6

Operation Manual / TRUMPF 951Introduction

You can nd further information, such as load capacity, dimensions and weight of all

track system parts in chapter “2.3 Track Mounting”, in the Gerriets Technic manual and

on our website www.gerriets.com.

IMPORTANT

The load capacity of the overall TRUMPF 95 system is determined by the

system’s weakest link. Do not load any component up to the maximum load

capacity as there is a risk of overloading hanging points.

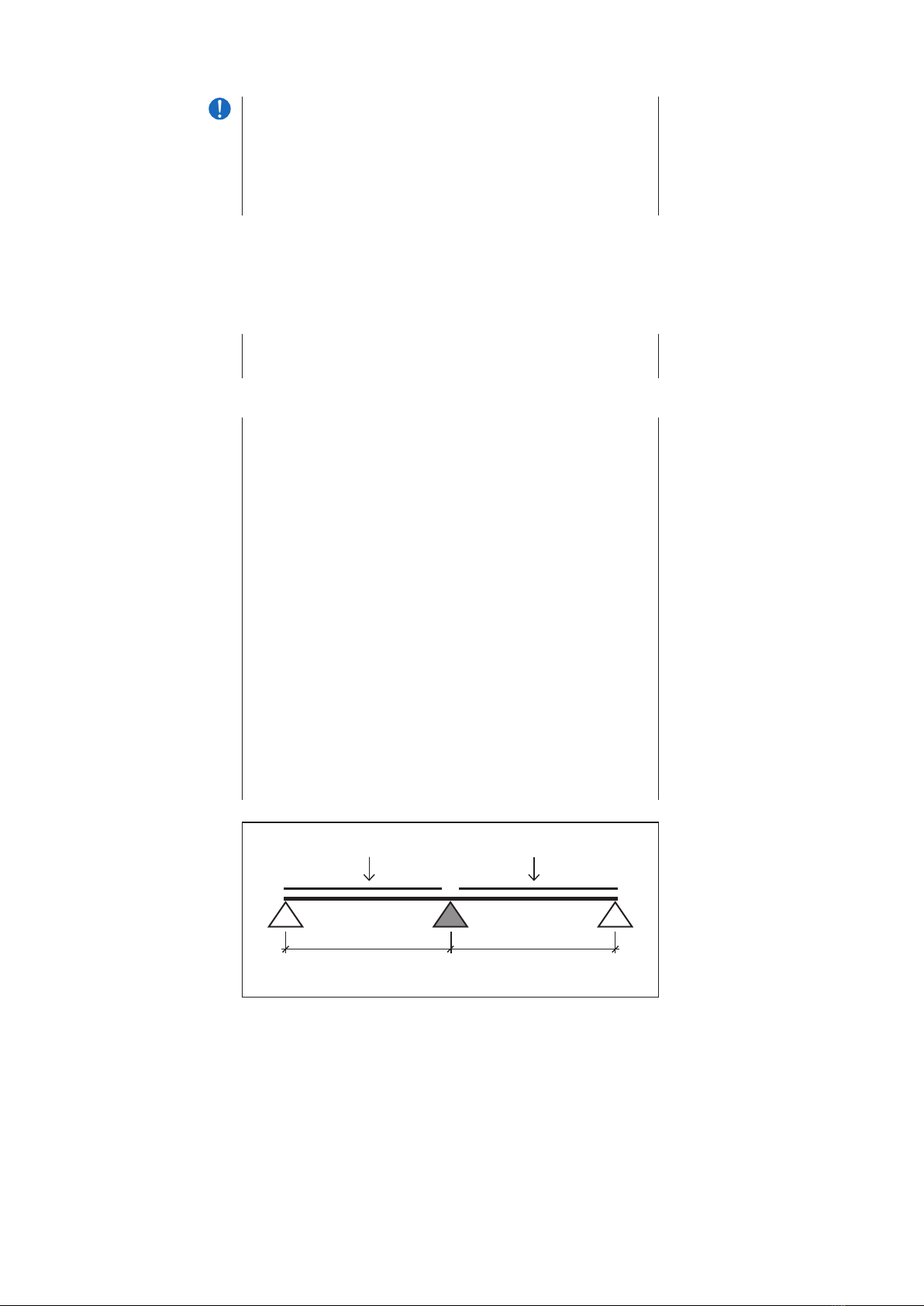

The track system should be designed with the load capacity of the hanging points:

The track system’s load (point load or uniform distributed load) is secured by the

hanging points.

The center hanging points’ weight load is higher than the weight load of the hanging

points at the end of the track (see also chapter 2.2.2).

The load capacity of the hanging points depend on the mounting nuts used. Replacing a

standard camlock nut with an adjustable nut or a HD nut can increase the load capacity.

If you still need a higher load capacity, or a replacement is not possible, you must

reduce the distance between the hanging points.

To dene the maximum hanging point distance for a given load weight, see the diagram

above.

IMPORTANT

Near a track splice the load bearing capacity of the track is lesser.

Compensate this fact by putting a suspension at a maximum distance of

100 mm from each track splice.

IMPORTANT

Make sure that under construction, suspension points and xing elements

being not part of the track system are dimensioned correctly.

1.7 Declaration of Conformity

1.8 System Options

According to the EU machinery directive (2006/42/EC) the Trumpf 95 track is considered

as a machine when it is used with a motorized operation system.

If Gerriets GmbH is assigned with setting up a complete Trumpf 95 system including

motor and control system we will conduct a conformity assessment. The CE mark will

be applied to the system.

If you merely procure the system components from Gerriets GmbH in order to set up the

system yourself, you are considered as the manufacturer according to the EU machinery

directive (2006/42/EC). In this case you are obliged to conduct the conformity testing

procedure yourself and Gerriets GmbH will only deliver a declaration of incorporation.

Manual or motor operation and control systems:

• ROPE-DRIVE: Manual operation with a continuous loop hemp rope Ø 22 mm.

• HAND-DRIVE: manual operation with hand crank.

• FRICTION-DRIVE: motor operation without rope. The motor moves via drive wheel

along the track.

• TRAC-DRIVE: Motor operation with continuous loop rope.

• G-FRAME 54 control unit.

• G-FRAME 54 frequency controller.

• Hand held remote control.

• Track switch, 2 positions, manual or motor operation, available with switch controller.

• Track switch, 3 positions, manual or motor operation, available with switch controller.