Table of Contents

Bottom Door Seal

.............................................................................................................................................................

19

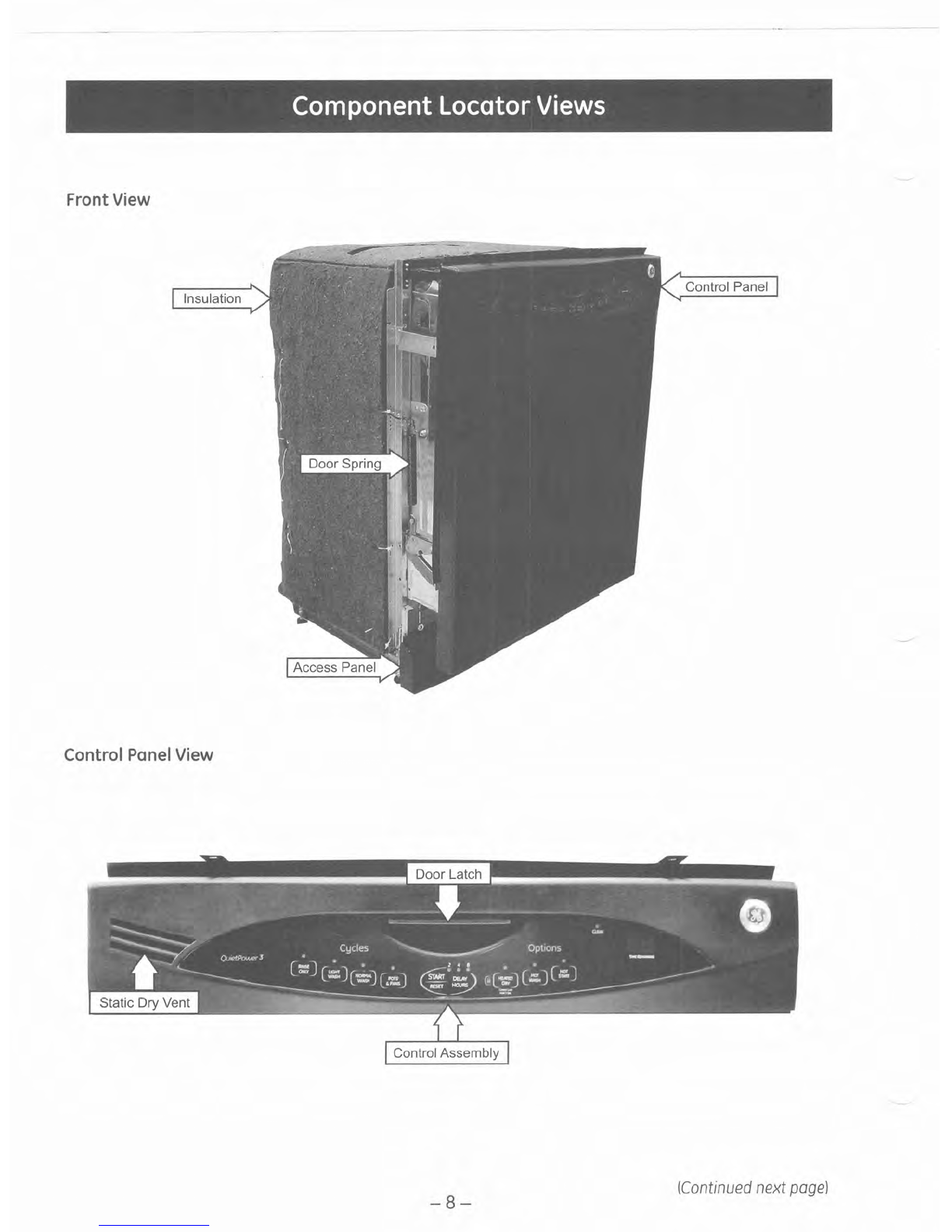

Component LocatorViews

..........................................................................................................................................

8

Control Assembly

..............................................................................................................................................................

12

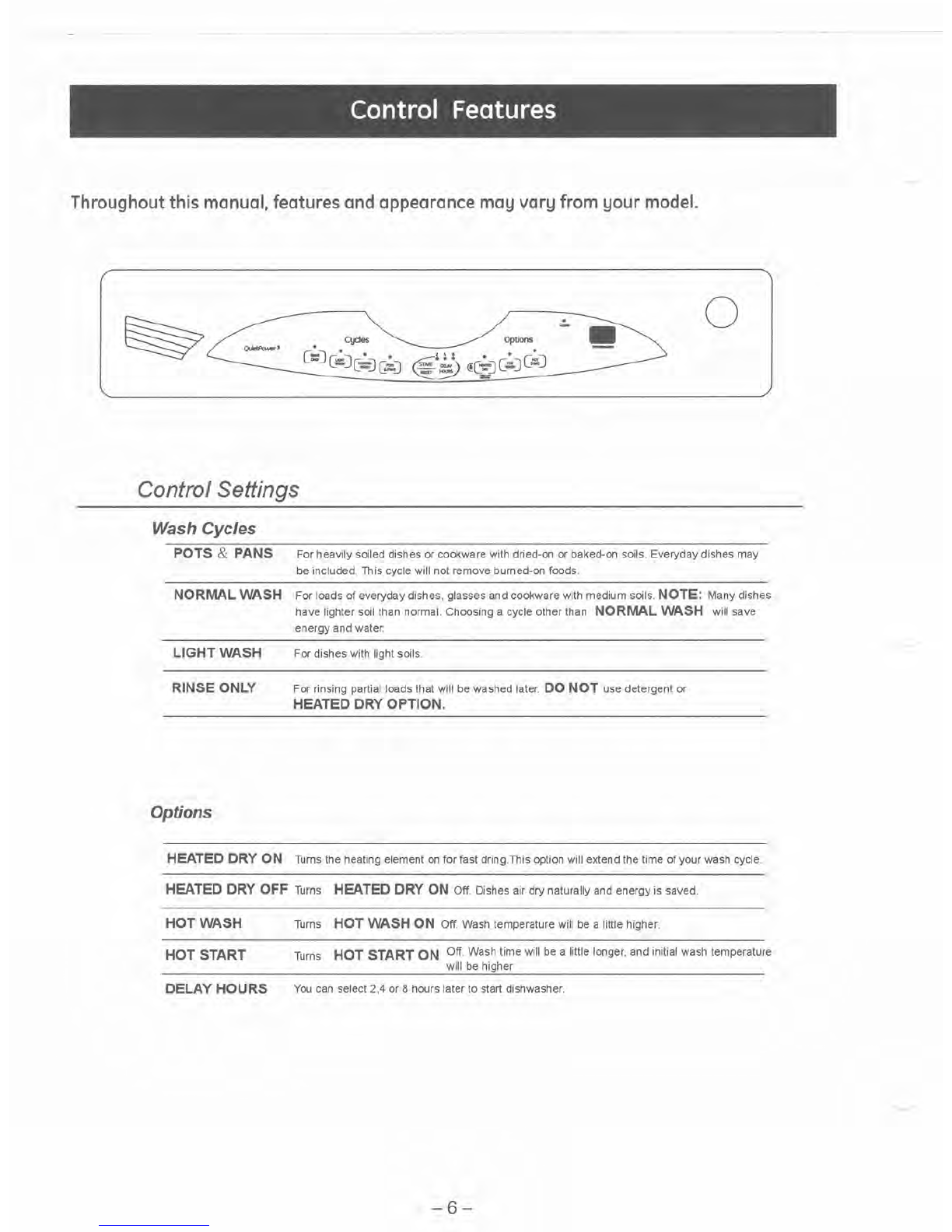

Control Features

...............................................................................................................................................................

6

Control Panel

......................................................................................................................................................................

11

~etergent/RinseModule

................................................................................................................................................

16

Diagnostics andService Information

......................................................................................................................

28

Dishwasher Components

..............................................................................................................................................

11

Door Assembly

................................................................................................................................................................

17

...........................................................................................................................

Door Latch and ReleaseAssembly 13

Door Panel

............................................................................................................................................................................

11

Door Switch Assembly

...................................................................................................................................................

15

Drain PumpAssembly

....................................................................................................................................................

24

Fill Funnel

.............................................................................................................................................................................

21

Heating Element

................................................................................................................................................................

19

Introduction

........................................................................................................................................................................

5

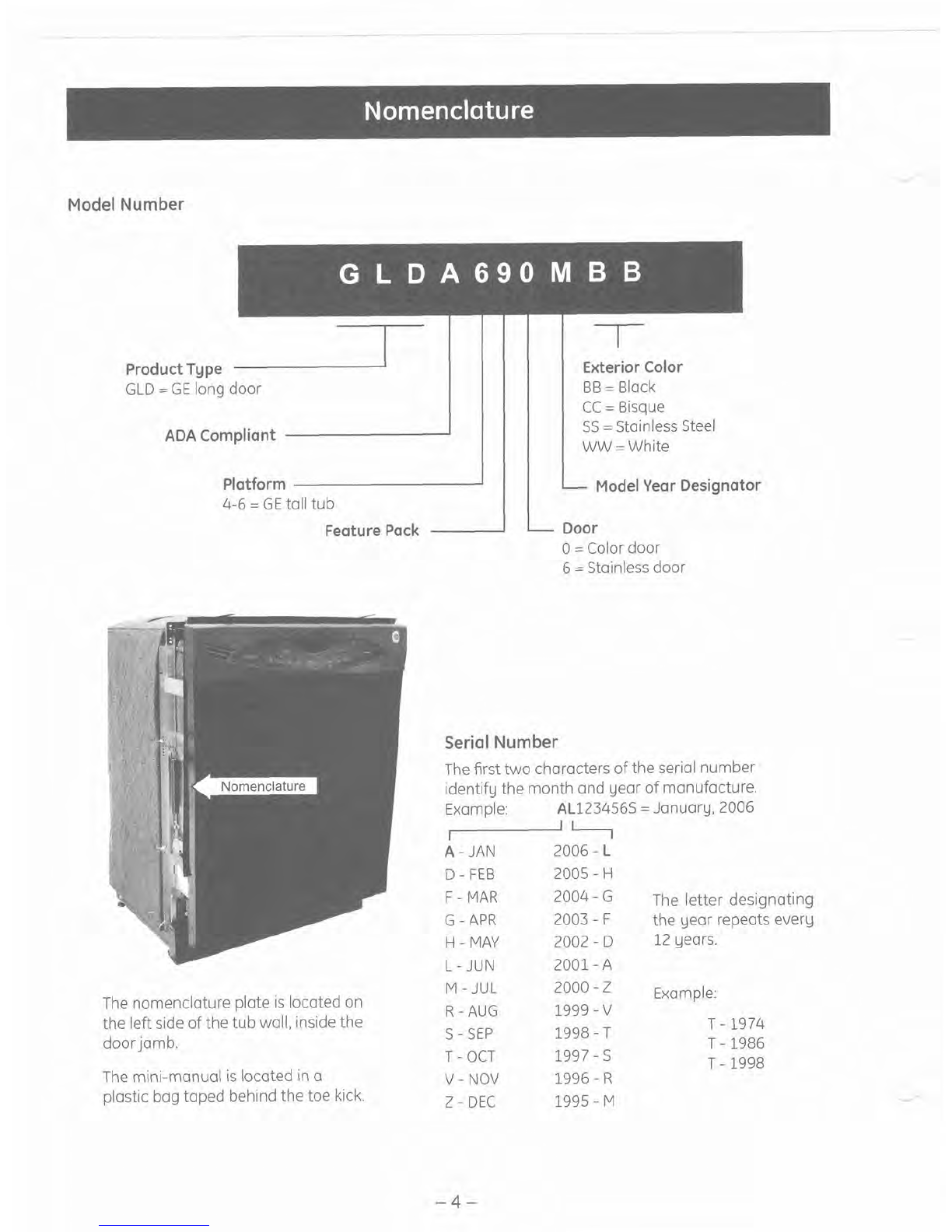

Nomenclature

...................................................................................................................................................................

4

PressureSwitch

.................................................................................................................................................................

23

Schematics andWiring Diagrams

............................................................................................................................

30

Service Test Mode

.............................................................................................................................................................

28

Specifications

.....................................................................................................................................................................

28

Static Dry System

.............................................................................................................................................................

12

Sump Assembly

.................................................................................................................................................................

27

Thermistor

............................................................................................................................................................................

26

...............................................................................................................................................................

Troubleshooting 29

Tub Seal

................................................................................................................................................................................

18

Warranty

..............................................................................................................................................................................

31

Wash Pump Assembly

..................................................................................................................................................

25

Water InletValve

..............................................................................................................................................................

22