GASMAX EC Operation & Maintenance Manual, Revision 3.5

Page 7

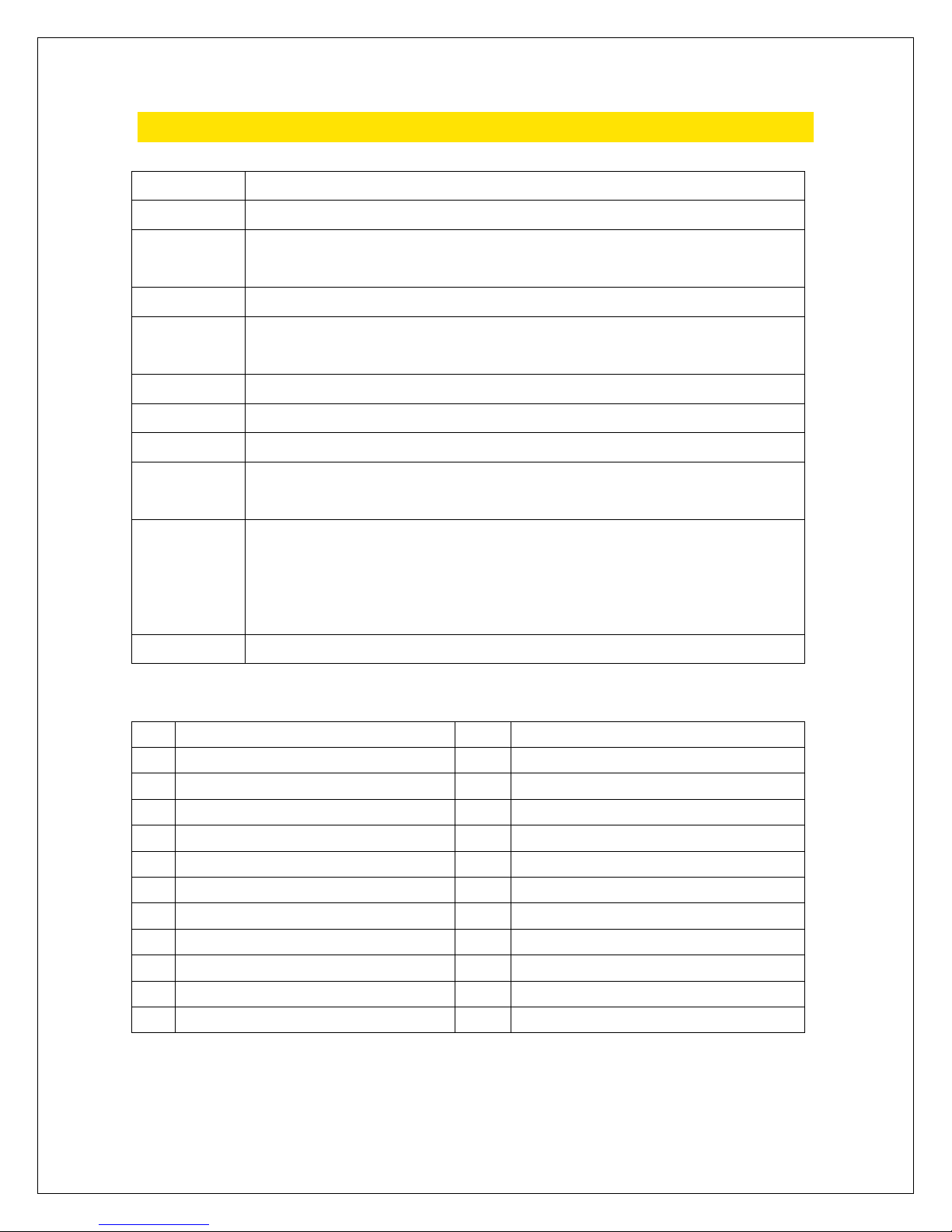

TABLE OF FIGURES

FIGU E 3-1: GASMAX EC TOXIC SENSO S .................................................................................................... 10

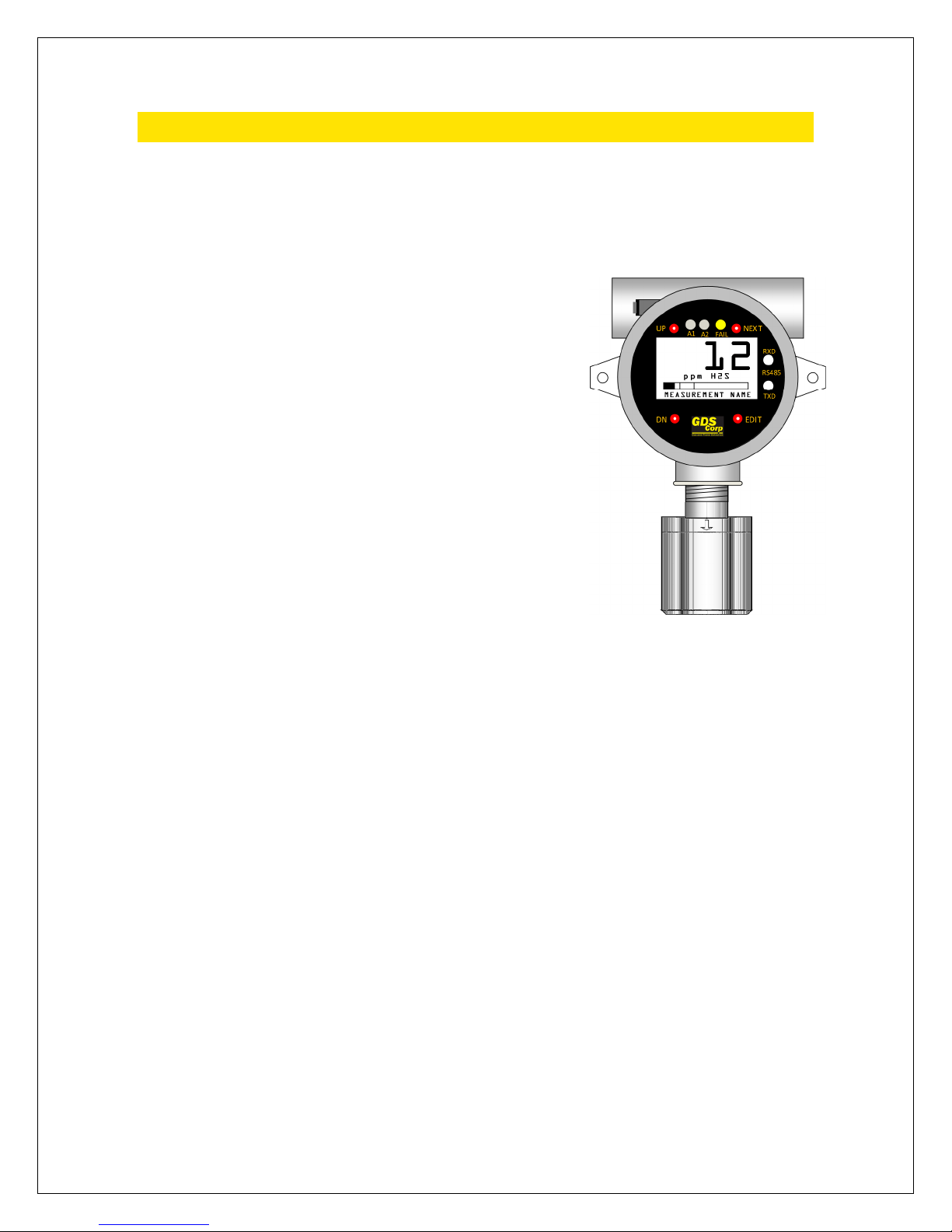

FIGU E 4-1: GASMAX EC EXPLOSION P OOF ENCLOSU E ........................................................................... 11

FIGU E 4-2: GASMAX EC EMOTE SENSO .................................................................................................. 12

FIGU E 4-3: GASMAX EC LOOP POWE WI ING .......................................................................................... 13

FIGU E 4-4: LOCAL SMA T TOXIC SENSO .................................................................................................. 14

FIGU E 4-5: GASMAX EC EMOTE SENSO WI ING .................................................................................... 15

FIGU E 4-6: GASMAX INT INSICALLY SAFE INSTALLATION .......................................................................... 16

FIGU E 4-7: GASMAX EC IS WI ING GUIDELINES ......................................................................................... 16

FIGU E 5-1: CALIB ATION SETUP ................................................................................................................. 19

FIGU E 5-2: CALIB ATION FLOWCHA T ...................................................................................................... 20

FIGU E 6-1: GASMAX EC DISPLAY SC EENS ................................................................................................. 21

FIGU E 6-2: GASMAX DATA DISPLAY SC EEN .............................................................................................. 22

FIGU E 6-3: GASMAX T END DISPLAY SC EEN ............................................................................................ 22

FIGU E 6-4: SENSO EPLACEMENT ............................................................................................................ 24

FIGU E 6-5: SMA T SENSO ECOGNITION SC EEN ................................................................................... 24

FIGU E 7-1: MAIN MENU FLOWCHA T ........................................................................................................ 26

FIGU E 7-2: SYSTEM CONFIG MENU ............................................................................................................ 27

FIGU E 7-3: SENSO LIFE T ANSMISSSION FO MAT ................................................................................... 28

FIGU E 7-4: ALA M SETTINGS MENU .......................................................................................................... 29

FIGU E 7-5: SENSO SETTINGS MENU ........................................................................................................ 30

FIGU E 7-6: CLOCK DELAY MENU ................................................................................................................. 31

FIGU E 7-7: CONT AST MENU ..................................................................................................................... 31

FIGU E 7-8: DIAGNOSTICS MENU ................................................................................................................ 32

FIGU E 7-9: SYSTEM SECU ITY MENU ......................................................................................................... 32

FIGU E 8-1: XMITTE CONFIG MENU .......................................................................................................... 33

FIGU E 8-2: TECHNICAL PAGE MENU ........................................................................................................... 34

FIGU E 8-3: SET GAIN TO UNITY MENU ....................................................................................................... 35

FIGU E 8-4: P EAMP GAIN SET MENU ......................................................................................................... 35

FIGU E 10-1: GASMAX EC + LOCAL SENSO SPA E PA TS .......................................................................... 39

FIGU E 10-2: GASMAX SENSO HEAD SPLASH GUA D & FLOW CELL ......................................................... 39

FIGU E 10-3: GASMAX EC EMOTE DI ECT SENSO HEAD ......................................................................... 40