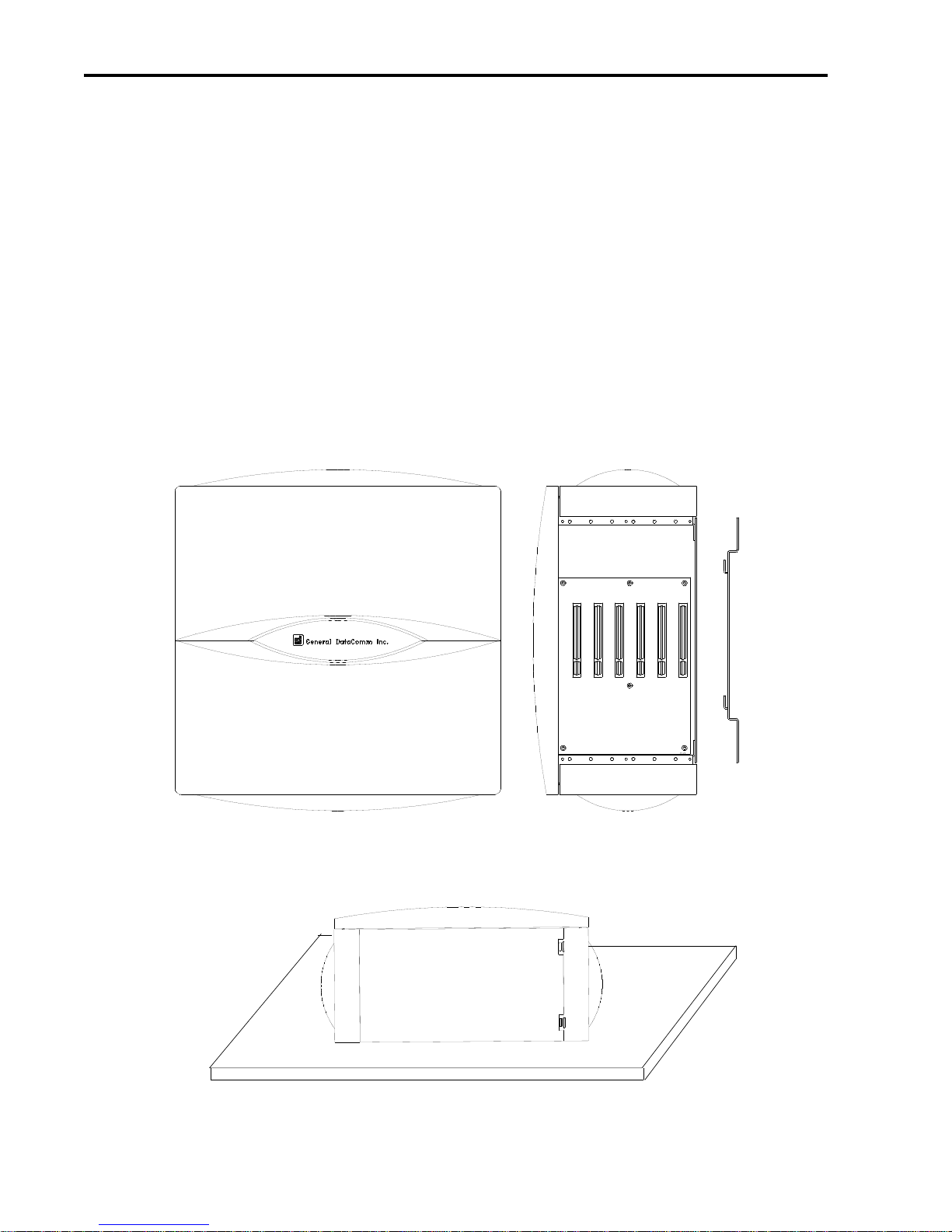

1-6 Wallmount Enclosure

GDC 086R601-001

Grounding for Safety and EMC

When AC powered, the enclosure must be connected to protective (earth) ground for safety

reasons. This is normally done via the power cord’s ground wire, or optionally via a separate

ground wire from a grounding post (chassis ground) on the rear panel.

Electromagnetic Compatibility (EMC) is maximized with the use of shielded cables for data

circuits. These shielded cables are connected to the chassis and thus to local earth ground. This

occasionally causes a problem if the equipment to which the unit is connected is at a different

ground potential than the unit.

A large ground current can flow in the shield of a shielded cable if it is connected to ground at

both ends, and the grounds at the two equipments are not at the same potential. To avoid large

currents, make sure that a potential difference of less than 0.25 V RMS exists between the ground

of the unit and the ground of the equipment to which it is connected. An alternative is to break

the shield continuity in the middle of a long cable run, or to connect the shield to ground at only

one end.

It is common practice to tie chassis ground and signal ground together. Signal ground is the 0V

reference for the digital circuits in the unit, and is also the reference for unbalanced data interfaces

such as EIA/TIA-232-E and RS423. Tying these grounds together is usually best for AC power

line noise immunity, but a problem can exist if signal grounds on two equipments (at different

chassis ground potentials) are connected together via a data cable. A large current can flow in the

signal ground lead (EIA/TIA-232-E pin 7). To prevent this, make sure the potential difference

between grounds is less that 0.25 V RMS.

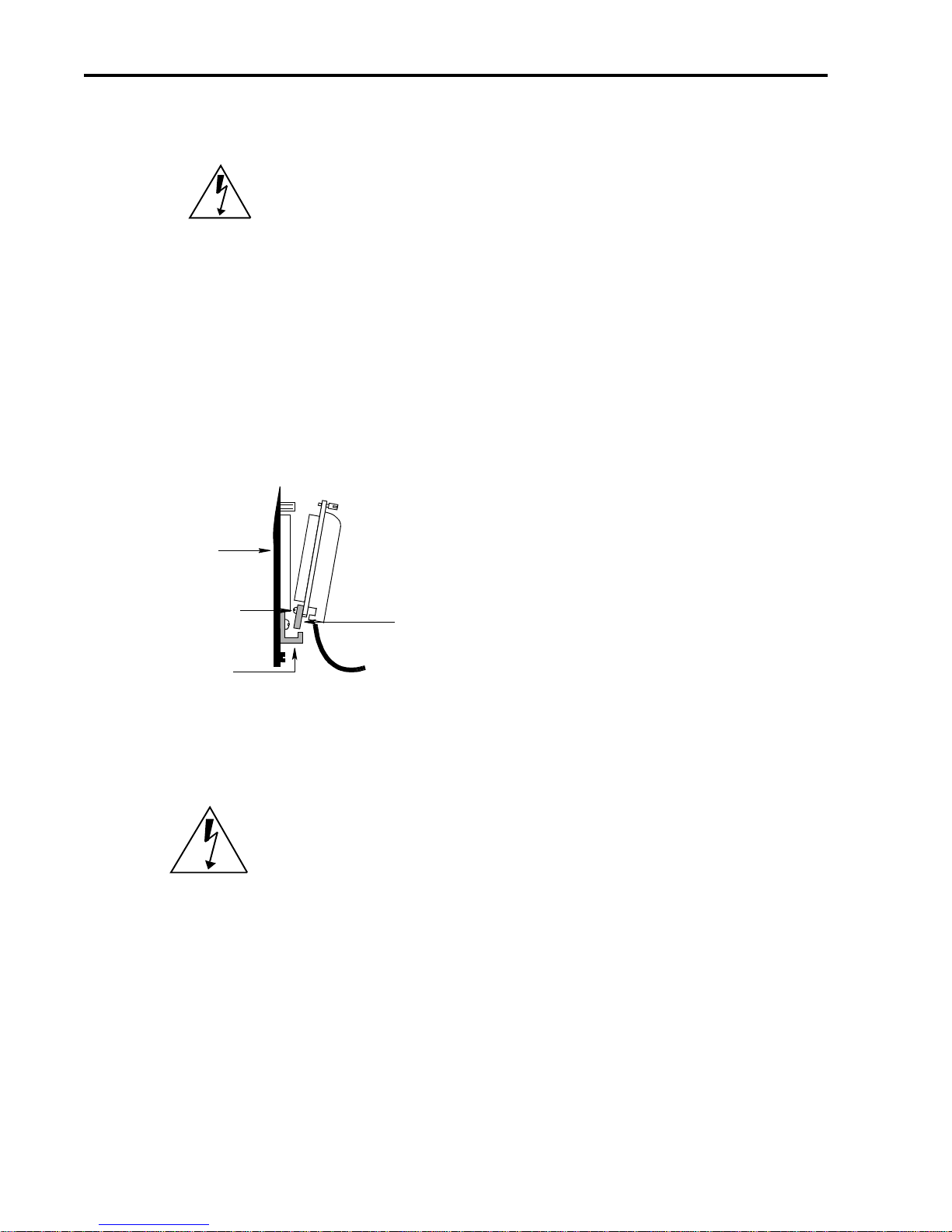

Chassis Grounding Post

The enclosure chassis is normally grounded through the ground lead of the IEC 320 AC

input receptacle. In addition, the chassis may be grounded by connecting a 16 AWG

minimum wire from the chassis grounding post, marked by the symbol located as shown

in Figure 1-3. This wire should be connected to the Building Telecommunications Ground.

Signal Ground

Signal ground andChassis Ground may be tiedtogether by wiring between the two terminal block

positions labeled SIG GND and CH GND. The unit is shipped with these two grounds connected

by a jumper. If required, this jumper may be removed to isolate the grounds.

E&M Ground

If you are using voice channels with Type I or Type V E&M signaling, the rear panel terminal

block position labeled E&M GND must be connected to the signaling ground of the switching

equipment (PBX). This ground connection is only used with E&M signaling types I and V.

The unit is shipped with a jumper that connects E&M GND to Chassis Ground. If the Metroplex

6000 Chassis Grounding Post is connected to the switching equipment’s ground, this is sufficient

toprovidethe returnpath.Otherwise,removethisjumperandconnecta wirefromthe E&M GND

position directly to the switching equipment ground.