1-800-345-8207

4

Section 1 - Safety & Warnings

This manual contains safety information that is important to know and understand. This information is provided for the

safety of installers, operators, and users of the Nitrogen enerator. To help recognize this information, observe the

following symbols.

Danger indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

Warning indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious injury.

Caution indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury.

Notice indicates important information, that if not followed may cause damage to equipment or property.

Important Notice to Users

The Installation and Owner’s Manual supplied with each unit must be read thoroughly and completely understood before

installation and operation of the Nitrogen enerator. All appropriate safety standards for handling of gases as determined by

local or national laws and regulations should be followed at all times.

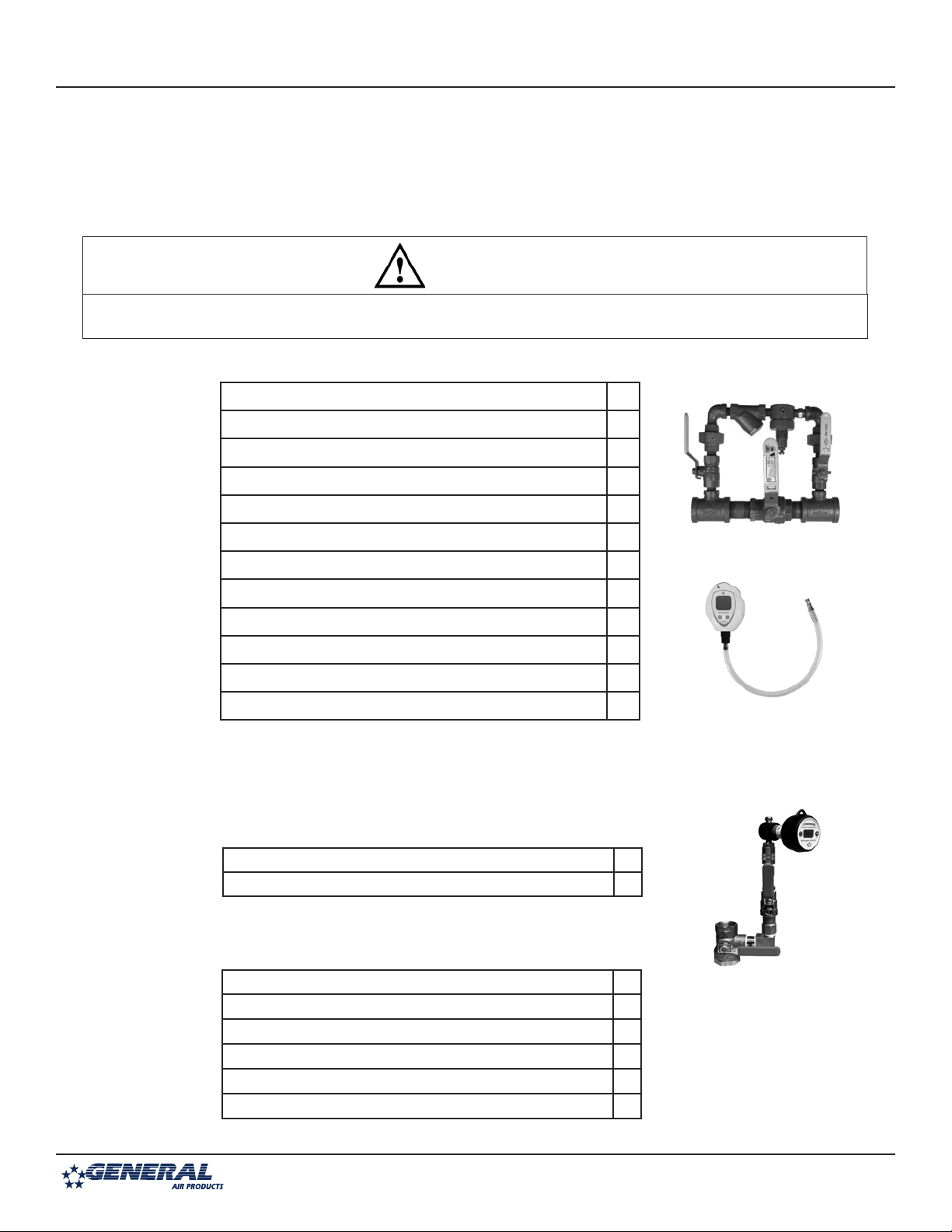

Unpacking

After unpacking unit, carefully inspect all parts and equipment for any damage that may have occurred during transit.

Make sure to tighten fittings, bolts, etc. before putting unit into service.

General Safety Information

Important: Read all of the safety information in this manual before operating this equipment. Use of the equipment in a

manner not specified within this manual may impair the protection provided by the generator and could result in an

unplanned release of pressure, which may cause serious injury or damage. Only competent personnel, who have been

trained, qualified, and approved by eneral Air Products should perform commissioning, servicing, and repair procedures.

When handling, installing, or operating this equipment, personnel must employ safe engineering practices and observe all

related local regulations, health, and safety procedures, and legal requirements for safety.

Ensure that the equipment is depressurized and electrically isolated, before carrying out any of the scheduled maintenance

instructions specified in this manual.

DANGER

WARNING

CA TION

NOTICE

Do not operate if damage occurred during shipping, handling,

or use. Contact eneral Air Products immediately.

WARNING