– 3 –

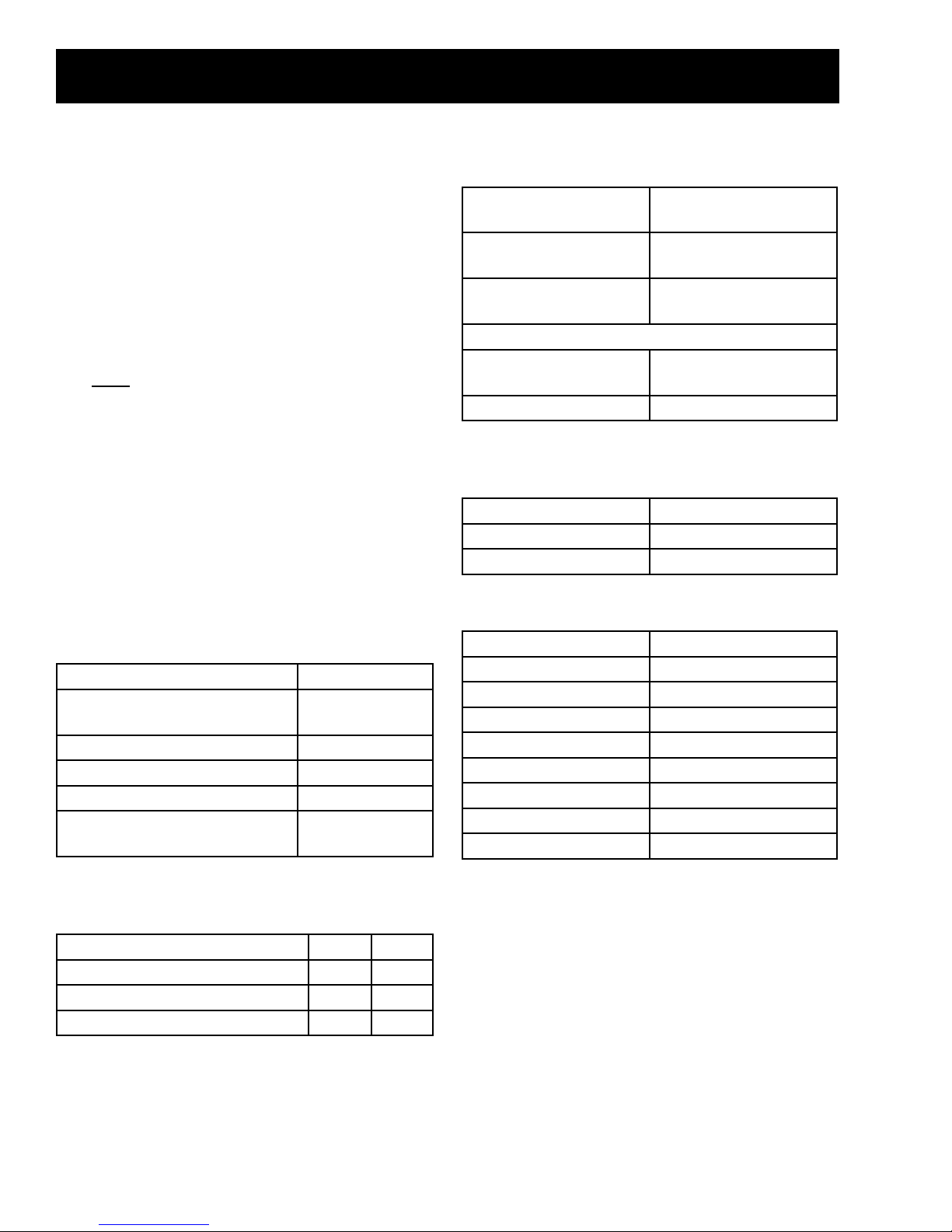

Table of Contents

(Continued next page)

Safety Requirements....................................................................................................................................................5

Introduction...................................................................................................................................................................... 6

Key Features and Updates........................................................................................................................................6

Nomenclature..................................................................................................................................................................7

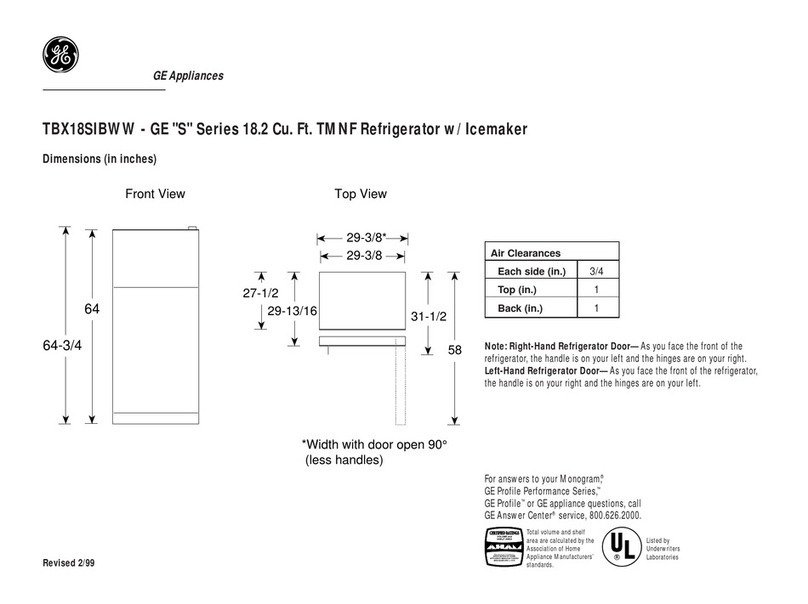

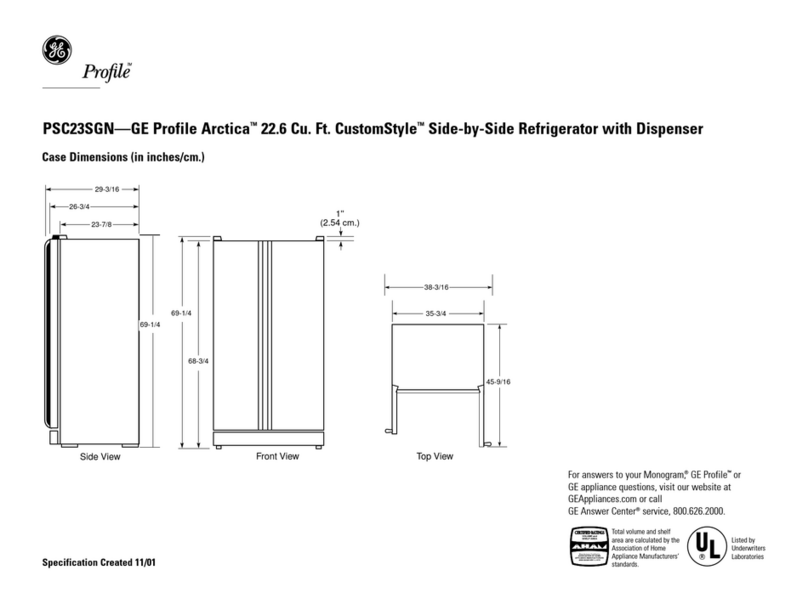

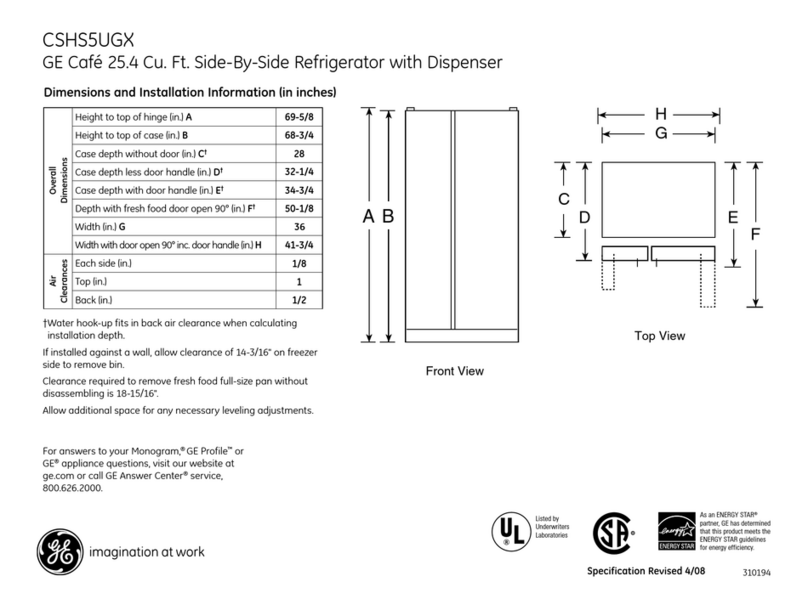

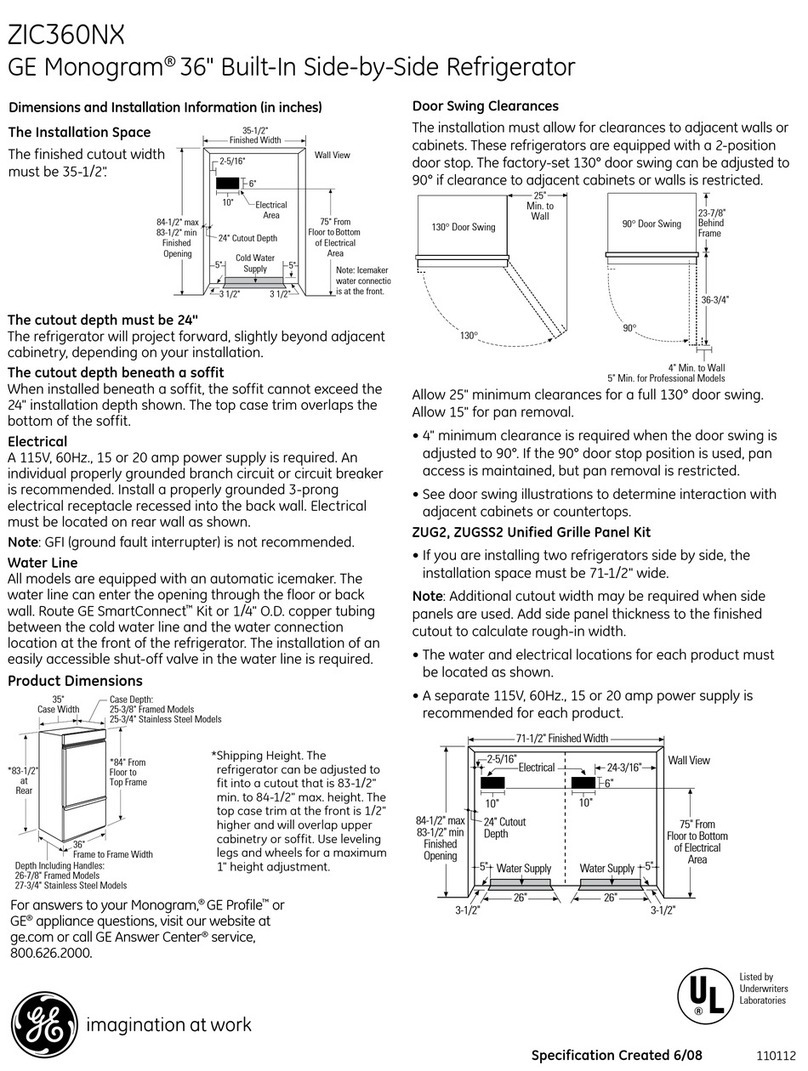

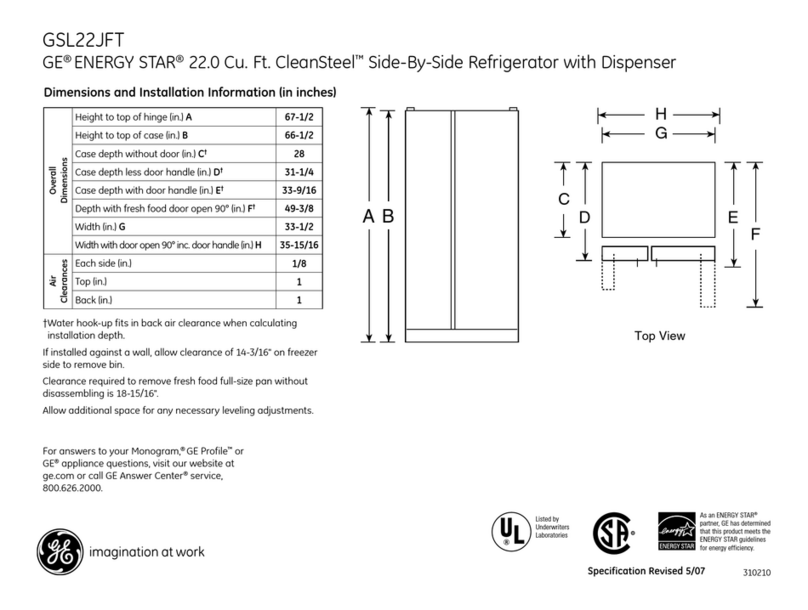

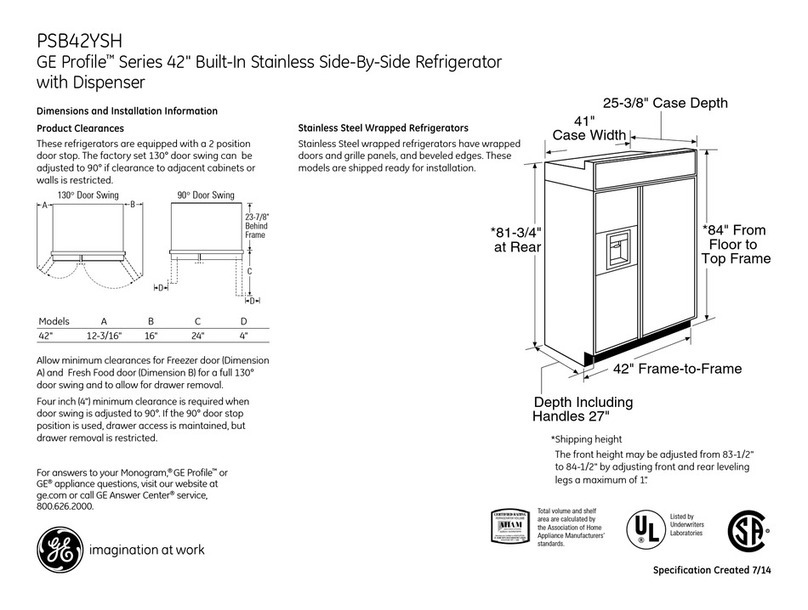

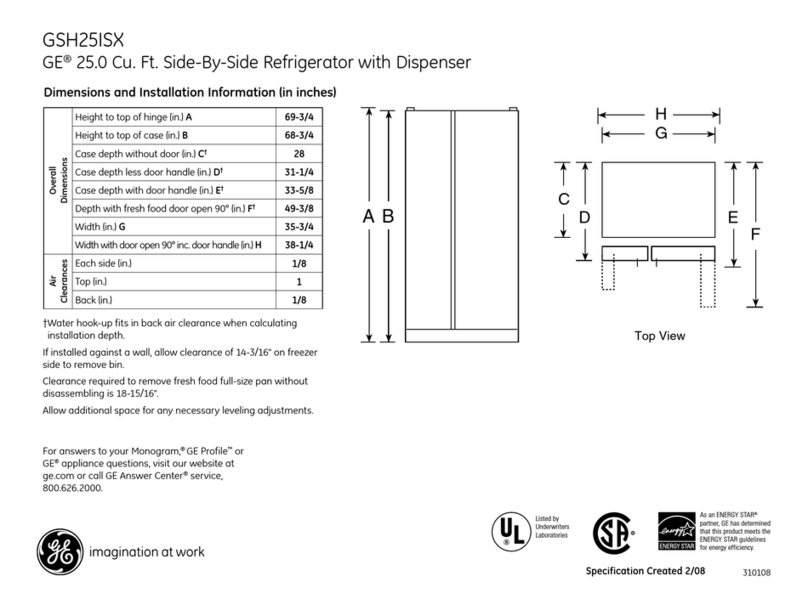

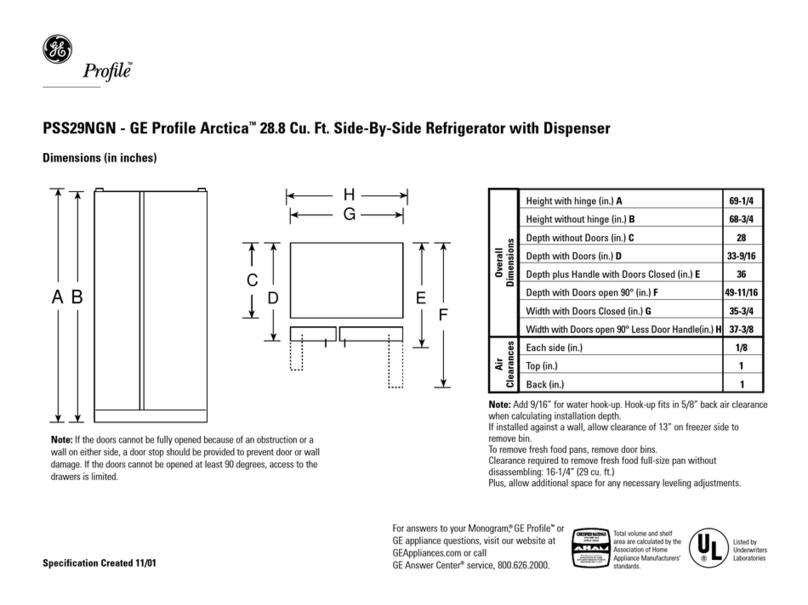

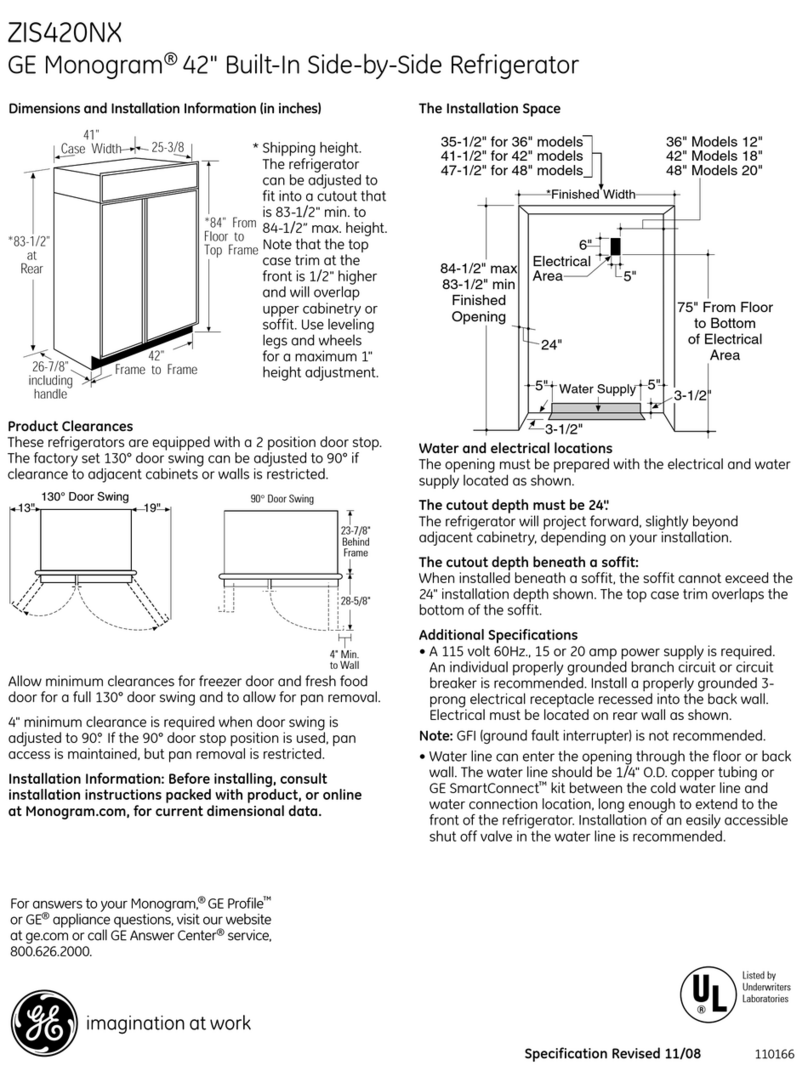

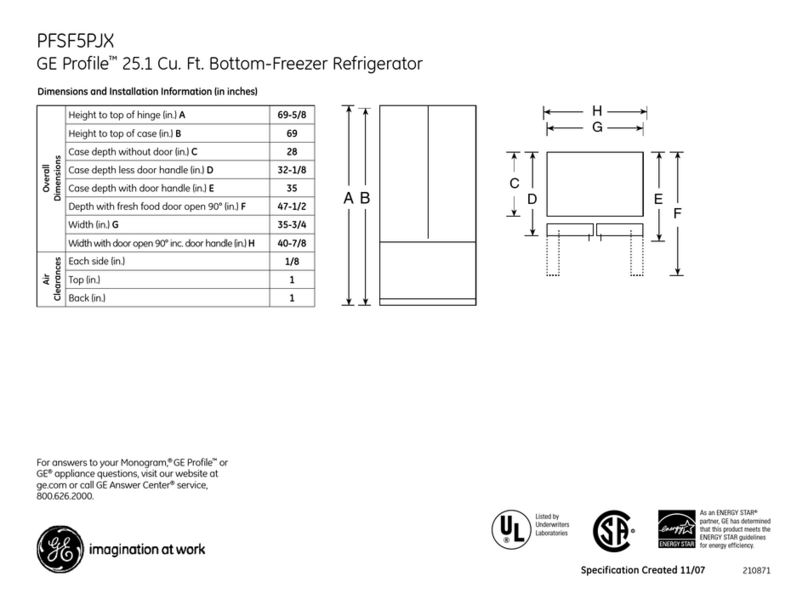

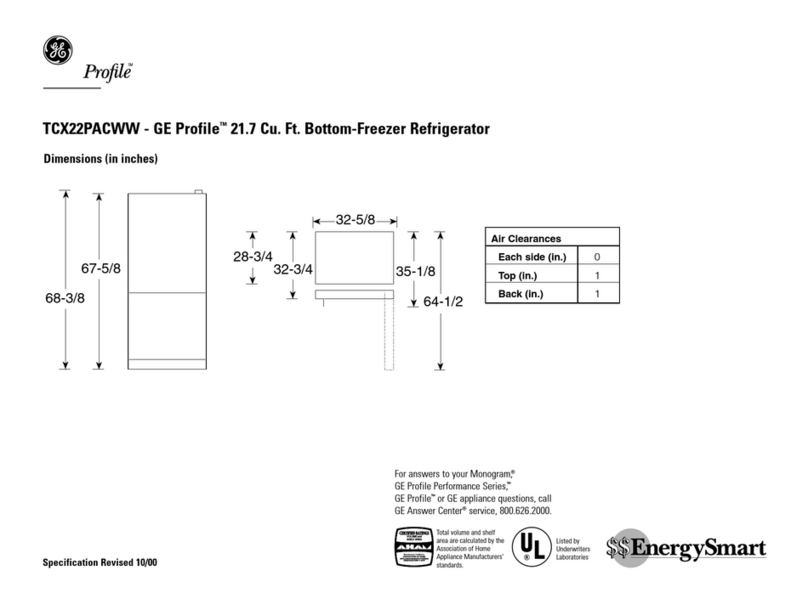

Product Specications.................................................................................................................................................8

Use & Care Manuals and Mini Manuals...............................................................................................................12

Refrigeration and Airow Diagram........................................................................................................................12

Installation Instructions ..............................................................................................................................................13

Product Specications.................................................................................................................................................15

Structure ............................................................................................................................................................................16

Control Panel.................................................................................................................................................................... 19

Fresh Food Compartment Air Ducts and Drain Tube.................................................................................... 20

Control Panel.................................................................................................................................................................... 21

Cold Control...................................................................................................................................................................... 22

Electro-Mechanical Defrost Control......................................................................................................................24

Defrost Controls..............................................................................................................................................................25

Defrost Control Operations .......................................................................................................................................26

Adaptive Defrost.............................................................................................................................................................27

Electronic Defrost Control (EDC)..............................................................................................................................28

EDC Process Flow Chart..............................................................................................................................................29

EDC Cooling ......................................................................................................................................................................30

EDC Defrost....................................................................................................................................................................... 31

EDC Dwell .......................................................................................................................................................................... 32

Freezer Components.................................................................................................................................................... 33

Ice Maker Troubleshooting Chart...........................................................................................................................35

Freezer Components.................................................................................................................................................... 36

Evaporator Fan Motor..................................................................................................................................................37

Freezer Components.................................................................................................................................................... 38

Freezer Section Defrost System..............................................................................................................................39

Defrost Circuit..................................................................................................................................................................42