Thank you for purchasing our product.

Our products have been manufactured with the latest technology, the highest quality

components and have gone through rigorous quality control tests at the factory, before

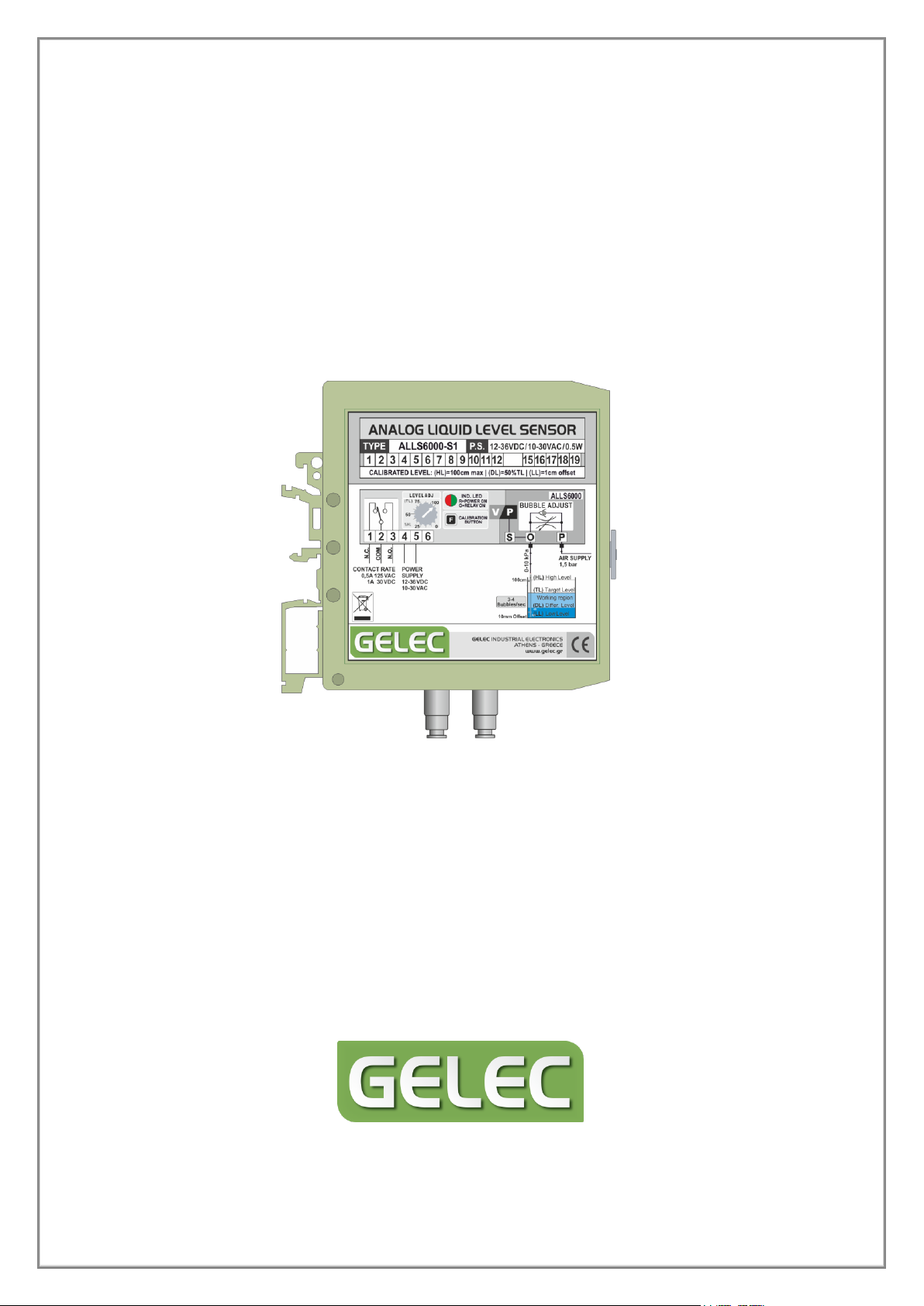

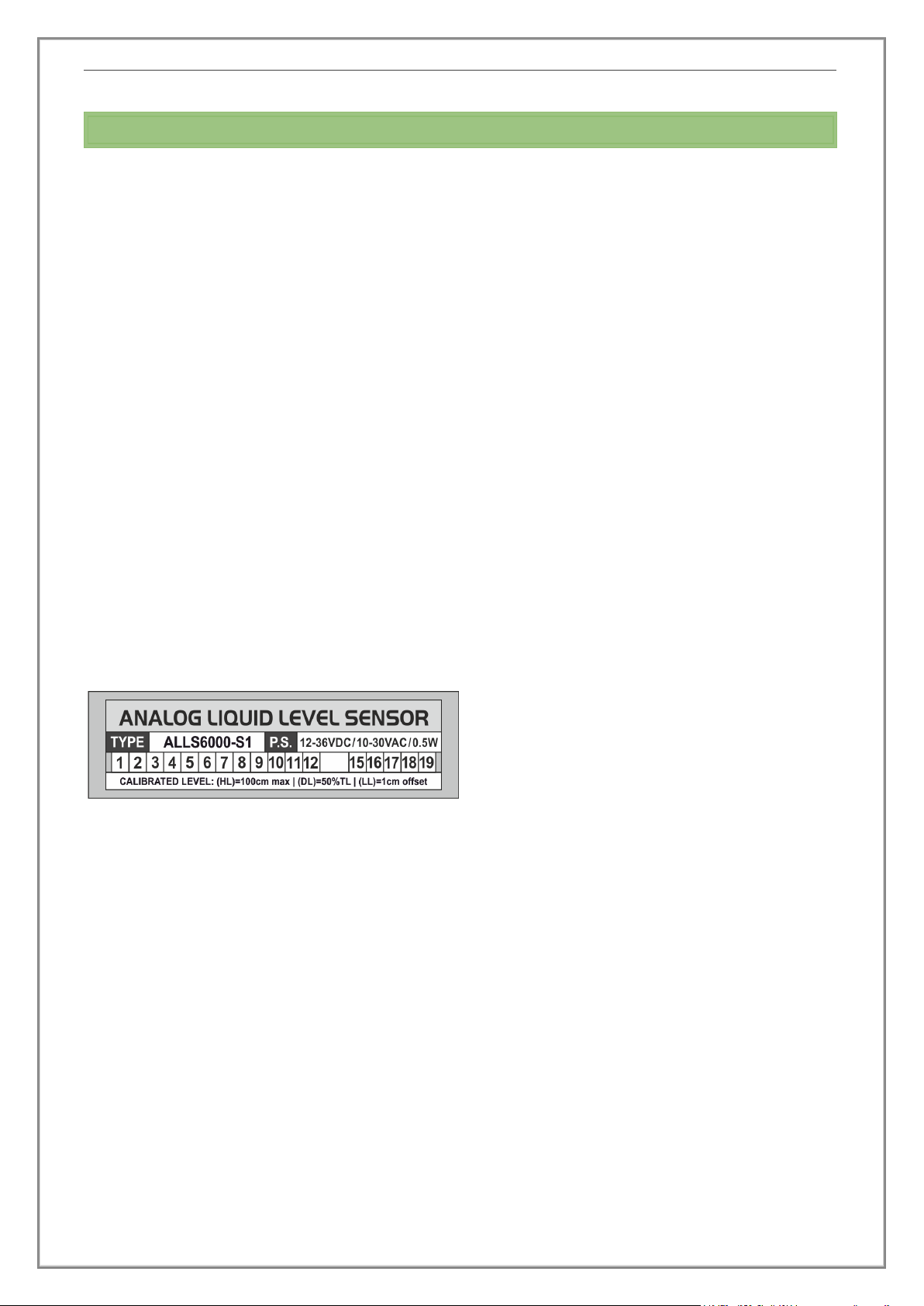

shipment. Make sure that the part number and type indicated in the identification label and

pack correspond to the part number or type of your order. After receiving, inspect the unit

to ensure that no damage have been caused during transportation.

GELEC and GELEC’s authorized distributors warrant to the original purchaser that the

product shall be free from defect in material and/or workmanship. The warranty period

begins on the purchase date (proof of purchase by invoice or delivery note) and is valid for

one (1) year. The guarantee period begins on the sales date (proof of purchase by invoice

or delivery note) and is valid for 1 year.

In the event of malfunction during the warranty period attributable directly to faulty

material and/or faulty construction and functional defects, GELEC and authorized

distributors will, at their option, either repair or replace the faulty product with the same or

similar model.

GELEC and authorized distributors shall have no obligation under this warranty, however, in

the following cases:

Any defect caused by freight damage, accident, disaster, faulty maintenance or

improper handling.

Any defect caused by modification, alteration, abuse, misuse or incorrect installation.

Any defect of the product caused by improper repair by third party other than GELEC

and GELEC's authorized distributors.

Any incompatibility of the products with subsequent technical innovations or

regulations.

Any defect of the product caused by external equipment.

Any defect of the product on which the original manufacturer’s labeling has been

altered or removed.

In case of complaint please contact our company or send the unit un-dismantled to your

local dealer. Any necessary replacement parts and necessary repair work are totally covered

free of charge.

All products are designed and produced by the manufacturer GELEC Co. Ltd to be in

compliance with the EU norms applying to them. GELEC is not responsible for direct or

indirect damages or malfunction caused by improper use or installation of the ALLS6000.