GE AIR 116 IN User manual

Other GE Air Conditioner manuals

GE

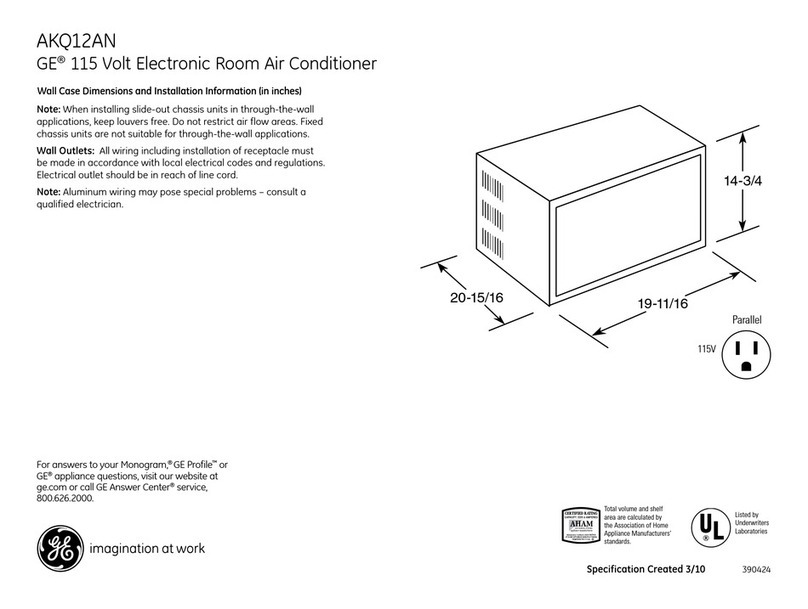

GE AKQ12AN User instructions

GE

GE Appliances AEW24 Operating instructions

GE

GE AKQ12DNT1 Operating instructions

GE

GE ASH124CRDWA User manual

GE

GE APWA12 Operating instructions

GE

GE AHH06 Operating instructions

GE

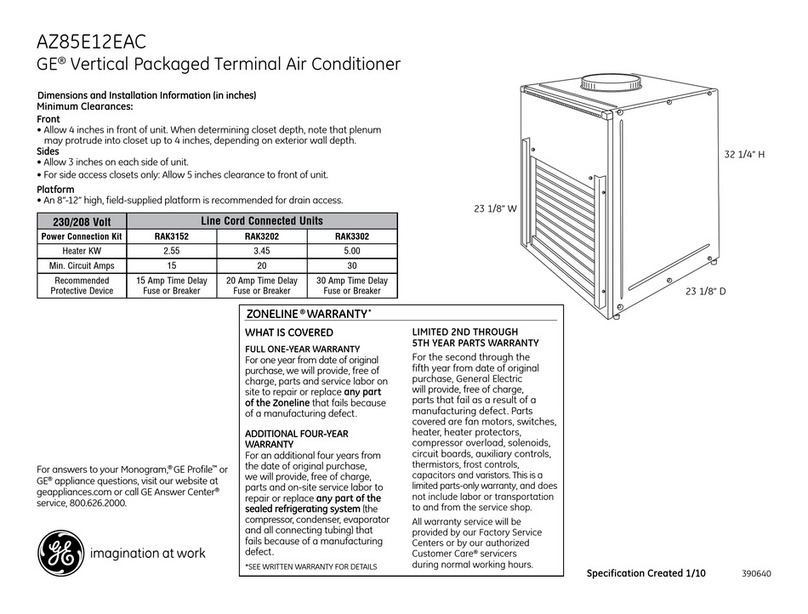

GE Zoneline AZ85E12EAC Manual

GE

GE AGE07 Operating instructions

GE

GE AEN10 Series Operating instructions

GE

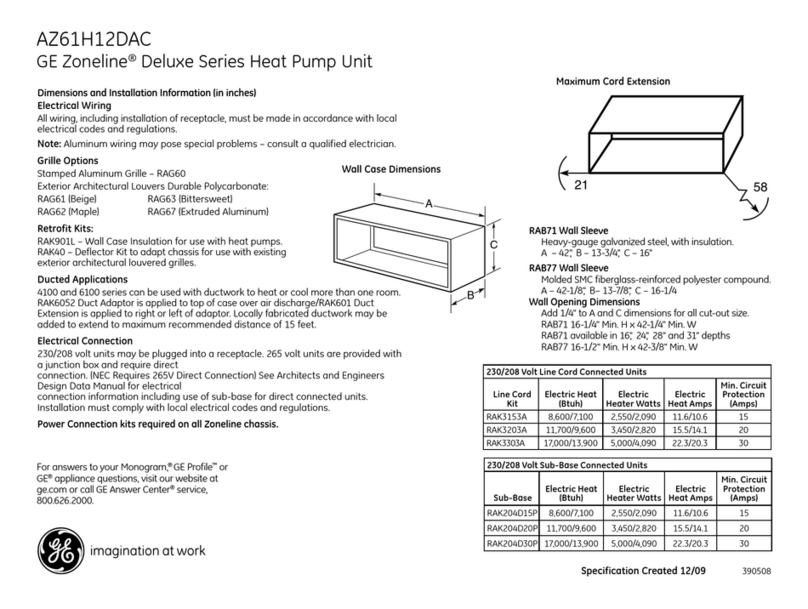

GE Zoneline AZ61H12DAC User instructions

GE

GE Appliances AKQ24DNT1 Original instructions

GE

GE Zoneline AZR Series User manual

GE

GE Zoneline 2500 Operating instructions

GE

GE AEL05LV Operating instructions

GE

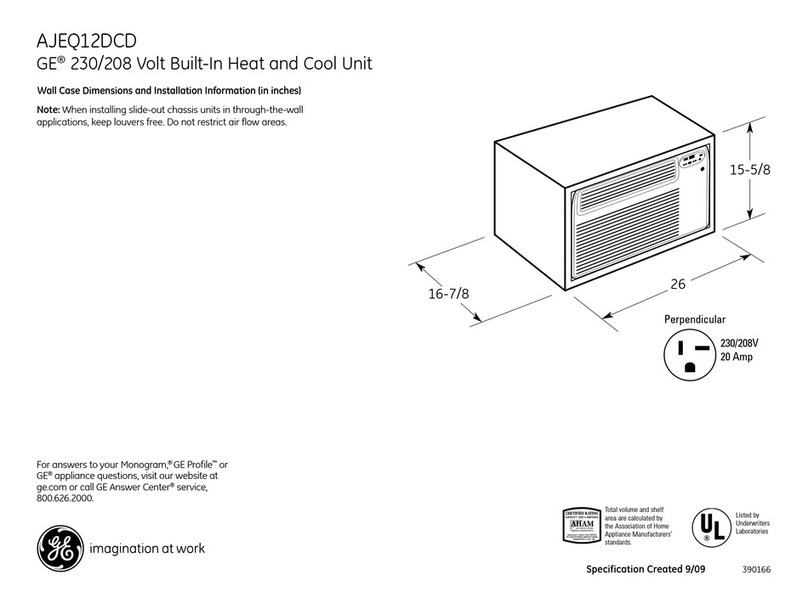

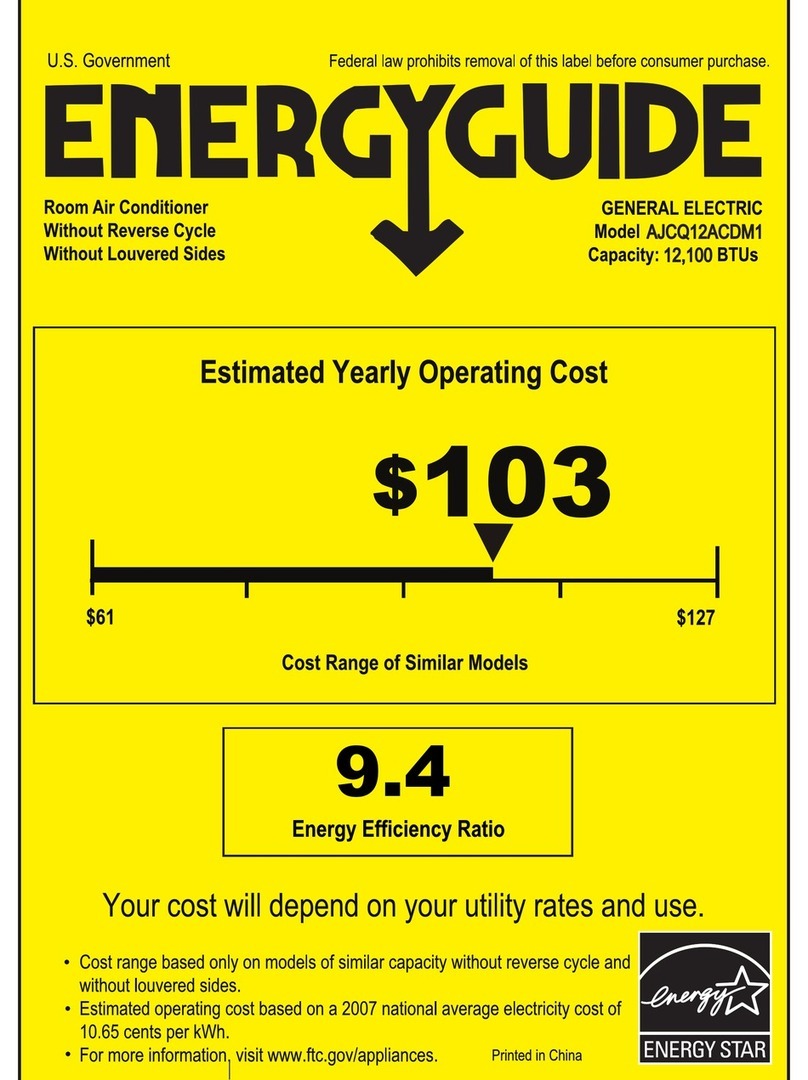

GE AJCQ12ACD Assembly instructions

GE

GE AVM18 Installation instructions

GE

GE AJEH12DC Operating instructions

GE

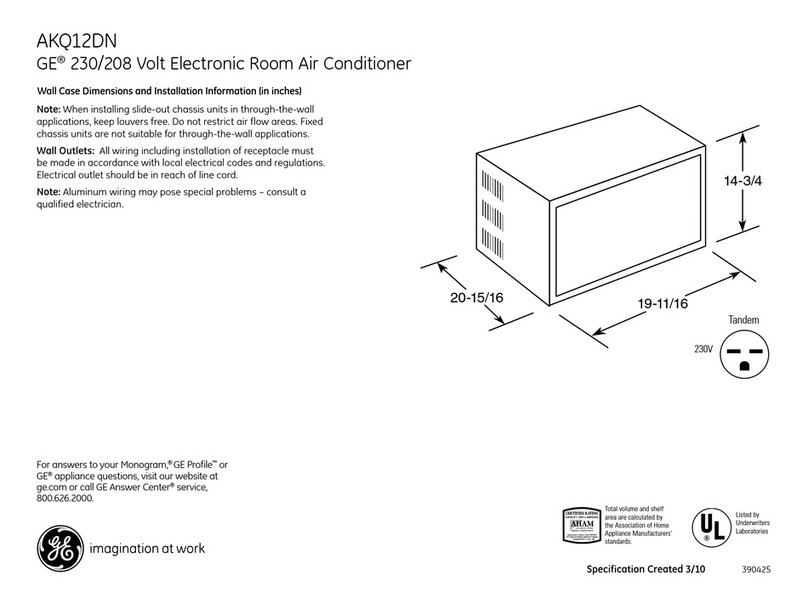

GE AKQ12DN User instructions

GE

GE Appliances AEE08 Operating instructions

GE

GE AHS14 Original instructions

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions