Wolf ATEX Turbolite – A-TL44C and A-TL45C

Operation and Maintenance Instructions

Please Retain - Read Before Use

EU Declaration of Conformity

The Wolf ATEX Turbolites A-TL44C and A-TL45C meet

all relevant provisions of the 2014/34/EU Explosive

Atmospheres (ATEX Equipment) Directive by virtue

of the issued EU type examination certicate,

demonstrating compliance with all relevant

harmonised standards and essential health and safety

requirements.

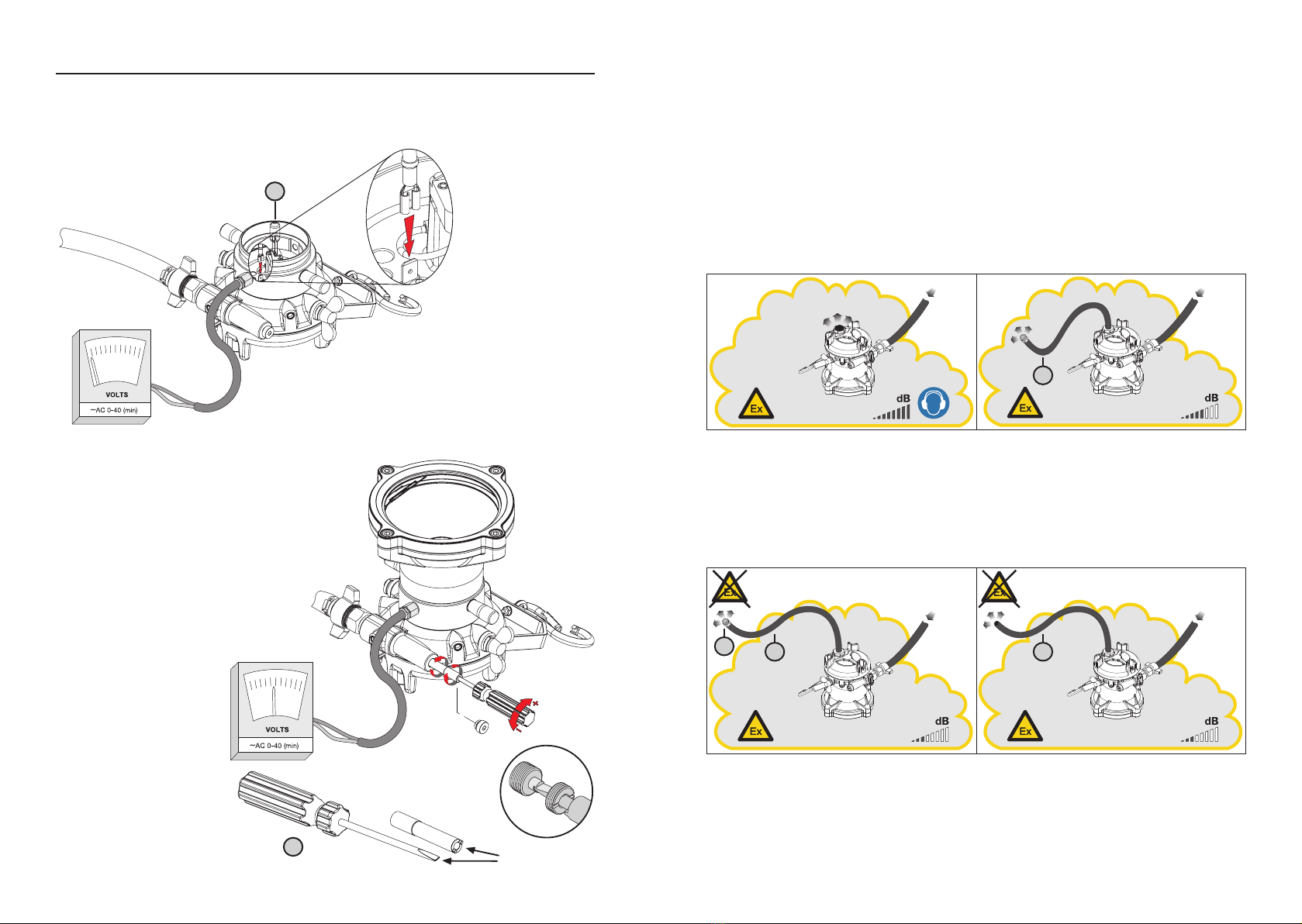

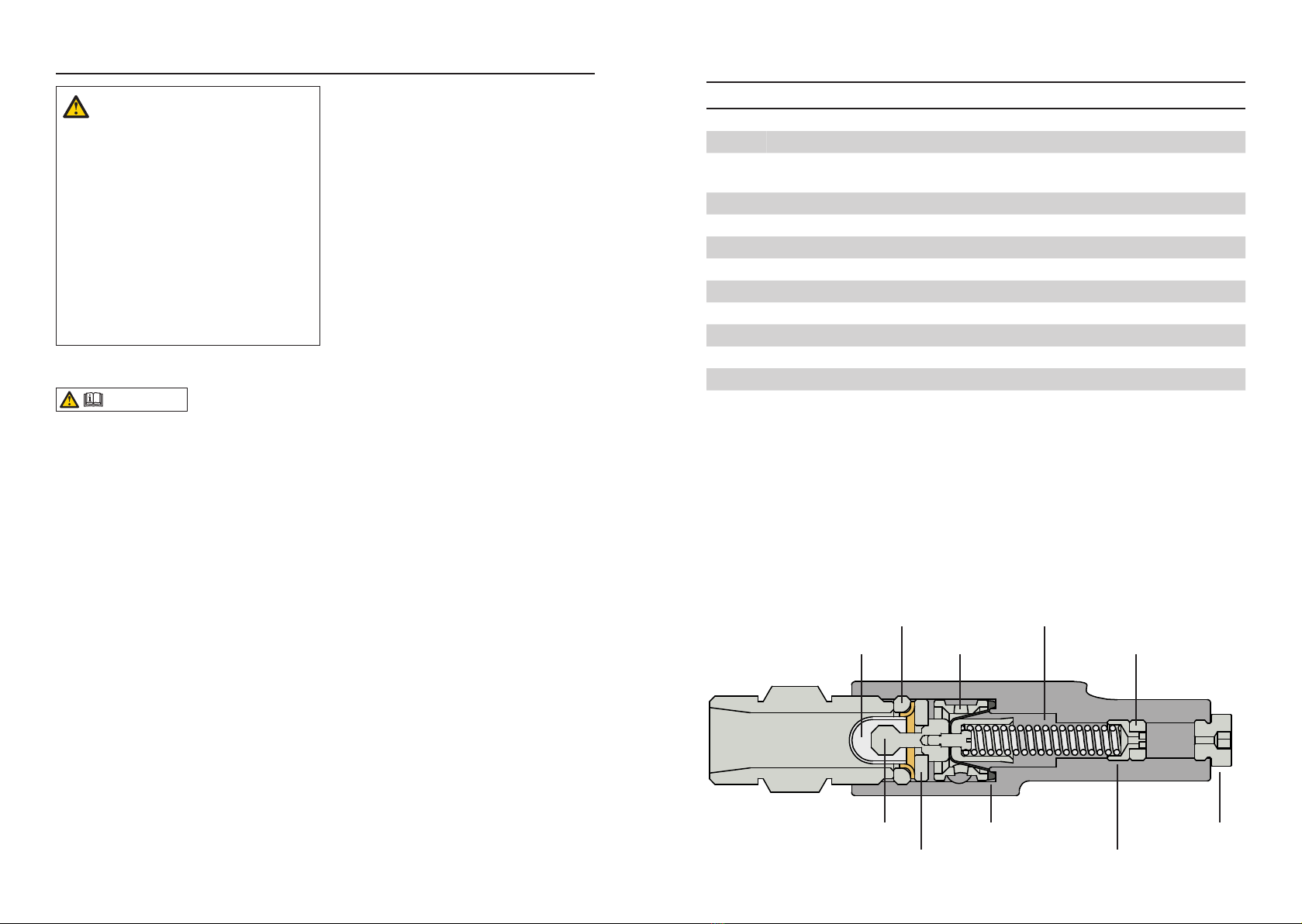

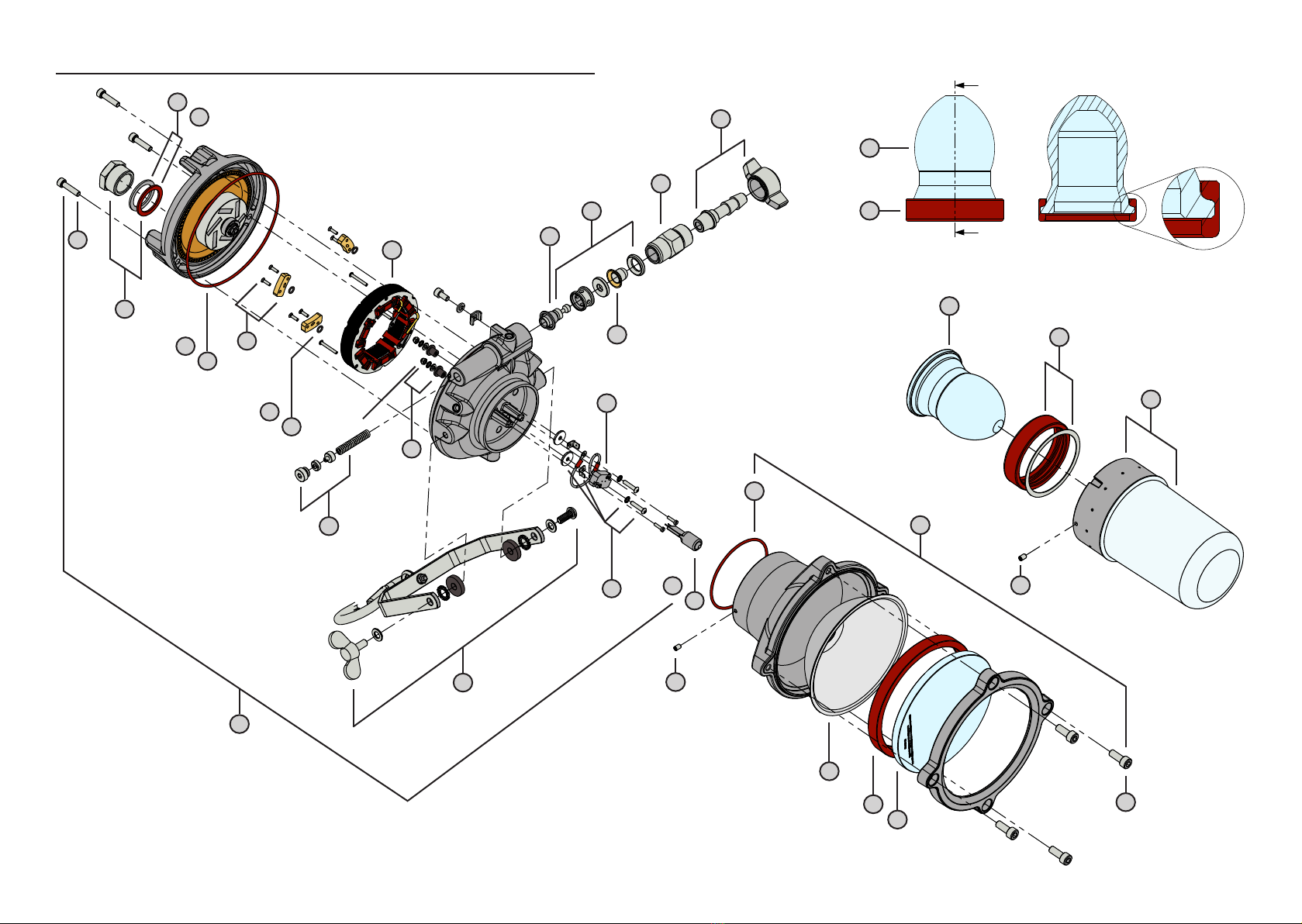

The Wolf ATEX Turbolite is powered with compressed

air that, once regulated, drives the turbine wheel

tted to the shaft. The magnet, also tted to the shaft,

rotates within windings, generating electricity and

powering a 24v 250watt tungsten halogen bulb. The

A-TL44C Baylight provides all round illumination; the

A-TL45C Floodlight gives directional illumination. Both

A-TL44C and A-TL45C models are constructed from

nickel plated aluminium.

The Wolf ATEX Turbolite is approved as Group II,

Category 2 equipment for use in zone 1, 2, 21 & 22

potentially explosive gases, vapours, mists and dusts

where the T4 temperature class/135°C maximum

surface temperature permits. Note, additional

accessories are required for use in zone 21 & 22.

Certication/Approval Codes:

Ex sb IIC T4 Gb

Ex sb IIIC T135ºC Db (refer to special conditions for safe use)

A-TL44C Ta = -15°C to +55°C

A-TL45C Ta = -20°C to +55°C

EU Type examination certicate: CML 22ATEX9542X

Notied Body:

Notied Body Number: 0598

Harmonised standard: EN IEC 60079-0:2018 and

applied standard IEC 60079-33:2012

Ingress protection level:

IP66 (when running) to EN60529:1992.

IP40 (when not running, keep protected from ingress of

water/dust).

The Wolf ATEX Turbolite is compliant with the

2011/65/EU RoHS Directive to the harmonised standard

EN IEC 63000:2018.

This declaration is issued under the sole responsibility

of Wolf Safety Lamp Company.

Alex Jackson – Managing Director,

Wolf Safety Lamp Company Ltd.,

Shefeld, S8 0YA.

Dated: 01 December 2023

II 2 G D

SGS FIMKO OY, PO Box 30 (Särkiniementie 3),

00211, Helsinki, Finland. IECEx Scheme Certification

Certicate Number: IECEx CML 22.0083X

Ex sb IIC T4 Gb

Ex sb IIIC T135ºC Db (refer to special conditions for safe use)

A-TL44C Ta = -15°C to +55°C

A-TL45C Ta = -20°C to +55°C

Ingress protection level:

IP66 (when running) to EN60529:1992

IP40 (when not running, keep protected from ingress of water/dust)

IEC Standards applied: IEC60079-0:2017, IEC60079-33:2012

IMPORTANT: SPECIAL CONDITIONS FOR SAFE USE (X)

1. This equipment shall only be supplied with air from

a clean, dry source that is free from contamination with

hazardous gas, dust or bres.

2. When this equipment is used in the presence of

combustible dust, the air outlet shall be tted with

additional hose so that it is piped to a safe area instead of

venting into the hazardous area.

3. The hoses that are tted to this equipment shall be

anti-static with a resistance between 104 Ω and 108 Ω.

UK Declaration of Conformity

The Wolf ATEX Turbolites A-TL44C and A-TL45C meet

all the statutory requirements of the Equipment and

Protective Systems Intended for Use in Potentially

Explosive Atmospheres Regulations 2016, UKSI 2016/1107

as amended by UKSI 2019/696 by virtue of the issued

UKEX type examination certicate, demonstrating

compliance with all relevant designated standards and

essential health and safety requirements.

Certication/Approval Code:

Ex sb IIC T4 Gb

Ex sb IIIC T135ºC Db (refer to special conditions for safe use)

A-TL44C Ta = -15°C to +55°C

A-TL45C Ta = -20°C to +55°C

UK Type examination certicate: CML 22UKEX9543X

Approved Body:

Approval body number: 1180

Designated standard: EN IEC 60079-0:2018 and applied

standard IEC 60079-33:2012.

The Wolf ATEX Turbolite is compliant with the Restriction

of the Use of Certain Hazardous Substances in Electrical

and Electronic Equipment Regulations 2012, UKSI

2012/3032 to the harmonised standard EN IEC 63000:2018.

This declaration is issued under the sole responsibility of

Wolf Safety Lamp Company.

Alex Jackson – Managing Director,

Wolf Safety Lamp Company Ltd.,

Shefeld, S8 0YA.

Dated: 01 December 2023

SGS Baseefa Ltd, Rockhead Business Park,

Staden Lane, Buxton, SK17 9RZ, UK.

II 2 G D

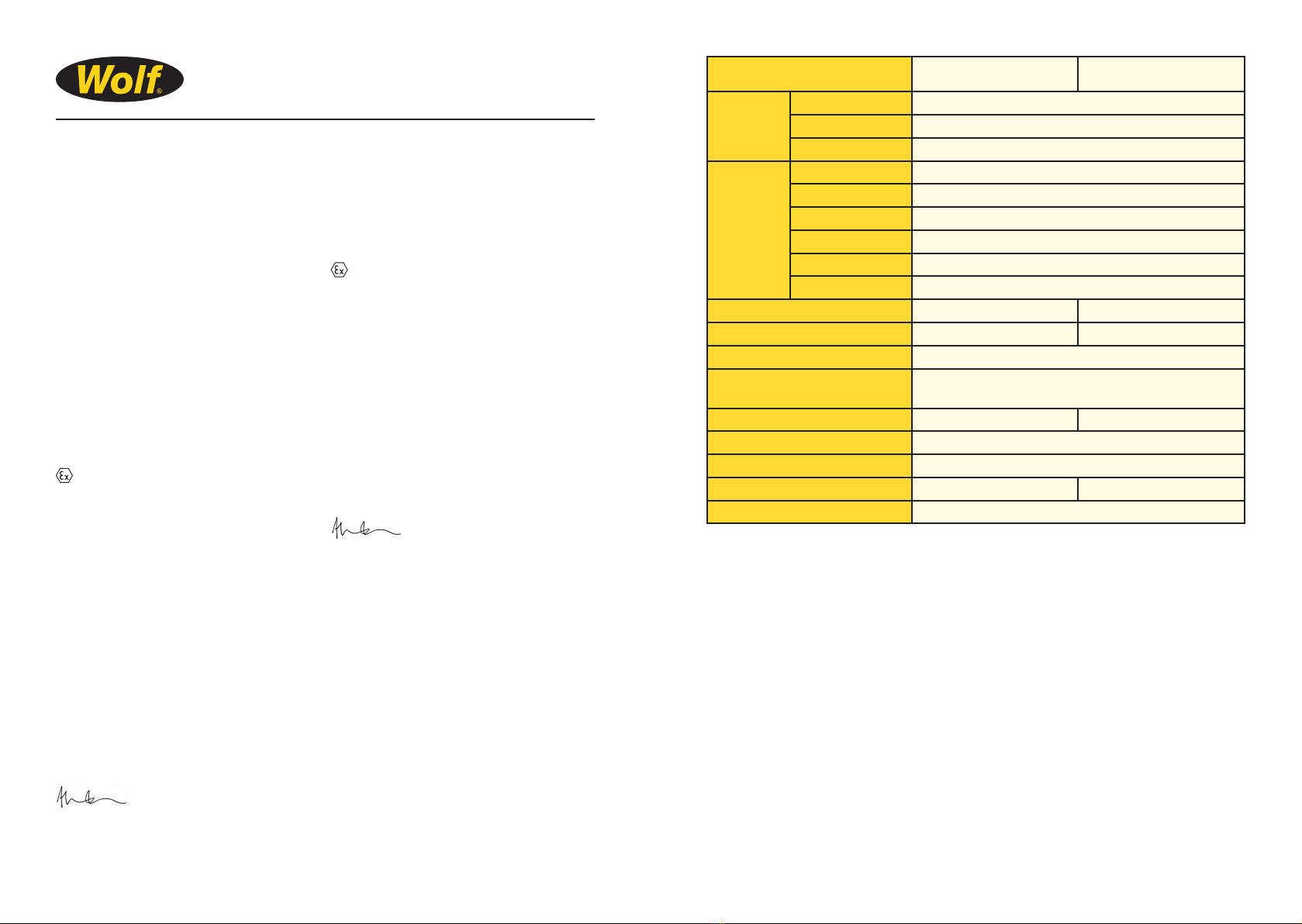

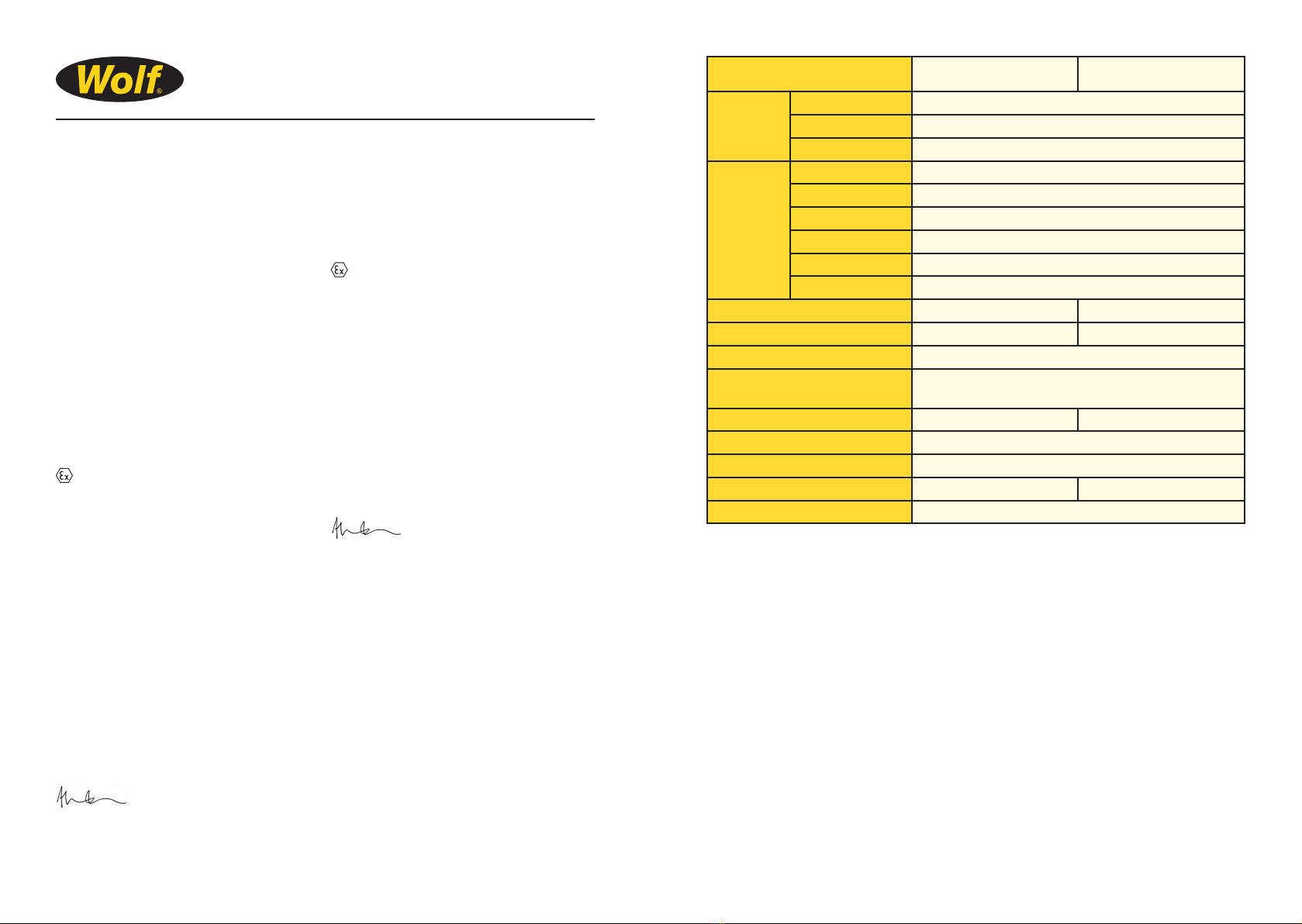

1 10

TECHNICAL DATA A-TL44C A-TL45C

Power Source Type Compressed Air Driven Turbo-Alternator Generator

Input Pressure Range 5-8 Bar

Consumption 0.75m³ / min.

Light Source Part Number A-129 (6,000lm, supplied as standard) / A-159 (9,000lm, alternative)

Type Halogen Filled Filament Bulb

Voltage 24V

Wattage 250W

Lumen Output 6,000lm / 9,000lm

Life 2,000hrs / 200hrs

Beam Type 360° Illumination 25° Flood

Lens Lens Ball Glass / Plastic Dome Toughened Glass

Enclosure Nickel Plated Aluminium

Ingress Protection IP66 when running*

IP40 when not running

Weight 4.4kg 5.3kg

Gas Temperature Class T4

Dust Surface Temperature T135°C

Lower Ambient Temp Limit -15°C -20°C

Upper Ambient Temp Limit 55°C

Wolf Safety Lamp Co. reserves the right to change technical specications without prior notice.

*Once pressurised, lamp may be used underwater. When using under water always start lamp

before submersing and ensure lamp is running until removed from water. Remote exhaust can be

used above water surface to eliminate bubbles. Depth of use limitations to be considered regarding

water pressure.

Disposal of Waste Material:

Disposal of packaging, parts and end of life products should be carried out in accordance with

applicable regulations.

The Wolf Safety Lamp Co. Ltd has a policy of continuous product improvement. Changes in design

details may be made without prior notice. Prices and design are subject to alteration without

notice. All products sold are subject to our conditions of sale. A copy of these instructions with any

relevant revisions can be found at www.wolfsafety.com.