Gates Radio Company BC-250GY-1 User manual

MODULATION TRANSFORMER INSTRUCTIONS

Please read these instructions before attempting to test

the modulation transformer in this transmitter.

The modulation transformer employed in this transmitter

may be of a type which will indicate unequal resistance

in the primary windings. An ohmmeter check of the wind-

ings may indicate that the transformer is defective;

whereas in reality, this is a normal reading and the

modulation transformer is performing normally.

In order to properly check this transformer outside of

the transmitter circuit, merely apply 117 volts, 60 cycle

a.c. to the secondary winding. Check the voltage on each

half of the primary winding. If the transformer is oper-

ating normally, then these voltages should be asproximately

equal.

Gates Radio Company

Quincy, Illinois

www.americanradiohistory.com

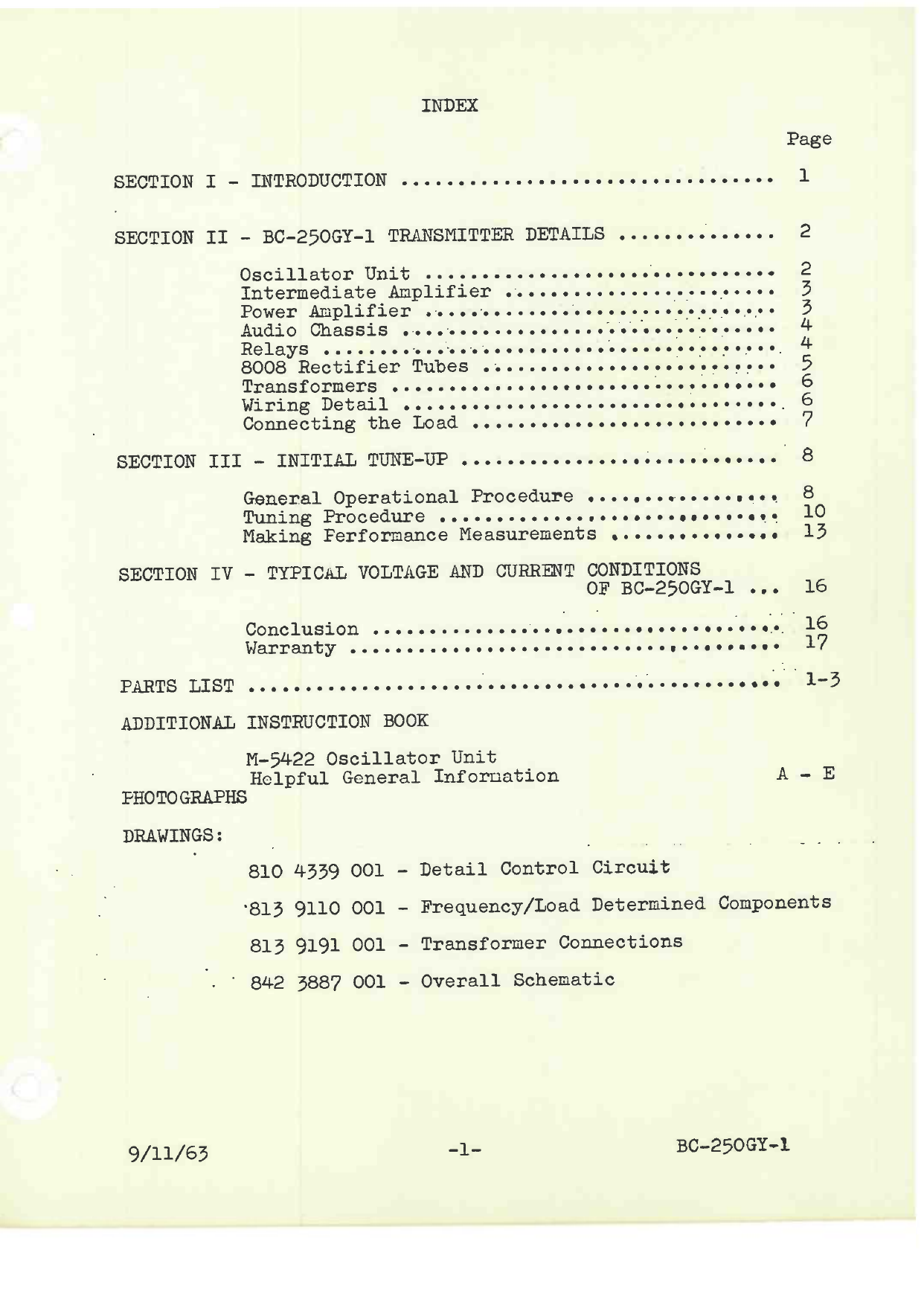

INDEX

Page

SECTION I - INTRODUCTION 1

SECTION II - BC-250GY-1 TRANSMITTER DETAILS 2

Oscillator Unit 2

Intermediate Amplifier 3

Power Amplifier 3

Audio Chassis 4

Relays 4

8008 Rectifier Tubes 5

Transformers 6

Wiring Detail 6

Connecting the Load 7

SECTION III - INITIAL TUNE-UP 8

General Operational Procedure 8

Tuning Procedure 10

Making Performance Measurements e 13

SECTION IV - TYPICAL VOLTAGE AND CURRENT CONDITIONS

OF BC-250GY-1 16

Conclusion 16

Warranty 17

PARTS LIST 1 -3

ADDITIONAL INSTRUCTION BOOK

M-5422 Oscillator Unit

Helpful General Information A - E

PHOTOGRAPHS

DRAWINGS:

810 4339 001 - Detail Control Circuit

.813 9110 001 - Frequency/Load Determined Components

813 9191 001 - Transformer Connections

842 3887 001 - Overall Schematic

9/11/63 -1- BC-250GY-1

www.americanradiohistory.com

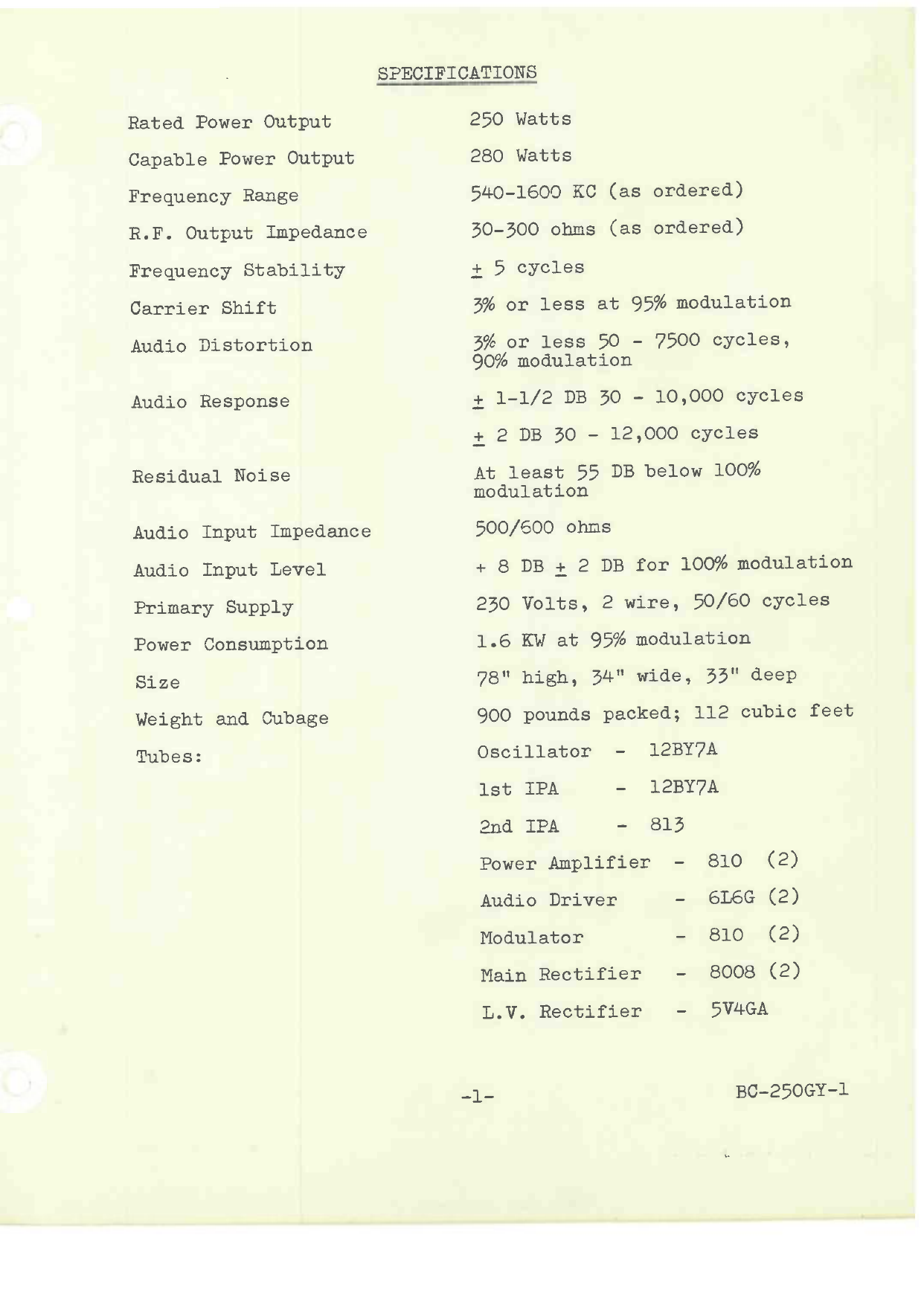

Rated Power Output

Capable Power Output

Frequency Range

R.F. Output Impedance

Frequency StTbility

Carrier Shift

Audio Distortion

Audio Response

Residual Noise

Audio Input Impedance

Audio Input Level

Primary Supply

Power Consumption

Size

Weight and Cubage

Tubes:

SPECIFICATIONS

250 Watts

280 Watts

540-1600 KC (as ordered)

30-300 ohms (as ordered)

+ 5 cycles

3% or less at 95% modulation

3% or less 50 - 7500 cycles,

90% modulation

+ 1-1/2 DB 30 - 10,000 cycles

+ 2 DB 30 - 12,000 cycles

At least 55 DB below 100%

modulation

500/600 ohms

+ 8 DB + 2 DB for 100% modulation

230 Volts, 2 wire, 50/60 cycles

1.6 KW at 95% modulation

high, 34" wide, 33" deep

78

900 pounds packed; 112 cubic feet

Oscillator - 12BY7A

1st IPA - 12BY7A

2nd IPA - 813

Power Amplifier - 810 (2)

Audio Driver

Modulator

Main Rectifier

L.V. Rectifier

-1-

6L6G (2)

810 (2)

8008 (2)

5V4GA

BC-250GY-1

www.americanradiohistory.com

SECTION

INTRODUCTION

The Gates BC-250GY Transmitter is a modern high fidelity

transmitter having every modern feature demanded by the modern

radio broadcasting station. When properly installed and main-

tained it will give years of trouble -free service.

The F.C.C. rated power of the BC-250GY transmitter is 250 watts

and is officially approved on the records of F.C.C. as a Gates

Radio Company Model BC-250GY Transmitter for amplitude modulation.

The radio frequency range of the BC-250GY transmitter is from

540 to 1600 KC. In each case specific frequency determining

components are supplied for operation of the transmitter on the

frequency specified when ordering. In certain rare situations

of critical antenna loading, the calculated frequency determining

components could be in error, making resonance and/or loading of

one or more circuits not complete. In such cases advise the

factory immediately.

The radio frequency output can be

load from 30 to 300 ohms, but can

components. It is also essential that

load impedance be specified. If this load impedance

active, such as with a direct fed tower,

will be required.

The radio transmitter unit is only one part of the station install-

ation. Each station has its own individual requirements dependent

on the plan of operation, location, etc. The Consulting Engineer

usually plans the transmitter and antenna system. At times, ad-

ditional special equipment will be desired. For this, consult

with the Gates Sales Engineering Staff, either the field repre-

sentative or at the factory office.

arranged to match a resistive

not do so with a single set of

in placing the order,

also is re-

compensating components

the

-1- BC-250GY-1

www.americanradiohistory.com

SECTION II

BC-250GY -1 TRANSMITTER DET^AILS

The following information on the BC-250GY transmitter pertains

to the general construction and operational detail surrounding

the transmitter itself. As in all modern transmitting equipment

it is best to look at the transmitter in its various sections

as pertaining to overall performance detail.

Oscillator Unit

The oscillator unit is located on the inside left of the cabinet,

facing the back, directly below the 813 intermediate amplifier

stage. This is the standard Gates M-5422 Oscillator Unit, using

vacuum crystals. It can be readily removed by loosening the four

mounting screws, and unplugging the connecting cable.

The operation of the M-5422 oscillator unit is explained in detail

in a separate section of this instruction book. The filament and

plate supply are obtained from a power supply on the audio driver

chassis; a part of this supply also is used for the modulator bias

voltage. A voltage divider delivers approximately 150 volts to

the M-5422 oscillator unit, and with this voltage the unit delivers

ample power to drive the following 813 stage.

The 813 stage is equipped with a grid current meter M8, mounted

on the 813 chassis. The M-5422 oscillator unit, which is oper-

ating when the filaments are on, can be tuned according to in-

structions for the maximum grid current reading on the meter M8.

This will be approximately 8 - 10 milliamperes without voltage on

the plate of the 813. The vacuum crystals have zero temperature

characteristics, and are operable on frequency as soon as the

tubes heat to normal emission. Any delay in setting the fre-

quency will be due to the requirements of the frequency monitor

having to reach a stable heat level. There are no gaps to set.

The crystals are normally received from the supplier after having

been calibrated in a M-5422 oscillator unit, and before shipment

are retested in the M-5422 oscillator unit supplied with the

transmitter. It can be anticipated that the frequency will be

within a very few cycles of the specified frequency, within the

range of adjustment of the frequency trimmer condensers.

9/11/63 -2- BC-250GY-1

www.americanradiohistory.com

Intermediate Amplifier

The 813 intermediate amplifier is located directly above the

oscillator unit (tube V6) and has its associated coil and tuning

condenser directly adjacent. The intermediate amplifier tank

coil is center tapped to ground with neutralization of the final

power amplifier to the opposite end from that of the grid drive

end. The screen voltage is obtained through two voltage dividing

resistors which are normally set at the factory to obtain approx-

imately 350 volts on the screen, allowing a margin for high line

voltage and furnishing ample drive for the power amplifier. The

plate current of the intermediate amplifier is indicated on meter

M6. The intermediate amplifier tunes to resonance by capacitor

C24, in the 813 tank circuit and is tuned to minimum plate cur-

rent.

On the plate coil L7, the taps (when used) should always be on

the same relative tap from the center tap. As much coil and as

low value of capacity to tune should be used, except to a point

of extremely low capacity which will tend to result in arcing

in the condenser.

In case of changing frequency to a new frequency from that pre-

viously supplied when manufactured, the following information

will be valuable. The tuning ranges will be as follows:

For 1200 KC to 1600 KC use 15 turns on each side of center tap

(first tap from center tap). The second tap from center (21

turns) will provide a tuning range from 1500 KC to 950 KC. The

full coil provides tuning from 720 KC to 1100 KC. Tuning from

650 KC to 720 KC requires the addition of a 200 mmfd. padding

condenser (C41), and from 550 KC to 650 KC, a 400 mmfd. padder.

Power Amplifier

The power amplifier consists of two 810 tubes operating in par-

allel. The load is connected through a low pass filter to the

inductive branch of the tank circuit, a system which minimizes

harmonic radiation. The final amplifier is resonated by means

of capacitor C33, and brought to exact frequency by the variable

capacitor C32. The value of C33 is determined by the carrier

frequency and is usually properly provided at time of shipment.

9/11/63 -3- BC-250GY-1

www.americanradiohistory.com

In some instances of unusual loading conditions, particularly

very low impedance antennas, the value of tank padding conden-

ser C33, may be affected as applied to normal charts and if the

amplifier will not resonate with the load applied, it would be

the antenna and would only be in case of direct coupling, infor-

mation as to the antenna or loading characteristics should be

immediately supplied to the factory.

Audio Chassis

The audio chassis is the hinged chassis on the right hand of the

cabinet facing the rear and accommodates the push-pull 6L6G (1622)

Class A audio driver, the push-pull Class B 810 modulator tubes

on the top of the chassis and also accommodates the combination

oscillator-bias supply and its associates 5Ú4G tube and the

vacuum type time delay relay E6. The output of the 810 modulator

tubes terminates to modulation transformer T3, located in the

bottom of the cabinet. The plate voltage to the 6L6G tubes is

approximately 375 volts. The modulator tubes operate at the full

plate voltage of the main power supply.

For under- chassis servicing of the audio deck, it is only neces-

sary to remove the knurled thumb screws and this chassis hinges

back revealing all under-chassis wiring and components for fast

servicing where required. It should be noted that the oscillator

bias power supply is so constructed that 60 volts is taken from

the negative side of this supply to provide bias voltage for the

modulators, which is individually adjustable by bias resistors

R4 and R5.

Relays

The thermal operating filament time delay relay is mounted on the

audio chassis; the control element being connected across the

filaments of the 6L6G tubes. In case of breakage of the time

delay relay by accident or failure, to resume operation

a temporary expedient can be had by removing the time delay tube

from the audio chassis and placing a jumper between terminals

67 and 68. In this way there is no time delay action and the

overloads may trip from a cold start. This is usually due to

the bias voltage not having obtained full value. By waiting a

few seconds after the initial start no trouble will be encountered

Using the transmitter without the time delay tube, of course, is

not recommended and the above is mentioned only for servicing and

emergency procedure.

(4/11/63 -4- BC-250GY-1

www.americanradiohistory.com

oduïator and sower ampliiier stages have overload relays in

the filament return circuits. These are normally open. When

the current becomes sufficient, the contacts close, completing

the circuit through an auxiliary relay with normally closed

contacts in series with the high voltage contactor coil. Under

normal operation, modulation may provide sufficient current to

cause the overload armature to pull open. If normally closed

contacts were used to operate directly in series with the plate

contactor coil, these modulation cycles would cause the contactor

to chatter, or possibly drop out, although no overload actually

occurs. Both overload relay coils are shunted by adjustable

resistors for setting the overload current point. The normal

unshunted operating current is 300 MA and shunting with resistors

gives a higher current rating. Increasing the amount that is

shorted out on the resistors R27 and R28, raises the current

required to trip the respective relay. The relays should trip

at about 400 milliamperes, heavy enough that the power amplifier

overload does not trip with normal tuning and the modulator over-

load does not trip with normal program. In the case of the mod-

ulators, the resistors also load the inductance of the coil, pre-

venting distortion through this element.

8008 Rectifier Tubes

The 8008 mercury vapor rectifier tubes are sensitive to temper-

ature. If the temperature is too high or too low, this type of

tube has a tendency to "arc-back" or conduct current in the re-

verse direction, resulting in a high voltage short circuit. When

the transmitter is operated where temperature is a problem, such

as-unattended and in a unheated building, or where the temperature

may become excessive, the mercury vapor rectifier tubes may be

directly replaced by a type using xenon or some other inert gas

and which is not nearly so sensitive to temperature, or with

minor modifications by semi-conductor rectifiers.

Another solution is to install a heating element inside the

transmitter cabinet with a thermostat control such as used for

furnaces, adjusted so that when the temperature drops below a

certain value such as 75 degrees, the heating element will be

energized. Similarly, if high temperature is a problem, an ex-

haust fan could be installed in the top of the transmitter, with

the thermostat operating when the temperature reached a value of

around 95 degrees. Operation of this equipment with mercury rec-

tifiers is NOT recommended above 120°F or below 45 °F ambient.

Q /11 /Fiji -5- Re-25flGY-1

www.americanradiohistory.com

Transformers

Several of the transformers are provided with voltage change

terminals. With these transformers, one side of the incoming

a.c. line always connects to terminal #1. The other side con-

nects to terminal #3 for normal voltage output on the secondary

at the specified load. The secondary voltage may be raised by

connecting to terminal #2 instead of terminal #3, or lowered

by connecting the line to terminal ##4 instead of connecting to

terminal #3. Transformer diagrams are included elsewhere in

this operating manual.

Wiring Detail

The power line connections are made directly to the fuse block A7.

Most wiring regulations require a service switch with fuses. The

local regulations should be checked so that the initial install-

ation will meet all requirements. The maximum normal transmitter

load current is 8.5 amperes. The wire size should be #8 or #10.

This transmitter requires 230 volts a.c. single phase power

source. It will not operate on a 208 volt power source without

modification, but is designed to operate either on 50 cycles or

60 cycles.

The audio input line connects to the terminal board at the bottom

rear of the modulator panel (right side, facing from rear). This

should be a shielded pair. The transmitter input is 500/600 ohms,

working equally well with either ohmage. Other input impedances

may be had by changing primary taps on the input transformer T8.

If the output amplifier to the transmitter does not have an out-

put pad, it is advisable to insert a fixed "H" pad, 500/500 ohms

having a loss of 5 or 6 DB to assure no reaction between trans-

mitter and amplifier and to introduce no errors in frequency

response.

The frequency monitor jack is fitted for a single pin connector

located on the radio frequency side panel at the bottom rear.

The modulation monitor connection is for a two pin connector.

Both pins are connected together. This insures that the two lines

will not be connected wrong. Small size co-axial cable should be

used. Sometimes audio cable is tried, the losses and capacities

are so high that seldom are the results satisfactory.

9/11/63 -6- BC- 250GY-1

www.americanradiohistory.com

The transmitter cabinet should be well grounded. The cabinet

itself should be grounded by cable to meet underwriters' regu-

lations. The radio frequency output, which is the cabinet stud

on the top of the cabinet adjacent to the feedthru bowl, should

go to the radio system ground. At least a 2" copper strap is

recommended. In some installations, this lead might be dressed

down inside the transmitter, behind the side panel to the base,

and connecting to a strap from there to the system ground.

Connecting the Load

The coaxial or open wire transmission line or the direct coupled

antenna connects to the feedthru insulators on the top of the

transmitter. In the case of coaxial transmission line or open

wire transmission line, the ground portion of the transmission

line should be firmly secured to the top of the cabinet also, so

that the ground path will not have to travel through the tríns-

mitter cabinet. Where desired, the coaxial transmission line may

be brought up through the bottom of the cabinet at any number of

the convenient locations as will be quickly obvious to the install-

ing engineer's eye.

9/11/63 -7- BC-250GY-1

www.americanradiohistory.com

SECTION III

INITIAL TUNE-UP

General Operational Procedure

Before proceeding with the initial tune-up let us recheck the

necessary things to be done before any voltage is applied to any

portion of the transmitter. Briefly, check the following list:

1 - Proper line voltage to fuse block A?.

2 - Froper location of all tubes in the sockets.

3 - Froper termination of the antenna or dummy antenna

equipment.

4 - Removal of all tie -down straps and other materials

used for shipping purposes.

5 - A recheck to be sure components removed for shipment

have been installed properly.

6 - Complete check of the transmitter with a screwdriver

and wrench to be sure all bolts, screws and other

connections that could possibly work loose in shipment

have been brought down securely.

7 - Looking over all wiring for broken solder connections,

making sure that everything is secure.

8 - Making certain the transmitter is well grounded and

that the ground to the transmitter is tied to the

main ground of the antenna system. THIS IS VERY

IMPORTANT. AT LEAST 2" COPPER STRAP RECOMMENDED.

9 - Making certain that transformers with voltage

correction taps have one side of the supply line

connecting to terminal #1.

10 - Making sure audio wiring has been properly shielded

and that the shields have been properly grounded,

and that no input wire runs in the same cable as an

output wire or a power cable.

In case the transmitter is located on the upper floor of a

building, particular attention must be paid to grounding of

the equipment. Additional ground busses and elimination of

varied ground potentials is highly important for good per-

formance and low noise.

With the transmitter ready to operate, the service switch is

closed and power supplied to the transmitter. Pressing the

"Filament ON" switch Sl, lights the tube filaments and the

power supply for the M-5422 oscillator unit. The oscillator

unit is tuned according to the directions given in the instruc-

tions for this unit. When the transmitter has been factory

9/11/63 -8- BC-250GY -1

www.americanradiohistory.com

tested on frequency, this should amount to no more than a check

on the tuning. The 813 stage is provided with a convenient grid

current meter, and the oscillator tuned for maximum grid current,

which should be 8 - 10 milliamperes with no voltage on the plate

of the tube.

Before applying the high voltage, set the modulation monitor

pick -up coil L12, for minimum coupling, at right angles and as

far removed from the tank coil as possible so as not to overload

the modulation monitor input. Set the two modulator bias rheo-

stats R4 and R5 to maximum bias voltage, that is, fully counter-

clockwise. Set the neutralizing condenser C28 at half capacity.

Remove the plate connector from one of the 8008 rectifier tubes,

making sure the connector is not grounded.

Disconnect the primary of the plate transformer Tl, terminals 1

and 2 or 3 whichever is used. When the filaments have been on

30 seconds, the time delay relay E6 closes and the "FILAMENT"

light will light. With the back door closed, pressing the high

voltage "ON" switch S2 should cause the plate contactor E4 to

close. Pressing the high voltage "OFF" switch should cause this

contactor to open. With the contactor closed in the high voltage

ON condition, opening the back door should cause the contactor

to open.

Opening the door and blocking or holding the door interlock switch

S4, the high voltage control can then be closed. With a wooden

dowel or insulating stick, push the armatures of the overload

relays El and then E2. In each case the auxiliary relay E3 should

operate and cause the plate contactor to open. CAUTION: The

armatures of these relays are in the 220 volt circuit and should

NEVER be touched with the body.

If the control circuit does not operate as described, some fault

exists and should be remedied before continuing. With the high

voltage transformer disconnected, no damage to equipment should

be incurred while testing the control circuits.

With the control circuits functioning properly, the high voltage

transformer may be reconnected, and the ridio frequency circuits

adjusted.

9/11/63 -9- BC-250GY-1

www.americanradiohistory.com

Tuning Procedure

Close the filament start switch which turns on filament and

oscillator. Set the filament voltage to 10 volts with the

filament rheostat. When the 30 second time delay relay E6

closes, and if the rear door is closed, high voltage may be

applied by pressing the "High Voltage ON" switch. With one

rectifier tube disconnected, slightly under half plate voltage

will be obtained. Tune the R.F. driver control C24 for minimum

current on the R.F. driver current meter M6. With the reduced

voltage, this should be 40 - 60 milliamperes. At the same time,

the power amplifier grid current meter M3 should show a reading

of 30 - 60 milliamperes.

The power amplifier tuning 032 can then be adjusted for a

minimum current reading on the plate current meter M4. This

value should be 100 - 120 milliamperes. The amount of current

can be controlled somewhat with the "Loading" control 034. Out-

put current should be indicated on the R.F. Line.Current meter Ml,

and should be approximately half the value for the particular

transmitter load given in the tabulation of "TYPICAL VOLTAGE

CONDITIONS" included in this instruction book.

The power amplifier shows no tendencies for parasitic or self -

oscillations, so no concern need be felt on applying plate vol-

tage without the stage being completely neutralized. Neutralizing

may be quickly and effectively done by tuning the plate condenser

C32 through the minimum current dip to 10 or 20 milliamperes on

each side, and watching the grid current as registered on the

meter M3. When first tried, the grid current may show a slight

increase on one side or the other of the minimum plate current

dip. Slowly moving the neutralizing condenser C28, tune back and

forth across the resonance dip with the plate tuning until a set-

ting for the neutralizing condenser is found where the current

does not increase when the plate is tuned off resonance. The

opposite side will show a pronounced decrease of grid current.

The main criteria is that the grid current shows no increase from

the minimum plate current point on either side of resonance, and

decreases if sufficient detuning is possible.

. 9/11/63 -10- BC-250GY-1

www.americanradiohistory.com

Shutting down the transmitter, the plate connection is again nade

to the 8008 rectifier tube. High voltage may then be re-applied,

and the transmitter adjusted to the final loading condition.

Typical readings are given in Section IV of this instruction book.

If a severe overload occurs with the application of high voltage,

note if the modulator current reads excessive. With a voltmeter,

measure the voltage on the modulator grids. This should be nega-

tive 50 to 60 volts to ground if the bias potentiometers are turned

to the maximum bias voltage position. If the bias is higher than

30 volts, the overload may be caused by a reversed audio feedback

loop causing high frequency oscillations. Removal of the connec-

tions to the plates of the modulator tubes will stop the overload.

The remedy is the reversal of the connections to terminals 81 and

83, or a temporary correction can be made by reversing the grid

or plate connections of the 810 modulator tubes.

It is difficult in these instructions to give loading information

as various types of loads are applied in almost each broadcasting

installation. Where a 70 ohm transmission line is provided, the

line current meter Ml is usually 0-3 amperes, while for a 250 ohm

transmission line meter Ml is usually 0-2 amperes. The formula

of I2R is usually employed in computing the proper line current

where the line impedance is known, and of course, is likewise

employed whrlre the antenna resistance is known in the case of

direct coupling. A dummy antenna of known value is usually pre-

ferable in the initial tune -up so that it can be determined

whether the transmitter is functioning properly and thus, full

attention can be given to the antenna loading problems for final

successful operation. The Ohmite D250 dummy antenna for 73 ohms

operates excellently where the transmission line is 73 ohms. Or,

in the case of 250 ohm transmission lines, four of these dummy

antennas may be wired in series which will give slightly higher

resistance than the open wire transmission line, but usually will

be satisfactory as the resistance is known.

As a less satisfactory dummy antenna, 150 watt lamp bulbs may be

employed which have a resistance of about 100 ohms, but are not

dependable as their resistance will vary with intensity. Two

may be paralleled to

be in series to give

with two in parallel

9/11/63

give a 50 ohm dummy antenna or three may

a 300 ohm dummy antenna. One in series

will give approximately 75 ohms. Two series

-11- BC-250GY-1

www.americanradiohistory.com

connected in series with two parallel connected will give approx-

imately 250 ohms. As light bulbs are highly reactive, the actual

load will be considerably removed from the proper condition

but will serve to allow a good preliminary checkup. As the

power amplifier tank circuit is directly affected by the load,

it is well to discount this in the subject of loading conditions.

The power amplifier tank is usually provided with a padding capac-

ity C33 in addition to the variable tuning capacity C32. The

tank capacity and the coupling capacities C34 and C35 determine

the harmonic suppression, a chart of recommended values for

various frequencies and common loadings is given elsewhere in

this instruction book. Special loading conditions may require

modification, and frequently the addition of a series condenser.

In this latter case, the condenser is between the line coil L11

and meter Ml. The proper loading of the transmitter to the

particular condition must be admitted as more or less on a cut-

and -try basis, adjusting C34 and the taps on coil 1,11; maintaining

the final power amplifier in complete resonance will eventually

produce the desired results where the load is not below 30 ohms

or exceeds 300 ohms. Final current into the line load on the

formula I2R is, of course, the answer to the correctness of the

load. The efficiency of the BC-250GY transmitter is 70% and

seldom over 75%. It should be remembered that efficiency is

measured into a known load,.and preferably a resistive load

designed for radio frequency operation. It should also be re-

membered that a radio transmitter of standard construction is

not normally inefficient when, of course, properly adjusted and

tuned. Thus, lack of efficiency in operation can usually always

be attributed to lack of proper loading conditions to the trans-

mitter itself, which is usually indicated by unbalanced line

currents in the case of a transmission line, and of course, can

be checked by making sure ground connections to the transmitter

are well nade directly to the radiating system of the antenna.

Abnormally high efficiency is quite frequently found to be in

the antenna system. This may be checked if a dummy antenna of

equavalent resistance is substituted for the line or antenna.

It may be found that the line current meter is measuring reactive

currents, which would give a false impression of efficiency.

9/11/63 -12- BC-250GY -1

www.americanradiohistory.com

When the power amplifier and R.F. Driver have been tuned, the

modulator currents may be set. With the two bias potentiometers

R4 and R5 turned fully counter -clockwise, there should be little

if any current indicated on the modulator current meter M2. Turn

one potentiometer until this meter shows 30 milliamperes current,

then bring the other potentiometer to a reading of 60 milliamperes.

The modulation monitor pick-up loop may now be adjusted. This

should be only enough to give just over the requirements of the

modulation monitor so that the modulation monitor "Carrier Set"

control is almost at maximum.

Making Performance Measurements

To make satisfactory ncise, distortion and response measurements,

it is necessary to have the proper measuring equipment. The Gates

SA-131 Proof of Performance kit contains the required instruments

for making these measurements. Checking noise or signal quality

by means of a radio receiver in the sane room as the transmitter

is generally not satisfactory, as quite often overloading of

sensitive circuits, or stray pickup, introduces effects in the

receiver which do not indicate the exact performance obtained.

The use of the SA-131 kit is fully explained in the instruction

book for the set.

The Gates M-5693 Modulation Monitor has provisions for making

performance measurements, other monitors may or may not have this

provision. Before accepting adverse readings when using a modu-

lation monitor as the diode source, determine the monitor is

suitable for this use. For normal program monitoring, the pick-

up from the power amplifier tank coil is satisfactory, but it

may be found that better results are obtained from a pick -up

loop coupled to a temporary turn or two in the radio frequency

output line. The amount of coupling to the diode may have con-

siderable effect. Generally, the coupling should be such that

with 100% modulation the distortion meter calibrate dial will be

at about one -half to two-thirds of the scale.

Preliminary performance measurements need be made on only three

frequencies, 50, 1000 and 5000 cycles. 50 cycles represents the

low frequency end, 1000 cycles the mid-frequency and best per-

formance, 5000 cycles the high frequency end, this frequency is

frequently higher in distortion than 7500 cycles.

9/11/63 -13- BC- 250GY-1

www.americanradiohistory.com

Distortion readings on these three frequencies can be taken.

Then with the 50 cycle frequency, hold the back door interlock,

apply the high voltage, and set for the distortion reading. Then

adjust the bias potentiometers for distortion below 3%, but not

necessarily the minimum possible distortion, as this adjustment

may increase the noise and distortion on other frequencies.

After this adjustment is made, recheck the other two frequencies

and the noise level. When setting the bias potentiometers, ex-

treme caution should be used, with preferably a second person

helping. If the performance is within specifications, a complete

frequency run may be made.

In case the distortion or noise is out of specifications, several

remedies may be tried. Different tubes may be tried, particularly

the 6L6G audio driver and 810 modulator tubes. Because a tube is

new out of a carton is no guarantee that it has not received some

damage in shipping.

The polarity of the modulation tránsformer may be reversed by

inter-changing the two modulator tube leads on the primary of the

transformer and connecting whichever way gives the best results

for all frequencies. The modulator grid connections could be

interchanged, and doing this requires that the feedback also be

reversed. Both reversals, that is, the driver and modulator

could be tried simultaneously. In each case, the modulator

bias should be adjusted for 50 cycle distortion below 3% if obtain-

able.

Some noise improvement can be obtained by proper phasing of the

audio system by the means just outlined so some cancellation is

obtained between the audio and radio frequency sections, but this

can easily upset the distortion performance. Considerable noise

variations can be encountered in the tuning of the radio frequency

part of the transmitter. Normally, the best noise reading will be

obtained when the 813 driver stage is tuned to the minimum plate

current. The power amplifier neutralizing has some effect. If

the radio frequency drive is low in any of the radio frequency

stages, some grid modulation is fed through to cause the noise.

The phasing mentioned is that the noise generated in the audio

section is opposed to.that generated in the radio section result-

ing in cancellation with the residual being the difference of

the two magnitudes. BC-250GY -1

9/11/63 -14-

www.americanradiohistory.com

The transmitter is thoroughly factory tested, and the phasing

and polarity selected for best performance. When components

are removed for shipping, the connections are tagged so that the

sane connections may be made again. Should any deviation occur

radically outside specifications, this may be due to damage to

components or tubes during shipping, or to a mis-interpretation

of connection instructions. If after a period of operation, the

performance is outside specifications, this may be due to tubes or

to some component aE:ing, such as a resistor changing value.

9/11/63 -5- BC-250G-1

www.americanradiohistory.com

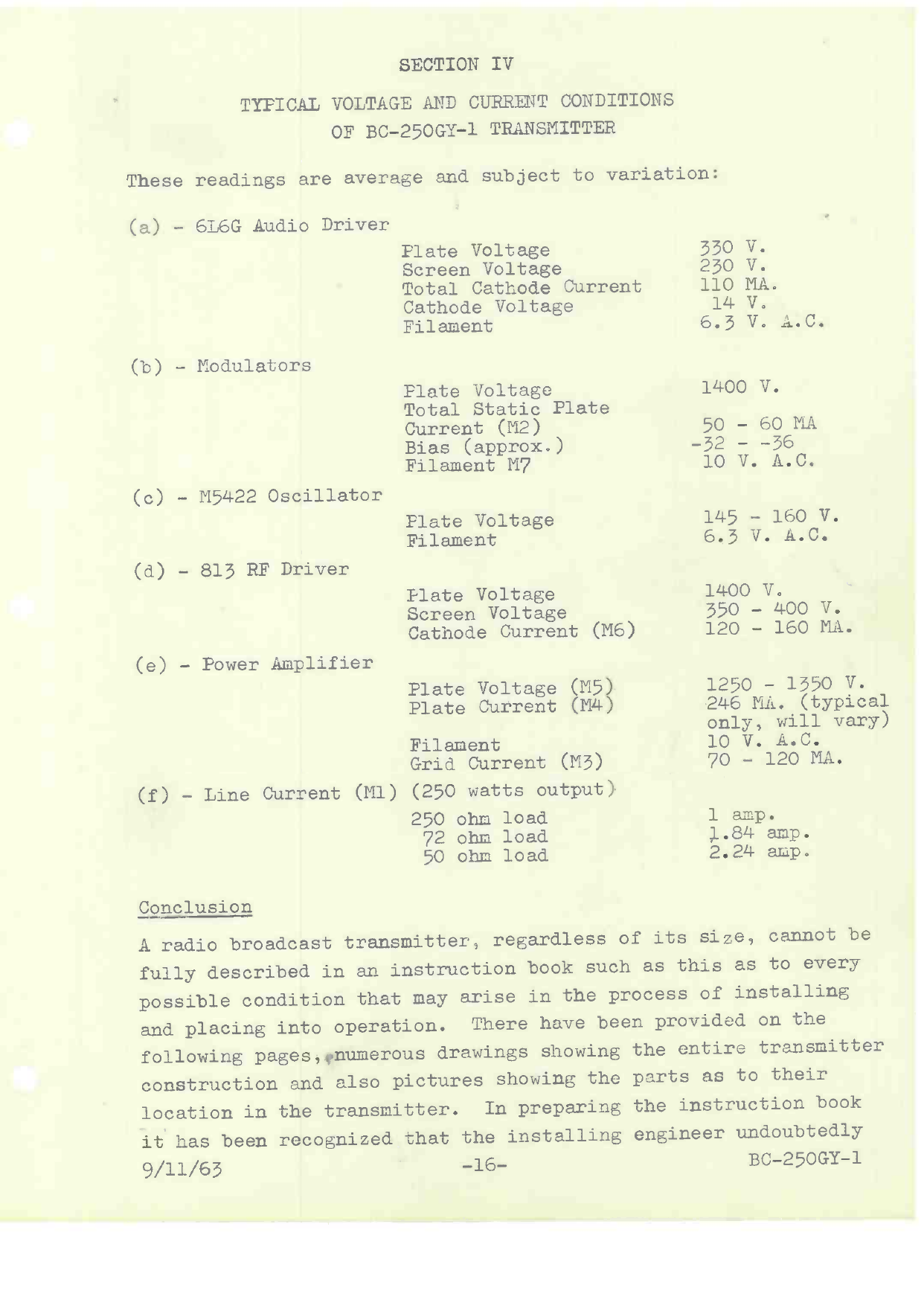

SECTION IV

TYPICAL VOLTAGE AND CURRENT CONDITIONS

OF BC-250GY-1 TRANSMITTER

These readings are average and subject to variation:

(a) - 6L6G Audio Driver

(b) - Modulators

(c) - M5422 Oscillator

(d) - 813 RF Driver

(e) - Power Amplifier

Plate Voltage

Screen Voltage

Total Cathode Current

Cathode Voltage

Filament

Plate Voltage

Total Static Plate

Current (M2)

Bias (approx.)

Filament M7

Plate Voltage

Filament

Ilate Voltage

Screen Voltage

Cathode Current (M6)

Plate Voltage (M5

Plate Current (M4

Filament

Grid Current (M3)

(f) - Line Current (M1) (250 watts output)

250 ohm load

72 ohm load

50 ohm load

330 V.

230 V.

110 MA.

14 V.

6.3 V. A. C.

1400 V.

50 - 60 MA

-32 - -36

10 V. A.C.

145 - 160 V.

6.3 V. A.C.

1400 V.

350 - 400 V.

120 - 160 MA.

1250 - 1350 V.

246 MA. (typical

only, will vary)

10 V. A.C.

70 - 120 MA.

1 amp.

1.84 amp.

2.24 amp.

Conclusion

A radio broadcast transmitter, regardless of its size, cannot be

fully described in an instruction book such as this as to every

possible condition that may arise in the process of installing

and placing into operation. There have been provided on the

following pages, »numerous drawings showing the entire transmitter

construction and also pictures showing the parts as to their

location in the transmitter. In preparing the instruction book

it has been recognized that the installing engineer undoubtedly

9/11/63 -16- BC-250GY-1

www.americanradiohistory.com

Table of contents

Other Gates Radio Company Transmitter manuals

Popular Transmitter manuals by other brands

Evikon

Evikon PluraSens E2227 user manual

Alligator

Alligator KC-9512 instruction manual

Sailor

Sailor T2031 Instruction book

Extron electronics

Extron electronics DVI 201 A D Tx/Rx Specification sheet

Cardin Elettronica

Cardin Elettronica TXQPRO486 quick start guide

Pfeiffer Vacuum

Pfeiffer Vacuum RPT 100 operating instructions