AIR HEATER PELLET STOVE BY GEKASMETAL

Page 8

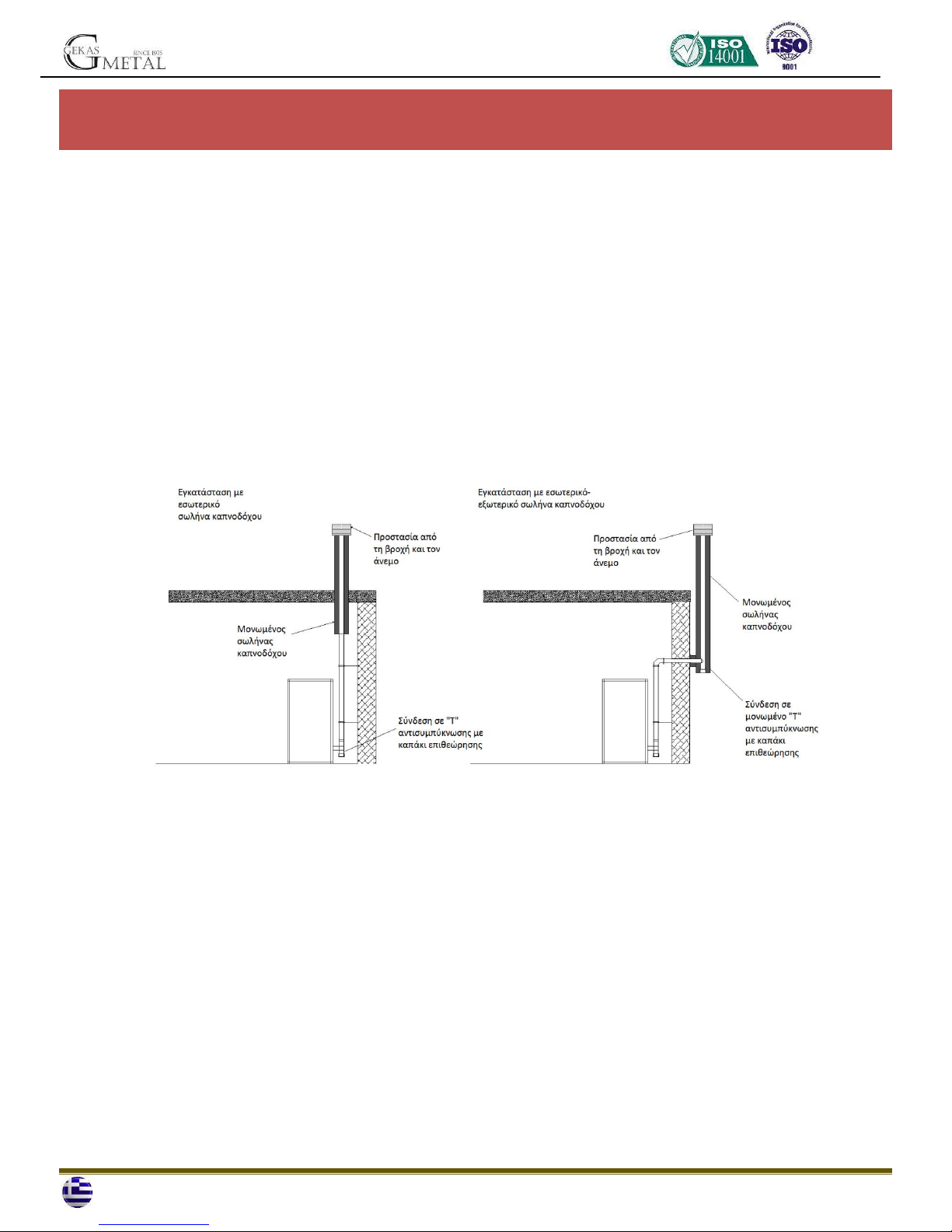

The placement of the fumes extraction pipes Φ80mm can be achieved whether on an installation with existing chimney (minimum surface 200cm² and with an inspection

chamber on the for annual cleaning), or on an installation without existing chimney, with the use of a tee pipe (with cap) connection. The line horizontally reaches the outside

of the building. Then, the chimney, which is fully insulated and has windbreak cap, stands vertically. All the connections should be sealed.

Fumes extraction system belonging to another appliance cannot be connected to the chimney of this appliance.

AIR INTAKE SYSTEM INSTALLATION

The appliance should be capable of using the necessary air to ensure proper function through external air pipes.

With air intake directly from the outside through a pipe (Φinternal 38mm and length max 1,5 m) connected to the special air reception that exists on the back side of the

appliance. A downward bow should be placed on the opening of the pipe on the outside for protection against wind. The air intake can be achieved directly from the

installation area, under the condition that on the wall near the appliance an air intake has been created which communicates with the outside of the building, with minimum

80 cm².

In both cases regular check should be performed, in order to ensure that nothing obstructs the air flow.

INSTALLATION OF SWIVEL OF FUMES RECEPTOR

The fume swivel or receptor that is required for the installation should be designed in such way in order to allow the proper gaslight connection between the fume linkage

and the appliance. The plug or receptor should provide good adjustment for the size of the pipe which is suggested by the constructor. When the linkage is adjusted over an

exit cotter the coating should have length, at least 25 mm for pipes with diameter 160 mm or less, and at least 40 mm for pipes with diameter bigger than 160 mm. In case

the fume linkage does not fit in a receptor, the depth of the insertion should be at least 25 mm .

The adjusters intended for the increase of the flue cotter/receptor diameter are allowed if they are part of the pellet stove. They should be tightly connected and fit with

every flue connection.

NOTE The sealing of the internal connections with heat resistant material or/ and rope, if needed, is suggested.

CONNECTION TO ELECTRIC NETWORK

Before the connection of the appliance to electric network check if the electrical installation is equipped with ground and differential switch, according to regulations.

Connect the appliance to an electric plug of 230v –50Hz voltage, avoiding the use of adaptors, multiplugs and extension.

Make sure that the connection wire does not make contact with warm parts of the heater, and, moreover, it is not subjected to any damage.

We remind you to always unplug the heater before performing any kind of maintenance or check.

TECHNICAL DOCUMENTATION OF INSTALLATION

When installation is finished, the installer should hand over, according to regulations, the compatibility statement of the installation to the owner of the appliance or his

representative. The compatibility statement concerns:

1) the manual of use and maintenance of the appliance and the installation constituents

2) installation manual (if expected).

We suggest the installer to request proof of documentation and save it, along with a copy of the technical documentation concerning the installation.

Installation performed by other persons

If the individual stages of the installation have been performed by different persons, each one should document the stage of the installation he/she performed for the benefit

of the costumer and the person responsible for the next stage.

3.FUMES EXTRACTION SYSTEM

GENERAL REQUIREMENTS

The generator functions under pressure and carries an extraction fan for the removal of the flue gas. Each appliance should be connected to a fumes extraction system and

ensure the proper distribution of combustion products in the atmosphere. The discharge of the combustion products should be on the roof. The direct discharge on the wall

or towards closed areas, even with an open roof, is forbidden. Specifically, the use of flexible extended metal pipes is not allowed. The fireplace should be discharged through

a fumes channeling pipe connected to the appliance. Therefore, the use of collective pipes or the placement of extractor hoods over the grate or the fumes channeling pipes

is not allowed. The fumes channeling pipe and the fireplace should constantly be connected, so that the grate does not touch the appliance. The placement in the internal of

the fumes extraction system of other pipes and airways, even of big size, is not allowed.

The constituent parts of the fumes extraction system should be chosen depending on the typology of the appliance which is to be installed, according to:

EN 14785 : 2006