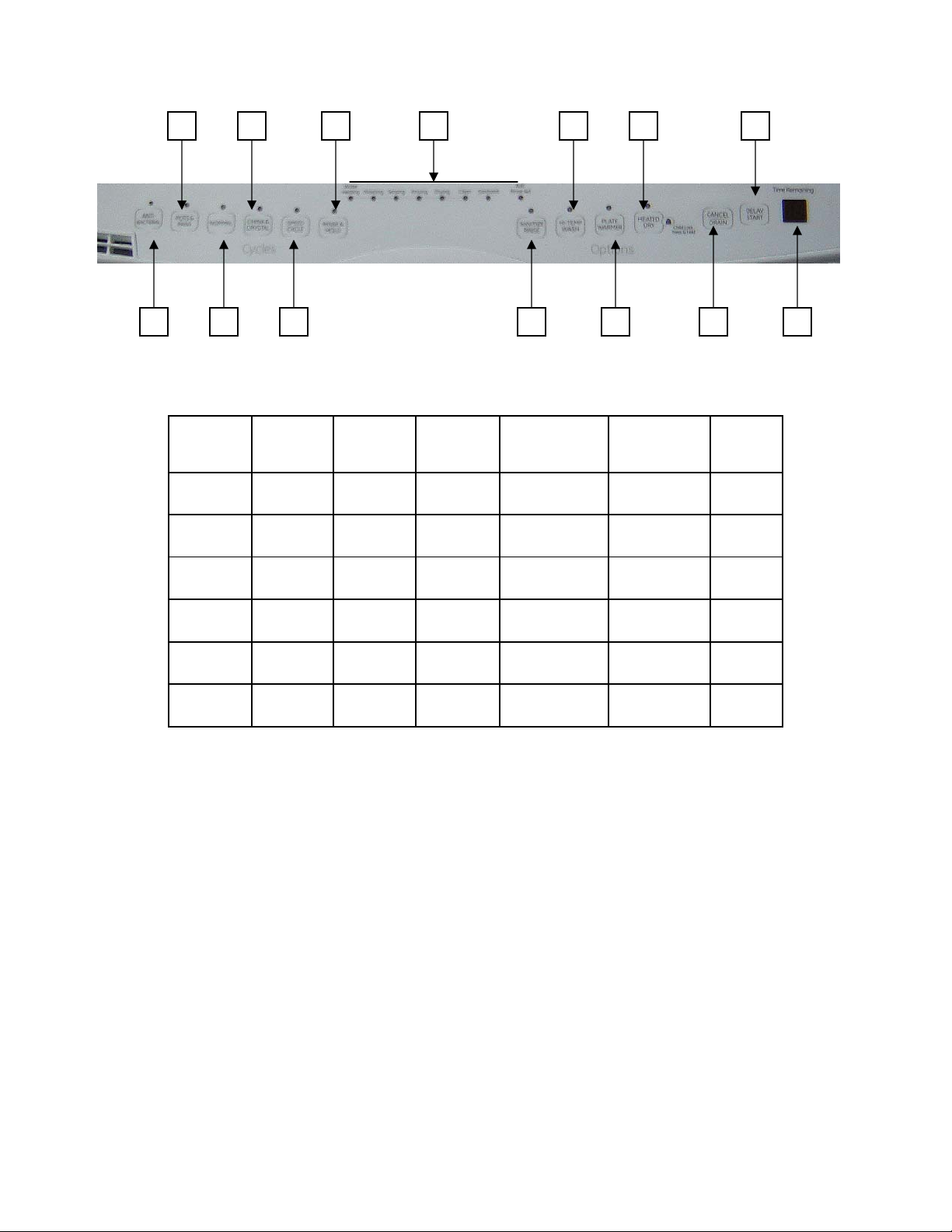

7

5. Rinse & Hold - Use this rinse cycle for rinsing dishes, glasses and silverware that will not be

washed right away.

Options

6. Sanitize Rinse - Select this option to raise the water temperature in the final rinse to

approximately 160°F (71°C). The SANITIZE RINSE option adds heat and time to the cycle. This

high temperature rinse sanitizes your dishes and glassware in accordance with NSF/ANSI

standard 184 for residential dishwasher. Certified residential dishwashers are not intended

for licensed food establishments. ANTI-BACTERIAL WASH automatically uses this option.

SANITIZE RINSE is an option with the POTS & PANS and NORMAL cycles.

7. HI-TEMP WASH is an option with the POTS & PANS and NORMAL cycles. Always use HI-TEMP

WASH if you have hard water.

8. Plate Warmer- Use the PLATE WARMER option to warm serving dishes or dinner plates.

9. Heated Dry- Select this option to dry dishes with heat. HEATED DRY is an option with the

ANTI-BACTERIAL WASH, POTS & PANS, NORMAL and CHINA cycles.

Child Lock - Press & hold CHILD LOCK you can lock the controls to prevent any selections

from being made. Or you can lock the controls after you have started a cycle.

Children cannot accidentally start a dishwasher by touching pads with this option selected.

To unlock the dishwasher controls, press and hold the HEATED DRY pad for 3 seconds. To

lock the dishwasher, press and hold the HEATED DRY pay for 3 seconds. An indicator light

shows when CHILD LOCK is activated.

10. Drain Cancel ( GLD8110 GLD8312) Start Reset (GLD9312) - To change a cycle after washing

starts.

GLD8110-PLD8312 Series: Touch the DRAIN/CANCEL pad to cancel the cycle. Then the

water is pumped out if needed. This takes approximately 2 minutes.

GLD9312 Series: Open the door slowly to prevent splash-out. Touch the START/RESET pad to

cancel the cycle. If the START/RESET light is on, close the door until the water pumps out (this

takes approximately 2 minutes) and the light stops flashing.

When the light stops flashing, the dishwasher can be reprogrammed and restarted.

11. Delay Hours - You can delay the start of a wash cycle for up to 12 hours (GLD8110 GLD8312)

or 24 hours (GLD9312). Press the DELAY START pad to choose the number of hours you want

to delay the start of the cycle; then press START/RESET.

NOTE: To cancel the DELAY START selection before the cycle begins, press the DELAY START

pad until the display is blank

12. Time Remaining – A two digit display that shows the wash time left. This may reduce or

increase based on the readings of the Clean Sensor. It will display in minutes up to 99.

Between 100 and 120 Minutes it will show 2h (2 hours) and between 120 and 180 minutes it

will show 3h (3 hours)