Table of Contents

Chapter 1 Installation.................................................................................... 1-1

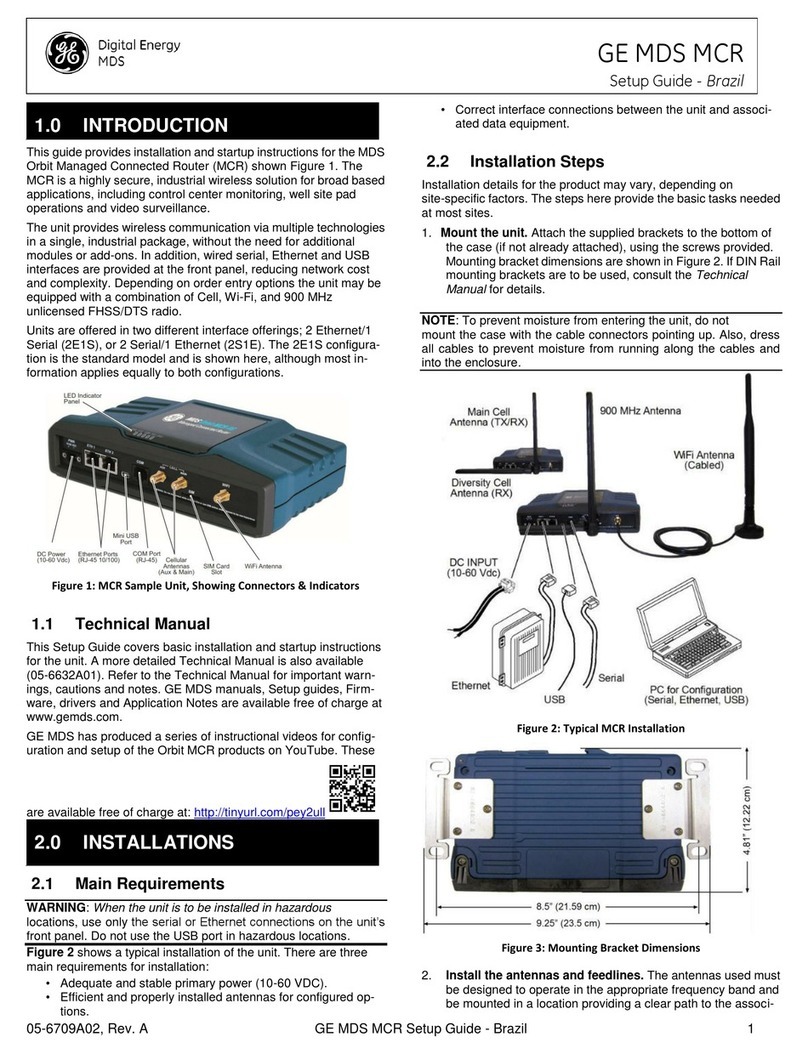

General......................................................................................................................................1-1

1+0/1+1 Installation .................................................................................................................1-4

2+2 XPIC Installation.............................................................................................................1-12

N+1 Split Mount Installation ................................................................................................1-16

Installation Configuration Illustrations..............................................................................1-18

Chapter 2 Initial System Setup..................................................................... 2-1

General......................................................................................................................................2-1

Initial Setup using the Craft Terminal..................................................................................2-2

Additional Setup using the NMS...........................................................................................2-5

Initial Setup for GE MDS Intrepid-HC HP/T.......................................................................2-14

Connecting Line Interfaces .................................................................................................2-32

Chapter 3 Acceptance & Commissioning Procedures............................... 3-1

Site Acceptance Procedure...................................................................................................3-2

1+0 Commissioning Procedure ............................................................................................3-7

1+1 Commissioning Procedure ............................................................................................3-9

2+0 XPIC Commissioning Procedure.................................................................................3-12

GE MDS Intrepid-HC HP Commissioning Log..................................................................3-15

Appendix A—Connector Pin-Outs...............................................................A-1

General......................................................................................................................................A-1

External Alarms Connector Pin-Out.....................................................................................A-2

Protection Connector Pin-Out...............................................................................................A-3

Modem-PPP Cross Cable Pin-Outs......................................................................................A-4

Wayside Channel Connector Pin-Outs................................................................................A-5

Appendix B—PPP/SLIP Driver Installation..................................................B-1

Appendix C—Frequency Information ..........................................................C-1