6

5

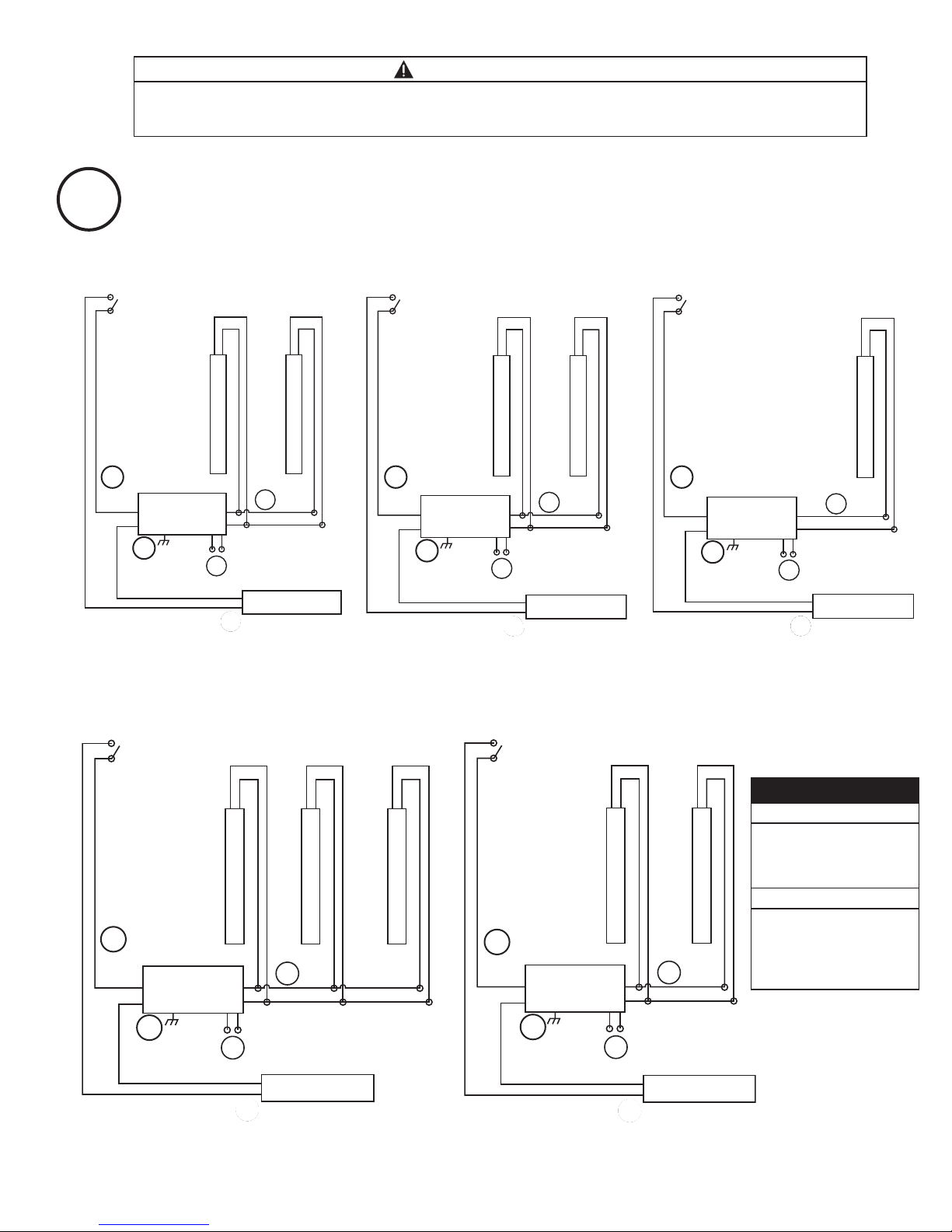

Connect LED Driver - Input

Connect LED Driver - Output

Connect Dimming Contacts – Output (Optional)

6

7

OPTION 1 – USING 3-WAY CONNECTO

Attach the supplied green/yellow ground wire from the

LED Driver to a grounded metal portion of the door frame.

Connect the original Line and neutral wires (or Line 1 and

Line 2 wires for 240 nominal VAC) to the 3-way connector

for the LED Driver input wires using the appropriate

matingconnector (Molex P/N 39-01-4030). Ensure that

the connector cavities are correctly populated per the

wire cavity table on page 5.

OPTION 2 – USING TWIST-ON WI E CONNECTO

Attach the supplied green/yellow ground wire from the

LED Driver to a grounded metal portion of the door frame.

Remove the 3-way connector from the LED Driver by cutting

the wires near the connector and strip the input wires. Using

the appropriate wiring diagram on page 5, connect the

original Line and neutral wires (or Line 1 and Line 2 wires for

240 nominal VAC) to the LED Driver leads using twist lock wire

connectors

or other connection method approved for low

temperature usage and stranded cable. Ensure that the

connector

cavities are correctly populated per wire cavity

table on page 5.

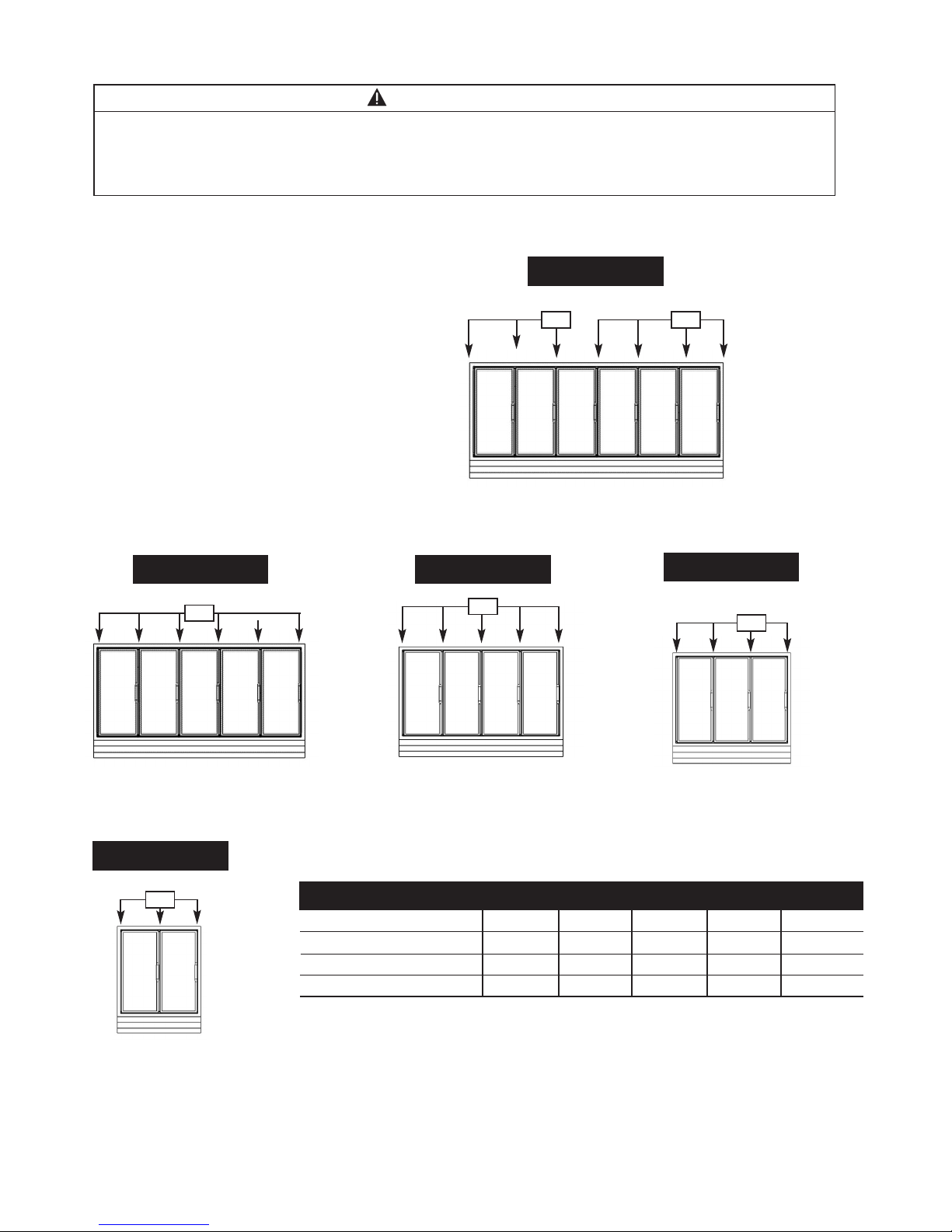

• Make input (AC) connections using one of the two options below:

• The LED Driver is required to be reliably bonded to the protective ground conductor.

• Make output (DC) connections using one of the two options below:

OPTION 1 – USING 4-WAY CONNECTO

Connect the LED Driver output leads to the LED Light leads

using the appropriate mating connector (Molex P/N 39-01-

4046). Terminals

installed should be crimped using approved

tooling and process per Molex specifications. Ensure that the

connector cavities are correctly populated per the

wire cavity table on page 5.

OPTION 2 – USING TWIST-ON WI E CONNECTO S

Remove the 4-way connector from the LED Driver by

cutting the wires near the connector and strip the output

leads. Using the appropriate wiring diagram on page 5,

connect the LED Driver output leads to the LED Light leads

using wire connectors or other connection method approved

for low temperature usage and stranded cable. (A)

For non-dimming applications, cap the unused wires with

4mm (5/32") twist on wire connectors.

OPTION 1 – USING 4-WAY CONNECTO

Connect the LED Driver dimming output leads to the

occupancy sensor or control system using the appropriate

mating connector (Molex P/N 39-01-4046). Terminals installed

should be crimped using approved tooling and process per

Molex specifications. Ensure that the connector cavities are

correctly populated per the wire cavity table on page 5.

(D)

OPTION 2 – USING TWIST-ON WI E CONNECTO S

Remove the 4-way connector from the LED Driver by

cutting the wires near the connector and strip the output

leads. Using the appropriate wiring diagram on page 5,

connect the LED Driver dimming output leads to the

occupancy sensor or control system using wire connectors

or other connection method approved for low temperature

usage and stranded cable. (D)

• To enable dimming operation, connect leads from occupancy sensor or control system (normally open contact) to the purple

and gray leads of the power supply.

• Make output (contact closure) connections using one of the two options below:

• The LED Driver is capable of step dimming from 100% power to 20% power when used with a normally

open contact closure

occupancy sensor system.

• When using the LED drivers for non-dimming applications, the dip switch setting must be set to #1 ON to

disable the dimming feature and achieve 100% illumination.

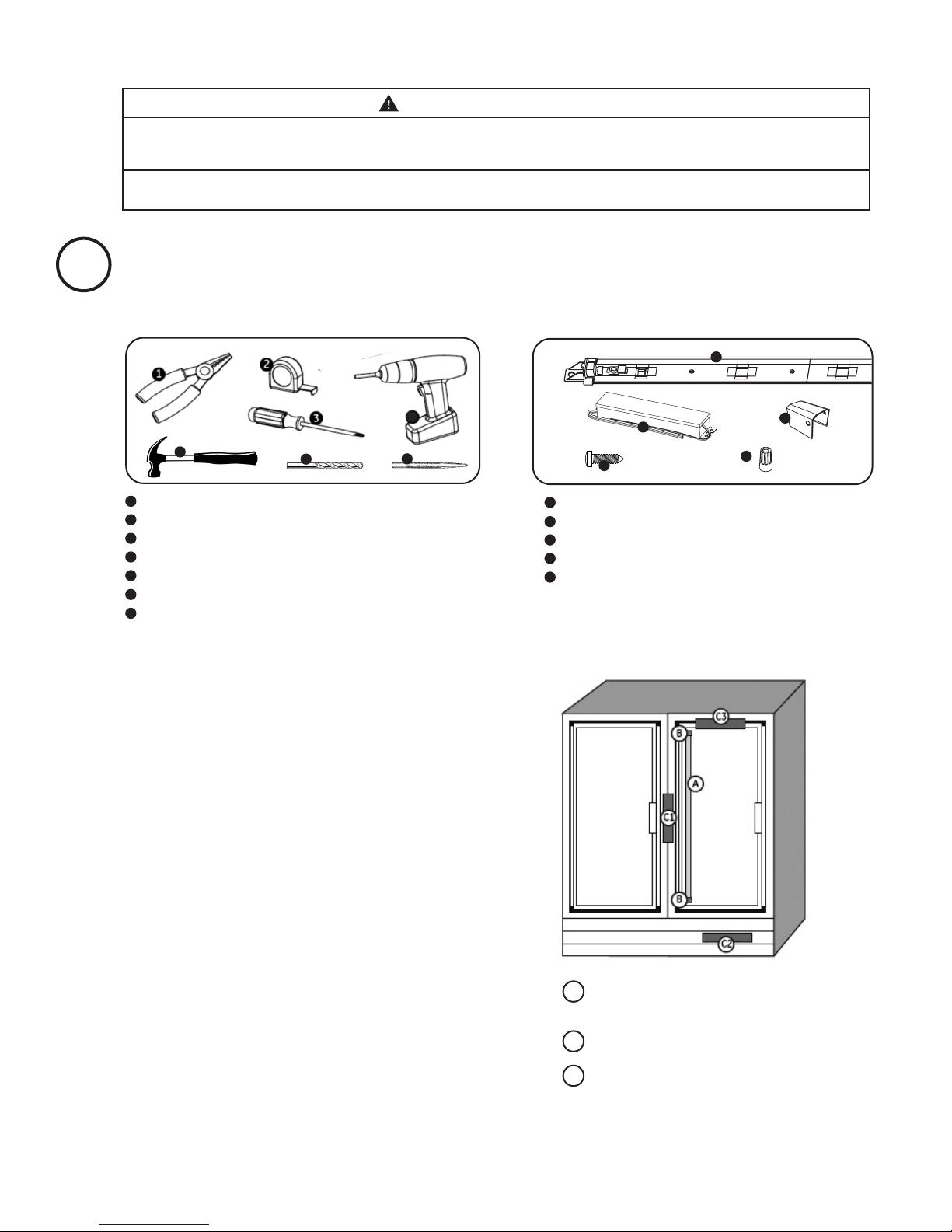

AA

C

D

B

C

D