– 8 –

Features and Benefits

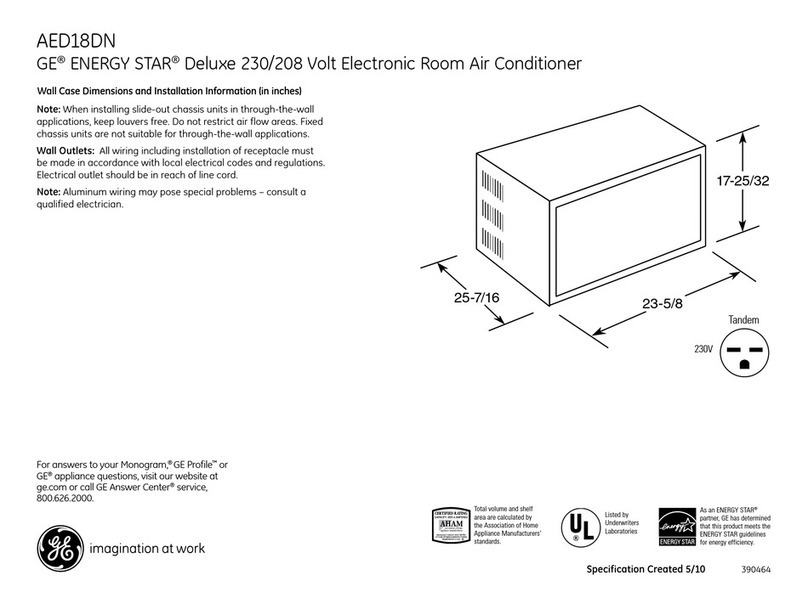

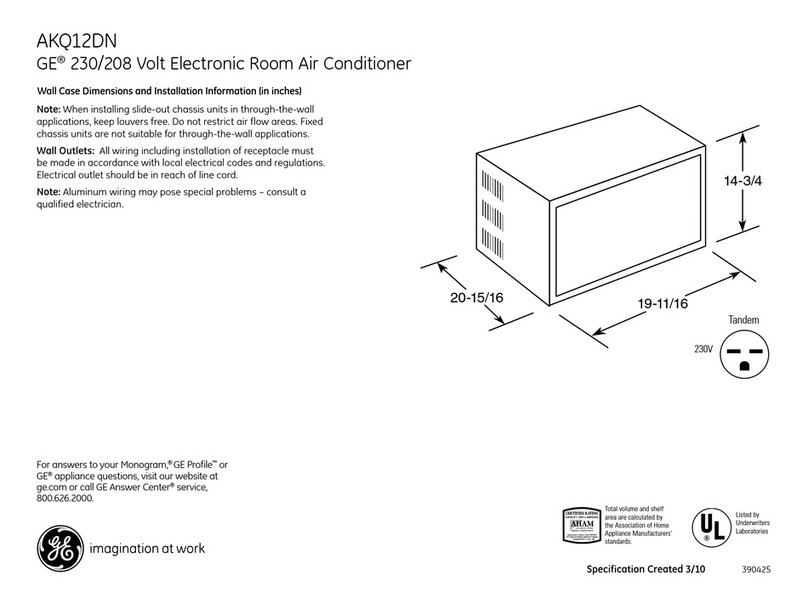

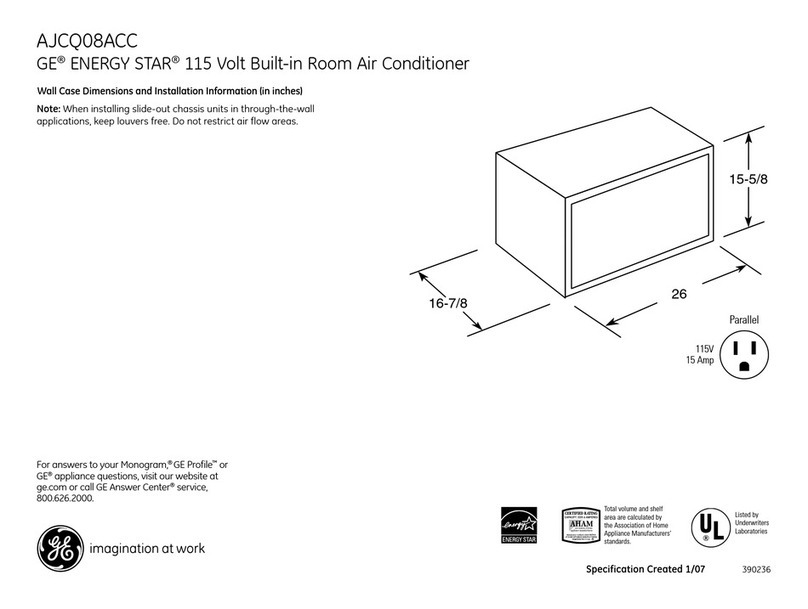

Standard Physical Dimensions

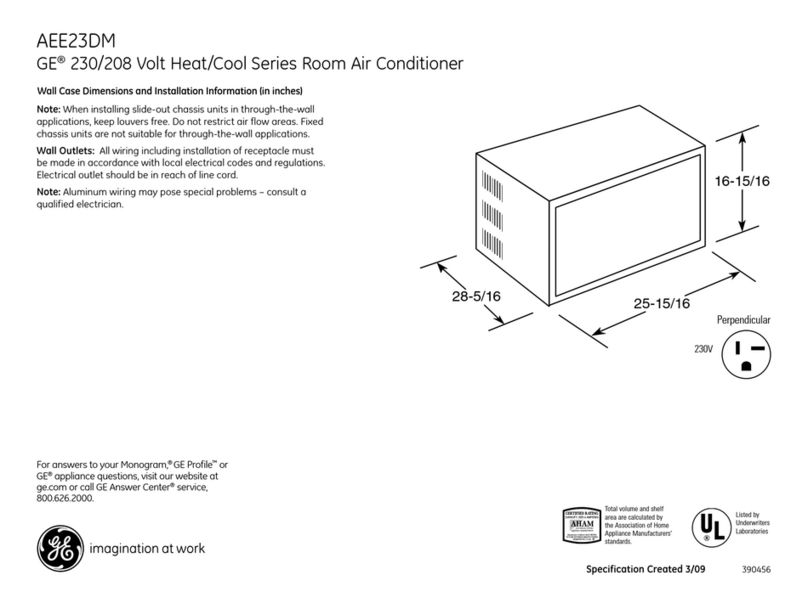

GE has maintained the same dimensions for

Zoneline air conditioners since 1961– 42 inches wide

x 16 inches high x 13 3/4inches deep. Replacement

of older units is made easy.

Weather-Protected Electrical Components

Vital electrical components are protected from the

weather by locating them on the indoor side of the

weather barrier.

Weather-Resistant Super Seal

Properly installed unit in a non-distorted case keeps

air leakage to a minimum. 7 CFM air infiltration with

25 MPH wind on non-Internal Condensate Removal

(ICR) units – 10 CFM on units with ICR. Industry

specification is 19 CFM of air infiltration.

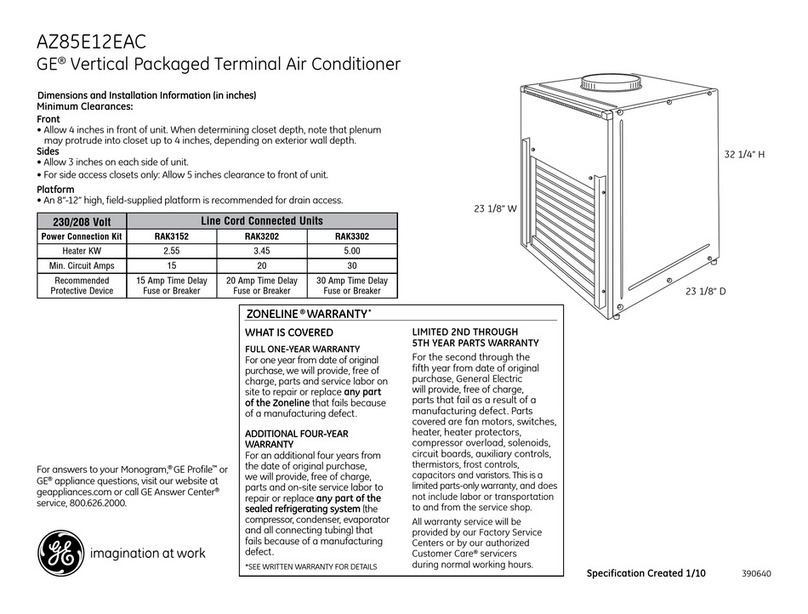

Heater Sizes to Meet Room Requirements

All units are equipped with a universal heater. The

resistance heat output is determined by a power

connection kit.

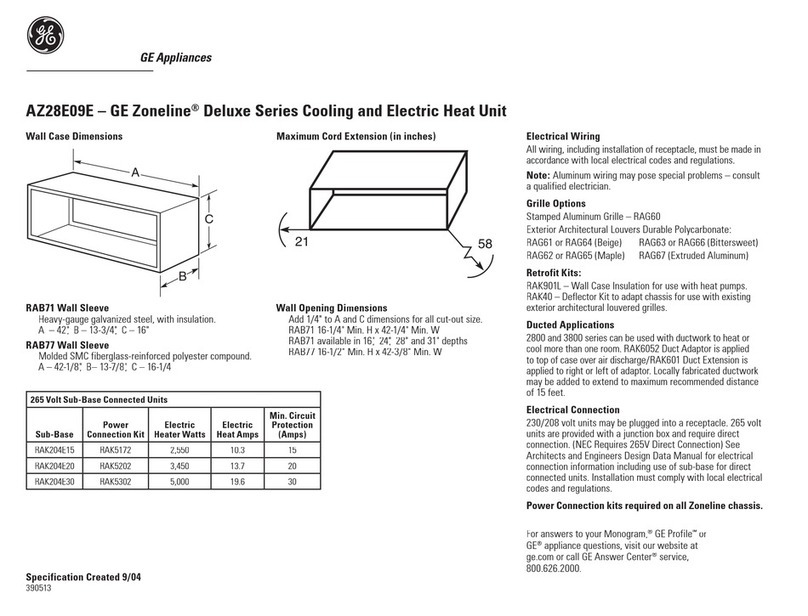

230/208-Volt - Line Cord Connected Units

2.55/2.09 KW with RAK3153 - 15-amp circuit

3.45/2.82 KW with RAK3203 – 20-amp circuit

5.0/4.09 KW with RAK3303 – 30-amp circuit

230/208-Volt - Sub-Base Connected Units

2.55/2.09 KW with RAK204D15P – 15-amp

circuit

3.45/2.82 KW with RAK204D20P – 20-amp

circuit

5.0/4.09 KW with RAK204D30P – 30-amp circuit

265-Volt

2.55 KW with RAK5172 – 15-amp circuit

3.45 KW with RAK5202 – 20-amp circuit

5.0 KW with RAK5302 – 30-amp circuit

Unit Controls

The 2800 and 3800 Series have locked-in-place

rotary knobs for temperature and operation

selection.

Highly Featured Microprocessor Controls

The microprocessor controls are programmed to

interface with the temperature sensors to maximize

comfort conditions for the room occupant and

provide outstanding features. Thermistors are used

to sense small changes in temperature to give

excellent room control and allow the microprocessor

to monitor and react to changing conditions.

•

•

•

•

•

•

•

•

•

Electric Resistance Heat Lock-Out

To maximize the savings of the heat pump

operation, the Zoneline heat pumps do not

utilize the resistance heater when the outdoor

temperature is above 46°F during normal operation.

The resistance heat is used in the Quick Heat

Recovery feature.

Automatic Emergency Heat

Automatically uses electric resistance heat if the

heat pump output is not sufficient to maintain

selected room temperature.

Reverse Cycle Heat Pump Defrost System

Standard on all Zoneline 3800 Series heat

pumps. Enables heat pump to operate at lower

temperatures when other systems switch to more

expensive electric resistance heat.

High Temperature Heat Pump Operation

Protection

Automatically protects the compressor if heat pump

is operated with high outdoor temperatures. The

power to the outdoor fan is turned off if the indoor

coil gets too hot during heat pump operation to

prevent damage to the compressor.

Quick Heat Recovery – Heat Pump Units

When the unit operation is changed from STOP or

COOL to HEAT, the electric resistance heaters are

used to warm the room to the thermostat set point.

This provides a faster room temperature increase

for greater guest comfort.

Fan Motors – Permanently Lubricated

All units have two fan motors for quiet operation

and maximum operating efficiency. Motors are

permanently lubricated to reduce the need for

maintenance, and totally enclosed to keep dirt and

water out of the motor windings.

2-Speed Outdoor Fan

The unit automatically selects the most efficient

speed for the outdoor fan. The operating sound

level is lower when the outdoor fan can operate in

low speed, yet there are situations where it must

operate in high speed. The unit changes the fan

speed automatically.

Indoor Fan Speed Selections – HIGH/LOW

Unit may be operated in HIGH HEAT or LOW HEAT or

HIGH COOL or LOW COOL.

Fan-Only Setting – HIGH/LOW

The unit provides the option of selecting either HIGH

or LOW speed for fan-only operation.