‐3 ‐

TableofContents

ACTIVEVENT………………………………………………………………………………………………………………………………...21

CIRCULATIONPUMPANDMOTOR………………………………………………………………………………………………….15

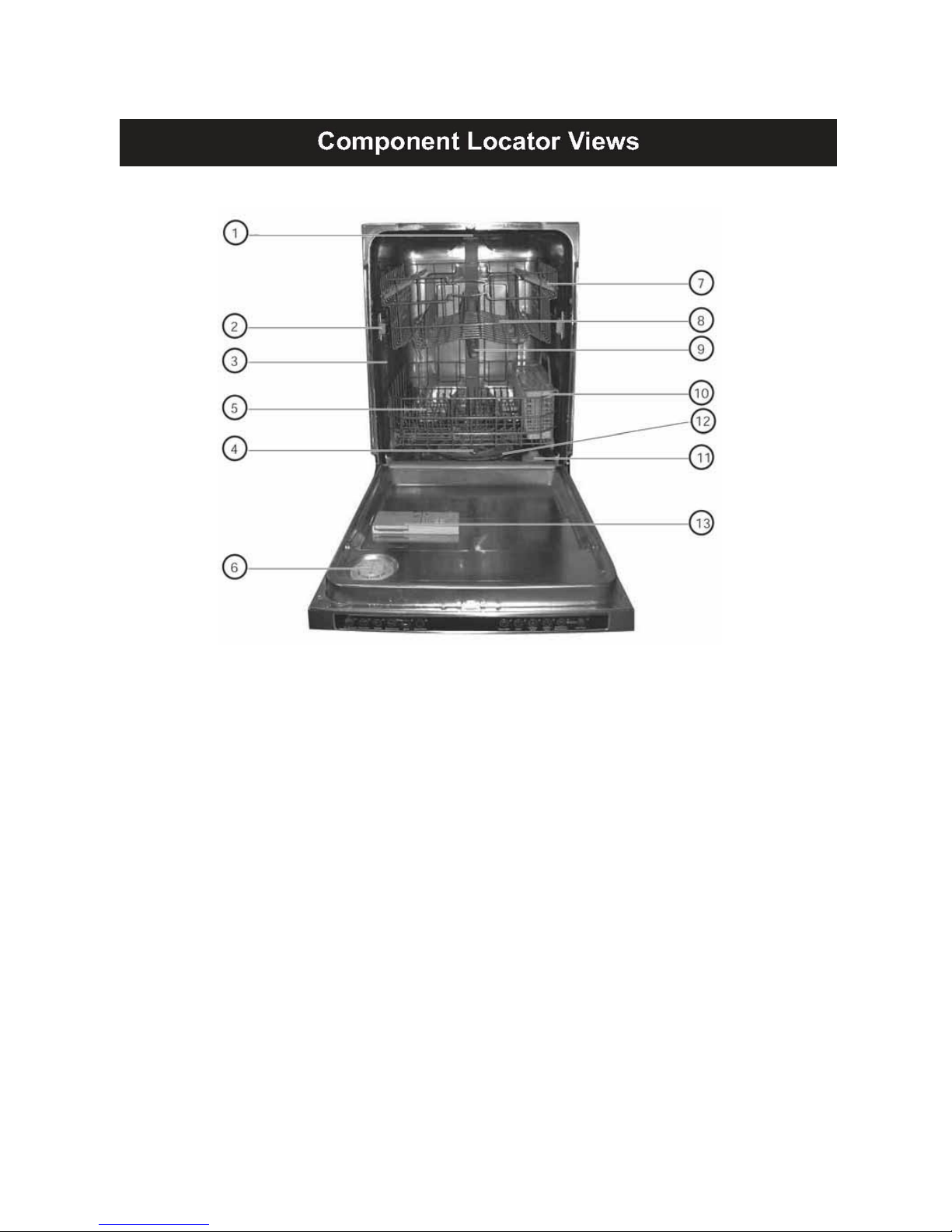

COMPONENTLOCATORVIEWS………………………………………………………………………………………………….…..10

COMPONENTS…………………………………………………………………………………………………………………….….……..13

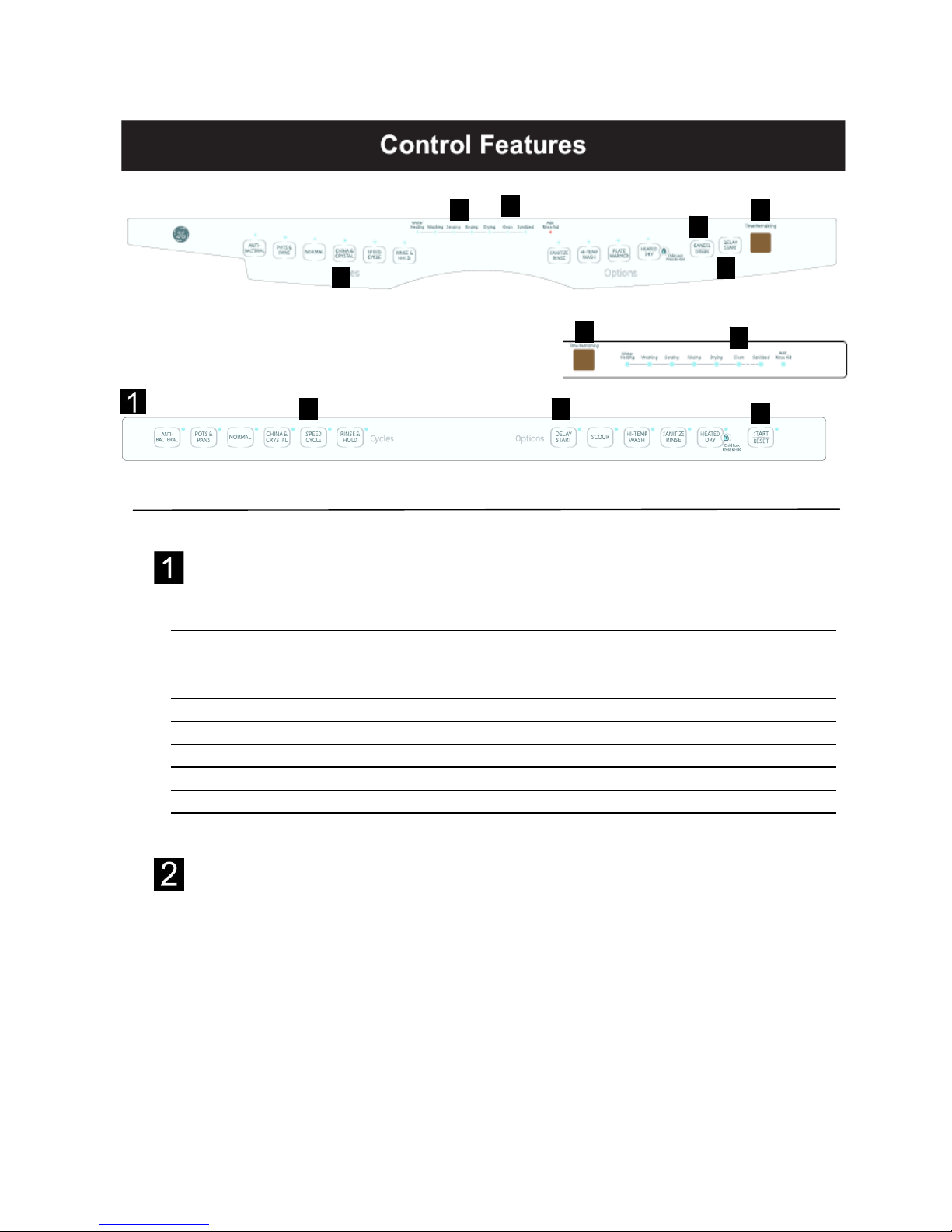

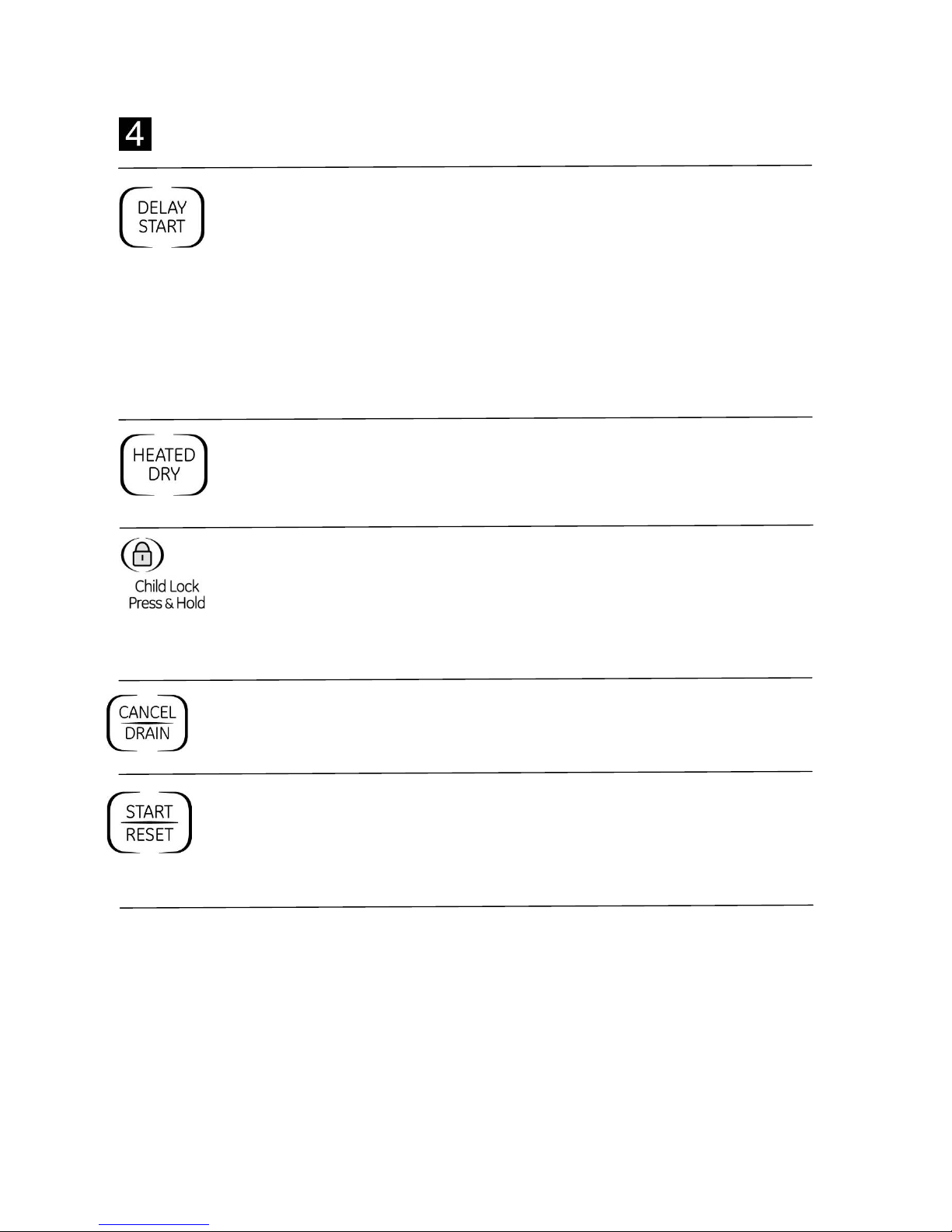

CONTROLFEATURES…………………………………………………………………………………………………..……………………6

CONTROLBOARD……………………………………………………………………………………………………………………..……20

TESTMODE……………………………………………………………………………………………………………………..…………….16

DETERGENT/RINSEMODULE………………………………………………………………………………………………..………..21

DOORINTERLOCKSWITCH………………………………………………………………………………………………..……………21

DOORPANEL………………………………………………………………………………………………..……………..…………………19

DRAINSYSTEM……………………………………………………….………………………………………………………….………….17

FILLFUNNEL……………………………………………………….………………………………………………………….…………..….14

HEATINGELEMENT………………………………………….………………………………………………………………………...….16

LOWERSPRAYWASHARM,FINEFILTER,ANDINLETCOVER…………………………………………………………..14

MAINCONDUIT……………………………………………………….………………………….……………………………………..….14

MEMBRANEKEYPAD………………………………………………………………………………..……………………..….…………19

MIDDLESPRAYARM………………………………………………………………………………..……………………..….………….13

NOMENCLATURE………………………………………………………………………………..……………………..….…………………4

SCHEMATIC………………………………………………….………………………………………….…………………..…….………….25

STRIPCIRCUITS………………………………………………….………………………………………….…………….…..…………….24

THERMISTOR………………………………………………….………………………………………….…………….…..……………….15

TOPSPRAYARM……………………….………………………………………….…………….…………………………...…………….14

TROUBLESHOOTING…………….………………………………………….…………….…………………………...……….….…….22

TURBIDITYSENSOR………………………………………………….………………………………………….…………….….……….17

USINGTHEDISHWASHERWITHTHEUPPERRACKREMOVED…………………………………………………………13

WASHCYCLES…………………………………………………………………………………………………………………………………15

WARRANTY………………………………………………….………………………………………….…………………..…….………….27

WATERVALVEANDFLOODSWITCH…………………………………….……………………………………..…….…………...17

WATERVALVETEST………………………………………….……………………………………………………………..….……….…18