Description

4.3. Beacon Type Terminal Configuration

4.3.1. AC Type Terminal Description

No. PCB SILK DESCRIPTION

1L1 AC Power (Live)

2L1

3L2 AC Power (Natural)

4L2

4.3.2. DC Type Terminal Description

No. PCB SILK DESCRIPTION

1 + DC + Power

2 + DC + Power

3 - DC - Power

4 - DC - Power

5.1. Operation Status Setting

■ By using #1 to #6 internal dip switch, operating tone can be selected. For types of tone, refer to the tone table in

Appendix A.

■ By using #7 to #8 internal dip switch, operating mode can be changed.

5.2.1. Dry Contact Configuration

■ Using COM terminal, control contact status of S1~S3.

www.gastron.com

16_17

GTL-200

Instruction Manual

[Figure 4. Dry Contact Configuration]

5.2.2. Wet Contact Configuration

■ Using DC+ power, select S1~S3 signal.

[Figure 5. Wet Contact Configuration]

5.2. External Contact Point Control

■ In order to select product operation and output tone, internal contact points (S1~S3) of warning light must be

controlled.

■ By using applicable contact point, it can control operation status and tone output. Refer to the operation status

setting table above for control mode.

■ For configuration of S1~S3 for tone output, refer to Method for Setting Tone in Appendix B.

■ Contact point control configuration can be set in Dry Contact and Wet Contact. Operation configuration

depending on Contact Type is set to internal Jumper configuration and related items are as follows.

■ For Mode 1, perform basic warning light configuration.

■

For Mode 2, it is used when power is inputted regularly and when it is controlled only using external contact points.

■ For Mode 3, it is a mode to manually stop tone output and used during setting.

[Table 5. Operation Description]

Mode Dip Switch Setting Power On Input External Contact Point

(S1, S2, S3)

#7 #8

Mode1 OFF OFF Beacon operation and

set tone output N/A

Mode2 OFF ON No Operation Beacon operation and

set tone operation

Mode3 ON OFF Beacon Operation Set tone Operation

5. Operation Method5. Operation Method

www.gastron.com

18_19

GTL-200

Instruction Manual

6.1. Combination Type 6.2. Sounder Type

[Figure 6. Combination Type Drawing] [Figure 7. Sounder Type Drawing]

6. Drawings and Dimensions6. Drawings and Dimensions

www.gastron.com

20_21

GTL-200

Instruction Manual

■ Avoid areas with electrical barriers such as rain water, etc. It is recommended to be installed in areas that are

easier to work in since regular maintenance is needed. Avoid areas with vibration or shock since they can affect

output values.

■

This equipment has explosion-proof construction for internal pressure and belongs to GROUP II for gas and vapor

in general work sites and chemical plants. It can be used in ZONE 1 (ONE) and ZONE 2 (TWO) hazardous sites.

■ Allowable temperature is 85 C or below, which corresponds to T6.

■ Surrounding temperature is in a range of -40 °C ~ 70 °C.

■ Relative Humidity: 5% ~ 99%

■ Installation Site: Indoor and Outdoor

■ Explosion Ignition Grade for the Gas or Vapor: Ex d IIC T6

■

During wiring work, use explosion-proof cable gland at cable inlet or tightly seal cable conduit during metal cable

wiring construction to prevent spread of flames in case of explosion or movement of gas, etc. through the cable

conduit within 50 mm.

■ When connecting the equipment with cable, screw thread must be tightened 5 threads or more.

■

Work in conditions satisfying other [Standards for Selection, Installation, and Maintenance, etc. of Explosion-proof

Electric Machine and Equipment Wiring, etc. at Work Site]

■ All materials used for cable inlet such as cable gland and sealing fitting, etc. and used as sealing unused inlets

must pass the verification!

6.3. Beacon Type

[Figure 8. Beacon Type Drawing]

7. Precautions before Installation6. Drawings and Dimensions

[Figure 9. High-Pressure Packing Type] [Figure 10. Y Sealing Compound]

Cable Cable

Inside Inside

Outside Outside

Lead-in unit connector

Lead-in unit connector

Charging compound

Cable-fixing device

Pipe for piping

Cable-fixing device

Sealing ring

Sealing

ring

Connector

Pipe for piping

Compressed

element

Connector for fixing

compressed element

www.gastron.com

22_23

GTL-200

Instruction Manual

Appendix A. Tone Table

■ Operating tones consist of 64 different types and is according to the table below.

TONE OUTPUT SIGNAL 신호 형태

Tone1 300Hz Continues

Tone2 340Hz Continues

Tone3 440Hz Continues

Tone4 554Hz Continues

Tone5 660Hz Continues

Tone6 800Hz Continues

Tone7 1000Hz Continues

Tone8 1200Hz Continues

Tone9 2000Hz Continues

Tone10 2400Hz Continues

Tone11 2850Hz Continues

Tone12 420Hz at 625msec on/off

Tone13 544Hz at 875msec on/off

Tone14 660Hz at 150msec on/off

Tone15 660Hz at 1800msec on/off

Tone16 745Hz at 500msec on/off

Tone17 800Hz at 250msec on/off

Tone18 800Hz at 250msec on / 1000msec off

Tone19 1000Hz at 250msec on/off

Tone20 1000Hz at 500msec on/off

Tone21 1000Hz at 250msec on / 1000msec off

Tone22 1000Hz at 1000msec on/off

Tone23 2400Hz at 250msec on/off

Tone24 2400Hz at 500msec on/off

Tone25 2850Hz at 1000msec on/off

Tone26 2850Hz at 150msec on / 100msec off

Tone27 700Hz at 2000msec on/off

Tone28 700Hz at 125msec on/off

Tone29 720Hz at 700msec on/ 300msec off

Tone30 970Hz at 500msec on/off, 1500msec off

Tone31 2850Hz at 500msec on/off, 1500msec off

TONE OUTPUT SIGNAL 신호 형태

Tone32 Reserved

Tone33 Reserved

Tone34 544Hz / 440Hz at 1000msec

Tone35 800Hz / 1000Hz at 125msec

Tone36 2400Hz / 2900Hz at 125msec

Tone37 800Hz / 1000Hz at 250msec

Tone38 800Hz / 1000Hz at 500msec

Tone39 1000Hz / 2000Hz at 500msec

Tone40 2400Hz / 2900Hz at 250msec

Tone41 500Hz - 1000Hz at 6Hz

Tone42 500Hz - 1200Hz at 0.3Hz

Tone43 660Hz - 1200Hz at 1Hz

Tone44 800Hz - 1000Hz at 1Hz

Tone45 800Hz - 1000Hz at 7Hz

Tone46 2400Hz - 2900Hz at 1Hz

Tone47 2400Hz - 2900Hz at 7Hz

Tone48 800Hz - 1000Hz at 50Hz

Tone49 2400Hz - 2900Hz at 50Hz

Tone50 1200Hz - 500Hz at 1Hz

Tone51 1400Hz - 1600Hz at 1000msec up / 500msec down

Tone52 500Hz - 1200Hz at 2500msec up, 500msec off

Tone53 500Hz - 1200Hz at 5000msec up, 250msec off

Tone54 800Hz / 660Hz at 1500msec off

Tone55 800Hz / 1000Hz at 180msec off

Tone56 250Hz - 1200Hz at 3sec up, 6sec, 3sec down

Tone57 250Hz - 800Hz at 3sec up, 6sec, 3sec down

Tone58 250Hz - 2400Hz at 6sec up, 6sec, 6sec down

Tone59 Simulated Bell

Tone60 wave-1

Tone61 wave-2

Tone62 wave-3

Tone63 wave-4

Tone64 wave-5

7. Precautions before Installation7. Precautions during Installation

www.gastron.com

24_25

GTL-200

Instruction Manual

Appendix B Method to Set Tone

■ To set output tone, when #7 and #8 of dip switches are turned OFF, it is outputted by setting from #1~6 of dip

switches after turning power ON, regardless of operation status of external contact points (S1~S3).

■ When #8 of dip switch is turned on, the output tone is decided by combination of #1~6 setting of dip switch and

external contact point (S1~S3) as shown in the table below.

No. DIP Switch

DIP S/W

#7,8 OFF DIP S/W #8 ON

Stage1 Stage2 Stage 3 Stage 4 Stage 5 Stage 6 Stage 7 Stage 8

1 2 3 4 5 6 S1 S2 S1+S2 S3 S1+S3 S2+S3 S1+S2+S3

1Tone1 Tone1 Tone10 Tone45 Tone22 Tone 60 Tone 61 Tone 5

2Tone2 Tone2 Tone10 Tone45 Tone22 Tone 60 Tone 61 Tone 5

3Tone3 Tone3 Tone10 Tone25 Tone39 Tone 60 Tone 61 Tone 5

4Tone4 Tone4 Tone10 Tone45 Tone22 Tone 60 Tone 61 Tone 5

5Tone5 Tone5 Tone10 Tone39 Tone45 Tone 60 Tone 62 Tone 6

6Tone6 Tone6 Tone10 Tone39 Tone45 Tone 60 Tone 62 Tone 5

7Tone7 Tone7 Tone22 Tone9 Tone45 Tone 60 Tone 62 Tone 5

8Tone8 Tone8 Tone22 Tone10 Tone45 Tone 60 Tone 62 Tone 5

9Tone9 Tone9 Tone22 Tone7 Tone39 Tone 60 Tone 63 Tone 5

10 Tone10 Tone10 Tone5 Tone45 Tone22 Tone 60 Tone 63 Tone 6

11 Tone11 Tone11 Tone5 Tone45 Tone22 Tone 60 Tone 63 Tone 6

12 Tone12 Tone12 Tone10 Tone39 Tone45 Tone 60 Tone 63 Tone 5

13 Tone13 Tone13 Tone4 Tone9 Tone45 Tone 61 Tone 62 Tone 5

14 Tone14 Tone14 Tone10 Tone45 Tone22 Tone 61 Tone 62 Tone 5

15 Tone15 Tone15 Tone10 Tone22 Tone39 Tone 61 Tone 62 Tone 5

16 Tone16 Tone16 Tone10 Tone22 Tone39 Tone 61 Tone 62 Tone 5

17 Tone17 Tone17 Tone10 Tone45 Tone35 Tone 62 Tone 63 Tone 5

18 Tone18 Tone18 Tone10 Tone22 Tone45 Tone 62 Tone 63 Tone 5

19 Tone19 Tone19 Tone10 Tone22 Tone45 Tone 62 Tone 63 Tone 5

20 Tone20 Tone20 Tone10 Tone22 Tone45 Tone 62 Tone 63 Tone 5

21 Tone21 Tone21 Tone10 Tone45 Tone22 Tone 63 Tone 64 Tone 5

22 Tone22 Tone22 Tone10 Tone45 Tone39 Tone 63 Tone 64 Tone 5

23 Tone23 Tone23 Tone5 Tone45 Tone22 Tone 63 Tone 64 Tone 6

24 Tone24 Tone24 Tone5 Tone45 Tone38 Tone 63 Tone 64 Tone 6

25 Tone25 Tone25 Tone5 Tone45 Tone38 Tone 64 Tone 60 Tone 6

26 Tone26 Tone26 Tone5 Tone45 Tone38 Tone 64 Tone 60 Tone 6

27 Tone27 Tone27 Tone10 Tone22 Tone45 Tone 64 Tone 60 Tone 5

No. DIP Switch

DIP S/W

#7,8 OFF DIP S/W #8 ON

Stage1 Stage2 Stage 3 Stage 4 Stage 5 Stage 6 Stage 7 Stage 8

1 2 3 4 5 6 S1 S2 S1+S2 S3 S1+S3 S2+S3 S1+S2+S3

28 Tone28 Tone28 Tone10 Tone22 Tone45 Tone 64 Tone 60 Tone 5

29 Tone29 Tone29 Tone10 Tone22 Tone45 Tone 61 Tone 63 Tone 5

30 Tone30 Tone30 Tone10 Tone 22 Tone 45 Tone 61 Tone 63 Tone 5

31 Tone31 Tone31 Tone5 Tone 45 Tone 22 Tone 61 Tone 63 Tone 6

32 Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

33 Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

34 Tone 34 Tone 34 Tone 4 Tone 45 Tone 22 Tone 61 Tone 64 Tone 5

35 Tone 35 Tone 35 Tone 10 Tone 22 Tone 45 Tone 61 Tone 64 Tone 5

36 Tone 36 Tone 36 Tone 10 Tone 22 Tone 45 Tone 61 Tone 64 Tone 5

37 Tone 37 Tone 37 Tone 10 Tone 22 Tone 45 Tone 62 Tone 64 Tone 5

38 Tone 38 Tone 38 Tone 10 Tone 22 Tone 45 Tone 62 Tone 64 Tone 5

39 Tone 39 Tone 39 Tone 22 Tone 7 Tone 45 Tone 62 Tone 64 Tone 5

40 Tone 40 Tone 40 Tone 10 Tone 22 Tone 39 Tone 62 Tone 64 Tone 5

41 Tone 41 Tone 41 Tone 10 Tone 45 Tone 39 Tone 64 Tone 61 Tone 5

42 Tone 42 Tone 42 Tone 10 Tone 45 Tone 39 Tone 64 Tone 61 Tone 5

43 Tone 43 Tone 43 Tone 10 Tone 45 Tone 22 Tone 64 Tone 61 Tone 5

44 Tone 44 Tone 44 Tone 10 Tone 45 Tone 22 Tone 64 Tone 61 Tone 5

45 Tone 45 Tone 45 Tone 10 Tone 22 Tone 39 Tone 64 Tone 63 Tone 5

46 Tone 46 Tone 46 Tone 10 Tone 22 Tone 45 Tone 64 Tone 63 Tone 5

47 Tone 47 Tone 47 Tone 10 Tone 22 Tone 45 Tone 64 Tone 63 Tone 5

48 Tone 48 Tone 48 Tone 10 Tone 39 Tone 45 Tone 64 Tone 63 Tone 5

49 Tone 49 Tone 49 Tone 10 Tone 22 Tone 39 Tone 64 Tone 62 Tone 5

50 Tone 50 Tone 50 Tone 35 Tone 9 Tone 22 Tone 64 Tone 62 Tone 5

51 Tone 51 Tone 51 Tone 10 Tone 45 Tone 22 Tone 64 Tone 62 Tone 5

52 Tone 52 Tone 52 Tone 10 Tone 45 Tone 22 Tone 64 Tone 62 Tone 5

53 Tone 53 Tone 53 Tone 10 Tone 45 Tone 22 Tone 60 Tone 64 Tone 5

54 Tone 54 Tone 54 Tone 6 Tone 22 Tone 39 Tone 60 Tone 64 Tone 5

55 Tone 55 Tone 55 Tone 6 Tone 22 Tone 45 Tone 60 Tone 64 Tone 5

56 Tone 56 Tone 56 Tone 10 Tone 45 Tone 39 Tone 60 Tone 64 Tone 5

57 Tone 57 Tone 57 Tone 10 Tone 45 Tone 22 Tone 62 Tone 60 Tone 5

58 Tone 58 Tone 58 Tone 10 Tone 39 Tone 22 Tone 62 Tone 60 Tone 5

59 Tone 59 Tone 59 Tone 6 Tone 39 Tone 22 Tone 62 Tone 60 Tone 5

60 Tone 60 Tone 60 Tone 10 Tone 45 Tone 22 Tone 61 Tone 62 Tone 5

61 Tone 61 Tone 61 Tone 10 Tone 45 Tone 22 Tone 60 Tone 62 Tone 5

62 Tone 62 Tone 62 Tone 10 Tone 45 Tone 22 Tone 60 Tone 61 Tone 5

63 Tone 63 Tone 63 Tone 5 Tone 22 Tone 39 Tone 61 Tone 62 Tone 6

64 Tone 64 Tone 64 Tone 5 Tone 22 Tone 39 Tone 62 Tone 63 Tone 6

7. Precautions before Installation7. Precautions during Installation

www.gastron.com

26_27

GTL-200

Instruction Manual

Version Contents Date

0.0 * Manual Initial Revision 2013. 03. 14

1.0 * Changed Tone Selection Method and External Contact Point Function 2013. 09. 19

2.0 * Added Tone Table and Contents for Each Product Type 2014. 01. 20

3.0 * Added Case body mount hole size 2014. 04. 04

4.0 * Corrected tone table 2014. 05.04

5.0 * Changed Sound Bracket

* Manual Version Modify 2013. 01. 28

5.1 * Added Dip Switch Function Stetting 2016. 06. 16

6.0 * Changed Font 2016. 11. 09

7.0 * Changed Explosion-proof Equipment Cable Entry Installation Regulation 45 cm → 50 mm 2017. 01. 20

8. Revision History

Table of contents

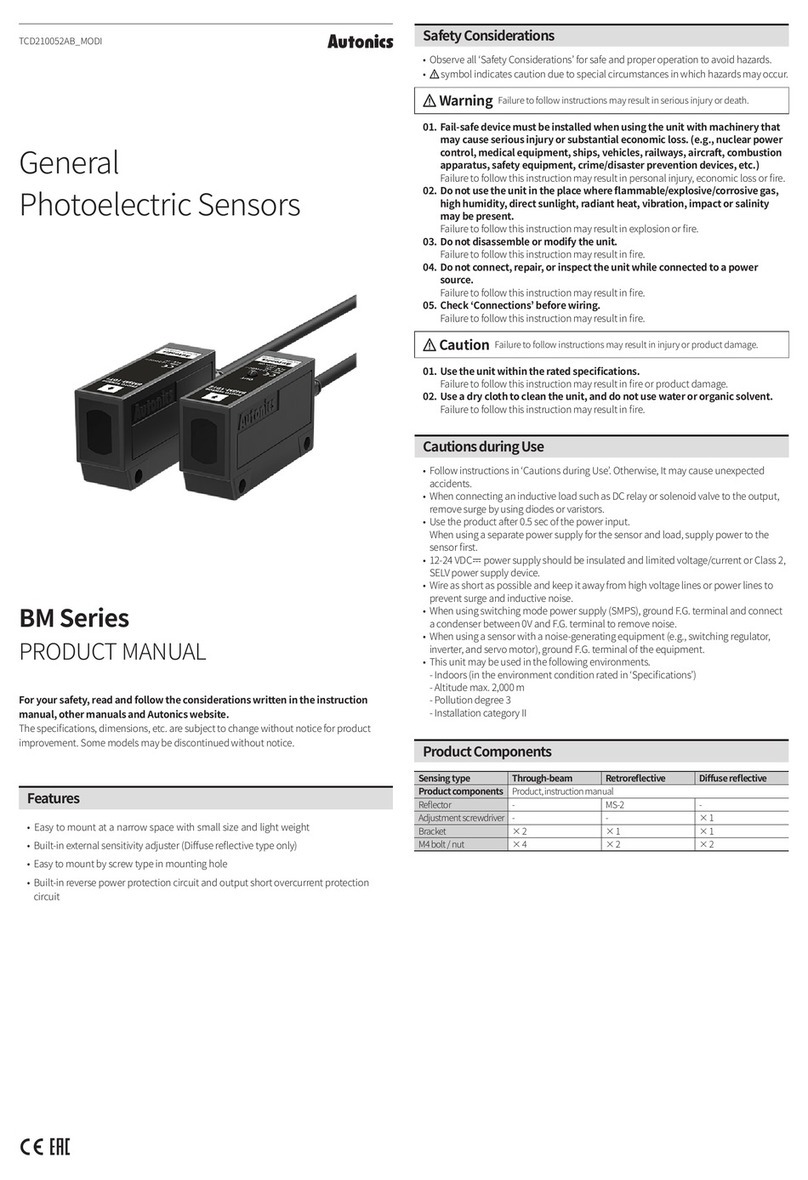

Other GASTRON Security Sensor manuals

Popular Security Sensor manuals by other brands

Meec tools

Meec tools 405-042 operating instructions

Velleman

Velleman HAA51 manual

Crown

Crown SWAN CAM installation instructions

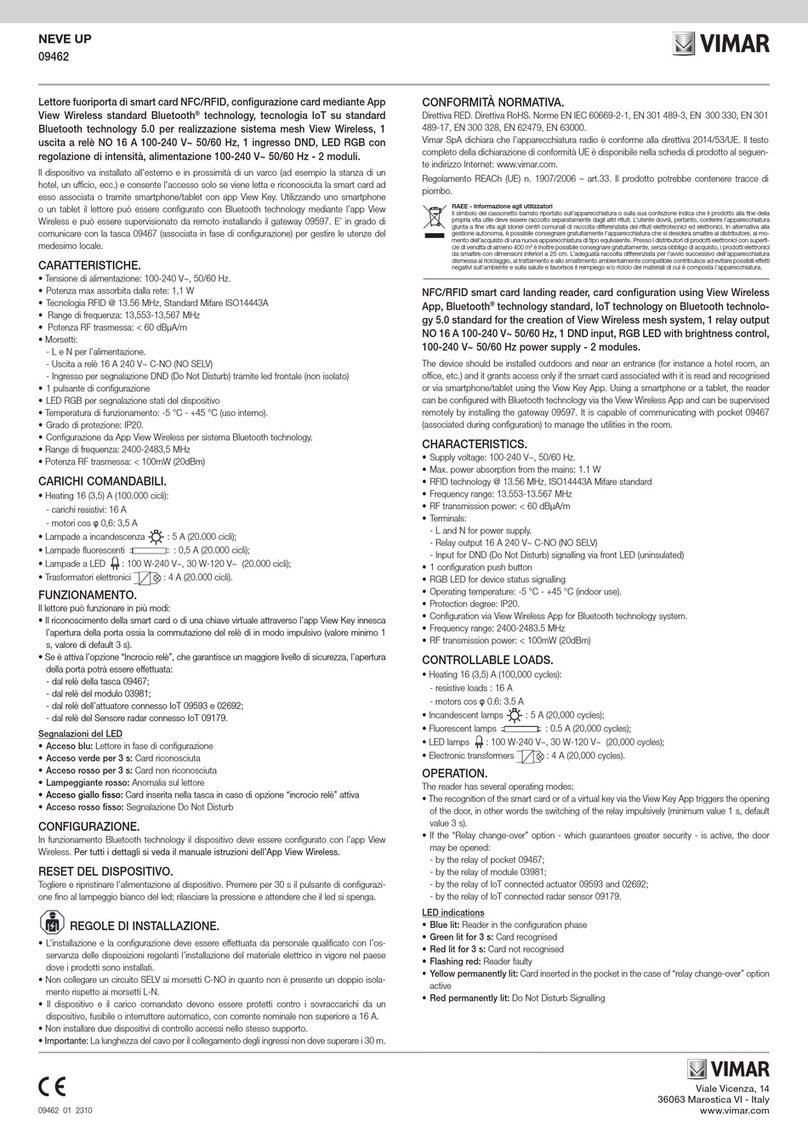

Vimar

Vimar NEVE UP 09462 manual

TRIGA

TRIGA TR-B300-6 Installation and maintenance instructions

Nortek Security & Control

Nortek Security & Control 2GIG e Series quick start guide

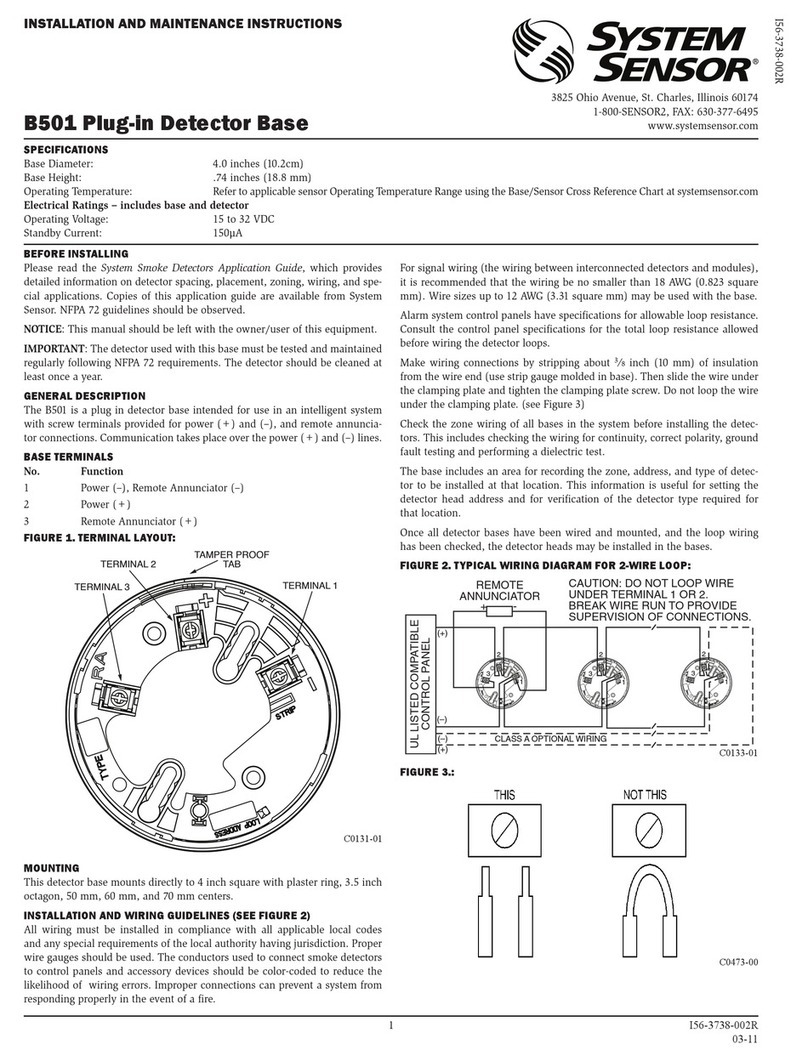

System Sensor

System Sensor B224RB Installation and maintenance instructions

ESYLUX

ESYLUX PD-C180i KNX ECO operating instructions

Level Waters

Level Waters EasyFill X MSX-3420 user manual

McGan

McGan MicroMed PD-8K Quick operation guide

ThermoFisher Scientific

ThermoFisher Scientific Vanquish VC-D11 operating manual

Cerberus

Cerberus DL500 installation manual