vacuum trap assembly or the suction regulator. Doing so may permanently damage

the suction regulator and void any and all warranties, express or implied.

A collection canister (reusable or disposable) MUST be used between the patient

and the suction regulator or vacuum trap, if used. If a vacuum trap is not used it is

recommended that a disposable hydrophobic bacterial filter be used between the

suction canister and the suction regulator to prevent overflow of the canister into

the suction regulator. Use of these filters may also prevent build up of aerosolized

particulate inside the suction regulator, thus reducing maintenance requirements

and extending the life of the unit.

VERIFYING REGULATOR OPERATION

NOTE: The proper operation of the suction regulator must be verified prior to each

use. Should the regulator not operate in accordance with the following, it must be

repaired by authorized personnel.

1) Ensure that the Mode selector is in the OFF (center) position.

2) Connect the regulator to a vacuum source (normally the wall-mounted inlet).

3) Occlude the regulator inlet, and turn the adjustment knob one full turn

clockwise.

4) Verify that the gauge needle does not move from the “0” position.

5) Move the Mode selector to the “REG” position.

6) Occlude the regulator inlet, and turn the adjustment knob counter-clockwise

until the gauge needle is at 0.

7) Keeping the inlet occluded, turn the adjustment knob one full turn clockwise.

The gauge should read between 120 and 170 mmHg.

8) Keeping the inlet occluded, turn the adjustment knob fully clockwise. The

gauge needle should move clockwise to the highest vacuum setting.

9) Move the Mode selector to the “FULL” position.

10) Occlude the regulator inlet. The gauge needle should move to the highest

vacuum setting.

11) Turning the adjustment knob should have no effect on the gauge reading when

the selector knob is in the FULL position.

12) Move the Mode selector to the “OFF” position. The needle should return to 0

If the regulator passes all of the above, it is ready for patient use. Failure of any of

the above requires that the unit be serviced by authorized personnel.

Once the operation of the regulator has been verified, it can be prepared for patient

use as follows:

1) Connect the regulator to the wall inlet, ensuring proper latching.

2) Move the Mode selector to “REG”.

3) Occlude the inlet or tubing.

4) Adjust the regulator knob to achieve the desired level of vacuum.

5) Attach the suction catheter and proceed.

NOTE: the suction regulator should always be turned OFF when not in use. This

3

882VR Disassembly Instructions

1) Disconnect the 882VR from the suction source

2) Sterilize the suction regulator using ETO or autoclave, for self-protection

3) Remove the four screws on the back of the unit

4) Turn the regulator adjustment knob counterclockwise to release the faceplate

5) The gauge can be gently lifted out of the socket

6) The regulator can be gently lifted out of the socket

7) One screw holds the Mode selector lever in place.

Reassembly is accomplished by performing the above steps in reverse order.

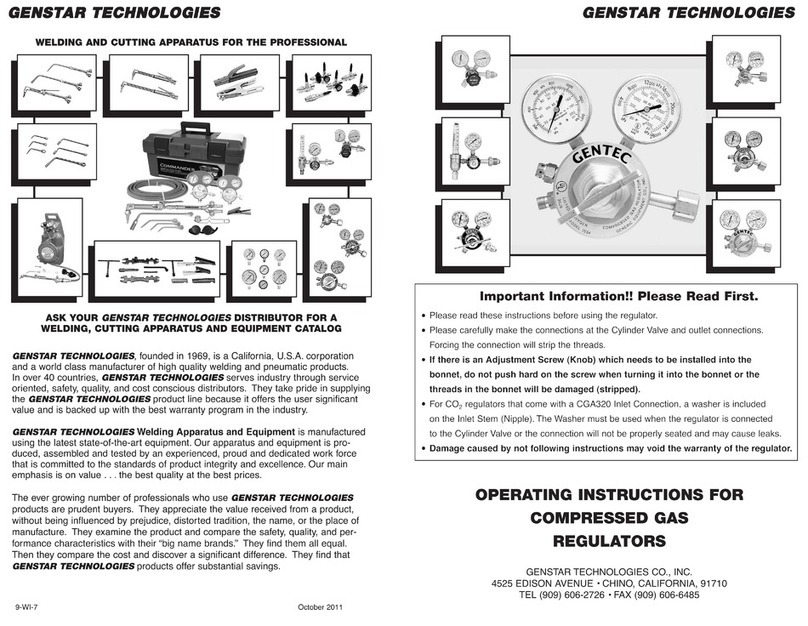

The following repair assemblies can be purchased from your Authorized GENTEC

distributor (refer to the exploded view on the next page):

Possible Back

Fittings

Ohio/Ohmeda

Chemetron

DISS Nut & Nipple

DISS Hand-Tight

Puritan-Bennett

Hose Barb

Possible Inlet Fittings

Vacuum Trap Assembly or Fitting Only

Hose Barb DISS Male

Figure 2 - Suction Regulator Configurations

DO NOT connect suction tubing directly to the vacuum trap, filter or suction regulator!

Vacuum Filter

4

The regulator can be cleaned by wiping the outside surfaces with disinfectants,

Virox (accelerated hydrogen peroxide), Clorox (sodium hypochlorite), and Cavi-

wipes. The internal flow path can be cleaned by suctioning a cold sterilant

through the unit, then allowing the unit to run for 30-45 minutes to dry the

interior.