work.

Fuse burnt

Cut off power source and change the same type

fuse. If fuse was burnt on end, it may be the problem

of connection; Find qualified professors to repair.

False or incomplete data

connection

Check, repair or change the data line. Ensure

connection is well and the first lamp’s single input is

connected with the controller output.

False address setting Check DMX address.

Problem of signal

connector of some fixtures

Pull out the signal output and input of one fixture.

Then connect both directly. If it works well, this

fixture is proved to be the failed one. Handle the rest

fixtures alike to check which fixture has problems. If

any problem, please connect the technician.

Reset normally, but

console

Abnormally or no

response.

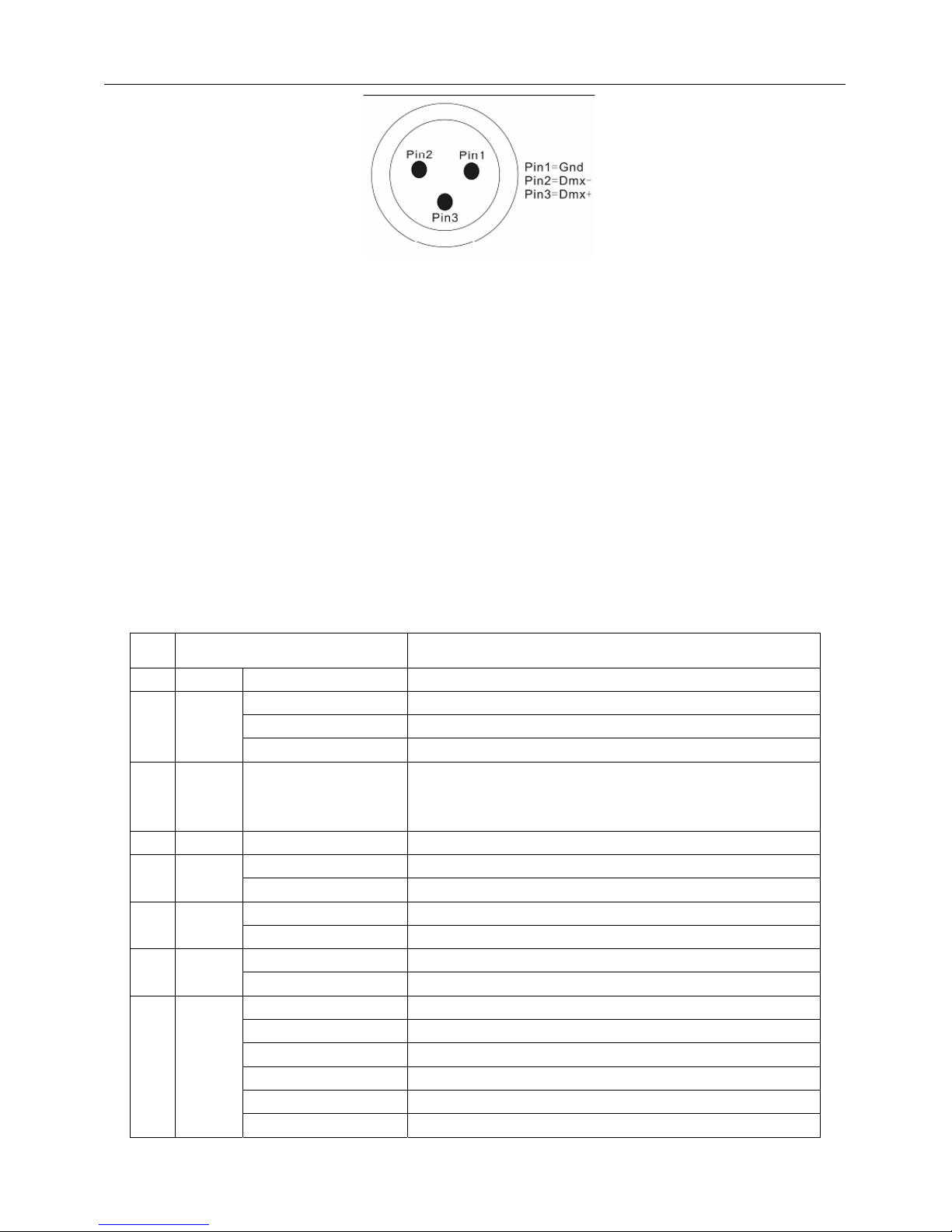

Signal output does not

match with the pin(pins2

and pins3 has a wrong

sequence)

Toggle the PHASE button on the controller to

reverse the polarity.

2. CLEANING

Though increasing reliability by designing well and we never stop to improve quality to lengthen lamp’s

lifespan. It is still indispensable to maintain it well by certain time in order to ensure best performance

First, clean fan and vent.

Favorable heat-dissipation and ventilation is vital to lamp’s normal work. So clean the fan and vent during a

certain time to guarantee smooth of wind path. Otherwise dust will barrier vent, which will affect the

performance because of over heat after working for some time.

Second, lens cleaning and maintenance

To ensure the best effect of lamp, please clean every lean or reflective setting. Use the soft cotton with some

lotion to clean it, but do not damage lens.

Third, check line during a certain time.

Check connecting line, wiring and ground line to ensure safety of using lamp during a certain time.

Forth, mechanical transmission part maintenance.

Check mechanical transmission part if it has any loose part during a certain time, such as a strap. Abrasion of

mechanical transmission part will affect stability of lamp work. If strap is loose, you should change it if

needed.

Page 17 of 18