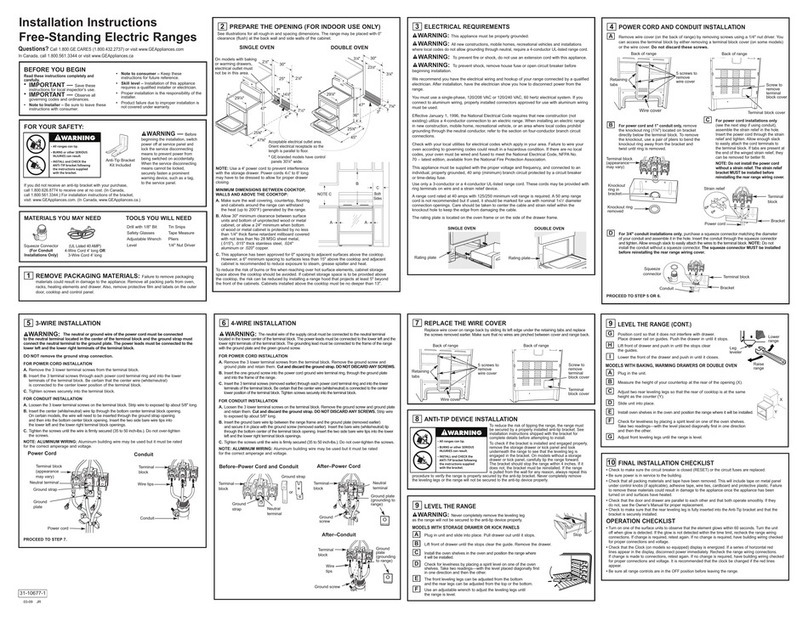

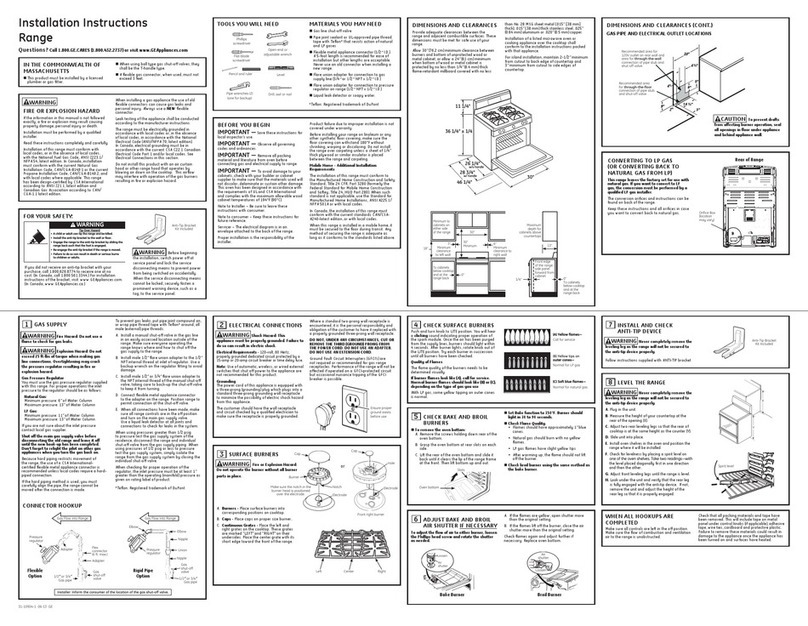

Before you begin--Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector's use.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions with your Owner's Manual for future

reference.

F!l,,,t:s,,u_,:_l This appliance must be properly grounded. See "Electric Supply", page 7.

For Monogram local service in your area,

1-800-444-1845.

For Monogram Service in Canada,

Call 1-888-880-3030.

For Monogram Parts and Accessories, call

1-800-626-2002.

If you received a damaged range, you should

contact your dealer:

Installation of this range requires basic

electrical, carpentry and mechanical skills.

Proper installation is the responsibility of the

installer. Product failure due to improper

installation is not covered under the GE

Appliance Warranty. See the Owner's Manual

for details.

CAUTION:

THESE RANGES SHOULD BE INSTALLED

IN CONJUNCTION WITH A SUITABLE

OVERHEAD VENT HOOD. Due to the high

heat capacity of this unit, particular attention

should be paid to the hood and duct work

installation to assure it meets local building

codes.

Standard countertop and island installations:

A 1200 CFM hood is recommended for 48"

ranges.

A 600 CFM hood is recommended for 30" and

36" Ranges.

Hoods should be 24" min. deep and the same

width as the cooktop.

grounding must comply with applicable codes.

In the absence of local codes, the gas range

should be installed in accordance with the

National Fuel Gas Code ANSI 223.1, latest

edition and National Electrical Code ANSI/

NFPA 70, latest edition.

CAUTION:

These ranges weigh up to 600 pounds. Some

disassembly will reduce the weight consider-

ably. Due to the weight and size of the range

and to reduce the risk of personal itl,jury or

damage to the product, TWO PEOPLE ARE

REQUIRED FOR PROPER INSTALLATION.

Check local building codes tor the proper

method of gas range installation. Local codes

vary. Installation, electrical connections and

Contents" Design Information

Models Available .................................................................................................................................. 3

Accessory Requirements ..................................................................................................................... 3

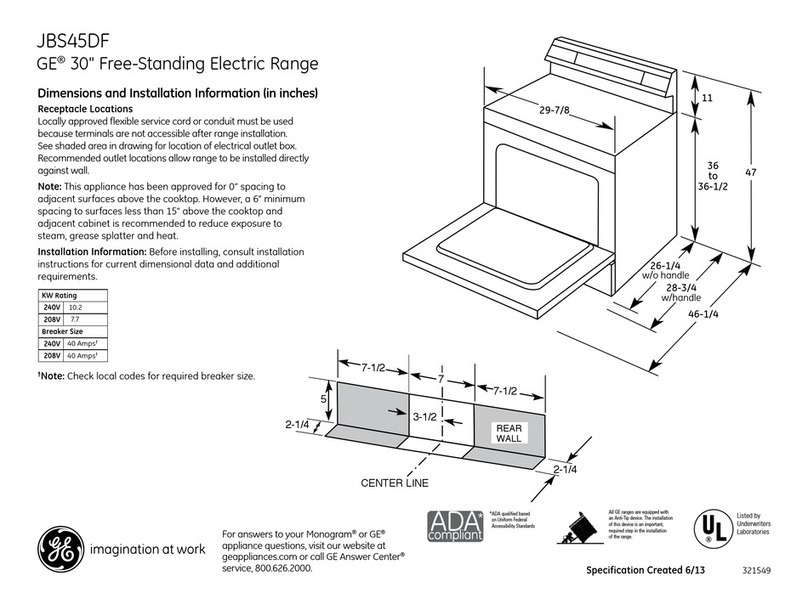

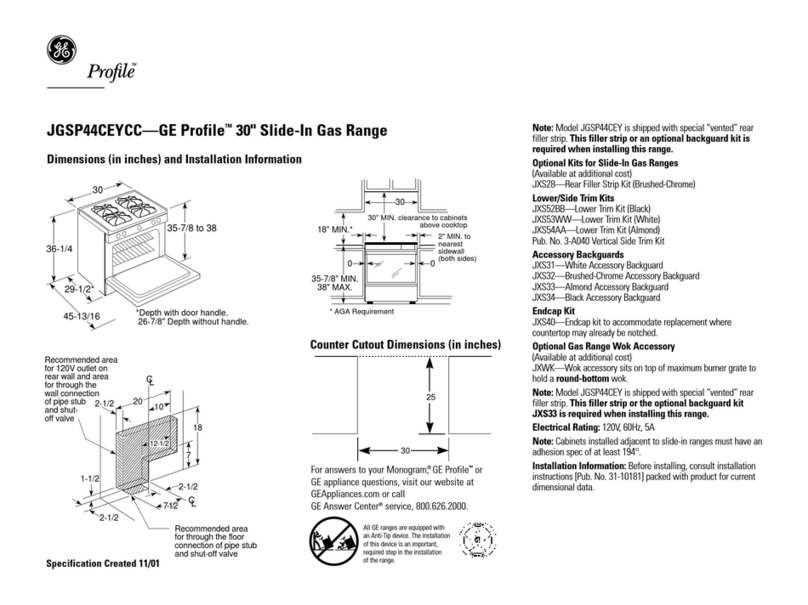

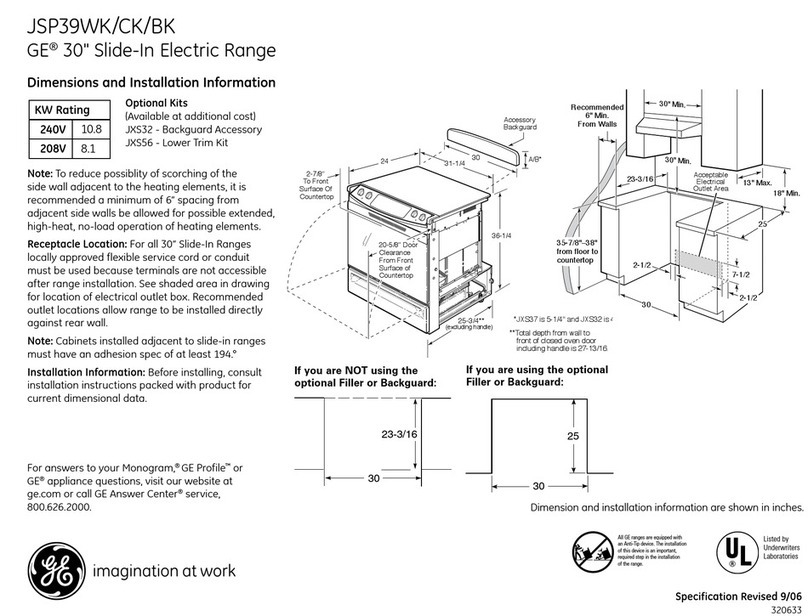

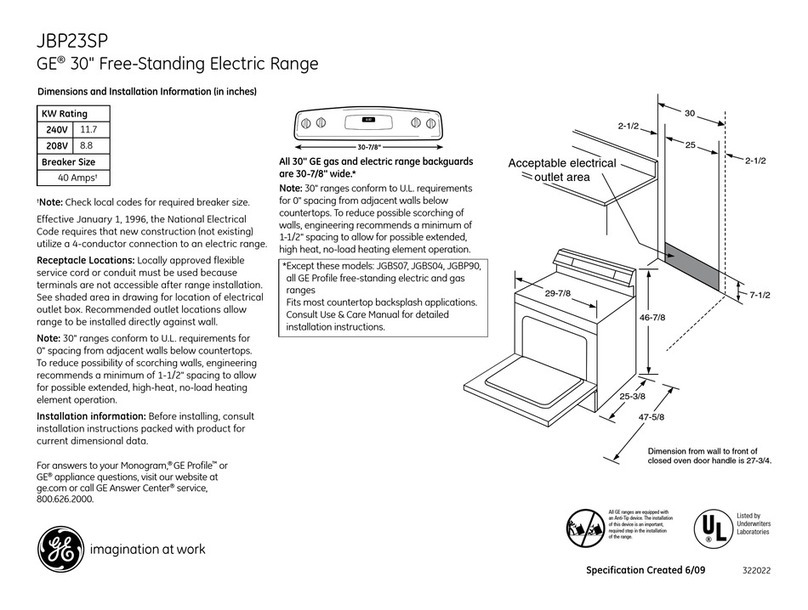

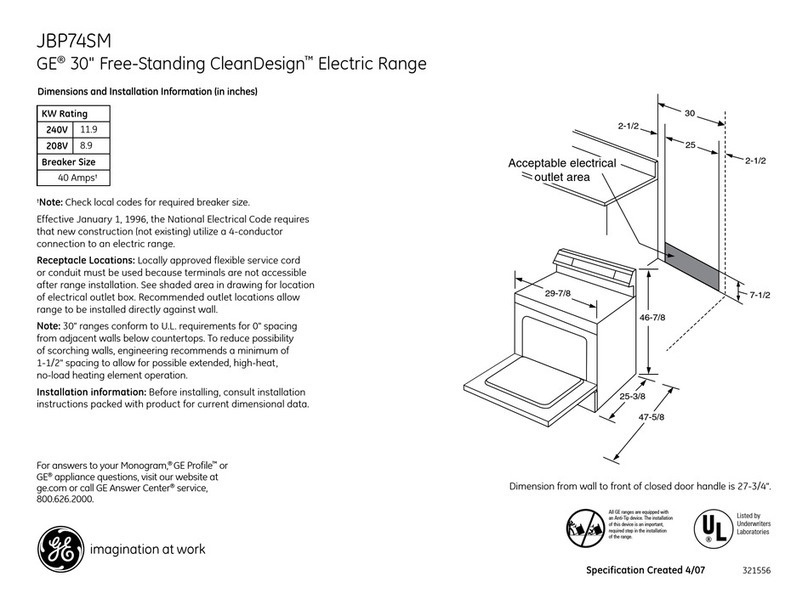

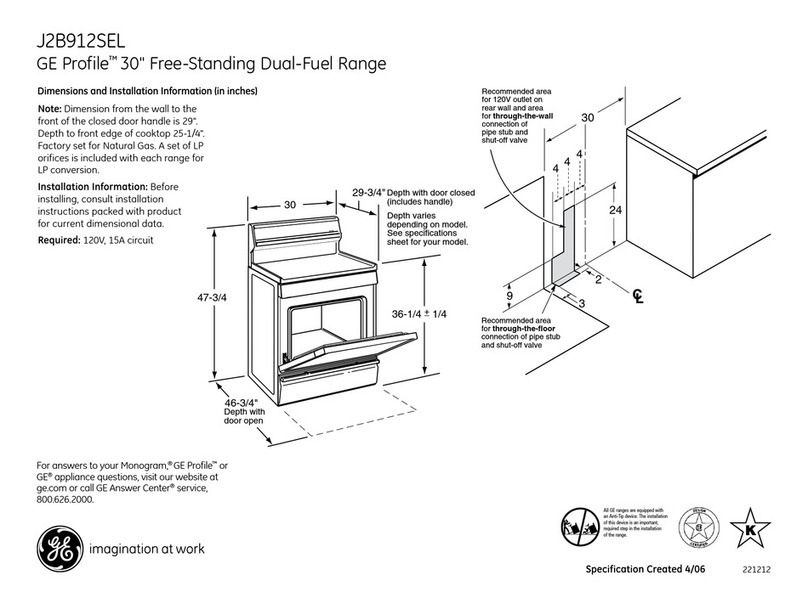

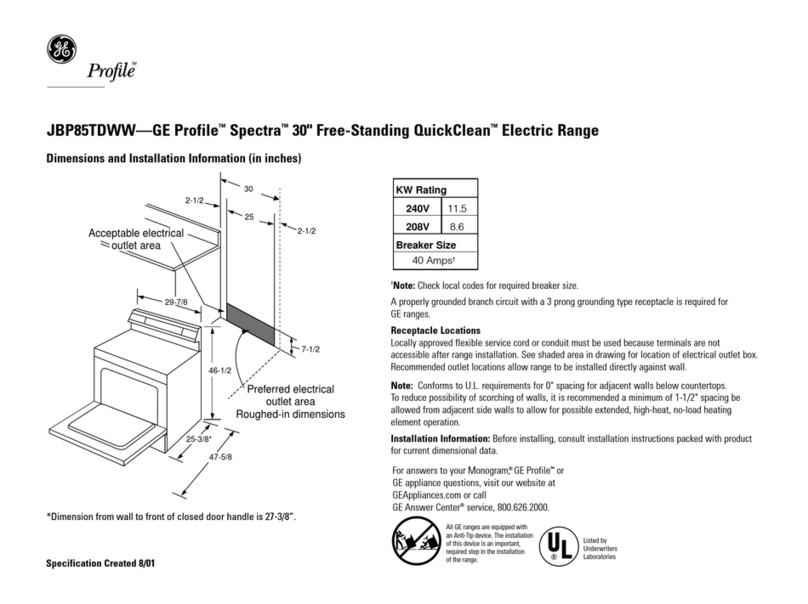

Models Dimensions and Clearances ............................................................................................... 4,5

Advance Planning ............................................................................................................................... 6

Tools & Materials Required ................................................................................................................ 6

Installation Preparation

Power Supply Locations ...................................................................................................................... 7

Installation

Step 1: Remove Packaging .................................................................................................................. 8

Step 2: Level the Range ...................................................................................................................... 9

Step 3: Install _mti-Tip Device ............................................................................................................ 9

Step 4: Connect Range to Gas .......................................................................................................... 11

Step 5: Install the Range Backguard ................................................................................................ 11

Step 6: Connect Electrical ................................................................................................................ 12

Step 7: Slide Range Into Position .................................................................................................... 12

Step 8: Replace Oven Doors ............................................................................................................. 12

Step 9: _ssemble & Adjust Burners ................................................................................................. 13

Step 10: Adjustable Low Burner Settings ........................................................................................ 13

Finalize Installation ........................................................................................................................... 13

2