SDT International SDT 8 User manual

SDT 8 - User Manual 1

SDT International

Ultrasonic multi-

transmitter

Type SDT 8 and SDT 8 Multisetting

User manual

Aim of the manual

This manual is directed to anybody who wishes to use

an ultrasonic transmitter in the framework of ultrasonic

inspection. This transmitter should work linked to an

appropriate receiver, such as the SDT 150, the SDT 170

or the SDT Sherlog.

This manual contains information on:

•how to operate the equipment ;

•possible faults ;

•characteristics ;

•the principle of ultrasounds.

The information relating to the declaration of

conformity of the European Community, to the

guarantee, package, to areas of use and

recommendations for use are also included.

Contents

Declaration of conformity........................................................... 2

Guarantee................................................................................. 2

Package.................................................................................... 2

Using the multi-transmitter ........................................................ 2

Recommendations .................................................................... 3

1. GENERAL PRESENTATION..............................4

2. IMPLEMENTATION............................................5

The position of the multi-transmitter.......................................... 5

Powering “ON”........................................................................... 5

Measurements .......................................................................... 5

Powering “OFF”......................................................................... 5

Recharging the battery.............................................................. 5

3. APPLICATIONS..................................................7

Navy.......................................................................................... 7

Aeronautics ............................................................................... 7

Automobiles .............................................................................. 7

Trains........................................................................................ 7

Buildings.................................................................................... 7

4. SDT 8 MULTISETTING.......................................8

5. OPERATIONAL PROBLEMS.............................9

Ultrasonic sensor ...................................................................... 9

Battery....................................................................................... 9

Control fuse............................................................................... 9

6. TECHNICAL CHARACTERISTICS ..................10

Transmission characteristics................................................... 10

ON/OFF switch........................................................................ 10

Supply..................................................................................... 10

Others ..................................................................................... 10

7. ANNEXES.........................................................11

The ultrasounds ...................................................................... 11

Propagation laws of the ultrasounds ....................................... 11

The bi-sonic mode................................................................... 11

Detection of a leak by ultrasound in an enclosed space.......... 12

The advantages of the SDT 8 ................................................. 12

2 SDT 8 - User manual

Declaration of conformity for

packaging in the European Union

The manufacturer

SDT INTERNATIONAL S.A.

Boulevard de l’Humanité 415

B - 1190 BRUSSELS

declares that the product

Ultrasonic multi-transmitter type SDT 8

being the object of the declaration, conforms with the

fundamental descriptions with regard to safety stipulated in the

CEM 89/336/EEC directive.

The equipment carries the conformity label .

To implement the safety prescriptions stipulated in the Directive

as well as possible, the following standards were taken into

consideration:

- the SDT 8 does not emit any electromagnetic waves (EMC);

- the SDT 8 is immunised against transmissions of external

electromagnetic waves (EMI);

- the SDT 8 is protected against electrostatic discharges

(ESD).

Note : The owner of the equipment is obliged to keep this

manual throughout the entire life of the device and to pass it on to

the new buyer if it is resold .

Brussels, 2 January 1996.

The Manager.

Guarantee

SDT International guarantees the SDT 8 against all

manufacturing defects during a period of two (2) years from

delivery, with the exception of the battery which is guaranteed for

a period of six (6) months. The guarantee covers the whole of the

equipment and consists of the free replacement of any defective

parts, due to either material or constructional defects.

This guarantee is cancelled if the product is damaged by

incorrect use or by accident, if the product is changed or altered

in whatever manner or if attempts to repair or open the product

are made without the permission of the SDT.

In the event of a defect, contact your SDT representative or the

SDT International company itself.

Under no circumstances can the SDT International company be

held liable for any financial, material or time loss, any corporeal or

other damage, resulting from loss of data, of any defect

whatsoever of the SDT 8 equipment or of any connected

equipment, even if it was informed of the possibility of damage.

Opening the unit without the permission of SDT International will

result in the cancellation of the guarantee and service.

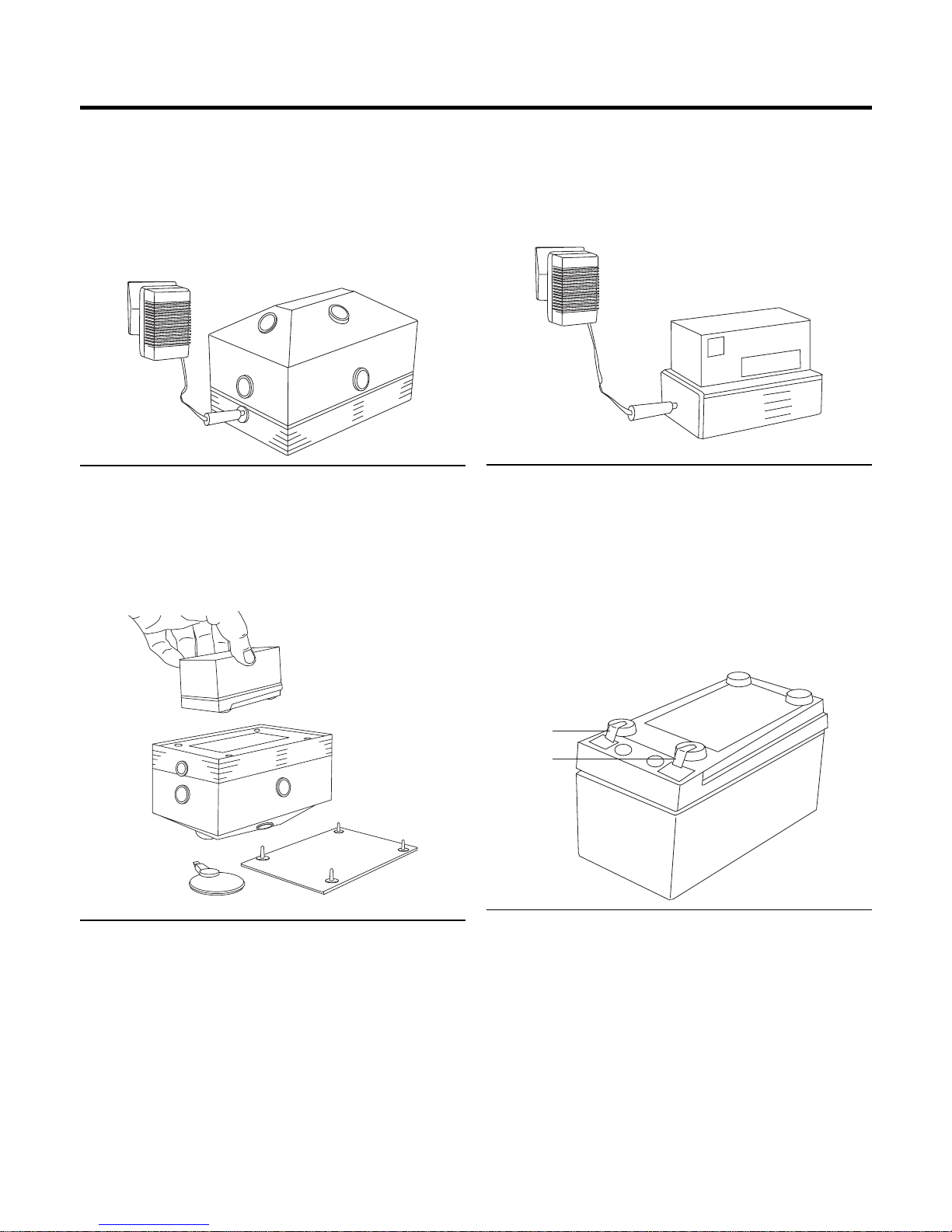

Package

The package includes following items:

1 - a multi-transmitter type SDT 8;

2 - a first gel lead-acid 12V - 1.2 Ah battery;

3 - a 220 V - 0.3 Ah charger;

4 - a case;

5 - a leathern bag;

6 - a second gel lead-acid 12 V - 1.2 Ah battery;

7 - an adapter;

8 - a screwdriver and a user manual (not shown).

1

2

3

4

5

6

7

The set of elements supplied

Using the multi-transmitter

This ultrasonic multi-transmitter is designed for detecting

openings in constructions or industrial products. It must work with

an ultrasonic receiver such as the as the SDT 150, the SDT 170

or the SDT Sherlog by applying the “Transmission-Reception”

method laid out in chapter 3 ‘Applications’. It must only be used

for this function, to the exclusion of all others.

We advise you to read this manual very carefully and to

implement the restrictions stated.

SDT 8 - User Manual 3

Recommendations

This manual must be read attentively before the equipment is

used and by any person likely to use it.

The multi-transmitter

•must be used with an appropriate SDT receiver;

•must be used outside any classified zone, due to the

absence of certificate for intrinsic and fireproof safety;

•must be used away from discharge of water and must never

be immersed.

It is important to prevent any foreign bodies entering the

ultrasonic sensors, such as grease, dust, etc. The use of

waterproof sensors is therefore obligatory;

•must be used within hygrometric and temperature limits

stipulated in the technical characteristics;

•may be used with a connected battery charger. The operator

must therefore respect the precautions linked to the use of

live equipments (conformity of connectors, state of cables,

authorisation, etc.).

The battery

It is a sealed, lead-acid battery. Therefore:

•short circuit of the terminals is dangerous;

•the battery must not be discarded onto a flame;

•recharging in a sealed box is prohibited due to gas leaks

(hydrogen);

•all mechanical shocks able to break the box may adversely

affect the life of the battery;

•in the case of electrolyte coming into contact with the skin,

rinse the contaminated area immediately with water;

•recharge the unused battery pack every three (3) months.

Operator security

•there is no likelihood of direct consequences for the hearing

capacities of the operator;

•the operator will take the necessary precautions when using

the multi- transmitter in areas where risk of falling exists (open

premises, working high- up, etc.);

•the operator will be particularly vigilant when entering or

staying in confined zones (holds, silos) where risks of

suffocation or lack of oxygen are possible.

Destruction of the equipment

When the SDT 8 becomes obsolete, the internal battery must

first be removed from the equipment. The battery will then be

given to a company specialising in the destruction of this type of

component.

The box and the other internal components can be scrapped.

The local legal regulations take precedence over this text and

must be respected scrupulously.

4 SDT 8 - User manual

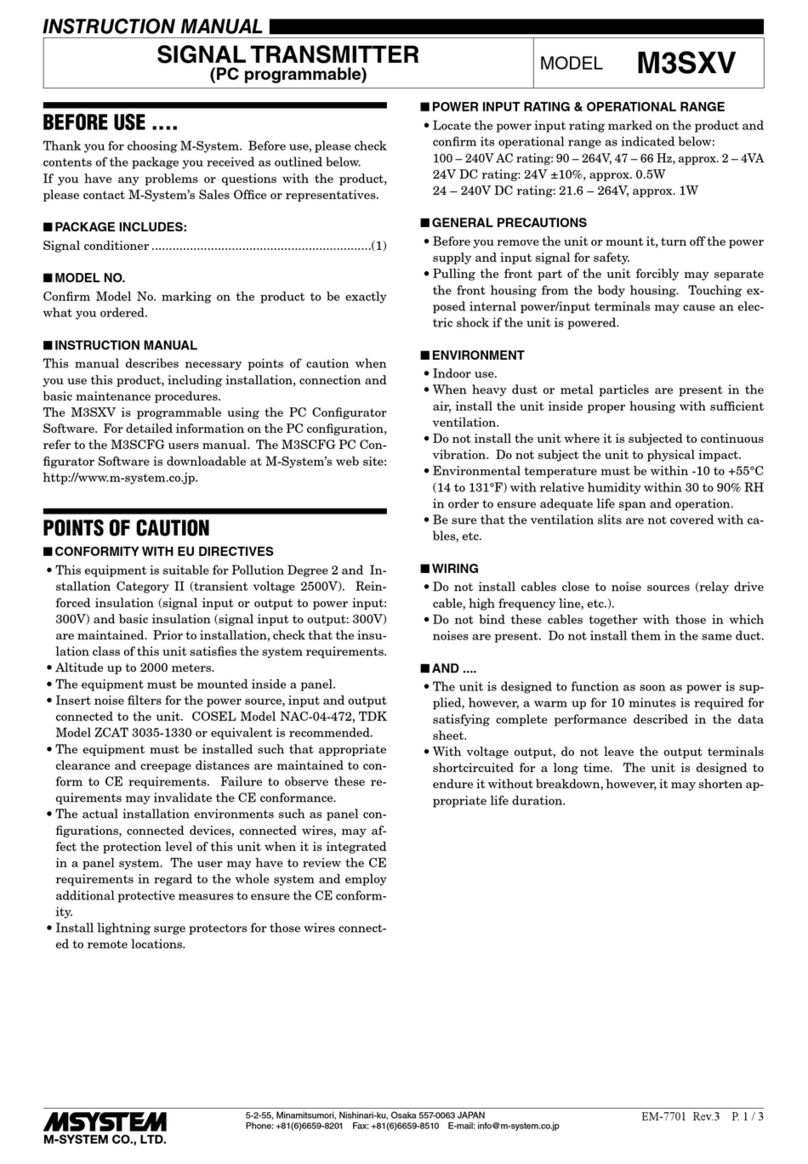

1 - General presentation

ON OFF

U

SDT 8

1

1

2

3

4

5

SDT 8 general view.

The SDT 8 is an ultrasonic transmitter. It comes in the form of a

box 160 x 100 x 95 mm. Equipped with a lead-acid battery, its

weight is 1500 grams. The range of temperatures for use is from

-10 C to +50 C.

NB: in some cases, the equipment may be used down to a

temperature of -25 C, as long as the equipment is not used for

more than 15 hours at a time.

1. The ultrasonic sensors

Eight sensors are laid out in the equipment in a such way that

they transmit in the volume of a hemisphere.

Each ultrasonic sensor is frequency and power stabilised.

The transmission frequency is 39.2 and 39.6 kHz (bi-sonic mode)

for a power of 125 mW.

2. Indicator

A red indicator integrated in the ON - OFF switch shows whether

the equipment is switched on and the charge level of the battery

according to the following code:

Indicator Equipment

On - Equipment switched on.

- Battery charge correct.

Flashing - Equipment switched on.

- Battery charge incorrect.

The speed of the flashing increases

as the charge decreases.

Off - Equipment switched off or

- Battery charge insufficient.

3. The ON-OFF switch

Located at the base, this switch enables the equipment to be

switched on (ON position) or stopped (OFF position).

4. The charge plug

Marked LOAD (charged), it enables the internal lead battery to be

recharged without taking the equipment apart. Overcharging is

not possible if the charger delivered with the equipment is used.

5. The battery

Lead-acid type and sealed, the battery is accessible after the

lower protection lid has been removed. The rated voltage is 12V

and its capacity is 1.2 Ah at 20 C; the autonomy is 2.5 hours for a

6 hour charge.

The position of the battery is not important, when the lead

terminals are directed to the inside of the multi-transmitter.

Warning: if a battery of a different brand than that of the

battery delivered must be fitted, it is essential to pay

attention to the arrangement of polarity of the terminal s.

This must conform with the diagram below. There is no

standardisation with regard to their arrangement.

+

-

+

-

The obligatory arrangement of the battery terminals

The battery terminals must conform with this layout.

Moreover, the user must refer to the general recommendations of

chapter 1 of this manual.

SDT 8 - User Manual 5

2 - Implementation

The position of the multi-transmitter

The multi-transmitter will be placed on its base, at the centre of

the volume to be inspected. Chapter 3 details the principle of

applications.

It must be noted that the SDT 8 may not be used in classified

zones nor in environments exposed to discharges of water.

ON OFF

U

SDT 8

The correct position of the multi-transmitter

Powering ON

This is done by pushing the switch to the ON position (1). The

operating light (2) should be lit. If this is not the case then refer to

chapter 5.

1

2

ON OFF

U

SDT 8

The indicator of the multi-transmitter

Measurements

These will be carried out by complementary receiving equipment

type SDT 150, SDT 170 or SDT Sherlog; the SDT 8 being the

ultrasonic transmitter. The operator should refer to the receiver

manual for the use of the equipments.

The multi-transmitter works in bi-sonic mode on frequencies

stabilised at 39.2 and 39.6 kHz, with total transmission power

also stabilised at 8 x 125 mW.

If local regulations allow it, the multi-transmitter may be supplied

by the charger during the measurements. The operator will

respect the safety measures for use in relation to electric shocks

caused by the use of equipments supplied by the mains.

The autonomy of the multi-transmitter will therefore no longer be

limited.

NB: the battery will not be recharged in this case.

Powering OFF

This is carried out by pushing the switch to the OFF position. The

operating light will be off.

ON OFF

U

SDT 8

Stopping of the multi-transmitter

Recharging the battery

This will be carried out:

•either to maintain the charge of the battery. A

continuous charge is not harmful to the life of the

battery, as long as the charger provided with the multi-

transmitter is used;

•or after the flashing of the indicator of the battery.

The following table details the state of battery charge in relation

to the information provided by the indicator:

Indicator Equipment

On - Equipment switched on.

- Battery charge correct.

Flashing - Equipment switched on.

- Battery charge incorrect.

The speed of the flashing increases as

the charge decreases.

Off - Equipment switched off or

- Battery charge insufficient.

Reminder: if local regulations permit, the multi-transmitter may be

supplied by the charger during the measurements. The autonomy

of the multi-transmitter be therefore no longer be limited. The

battery does not require recharging in this case.

6 SDT 8 - User manual

Without removing the battery

Proceed as follows:

•connect the plug to the socket marked LOAD on the multi-

transmitter;

•connect the charger to the mains;

•leave it on charge for 6 hours for a completely flat battery.

There is no maximum charge indicator.

LOAD

U

SDT 8

Recharging a battery without removing.

When removing the battery

Proceed as follows:

•remove the lid at the base of the multi-transmitter by

means of the screwdriver provided and remove the

battery;

U

SDT 8

SDT International

B 1190 Brussels

Removing the battery.

•connect the charger to the mains;

•connect the plug to the battery’s support socket;

•place the battery in the support, contacts inside. There is no

preferential direction for the battery.

Batterie

U

SDT

The battery connected to the charging pack.

•leave the battery on charge for 6 hours for a completely flat

battery. There is no indicator for a maximum charge.

It is advisable to recharge when the battery has not been used

for two weeks.

Warning: if a battery of a different manufacturer than that of

the battery delivered must be fitted, it is essential to pay

attention to the arrangement of the terminals polarity. This

must conform with the diagram below. There is no

standardisation with regard to their arrangement.

+

-

+

-

The battery terminals must be placed in this arrangement.

SDT 8 - User Manual 7

3 - Applications

This chapter describes some of the principle applications of the

multi-transmitter SDT 8. They do not cover all areas as each user

may use the equipment for his own personal needs.

Navy

One of the principal applications for the SDT 8 in the navy is to

monitor the untightness of the hatchcover joints of the holds. The

holds of liners must be protected against the entry of water from

the sea in the context of transporting perishable products (wheat,

sugar, steel, etc.).

The usual method, consisting of unloading the boat and watering

the hatches by means of a water hose to monitor the joints,

becomes redundant with the use of the SDT 8. This can merely

be placed on the cargo.

NB: see the comments regarding the safety of the operator on

page 3 ‘Recommendations’.

Aeronautics

Joints of the doors

Detecting leaks from the joints of the doors, portholes and the

cockpit is simplified. Functioning in bi-sonic mode (see annex)

enables the elimination of dead zones.

Leaks in the fuselage

The SDT 8 will be located at the centre of the volume to be

controlled. A localisation probe used with the SDT detector for

example will ensure precise detection.

Other monitoring possibilities

The SDT 8 may also be used to monitor the bulkhead,

compartments, windows, etc.

Monitoring in aeronautics is particularly appreciated

Automobiles

The SDT 8 may be used in the context of manufacturing

applications in order to detect wind noises and infiltrations of

water. Therefore, for many automobile manufacturers, the

ultrasonic technology is already replacing monitoring using water.

The multi-transmitter located inside the vehicle enables the

windscreen, doors and windows joints to be checked.

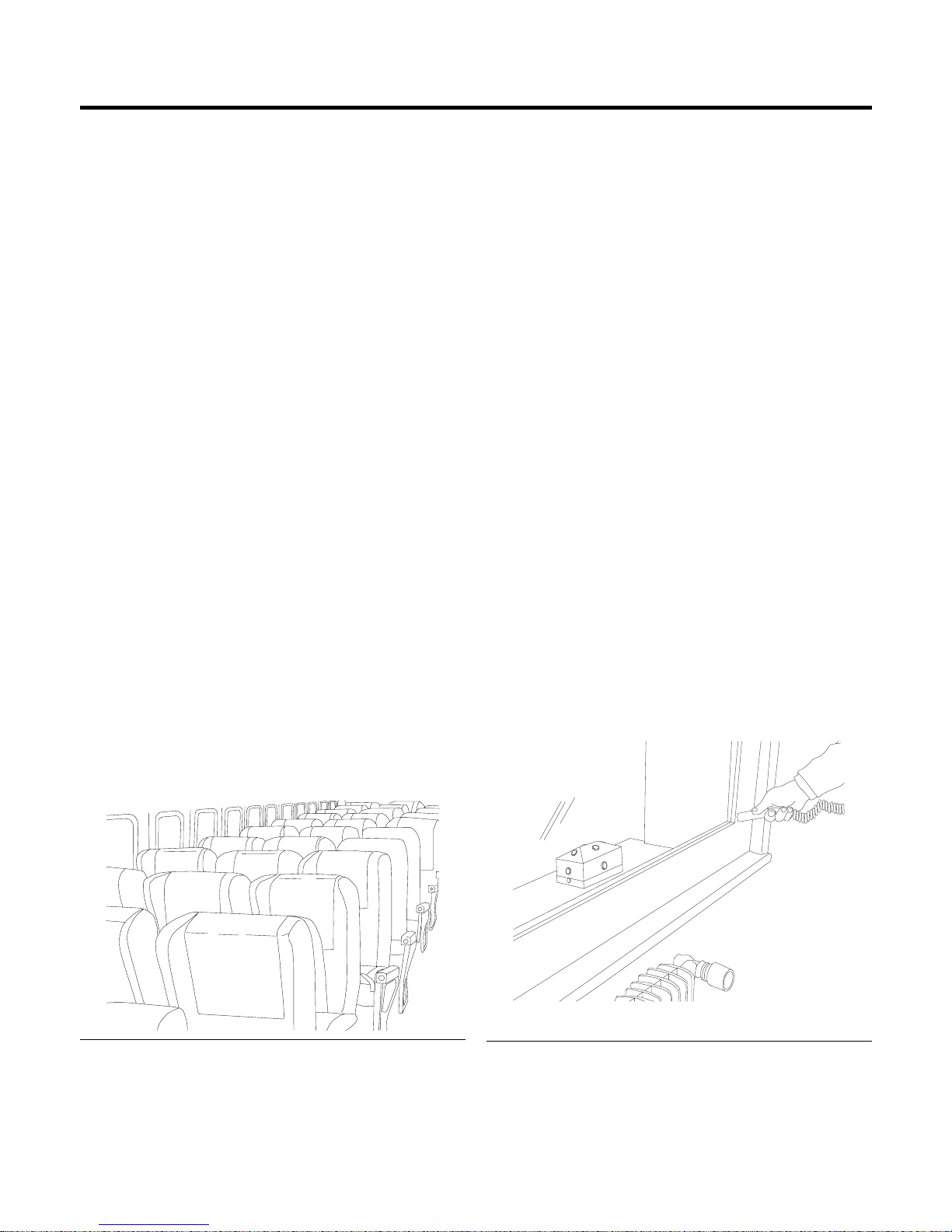

Trains

The SDT 8 has enough power to fill the volume of a refrigeration

carriage for example with ultrasounds. It would therefore be easy

to detect leaks from the external joints and locks.

Buildings

Numerous checks may be carried out with the ultrasonic sound,

such as for roof and wall leaks, etc.

Window joints

The SDT 8 would be located outside, on scaffolding for example,

on the one hand to ensure the safety of the operator, and on the

other hand to eliminate outside noise.

While checking windows, some vibrations tend to pass via the

centre of the window. This place must be ignored. Concentrate

on checking the edges where the risk of leaks is greatest.

The level of the signals is more significant there.

Checking the tightness of a window.

8 SDT 8 - User manual

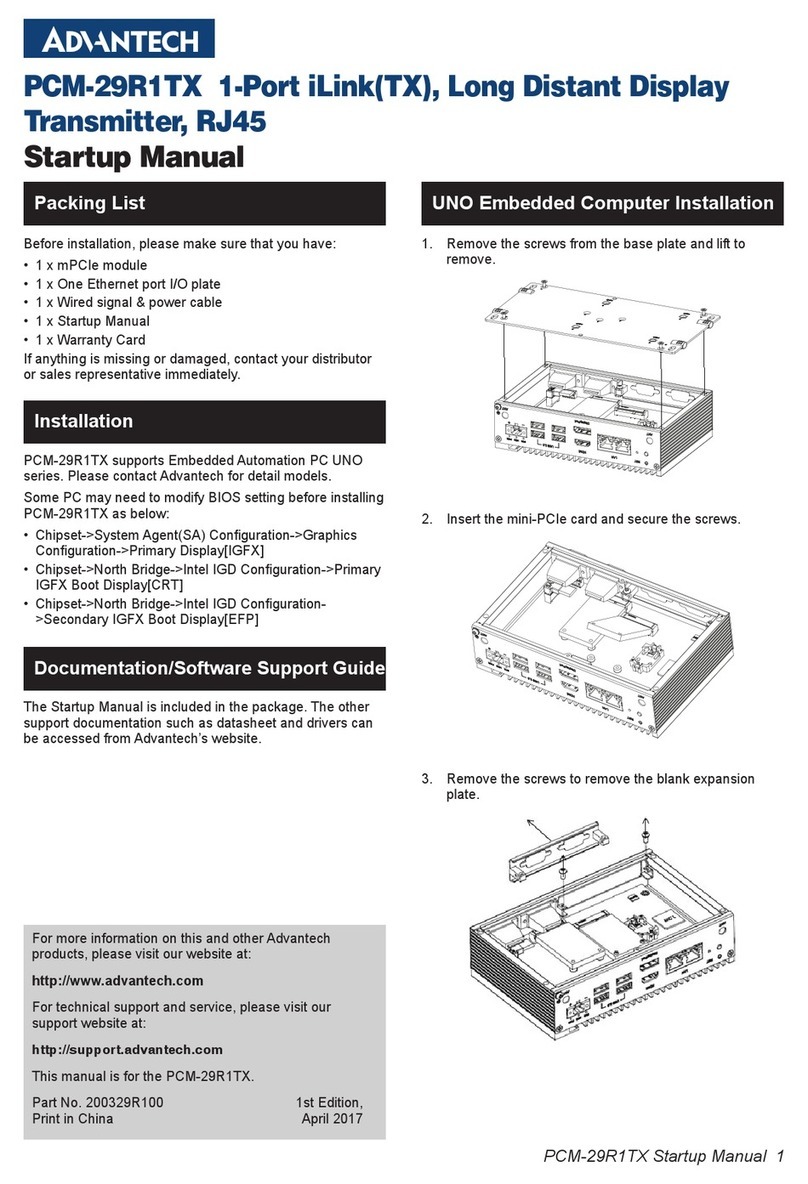

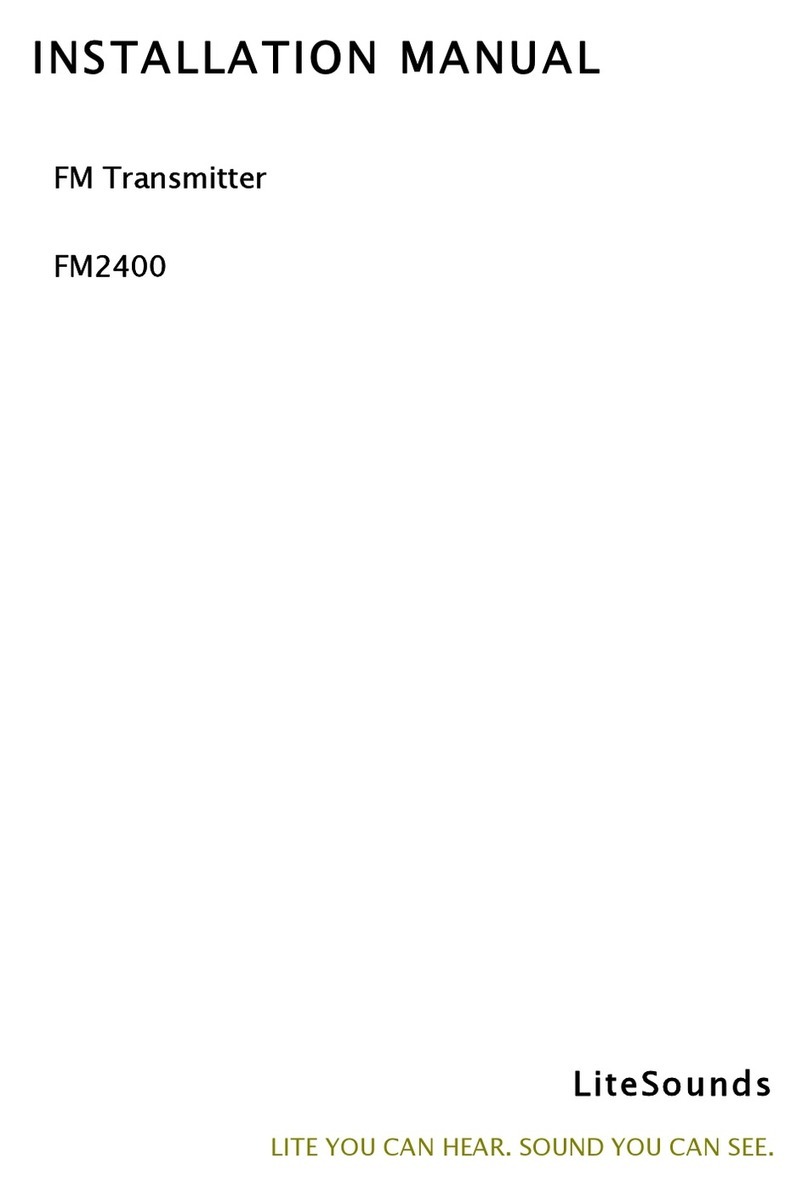

4 - SDT 8 Multisetting

Main field of application

It is used in situations where the emitted ultrasonic power must be adjustable to the volume that has to be controlled, mainly in the

tightness control of large volumes which cannot be pressurized or depressurized.

Description

This equipment is an adjustable (six positions) ultrasonic transmitter used in combination with an SDT Ultrasonic Detector. Eight (8)

oriented ultrasonic transducers are localized all around the unit, for a variable 8x 125 mW ultrasonic power.

A 6 position selector allows the choice of the ultrasonic power.

Transmission

power Power control in 6 levels:

Typical value from 1 to 6: -20dB, -15dB, -9dB, -6dB, -2dB, Max

This combination is an accurate and reliable tool for testing the tightness of every kind of object or volume.

View of the ultrasonic type SDT 8 multisetting transmitter.

075

6 position selector

SDT 8 - User Manual 9

5 - Operational problems

This chapter focuses on the principal operational defects.

Ultrasonic sensor

One or more sensors may be defective following:

•a mechanical shock: return the equipment to your

distributor for a change of one or more sensors;

•water in the sensors: leave to dry and check that there is

no water left, etc.

In both cases the transmission power is significantly limited or

even non-existent, as the receiver will confirm.

Battery

Warning: if a battery of a different manufacturer than that of

the battery delivered must be fitted, it is essential to pay

attention to the arrangement of the terminals polarity. This

must conform with the diagram below. There is no

standardisation with regard to their arrangement.

+

-

+

-

The battery terminal spade tags must be conform to this layout.

A flat or defective battery prevents the correct functioning of the

multi-transmitter. The characteristics of the battery are:

•a gelled lead-acid battery

•normal voltage: 12V

•capacity: 1.2 Ah

•charge current: O.4 A max.

As a method of control, an indicator enables the condition of the

battery charge to be determined quickly. It has the following

codes:

Indicator Equipment

On - Equipment switched on.

- Battery charge correct.

Flashing - Equipment switched on.

- Battery charge incorrect.

The speed of flashing increases as the

charge decreases.

Off - Equipment switched off or

- Battery charge insufficient.

1

ON OFF

U

SDT 8

Position of the battery charge indicator

Control fuse

Despite the presence of a correctly charged battery, the receiver,

in good working order, does not receive any ultrasonic signal.

This fault may be due to the triggering of a chemical control fuse

of the internal electronics.

Contrary to a standard type, such a fuse contains a progressive

reset time corresponding to the following curve

Initial resistance

Resistance (without scale)

Time

1 to 5 minutes

Resistance after

triggering

Resistance after

triggering

24 hours

1 to 5 minutes

Automatic reset curve of the chemical fuse

The general causes of the triggering are:

•fault in the internal electronics;

•battery polarity is incorrect.

NB:

•never replace the chemical fuse with a different type;

•successive occurrences of triggering are caused by a fault

in the equipment.

It is therefore advisable to return the equipment to the

distributor for repairs.

10 SDT 8 - User manual

6 - Technical characteristics

Transmission characteristics

Function: Ultrasonic multi-transmitter.

Number of sensors: Eight (8).

Frequencies: Stabilised at 39.2 and 39.6 kHz (bi-sonic mode).

Transmission power: Stabilised at 8x125 mW.

Dispersion: 8x60° .

ON/OFF switch

Command: By ON-OFF switch.

Visual indication: ON - OFF/battery charge control indicator.

Supply

Voltage/capacity: 12V DC/1,2 Ah.

Battery: Gelled lead-acid rechargeable.

Recharge: By means of an external charger and integrated

connector (without removing the battery) or by using a charge

adapter (removing the battery).

Autonomy: 2.5 hours at 20°C.

Charging time: 6 hours.

Safety: Chemical control fuse with automatic reset.

Others

Temperature range: -10° C to +50° C(*)

Measurements:

Length: 160 mm

Width: 100 mm

Height: 95 mm

Weight: 1.5 kg

Guarantee: SDT International guarantees the SDT 8 against all

manufacturing defects during a period of two (2) years from

delivery, with the exception of the battery which is guaranteed for

a period of six (6) months. The guarantee covers the whole of the

equipment and consists of the free replacement of any defective

parts, due to either material or constructional defects.

See also the guarantee paragraph on page 2.

(*): in some cases the equipment may be used down to a

temperature of -25° C on condition that the equipment is not used

for more than 15 hours at a time.

SDT 8 - User Manual 11

7 - Annexes

The ultrasounds

They occur above the audible range of the human ear, i.e. over

20kHz. Only a specialised detection equipment can detect their

presence.

The ultrasounds created by the SDT 8 are generated by

transmitters made out of piezoelectric quartz crystals. These

work like ultrasonic loud speakers. They transmit a frequency

around 40 kHz.

The propagation laws of the ultrasounds

In order to achieve improved use of an ultrasonic

transmitter/receiver set, it is important to know the laws governing

the propagation of ultrasounds.

Main properties of the ultrasonic sensors

Due to the fact that its frequency approaches 40 kHz, ultrasounds

are very directional. With their short wavelength, ultrasounds

cannot spread as quickly as the broad waves of the audible

sound.

In order to compensate for the ultra-directional directivity of

ultrasound, the multi-transmitter uses 8 transmission sensors set

out in such a way as to cover a volume comparable to that of a

hemisphere.

Each sensor of the SDT 8 transmits at a solid angle of 60° . Due

to their arrangement on the SDT 8’s box, the ultrasonic rays

cross over each other to ensure a sufficient sound density for the

optimal detection of leaks.

Ultrasounds and solid materials

When an ultrasonic wave meets another material, there is:

•reflection on the first material;

•refraction in the second material;

•absorption in the second material.

Ultrasonic

wave

Air Metal Air

Reflection Refraction

Absorption

The three phenomena observed when ultrasound passes through a

material

Hence, each time an ultrasonic wave passes from one material to

another, these phenomena occur in different proportions.

Ultrasounds and liquid materials

When ultrasounds pass through the air and into a liquid, most of

the energy is reflected.

When the ultrasounds pass through a liquid and then meets air,

most of the energy is refracted or passes into the air with a slight

change of direction.

When the ultrasounds pass through a continuous environment

such as air or water and encounters a second material such as

foam, a large part of the energy is absorbed.

The bi-sonic mode

The necessity of the bi-sonic mode

An ultrasonic source (A) placed in an enclosed environment,

initially emits a first wave (B).

A B

The ultrasonic source (A) and the first wave (B).

This first wave is then reflected a first time (C) and a second time

(D). C and D are called secondary waves.

These secondary waves react in such a way as to produce

interference patterns which create null points or ‘dead zones’ (E)

in the inspection areas.

D C

EE E EEE

The initial reflection (C), the second (D) and the dead zones (E)

Where a null ultrasonic activity occurs, the probability of detecting

a leak is greatly reduced. This is why the elimination of the

permanent waves is important to ensure effective detection in an

enclosed environment. This elimination of the permanent waves

is carried out by using the bi-sonic mode.

12 SDT 8 - User manual

The operation of the bi-sonic mode

The bi-sonic mode uses two ultrasonic frequencies of 39.2 and

39.6 kHz commutated 9 times a second. Although each

frequency has its own pattern of permanent waves, the automatic

cycle commutation leads the movement of the null points at the

same rhythm (9 times a second). This technique also eliminates

the problem of the permanent waves.

Two other advantages are drawn directly from this bi-sonic

technique:

•the commutation between these two ultrasonic

frequencies produces a sound (beating) recognisable by

the human ear, which facilitates the detection of leaks;

•the increase of about 20% in the ultrasonic density in the

zone to be inspected compared with any other current

technique.

Detection of a leak by ultrasound in an

enclosed space

The ultrasonic transmitter is placed in the volume or the zone to

be tested. From the other side of the wall, by means of an

appropriate receiver, the possible presence of ultrasonic waves

can be detected. These use any crack or lack of matter as their

route.

UP

DOWN

ON

OFF

UU

U

SDT

The detection of a leak by means of an ultrasonic transmitter-receiver set.

The advantages of the SDT 8

The SDT 8 thus enables significant volumes (125,000 m³) to be

filled perfectly with ultrasonic waves. An opening of a few

micrometres or more hardly offers any resistance to the 40kHz

ultrasounds. It is then possible to fill with ultrasounds, a cavity, a

room, a vehicle, etc. and to detect the leak exactly by means of a

receiver placed on the other side of the wall.

SDT 8 - User Manual 13

14 SDT 8 - User manual

SDT 8 Multi-transmitter/User Manual/Version 05-2008

Manufacturer : Distributed by :

SDT INTERNATIONAL S.A.

Boulevard de l’Humanité 415

B-1190 Brussels

BELGIUM

Phone : + 32.2.332.32.25

Fax : + 32.2.376.27.07

SDT 8 - User Manual 15

Table of contents