– 6 –

ELECTRICALSPECIFICATIONS

Temperature Control (Position 5)....................... 32 - 4°F

Defrost Control... 60 hrs @ 40 mins with no door opening

Overtemperature Thermostat....................... 140 - 110°F

Defrost Thermistor.................................................70°F

Electrical Rating: 115V. AC, 60 Hz.................1 - 5 Amp.

Maximum Current Leakage................................0.5 mA

Maximum Ground Path Resistance...............0.14 Ohms

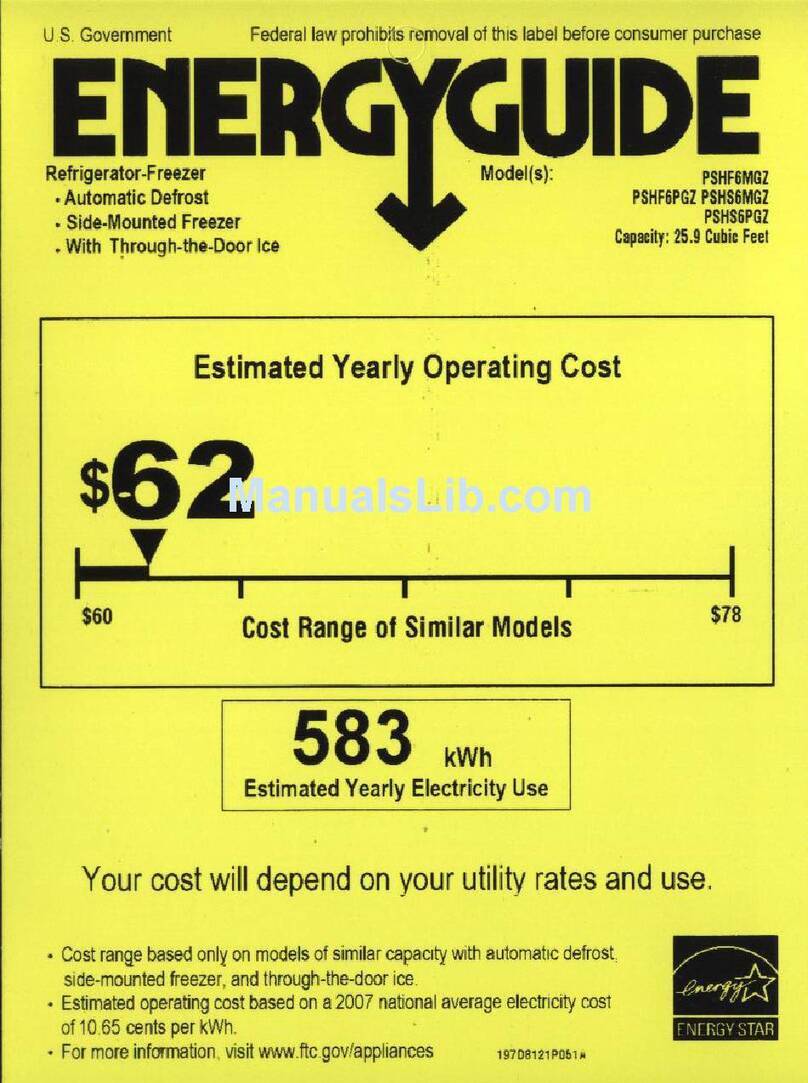

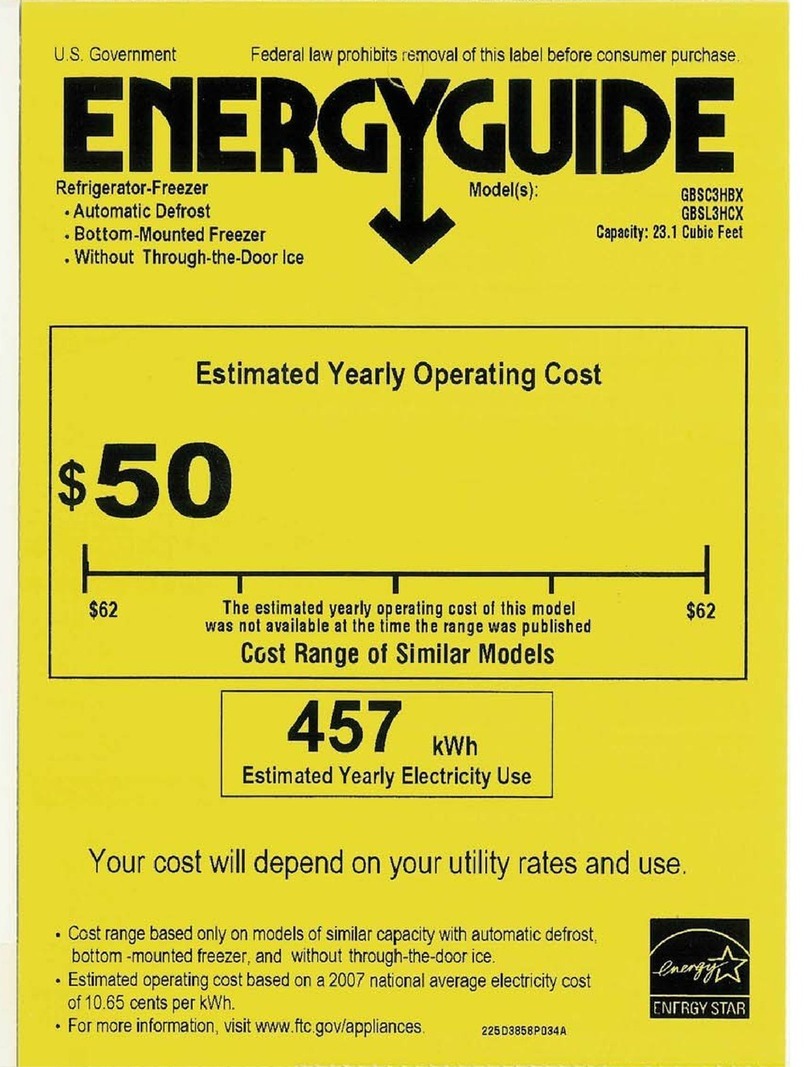

Energy Consumption.......507 kWh/yr for 20 cu/ft models

Energy Consumption.......520 kWh/yr for 22 cu/ft models

NOLOADPERFORMANCE

Control Position: 5-5

And Ambient of:................................................... 90°F

Fresh Food, °F..................................................32 - 42

Frozen Food, °F.................................................. -5 - 5

Percent Running Time....................................... 45 - 65

REFRIGERATION SYSTEM

Minimum Compressor Capacity Vacuum.............. 22 in.

Minimum Equalized Pressure

@ 70°F ................................................... 38 PSIG

@ 90°F.................................................... 49 PSIG

Refrigerant - R - 134a...................................... 4.06 oz.

Compressor .............................................. 690 BTU/hr

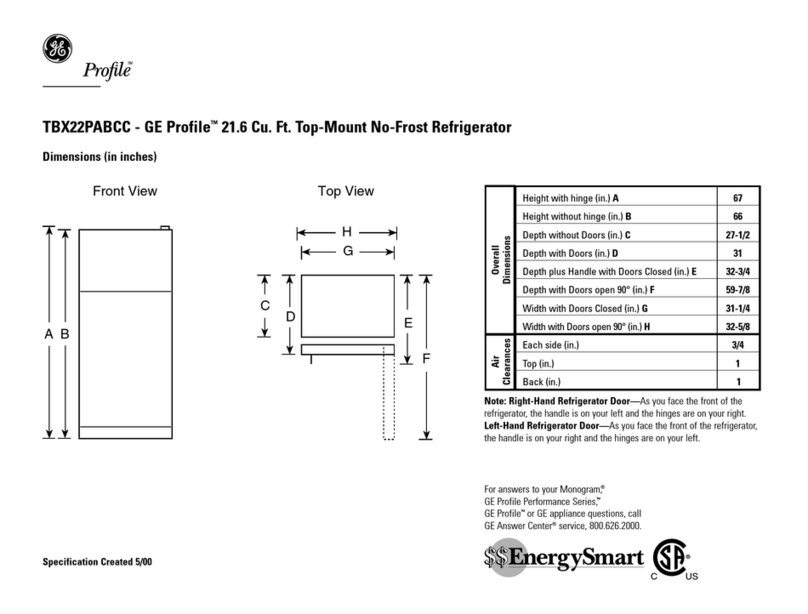

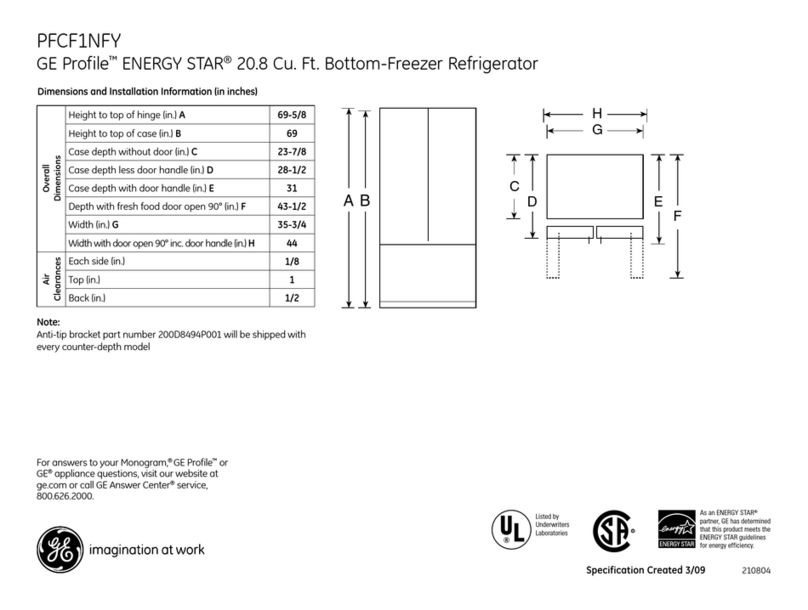

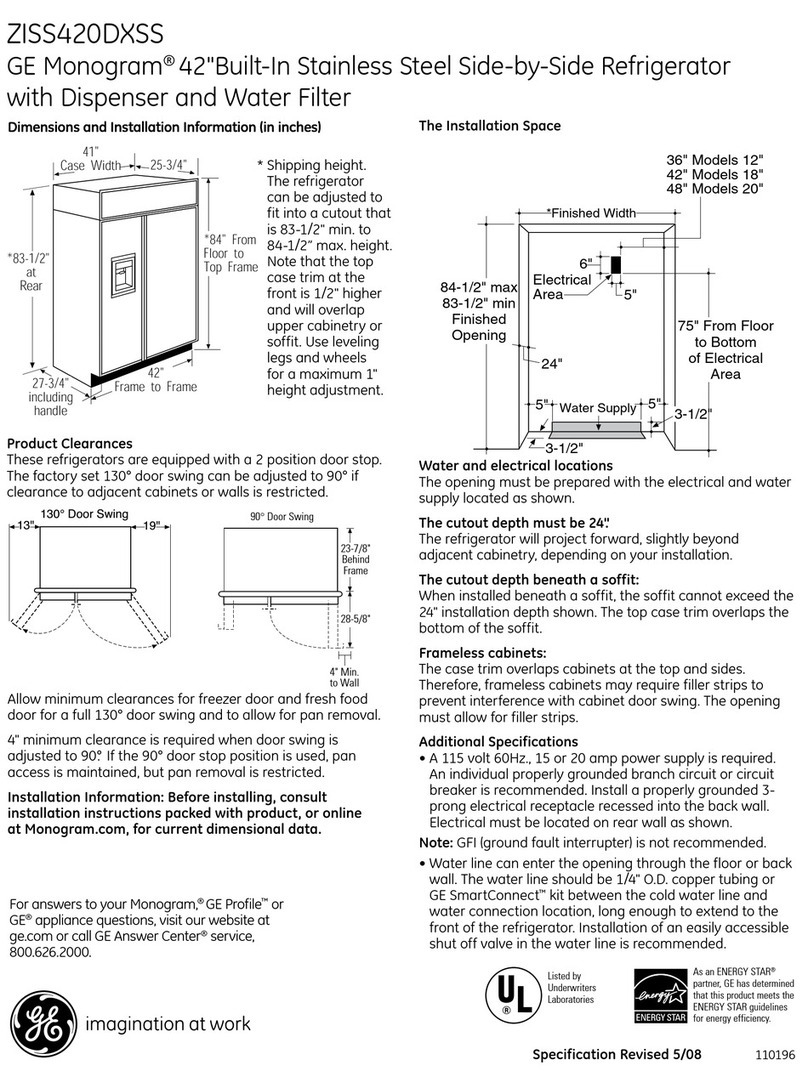

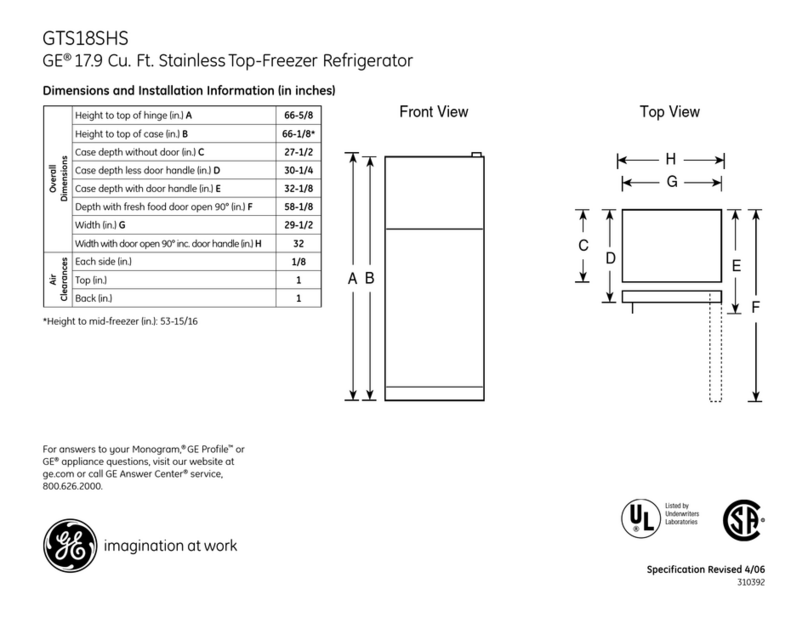

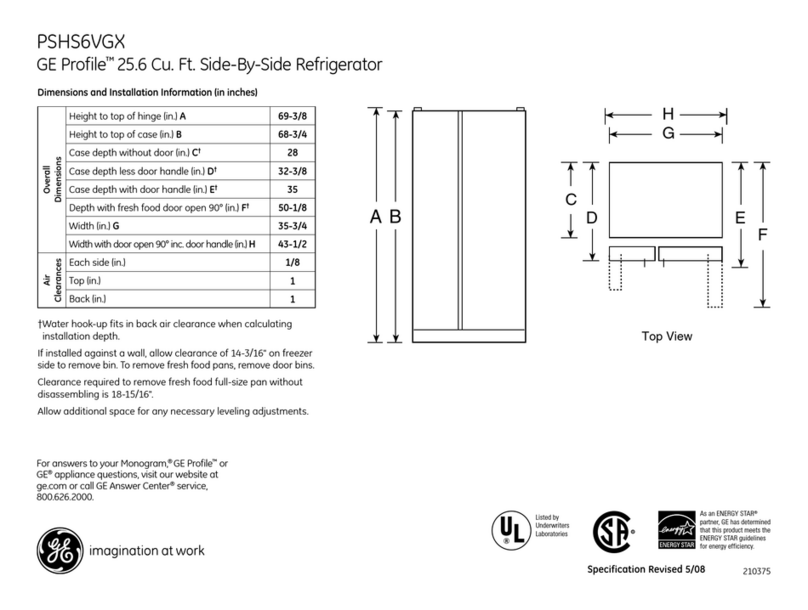

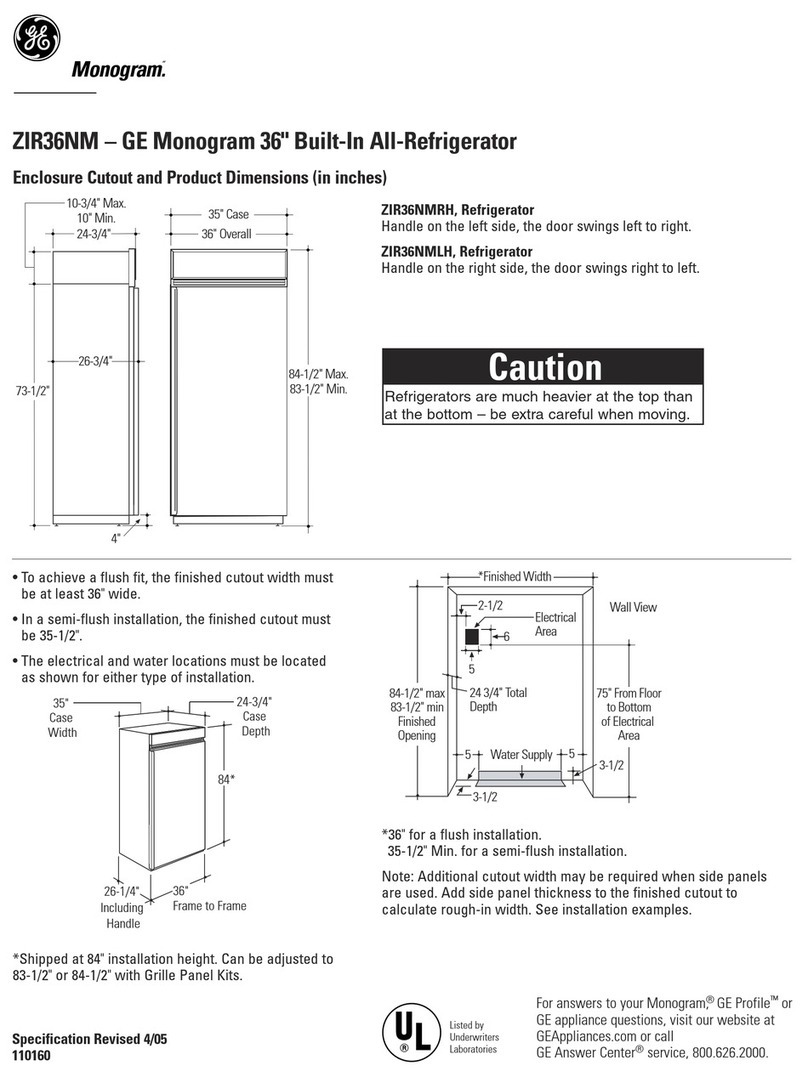

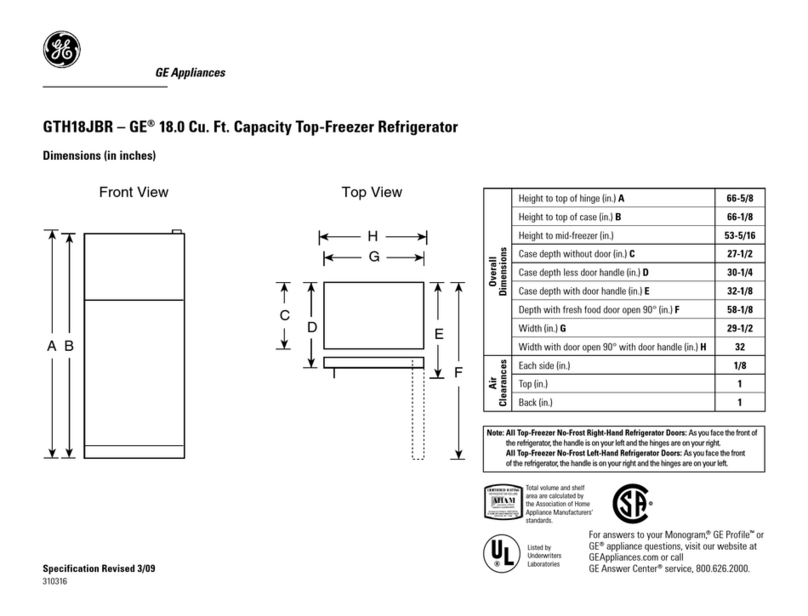

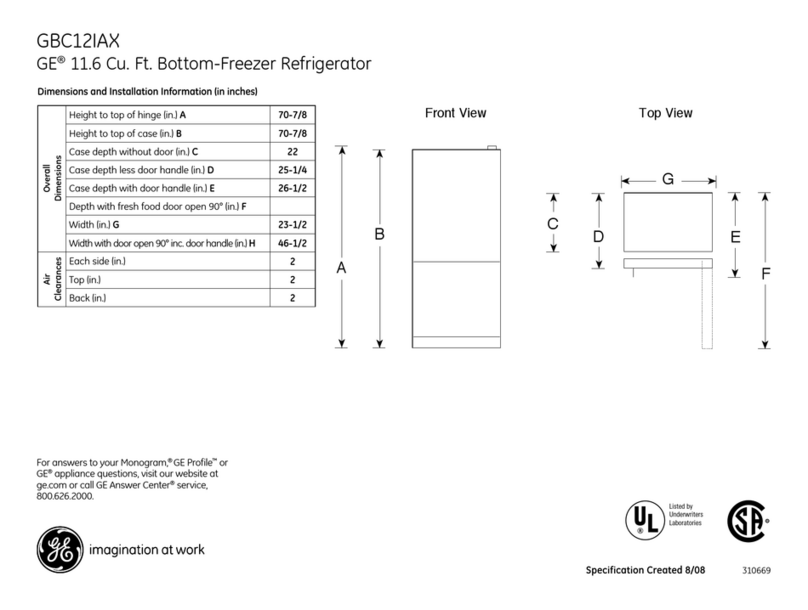

INSTALLATION

Clearance must be provided at top, sides and rear of the

refrigerator for air circulation.

AT TOP............................................................. 1 inch

AT SIDES................................................... 0.125 inch

AT REAR.......................................................... 1 inch

Technical Data

Airflow (CabinetInterior)

The evaporator fan forces air through the

evaporator into the freezer compartment.

Air from the evaporator is also forced through the

electronic damper to the top of the air tunnel,

through the fresh food compartment, and returns

to the evaporator.

The fresh food compartment receives chilled air

through an electronic damper at the bottom, rear

of the fresh food compartment. The damper is

controlled by the main control board. When open,

the damper allows chilled air from the freezer to

move into the fresh food compartment.

Air returns from the fresh food compartment to the

freezer compartment via two vents located to the

left and right of the air tunnel.