GATmatic GM-720 User manual

GM-720 A/C System Maintenance Centre

GM-720

A/C System Maintenance

Centre

GM-720 A/C System Maintenance Centre

Safety

The machine is designed to be used and repaired by qualified personnel only.

The machine designed for use in recovering the R134a refrigerant fluid used in

the air-conditioning (A/C) systems of motor vehicles. Fill the A/C system with the

quantity of refrigerant recommended by the manufacturer.

Check the vehicle use and maintenance manual for the type of refrigerant fluid

used by the A/C system. Do not mix different type of refrigerant otherwise can

easily lead to malfunction of the machine.

Keep away from moving parts and rotating elements such as cooling fans,

alternators and heating components, etc to avoid harm.

Wear protective clothing gloves and goggles.

As automotive air conditioning pipe flushing, the operator must be fully familiar

with automotive air conditioning system and operation of the machine. Check

whenever the engine is turned off that the ignition key is turned to the full OFF

position!

Do not expose the machine to direct sunlight or rain. Use only in well-ventilated

work areas.

Never exceed 30 ° tilt in transit process upside down is strictly prohibited.

Do not touch the machine high voltage power supply section, and do not maintain

the machine as power on.

GM-720 A/C System Maintenance Centre

Care of the manual.

TABLE OF CONTENTS

1. Introduction ................................................................................................................................................... 1

1) Outline ...........................................................................................................................................................1

2) Features ......................................................................................................................................................... 1

3) Specifications ................................................................................................................................................ 1

2. Functions ....................................................................................................................................................... 2

1) Primary functions ..........................................................................................................................................2

2) Subsidiary functions ......................................................................................................................................2

3. Operation ....................................................................................................................................................... 3

1) Parts descriptions .......................................................................................................................................... 3

2) First use ......................................................................................................................................................... 4

3) Recovery/Recycling ......................................................................................................................................5

4) Preparations before Flushing ........................................................................................................................ 5

5) Flushing & Recovery .................................................................................................................................... 6

6) Vacuum ..........................................................................................................................................................6

7) New oil adding ..............................................................................................................................................7

8) Recharging .................................................................................................................................................... 7

9) Maintenance .................................................................................................................................................. 7

10) Parameter setting and inquiring .................................................................................................................. 9

GM-720 A/C System Maintenance

Centre

1

1. Introduction

1) Outline

GM series A/C system maintenance equipment is with the latest design

technique which uses the best control principle and the manufacturing

process.

GM-720 A/C System Maintenance Centre is intelligent equipment collecting of

the A/C flushing, recovery, recycling, recharging and other functions in one. It’s

with the beautiful shape, humanized operation interface, and advanced

manufacturing processes to make the A/C maintenance professional and

simple.

2) Features

A. Internal pipeline of A/C system flushing, effectively cleared the internal

greasy and fouling, to restore the A/C system performance.

B. With forward flushing, reverse flushing, and pulse flushing functions, which

greatly improve the cleaning effect.

C. Using large-size glass tube with LED backlighting, can effectively observe

the entire cleaning process.

D. Vertically installing the HP & LP gauges let the operator be able to observe

the pressure parameters timely even in the car.

E. Unique design of the pipeline to achieve the high recycling rate no matter

with the gas or the liquid.

F. Easy to operate with the concise operating interface.

3) Specifications

A. Voltage input: AC220V±10%~50/60Hz

B. Compressor:12.12cm3

C. Vacuum pump: 7.2m3/h,10Pa

D. Load cells: ±10g

E. Tank: 12L

GM-720 A/C System Maintenance

Centre

2

F. Oil bottle: 250ml,double

G. Working pressure: max. 20bar

H. HP gauge: -1bar~3.5MPa

I. LP gauge: -1bar~1.5MPa

J. P gauge: -1bar~3.5MPa

K. Backlighting:LED

2. Functions

1) Primary functions

A. Flushing

B. Recovery/Recycling

C. Used oil discharging

D. Vacuum

E. New oil filling

F. Recharging

2) Subsidiary functions

A. Refrigerant supplying

B. Load cell calibration

C. Recharging tank exchanging procedure

D. Maintenance procedure for dry filter

E. Alarms

F. Parameters setting

G. Parameters inquiring

GM-720 A/C System Maintenance

Centre

3

3. Operation

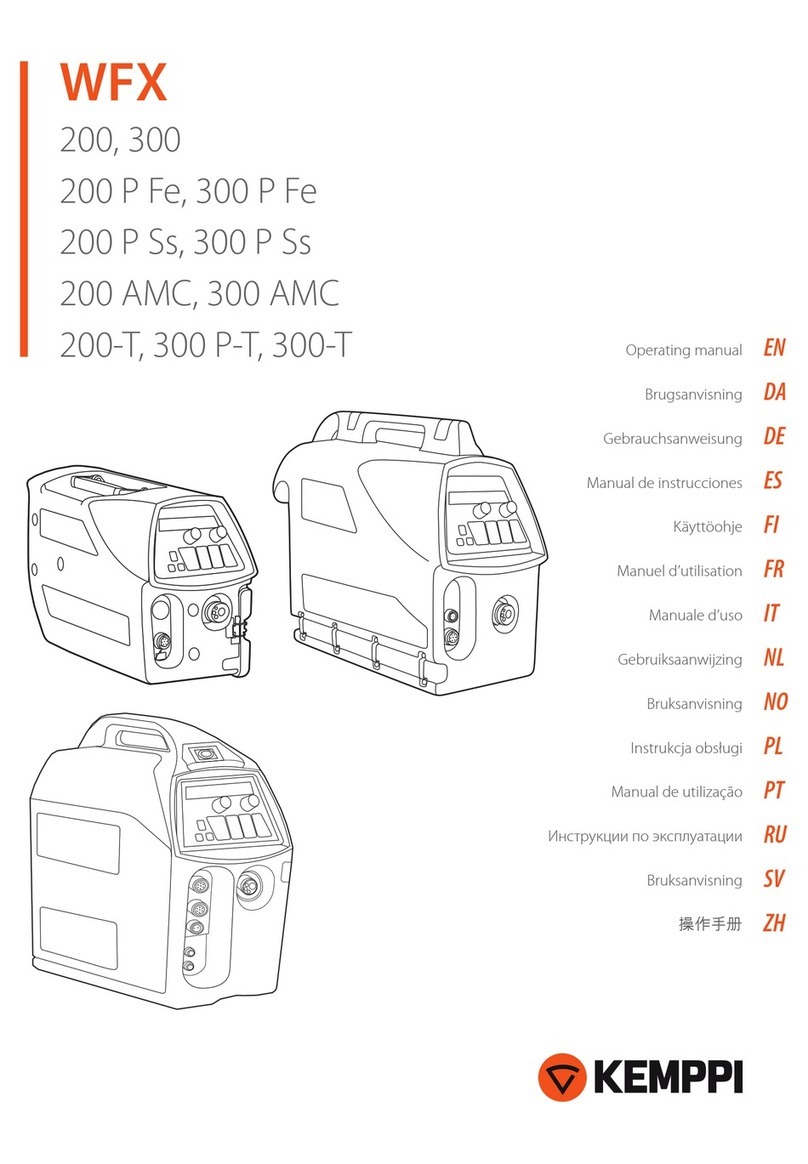

1) Parts descriptions

HP gauge

New oil bottle

Used oil bottle

Operation panel

Displayer

LP gauge

Switch for used oil discharge

Switch for new oil adding

HP port

Auxiliary Port

P gauge

Window

LP port

GM-720 A/C System Maintenance

Centre

4

2) First use

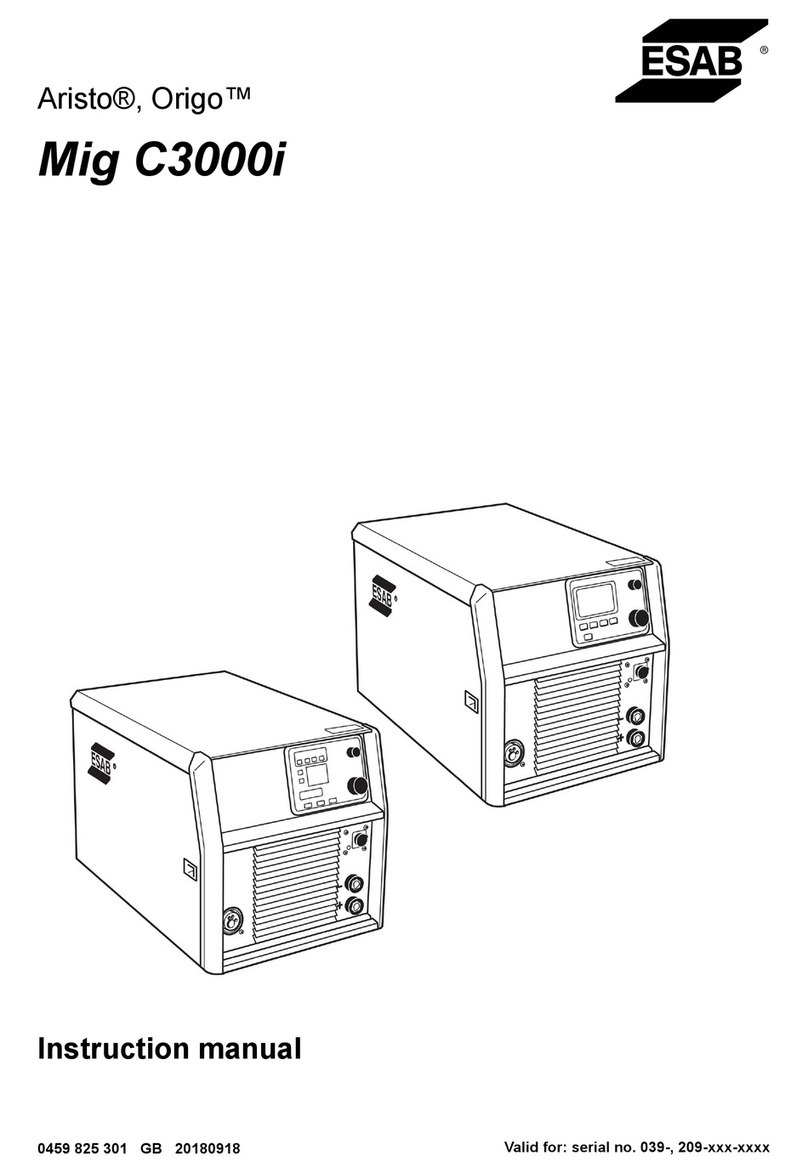

A、Unscrew the electronic scale support screw before using the equipment.

B、Please supply about 4 kg refrigerants into the tank of equipment so that all

of the functions can be run normally.

C、Fix the refrigerant tank (Recharging tank) on the load cell.

From the back.

Unscrew the

support screw.

Parameter increase key

Parameter increase key

Enter key

Recovery key

Min indicator

Kg indicator

LED displayer

Vacuum key

Recharge key

Start key

Stop key

Recharging Tank indicator

Flush key

GM-720 A/C System Maintenance

Centre

5

1st Connect the hose port with needle to the Recharging Tank port of the machine and connect

another port of the hose to the refrigerant tank.

2nd Open the valve of the refrigerant tank and place it upside down on the load cell pan.

3rd Fix it with the accessories.

Note: If you need not using the auxiliary load cell, please fix it as the manufactory.

Warning: Non-pedal the auxiliary load cell!

D、Please read this user manual carefully before operating.

3) Recovery/Recycling

A、Pres key to select the Recovery/Recycling function:

B、The LED displays the weight of refrigerant in the cleaning tank (internal

tank).

C、Presses “START” key to run.

D

、

It will stop running and discharge the used oil automatically when the

recovery/recycling process finish.

Note: also be able to discharge the used oil by press the switch.

E、During the running process, if it displays a code as F00-, please refer to

the APPENDIX: ALARM CODE TABLE.

4) Preparations before Flushing

A、To check if there has enough refrigerant in the tank. The volume should be

4~6 kg.

B、Empty the used oil bottle.

C、Check the automotive A/C system. If there has any leakage, it must be

repaired firstly to avoid refrigerant leak during flushing process.

D、Check if the automotive air-conditioning can run normally.

GM-720 A/C System Maintenance

Centre

6

5) Flushing & Recovery

A、Before flushing the pipeline of automotive A/C system, please turn on A/C

system and run it for 5 to 10 minutes. And set it as the lowest temperature

and medium wind.

B、Turn off the automotive air conditioning.

Warning: do not start the air conditioning during the flushing process!

Otherwise, it easily causes damages to the air-conditioning and risk

of accident!

C、Press key to select the “Recovery/Flushing” function.

D、The LED displays the flushing time.

E、Set the flushing time by pressing “+” or “-” key and press “ENTER” key to

conform it. In order to achieve good flushing performance, the flushing

time should be more than 30 minutes. Normally, the good flushing time is

about 45 minutes for car.

Note: The flushing time does not include the time of recovery

process. Once the flushing is finished, the machine will run the

recovery function automatically.

F、Press “START” key to run the function.

G、Then the forward flushing, reverse flushing and pulse flushing will be

run.

H、If it displays code as F00- during the process, please refer to the

APPENDIX: ALARM CODE TABLE.

I、After flushing process finished, the recovery process run automatically.

J、When the whole process finished, it drain the used roil automatically.

Notice: it’s normal for that there have action sound of the solenoid

valve during the working process. Please do not stop it.

6) Vacuum

A、Press key to select the vacuum function.

B、The LED displays the vacuum time.

GM-720 A/C System Maintenance

Centre

7

C、Set the vacuum time by pressing "+" or "-" and press the "ENTER" key to

confirm it. It should be more than 15 minutes. Generally, it needs 15

minutes at least for the air conditioning only with front wind and 20 minutes

for with the front and rear wind.

D、Press “START” key to run it.

E、When the time is finished, it will stop automatically.

F、If it displays code as F00- during the process, please refer to the

APPENDIX: ALARM CODE TABLE.

7) New oil adding

A、Pour new oil into the new oil bottle.

Note: add new oil more 20ml than the used oil drained out to avoid

the air into the air conditioning system.

B、After vacuum, press the switch of the new oil bottle to control the new oil

filling.

Warning: please do not press the switch of the new oil bottle anytime

when the automotive air conditioning system in non-vacuum state,

otherwise it have the risk of explosive bottles!

8) Recharging

Note:

i. Here you can choice the cleaning tank (internal tank) or recharging

tank (external tank) to recharging the refrigerant into the A/C system.

ii. When the led as is on, it means that recharge the refrigerant from the

GM-720 A/C System Maintenance

Centre

8

recharging tank (external tank). Otherwise, from the cleaning tank (internal tank).

iii. It’s by cleaning tank (internal tank) to recharge as default. After fixed

the recharging tank (external tank), you can set to recharge refrigerant

from the recharging tank (external tank). The setting ways is referring

to the PARAMETER SETTING.

iv. When the refrigerant in the recharging tank (external tank) is not

enough, please exchange one tank of refrigerant. The exchanging

ways is referring to the RECHARGING TANK EXCHANGING.

Operations;

A、Press the key to select recharging function.

B、The led displays the amount of recharging.

C、Set filling amount by press “+” or “-” key, and then press “ENTER” key.

Note: set the filling amount according to automotive user manual.

The unit is kg.

D、Presses “START” key to run.

E、Stop automatically after recharging finished.

Note: In the filling process, if LED displays alternately the remaining

amount of filling and the letters "AC", it means that you need to turn

off the HP coupler and turn on the car air-conditioning to complete

the filling process. Later, you should supply new refrigerant into the

tank.

9) Maintenance

A、Calibration of load cell

When the load cell is not precise,it needs to be calibrated.

Calibrating procedure as below:

i. Prepare a 15 kg weight. And remove the refrigerant tank from scale pan

and keep the pan empty.

Note: do not disconnect the red and blue hose from the refrigerant

tank. It’s better put the refrigerant tank on a lower stage.

ii. Press and hold “STOP” key then power on the equipment. Press”+”or ”-”

to select the load cell of cleaning tank (internal tank, SEN1) or of the

recharging tank (external tank, SEN2). Press “ENTER” key to the

calibration process.

GM-720 A/C System Maintenance

Centre

9

iii. The LED displays “1” in flushing.

iv. Press "ENTER" key to do the empty plan calibration. Then the LED will

display “2” in flushing. Note: If LED shows “ERR1”,please refer to the

APPENDIX: ALARM CODE TABLE.

v. Put the 15 kg weight onto the scale pan and press “ENTER” key. Then

LED displays the weight value and adjusts the value to 15 by press “+” or

“-”key.

Note: if the weight is 20kg, the value must be set to 20.

vi. Press “ENTER” key to do the scale linear calibration. Then the LED

displays “END” to mean it’s successful for the calibration.

Note: if LED shows “ERR2”, please refer to the APPENDIX: ALARM

CODE TABLE.

vii. Then power off and replace and fasten the refrigerant tank onto the scale

pan.

B、Exchange dry filter

The dry filter must be exchange after used a period. The machine has set the

exchange time. When the dry filter reaches the life time, the LED will show

code “F004”. Now the dry filter must be exchanged.

i. Press and hold (VACUUM) key and power on the equipment.

ii. Press “START” key to do the first step automatically.

iii. Replace the used dry filter with a new one then press “ENTER” key.

iv. Input the dry filter ID. Please refer to the chapter PARAMETER

SETTING.

v. Power off and dry filter exchange procedure finish.

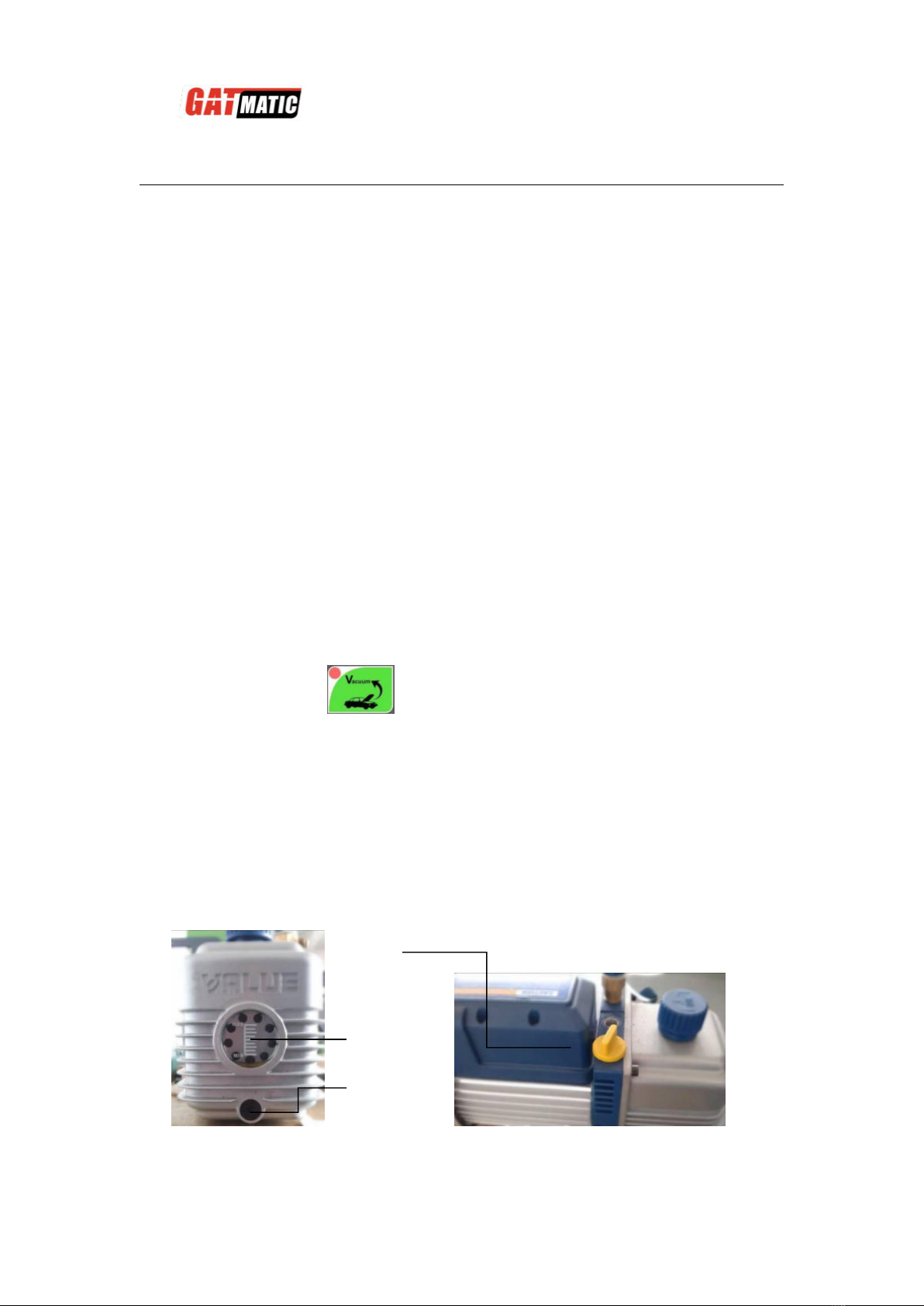

C、Change vacuum pump oil

i. When the pump oil became cream or the LED displays “F008”, the

vacuum pump oil must be changed.

Window

Drain port

Fill port

GM-720 A/C System Maintenance

Centre

10

ii. Step 1: unscrew the block of the drain port to drain entirely out the old oil.

Then re-back the block to the drain port.

iii. Step 2: unscrew the cap of the fill port and then fill the new oil slowly into

the vacuum pump until the oil level reach at the center site. Then

re-back the cap to the fill port.

Note: the new vacuum pump oil cannot be filled too much into the

vacuum pump otherwise it will spray out when working.

D、Recharging tank exchange

When there is no enough refrigerants in the recharging tank, it needs

to change a new tank of refrigerant in time so that the recharging

function can be run.

i. Press and hold the (flushing) key to power on.

ii. The LED displays the remained amount in the recharging tank.

iii. Press the “ENTER” key.

iv. When the LED displays the “CH”, please change a new tank of

refrigerant and fix it well.

v. Power off and exchange ok.

10) Parameter setting and inquiring

A、Parameter setting

i. Here can set the cleaning tank or recharging tank as the default

recharge tank.

ii. Press and hold the "START" key and power on the equipment to enter

the mode.

The LED displays the parameter code and you can change the code

by press "+” or “-" key.

iii. The LED displays “P3”.

iv. Press “ENTER” into setting mode. Press “+”or”-” to select the setting

value.

g: Set the unit is KG/G as default.

lb: Set the unit is LB as default.

v. Press “ENTER” to save.

vi. The LED displays “P4”.

GM-720 A/C System Maintenance

Centre

11

vii. Press “ENTER” into setting mode. Press “+”or”-” to select the setting

value.

C-1: Set the cleaning tank (internal tank) as default. This is also default

of nufactory.

C-2: Set the recharging tank (external tank) as default.

viii. Press “ENTER” to save.

ix. Power off.

B、Parameter inquiring

i. Press and hold (Recharging) key to enter parameter inquiring

mode.

ii. In this mode five parameters can be inquired.

The LED displays the parameter code and you can change the code by

press "+” or “-" key.

iii. Code “C”: total worked time of the compressor

When LED displays code "C", please press "OK" key to show the total

worked time.

iv. Code “P”: total worked time of the vacuum pump

When LED displays code "P", please press "OK" key to show the total

worked time.

v. Code “F”: volume of refrigerant dealt with by dry filter.

When LED displays code "P", please press "OK" key to show the total

worked time.

Reset this code by press together “Fill” and “Stop” keys and the ways of

dry-filter ID is as follows:

Dry filter ID is with 4 digits, and you need to set one by one.

When one digit is in flash, it means you can set it by press "+” or “-" key,

and press “OK” key to confirm it.

Set a same value according to the ID pasted on the dry-filter.

Only you set the correct 4 digits, the equipment can accept it

Note: The code used already will be not able to be accepted again.

vi. Code “CON”: total times of the equipment being operated.

vii. Code “SN”: the equipment serial number

GM-720 A/C System Maintenance

Centre

12

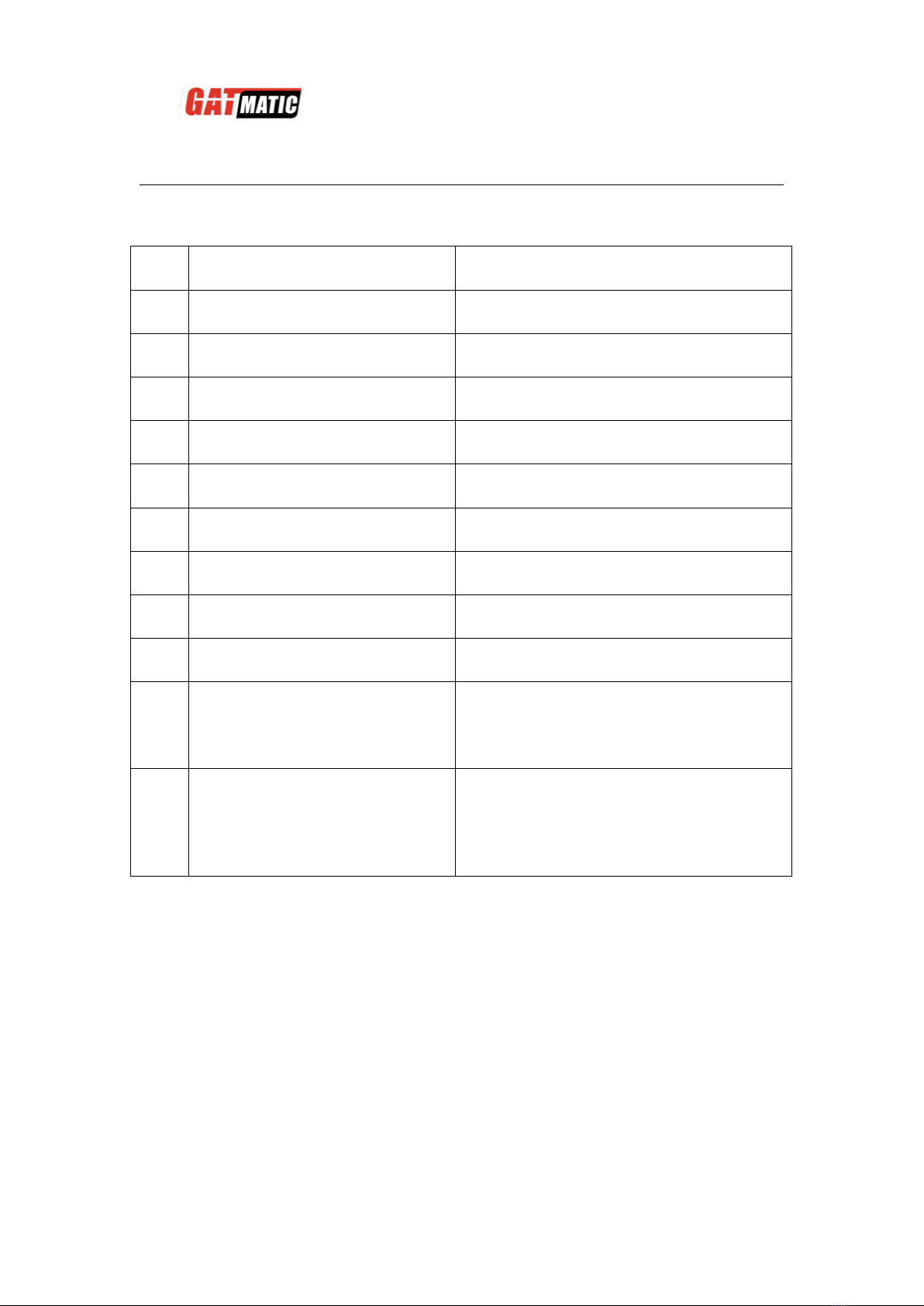

APPENDIX: ALARM CODE TABLE

Cod

e

Descriptions

Emergency Method

F00

1

No enough refrigerant in

cleaning tank

Supply refrigerant in time.

F00

2

Too much refrigerant in tank

Transfer some refrigerant to another

tank.

F00

3

High pressure

Stop use for a period.

F00

4

No refrigerant to recovery

Run next function.

F00

5

Cannot vacuum

Recovery first and then run vacuum.

F00

6

Exchange dry-filter

The dry-filter is life-end.

F00

7

Vacuum pump maintenance

Change the pump oil in time.

F00

9

No enough refrigerant in

recharging tank

Change a new tank of refrigerant.

F01

0

Prohibit changing the

recharging tank

Here has enough refrigerant in the

tank.

ERR

1

Load cell calibration error at

step 1

Check if the scale pan empty.

Check the connection of signal cable

being ok.

Check if the load cell is damaged.

ERR

2

Load cell calibration error at

step 2

Check if the weight has been put onto

the scale pan.

Check the connection of signal cable

being ok.

Check if the load cell is damaged.

Table of contents

Popular Welding System manuals by other brands

Comparc

Comparc DELTA MIG 455 owner's manual

Lincoln Electric

Lincoln Electric RANGER IM604-B Operator's manual

LENCO

LENCO L-6000 LENCOSPOT MARK III manual

ESAB

ESAB Caddy Tig 2200iw instruction manual

Chicago Electric

Chicago Electric 8878 Assembly and operation instructions

Riland

Riland CUT 100GT user manual