– 4 –

Front Control Console.........................................................................................................................................................31

Front Control UI, Light Pipe and Buttons...........................................................................................................32

Pocket Handle (Front Control Only)......................................................................................................................32

Top Control Panel, UI, Light Pipe and Buttons.........................................................................................................32

Top Control Console Cover.......................................................................................................................................34

Outer Door Panel...................................................................................................................................................................34

Hinges........................................................................................................................................................................................34

Inner Door Panel...................................................................................................................................................................35

Door Strike................................................................................................................................................................................35

Door Gasket.............................................................................................................................................................................35

Vent Parts.................................................................................................................................................................................36

Power Dry System Removal...............................................................................................................................................36

Detergent Dispenser...........................................................................................................................................................37

Floor Protect Pan...................................................................................................................................................................38

Sump Module..........................................................................................................................................................................40

Sump Gasket ..........................................................................................................................................................................42

Installing Sump Module.....................................................................................................................................................42

Electronic Controls..........................................................................................................................................................................43

Consumer Error Mode.........................................................................................................................................................43

Service Mode...........................................................................................................................................................................44

Diagnosing Electronic Control Boards........................................................................................................................44

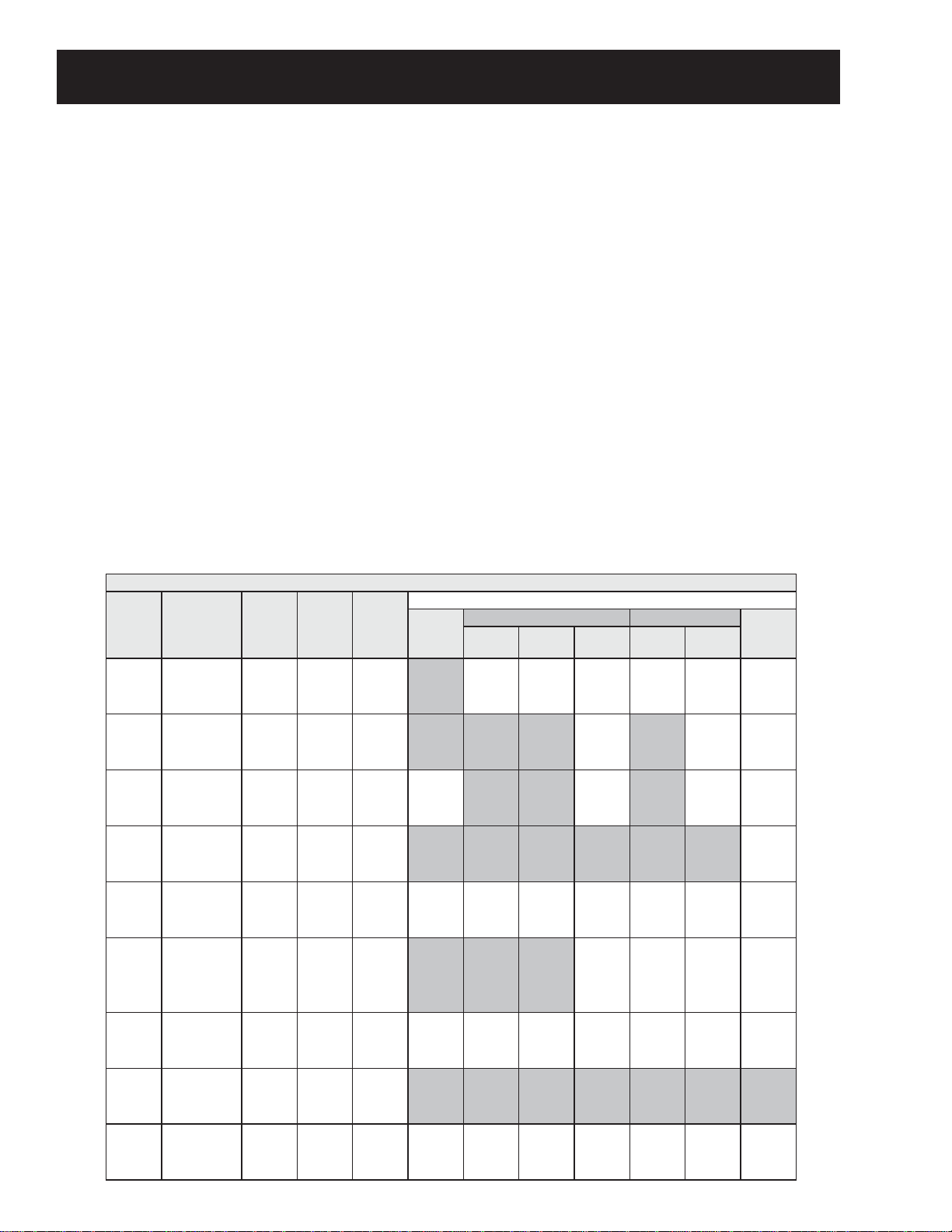

Main Control Diagnostics..................................................................................................................................................45

On the Main Control Board CSM....................................................................................................................................46

UI Diagnostics.........................................................................................................................................................................48

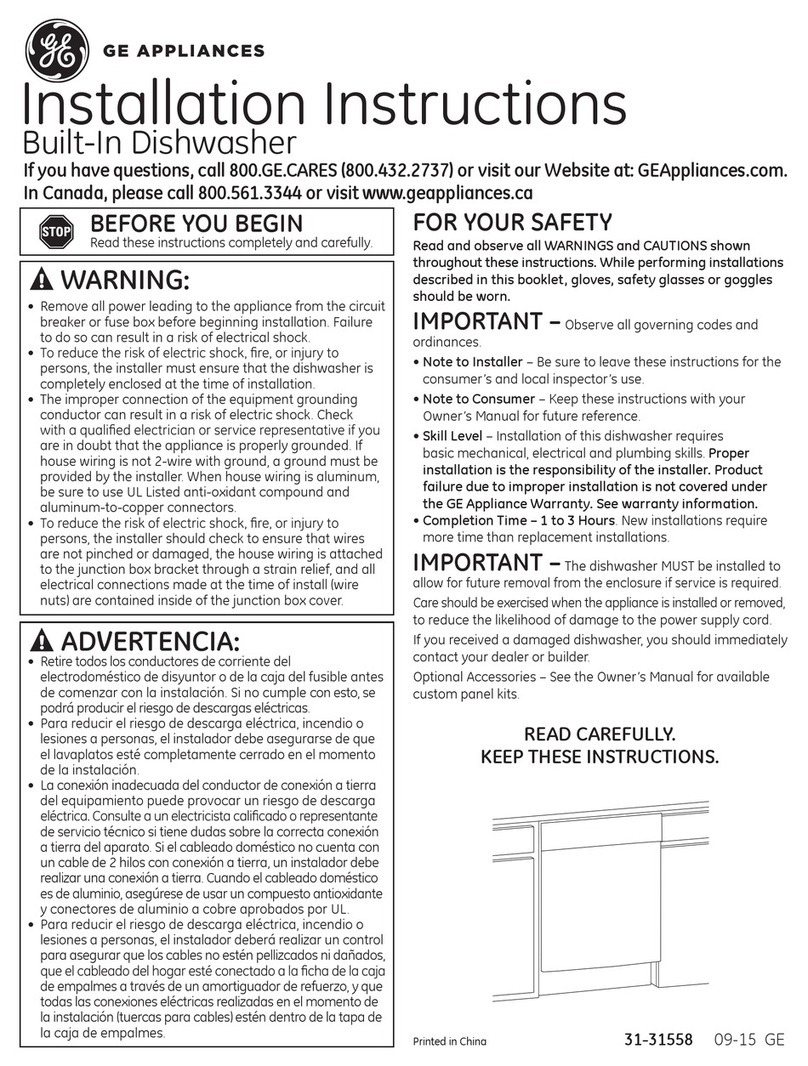

Fill System...........................................................................................................................................................................................49

Water Level..............................................................................................................................................................................49

Diagnostics..............................................................................................................................................................................50

Flood Float and Switch.......................................................................................................................................................51

Fill Funnel and Hose ...........................................................................................................................................................51

Fill Valve.....................................................................................................................................................................................52

Circulation System..........................................................................................................................................................................53

Diagnostics..............................................................................................................................................................................54