GGM gastro SD.15 User manual

1

CUTTER MIXER

Kasap Tip Dik Buzdolapları

CONTENTS

A GENEREAL INFORMATION Page 2

A1 PRODUCT DESCRIPTION Page 3

A2 TECHNICAL INFORMATION Page 3

A3 TRANSPORTATION Page 4

A4 UNPACKING Page 4

B INSTALLATION Page 4

C SAFETY INSTRUCTIONS Page 5

D OPERATION Page 6

E CLEANING & MAINTENANCE Page 8

F TROUBLESHOOTING Page 9

G SPARE PART LIST- EXPLODING DRAWINGS Page 10

H ELECTRIC CIRCUIT SCHEMA Page 15

2

CUTTER MIXER

Kasap Tip Dik Buzdolapları

A GENERAL INFORMATION

Before installing the appliance, read operation and maintenance instructions

carefully.Wrong installation and part changing may damage the product or may cause

injury on people.These are not in our company’s responsibility to damage the

appliance intentionally,negligence,detriments because of disobeying instructions and

regulations,wrong connections.Unauthorized intervention to appliance invalidates the

warranty.

1. This instruction manual should be kept in a safe place for future reference.

2. Installation should be made in accordance with ordinances and security rules of

that country by a qualified service personnel.

3. This appliance has to be used by trained person.

4. Please turn off the appliance immediately in the event of malfunction or failure.The

appliance should be repaired only by authorized service personnel.Please demand

original spare part.

3

CUTTER MIXER

Kasap Tip Dik Buzdolapları

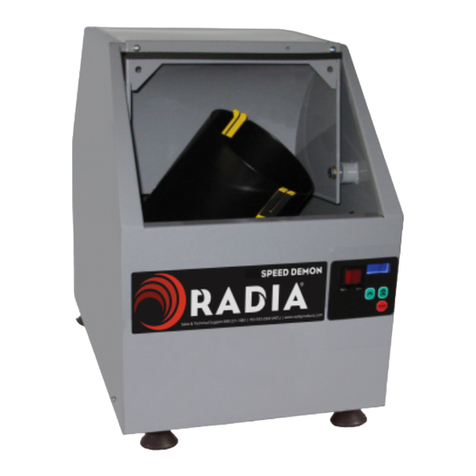

A1 PRODUCT DESCRIPTION

*Professional Cutter Mixer,that provides high efficiency has been designed to be used in

industrial kitchens.

Product Code

Dimensions (mm)

Weight (kg)

Packaging

Dimensions (mm)

SD.07

640x615x1045

60

390x660x1130

SD.09

718X684X1245

70

750X750X1285

SD.15

380x623x512

46

410x660x650

A2 TECHNICAL INFORMATION

Product

Code

Capacity

(lt)

Tank

Dimensions

(mm)

Power

(Kw)

Operating

Voltage

(V)

Cable

(mm²)

Fuse

(A)

SD.07

20

293x293

1,5-2,5

380

5x1,5

32

SD.09

50

400X400

3,5-5,5

380

5X1,5

32

SD.15

15

290x220

0,60-0,90

380

5x1,5

32

4

CUTTER MIXER

Kasap Tip Dik Buzdolapları

A3 TRANSPORTATION

*This appliance can be moved by hand from area to area.Do not crash and drop the appliance

while transporting.

A4 UNPACKING

*Please unpack the package according to the security codes and ordinances of current

country and get rid from the pack.Parts which contacts with food are produced by stainless

steel.All plastic parts are marked by material’s symbol.

*Please check that all the parts of appliance had come completely and if they are damaged or

not during the shipping.

B INSTALLATION

*Please place the product to straight and sturdy ground,please take necessary steps against

possibility of overturn.

*Technician who will serve for installation and service for the appliance must be professional

on this subject and must have installation and service licenses by the company.

*Connection to Electric Power Supply must be done by authorized person .

*Please be sure that the voltage connected to appliance must be equal with the voltage which

is on appliance’s label.

This appliance must be connected to an earthed outlet in accordance with safety rules

and standards.

*Appliance’s earthing must be connected to earthing line on panel which is nearest to electric

installation.

*Connection to the main fuse and leak current fuse must be done in accordance with the

current regulations.

!

5

CUTTER MIXER

Kasap Tip Dik Buzdolapları

C SAFETY INSTRUCTIONS

*Do not use the appliance in insufficient lighted place.

*Do not touch the moving attachments while the appliance operates.

*Do not install the appliance in the presence of flammable or explosive materials.

*Do not operate the appliance when the machine is empty.

*Do not load so less or more than appliance’s capacity.

*Do not attempt to use the appliance without suitable protective equipments.

*Because of any reason if there is a fire or flame flare where the appliance is

used,turn off all gas valves and electric contactor switch quickly and use fire

extinguisher .Never use water to extinguish the fire.

*All the damages because of not having earthing connection will not be on

warranty.

*Do not put your hands into the cutting tank while the appliance is operating.

!

!

!

!

!

!

!

6

CUTTER MIXER

Kasap Tip Dik Buzdolapları

D OPERATION

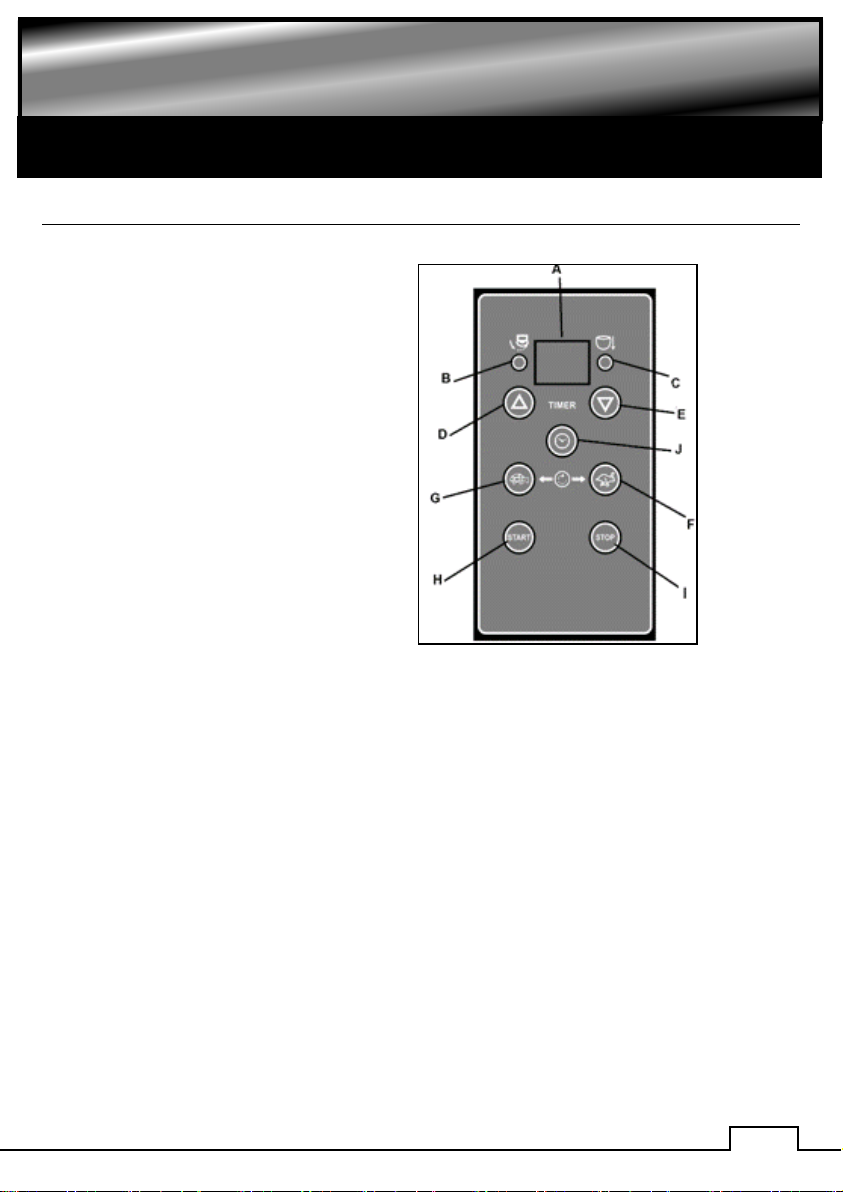

*Control Panel;

A: Digital Indicator

B: Lid is opened error

C: Bowl error

D-E : Speed setting

F-G : Timer setting

H: Start switch

I : Stop switch

J: Stop time

SD.07-SD.09

*Operating;

•Before operating the appliance,clean the blade and tank with wet cloth and dry.

•Provide the ducts on cutting blades to pass on to the shaft.

•Open the appliance’s upper lid and fill the materials into the vegetable tank.

•Press START button to operate the appliance.

•If the appliance operates with 380 V,while plugging during first operation ,pay attention to

be operated on the direction of arrow.

•If it is wanted to add material without opening the lid while the appliance is working,solid

materials can be added through lid space after dividing into small pieces.

•For adjusting the speed of the mixer,press (G) for low and press (F) for high.

•Press ‘’timer’’ button to set desired time using the buttons up/down. When time

expires,the appliance will stop.

•Turn off the timer to operate the appliance pressing stop button.

•In order to take off the materials ,first open the lid and unsettle the cutting blade.Careen

the bowl by turning the overturning handle to down.

•After taking off the materials,provide the bowl to be in vertical position by lifting bowl

handle up.

•After the operation completed,unplug the power supply.

7

CUTTER MIXER

Kasap Tip Dik Buzdolapları

*Control Panel;

A: Digital Indicator

B: Lid is opened error

C: Bowl error

D-E : Speed setting

F-G : Timer setting

H: Start switch

I : Stop switch

J: Stop time

SD.15

*Operating;

•Before operating the appliance,clean the blade and tank with wet cloth and dry.

•Provide the ducts on cutting blades to pass on to the shaft.

•Open the appliance’s upper lid and fill the materials into the vegetable tank.

•Press START button to operate the appliance.

•If the appliance operates with 380 V,while plugging during first operation ,pay attention to

be operated on the direction of arrow.

•If it is wanted to add material without opening the lid while the appliance is working,solid

materials can be added through lid space after dividing into small pieces.

•For adjusting the speed of the mixer,press (G) for low and press (F) for high.

•Press ‘’timer’’ button to set desired time using the buttons up/down. When time

expires,the appliance will stop.

•Turn off the timer to operate the appliance pressing stop button.

•In order to take off the materials ,first open the lid and unsettle the cutting blade.Careen

the bowl by turning the overturning handle to down.

•After taking off the materials,provide the bowl to be in vertical position by lifting bowl

handle up.

•After the operation completed,unplug the power supply.

•

8

CUTTER MIXER

Kasap Tip Dik Buzdolapları

E CLEANING & MAINTENANCE

➢CLEANING AND MAINTENANCE AFTER EVERY USE

•Clean outer surface of appliance,tank and cutting blade with hot water and then dry.

•Always turn off the appliance and disconnect from the power supply before cleaning.

•Do not use abrasive cleaning chemicals as these can leave harmful residues.

•Do not clean the appliance by spraying water directly,otherwise electric motor may

get damaged.

➢PERIODIC CLEANING AND MAINTENANCE

•Maintenance should be done by qualified person.

•Get the periodic maintenance of the appliance once in every 15 days.

•The Cutter Mixer requires low maintenance (Motor and ball bearings are lubricated ).

•Maintenance of appliance’s contactor should be done by compressed air according

to frequency of use.

•Maintenance of cutting blade ;

- Grind the blade with aqueous grinding wheels without disrupting blade angle.

9

CUTTER MIXER

Kasap Tip Dik Buzdolapları

F TROUBLESHOOTING

THE APPLIANCE DOESN’T OPERATE

1. Check if the appliance is plugged in.

2. Check the electrical connections and

voltage.

3. Check the bowl’s lid.

THE APPLIANCE IS NOISY

1. Check the cutting blades.

2. Check that if there is material

accumulated in the tank.

3. If the motor is noisy,stop it and call

authorized service.

THE APPLIANCE STOPPED

1. The appliance can stop due to low

voltage.In this situation check the

voltage

2. If the appliance is overloaded,turn off

the appliance and allow to cool down by

taking off some materials from bowl

ERROR MESSAGE(SD.07-SD.09)

E3: Bowl error

ERROR MESSAGE(SD.15)

E1: Motor error

E3: Bowl error

•If Cutter Mixing is not done at suitable quality

•If any function of security doesn’t work

➢Do not use the appliance.

*If these problems are still going on,contact with our authorized service.

10

CUTTER MIXER

Kasap Tip Dik Buzdolapları

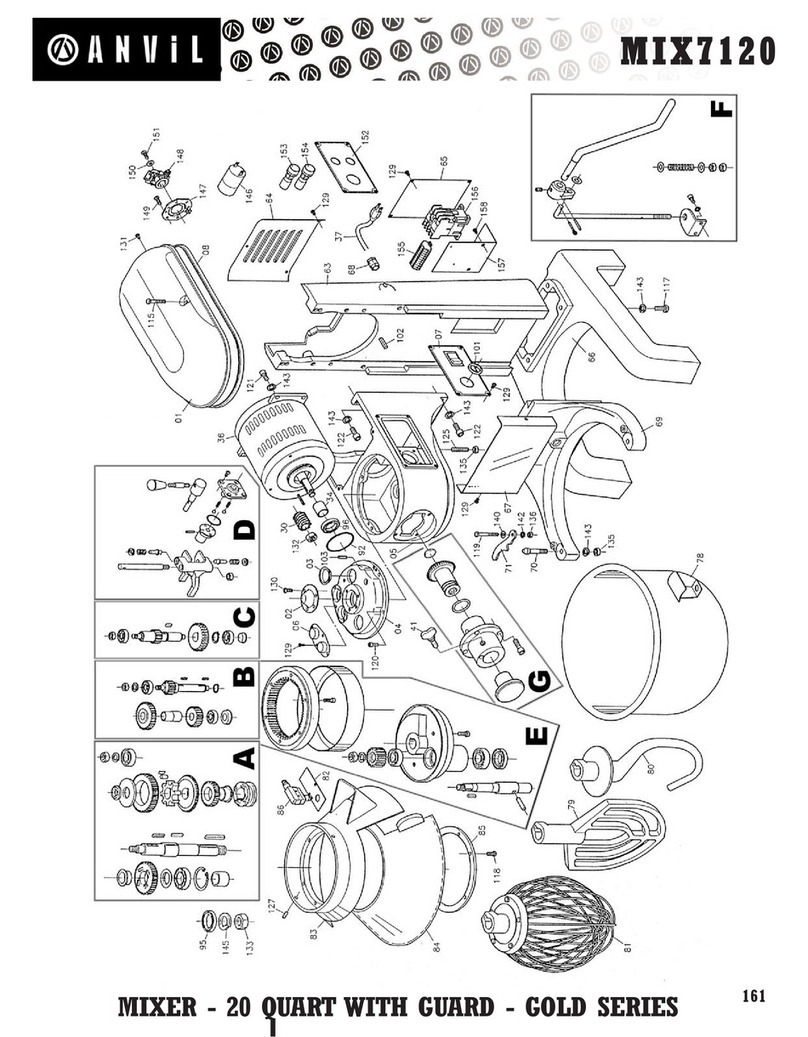

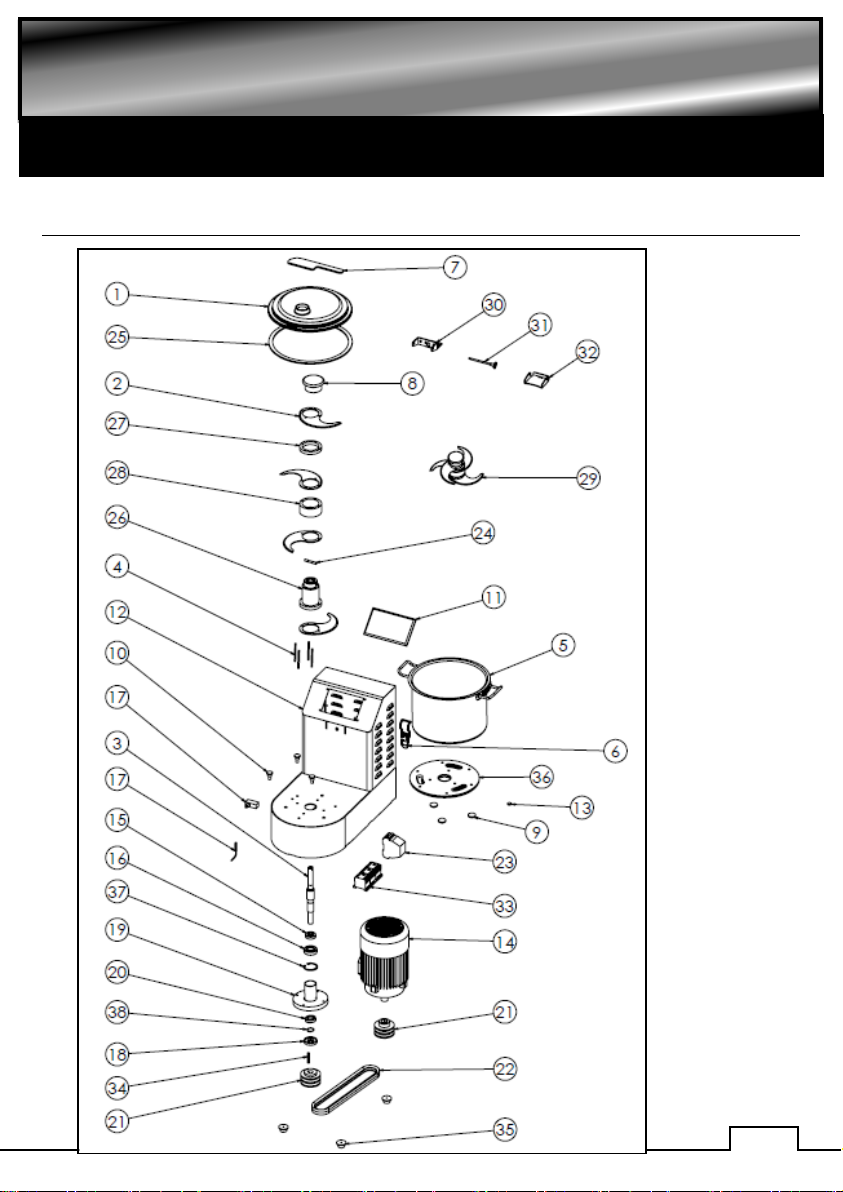

G SPARE PART LIST- EXPLODING DRAWINGS

11

CUTTER MIXER

Kasap Tip Dik Buzdolapları

G SPARE PART LIST- EXPLODING DRAWINGS

PRODUCT CODE:SD.07

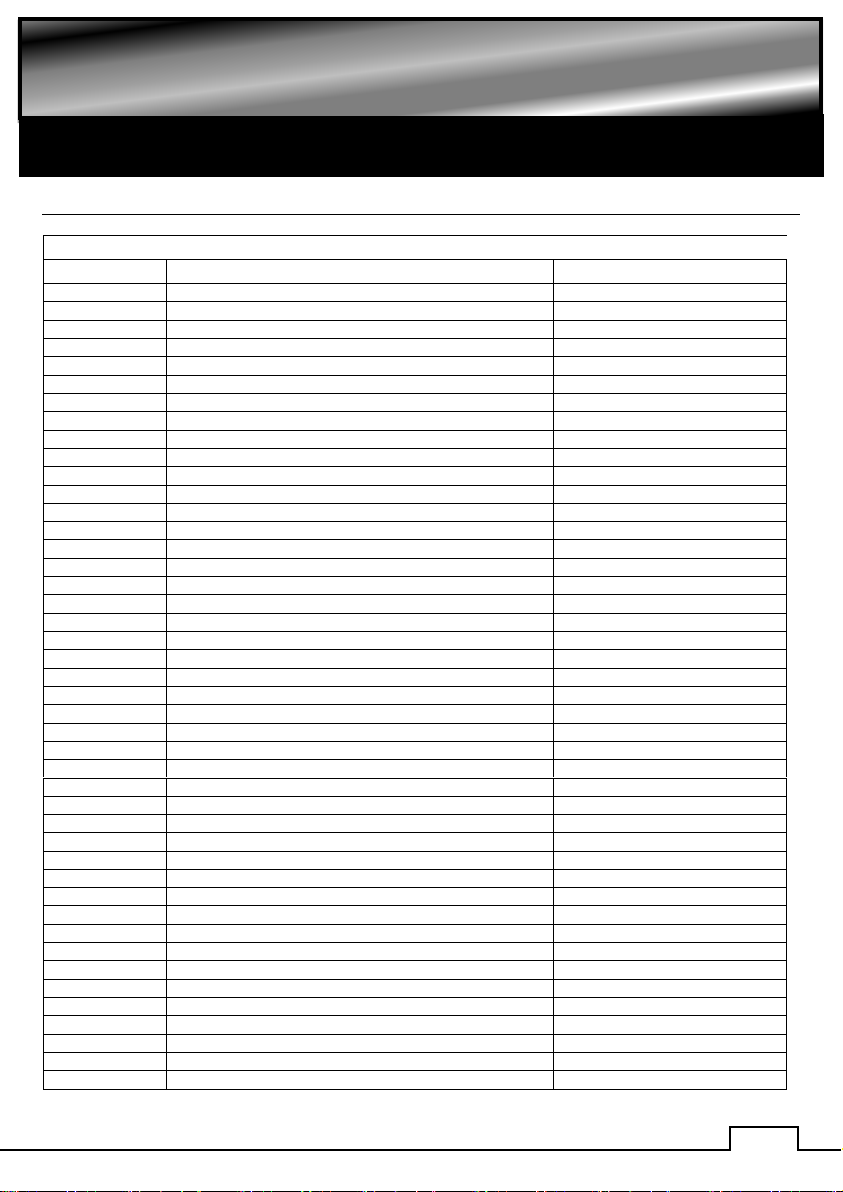

NO

PRODUCT NAME

P.CODE

1

LID

Y.SD.07.001

2

BOWL RUBBER

Y.SD.07.002

3

BLADE

Y.SD.07.003

4

BALL BEARING (4904)

Y.SD.07.004

5

MAGNET

Y.SD.07.005

6

BOWL

Y.SD.07.006

7

LOCK LATCH

Y.SD.07.007

8

SCRAPER PLASTIC

Y.SD.07.008

9

BOWL STOPPER PLASTIC

Y.SD.07.009

10

BOWL BOTTOM PLASTIC

Y.SD.07.010

11

BLADE FIXATION

Y.SD.07.011

12

BOWL PLATFORM

Y.SD.07.012

13

SHAFT PLASTIC

Y.SD.07.013

14

SEAL (35*52*10)

Y.SD.07.014

15

SEAL (30*47*7)

Y.SD.07.015

16

MOTOR

Y.SD.07.016

17

MOTOR SAFETY

Y.SD.07.017

18

HINGE PIN

Y.SD.07.018

19

TURNOVER HANDLE PLASTIC

Y.SD.07.019

20

HINGE

Y.SD.07.020

21

TURNOVER HANDLE

Y.SD.07.021

22

BLADE HANDHOLD

Y.SD.07.022

23

FLAKE

Y.SD.07.023

24

SHORT SHAFT

Y.SD.07.024

25

PANEL

Y.SD.07.025

26

BIG SHAFT BEARING

Y.SD.07.026

27

SMALL SHAFT BEARING

Y.SD.07.027

28

BASE FRAME

Y.SD.07.028

29

SWITCH

Y.SD.07.029

30

FEET

Y.SD.07.030

31

SENSOR

Y.SD.07.031

32

BLADE BODY ALUMINIUM

Y.SD.07.032

33

THIN BLADE BODY

Y.SD.07.033

34

THICK BLADE BODY

Y.SD.07.034

35

BLADE GROUP

Y.SD.07.035

36

SEGMAN (471-25)

Y.SD.07.036

37

MOTOR SHAFT

Y.SD.07.037

38

LONG SHAFT

Y.SD.07.038

39

THERMIC

Y.SD.07.039

40

CONTACTOR DİLEM 09-30-10

Y.SD.07.040

41

LID HINGE

Y.SD.07.041

42

BEARING BLOCK BOTTOM CASTING

Y.SD.07.042

43

SEAL (20*37*10)

Y.SD.07.043

44

BOWL BOTTOM PIN

Y.SD.07.044

12

CUTTER MIXER

Kasap Tip Dik Buzdolapları

G SPARE PART LIST- EXPLODING DRAWINGS

PRODUCT CODE:SD.09

NO

PRODUCT NAME

P.CODE

1

LID

Y.SD.09.001

2

BOWL RUBBER

Y.SD.09.002

3

BLADE

Y.SD.09.003

4

BALL BEARING (6806)

Y.SD.09.004

5

MAGNET

Y.SD.09.005

6

BOWL

Y.SD.09.006

7

LOCK LATCH

Y.SD.09.007

8

SCRAPER PLASTIC

Y.SD.09.008

9

BOWL STOPPER PLASTIC

Y.SD.09.009

10

BOWL BOTTOM PLASTIC

Y.SD.09.010

11

BLADE FIXATION

Y.SD.09.011

12

BOWL PLATFORM

Y.SD.09.012

13

SHAFT PLASTIC

Y.SD.09.013

14

SEAL (45*62*10)

Y.SD.09.014

15

SEAL (40*55*10)

Y.SD.09.015

16

MOTOR

Y.SD.09.016

17

MOTOR SAFETY

Y.SD.09.017

18

HINGE PIN

Y.SD.09.018

19

TURNOVER HANDLE PLASTIC

Y.SD.09.019

20

HINGE

Y.SD.09.020

21

TURNOVER HANDLE

Y.SD.09.021

22

BLADE HANDHOLD

Y.SD.09.022

23

FLAKE

Y.SD.09.023

24

SHORT SHAFT

Y.SD.09.024

25

PANEL

Y.SD.09.025

26

BIG SHAFT BEARING

Y.SD.09.026

27

SMALL SHAFT BEARING

Y.SD.09.027

28

BASE FRAME

Y.SD.09.028

29

SWITCH

Y.SD.09.029

30

FEET

Y.SD.09.030

31

SENSOR

Y.SD.09.031

32

BLADE BODY ALUMINIUM

Y.SD.09.032

33

THIN BLADE BODY

Y.SD.09.033

34

THICK BLADE BODY

Y.SD.09.034

35

BLADE GROUP

Y.SD.09.035

36

SEGMAN (471-40)

Y.SD.09.036

37

MOTOR SHAFT

Y.SD.09.037

38

LONG SHAFT

Y.SD.09.038

39

THERMIC

Y.SD.09.039

40

CONTACTOR DİLEM 09-30-10

Y.SD.09.040

41

LID HINGE

Y.SD.09.041

42

BEARING BLOCK BOTTOM CASTING

Y.SD.09.042

43

SEAL (30*42*7)

Y.SD.09.043

44

BOWL BOTTOM PIN

Y.SD.09.044

13

CUTTER MIXER

Kasap Tip Dik Buzdolapları

G SPARE PART LIST- EXPLODING DRAWINGS

14

CUTTER MIXER

Kasap Tip Dik Buzdolapları

G SPARE PART LIST- EXPLODING DRAWINGS

PRODUCT CODE:SD.15

NO

PRODUCT NAME

P.CODE

1

LID

Y.SD.15.001

2

BLADE

Y.SD.15.002

3

BEARING BLOCK SHAFT

Y.SD.15.003

4

BLADE FIXATION

Y.SD.15.004

5

BOWL

Y.SD.15.005

6

LOCK LATCH

Y.SD.15.006

7

SCRAPER PLASTIC

Y.SD.15.007

8

BLADE HANDHOLD

Y.SD.15.008

9

BOWL STOPPER PLASTIC

Y.SD.15.009

10

BOWL BOTTOM PIN

Y.SD.15.010

11

PANEL

Y.SD.15.011

12

BASE FRAME

Y.SD.15.012

13

MAGNET

Y.SD.15.013

14

MOTOR

Y.SD.15.014

15

SEAL (20*42*10)

Y.SD.15.015

16

BALL BEARIBG (6004)

Y.SD.15.016

17

SENSÖR

Y.SD.15.017

18

SEAL (25*52*10)

Y.SD.15.018

19

BEARING

Y.SD.15.019

20

BALL BEARING (6205)

Y.SD.15.020

21

BEARING BLOCK PULLEY

Y.SD.15.021

22

BELT (13X850)

Y.SD.15.022

23

THERMIC

Y.SD.15.023

24

PIN

Y.SD.15.024

25

PAN RUBBER

Y.SD.15.025

26

ALUMINIUM BLADE BODY

Y.SD.15.026

27

THIN ALUMINIUM BLADE

Y.SD.15.027

28

THICK ALUMINIUM BLADE

Y.SD.15.028

29

BLADE GROUP

Y.SD.15.029

30

BODY HINGE SHEET METAL

Y.SD.15.030

31

HINGE SHAFT

Y.SD.15.031

32

LID HINGE SHEET METAL

Y.SD.15.032

33

CONTACTOR DİLEM10

Y.SD.15.033

34

WEDGE

Y.SD.15.034

35

FEET

Y.SD.15.035

36

BOWL BOTTOM PLASTIC

Y.SD.15.036

37

SEGMAN (472-52)

Y.SD.15.037

38

SEGMAN (471-25)

Y.SD.15.038

15

CUTTER MIXER

Kasap Tip Dik Buzdolapları

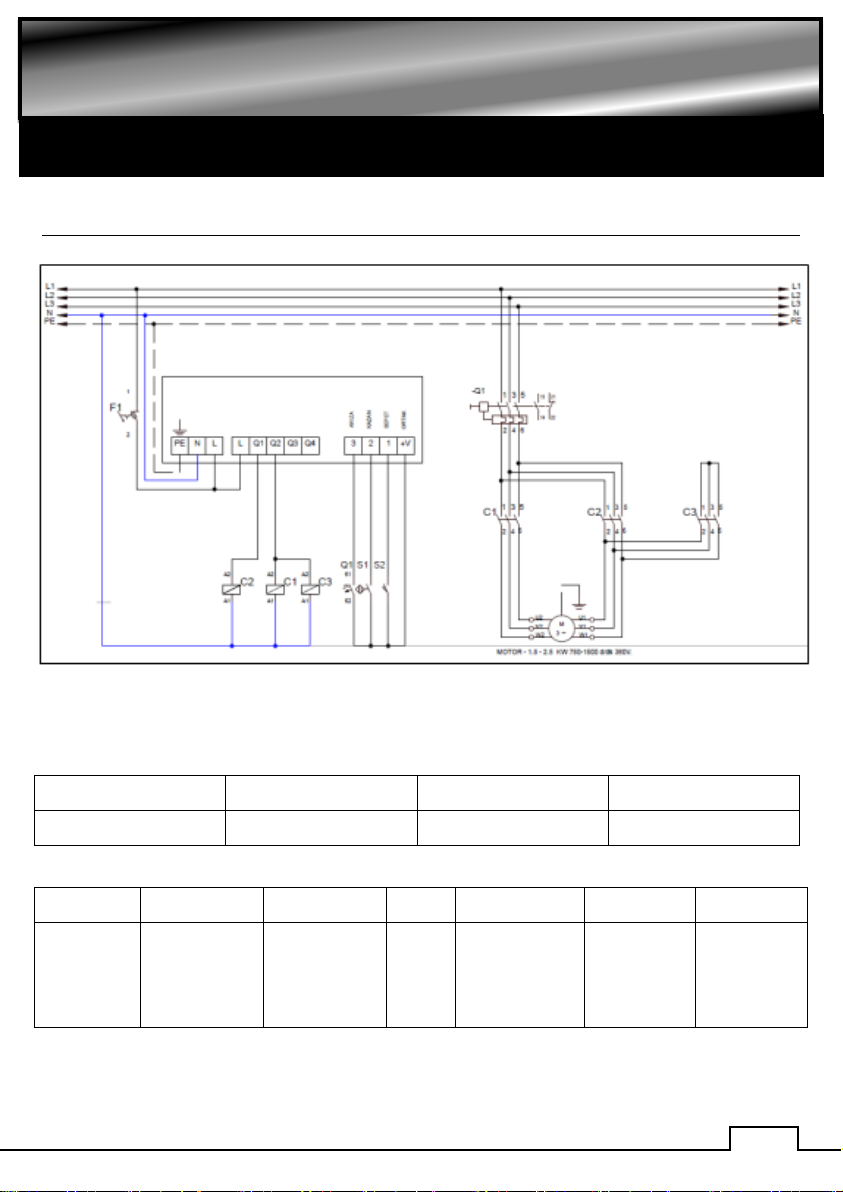

H ELECTRIC CIRCUIT SCHEMA

PRODUCT CODE

POWER (KW)

RPM

VOLTAGE

SD.07

1,5/2,5

750/1500

380

Q1

C2

C3-C4

M

S1

S2

F1

Motor

Safety

Relay

2.Speed

Contactor

1.Speed

Contactor

Motor

Bowl

Magnetic

Sensor

Basket

Magnetic

Swich

Control

Panel

Fuse 1X4A

16

CUTTER MIXER

Kasap Tip Dik Buzdolapları

H ELECTRIC CIRCUIT SCHEMA

PRODUCT CODE

POWER (KW)

RPM

VOLTAGE

SD.09

3,5/5,5

750/1500

380

Q1

C2

C3-C4

M

S1

S2

F1

Motor

Safety

Relay

2.Speed

Contactor

1.Speed

Contactor

Motor

Basket

Magnetic

Sensor

Bowl

Magnetic

Swich

Control

Panel Fuse

1X4A

17

CUTTER MIXER

Kasap Tip Dik Buzdolapları

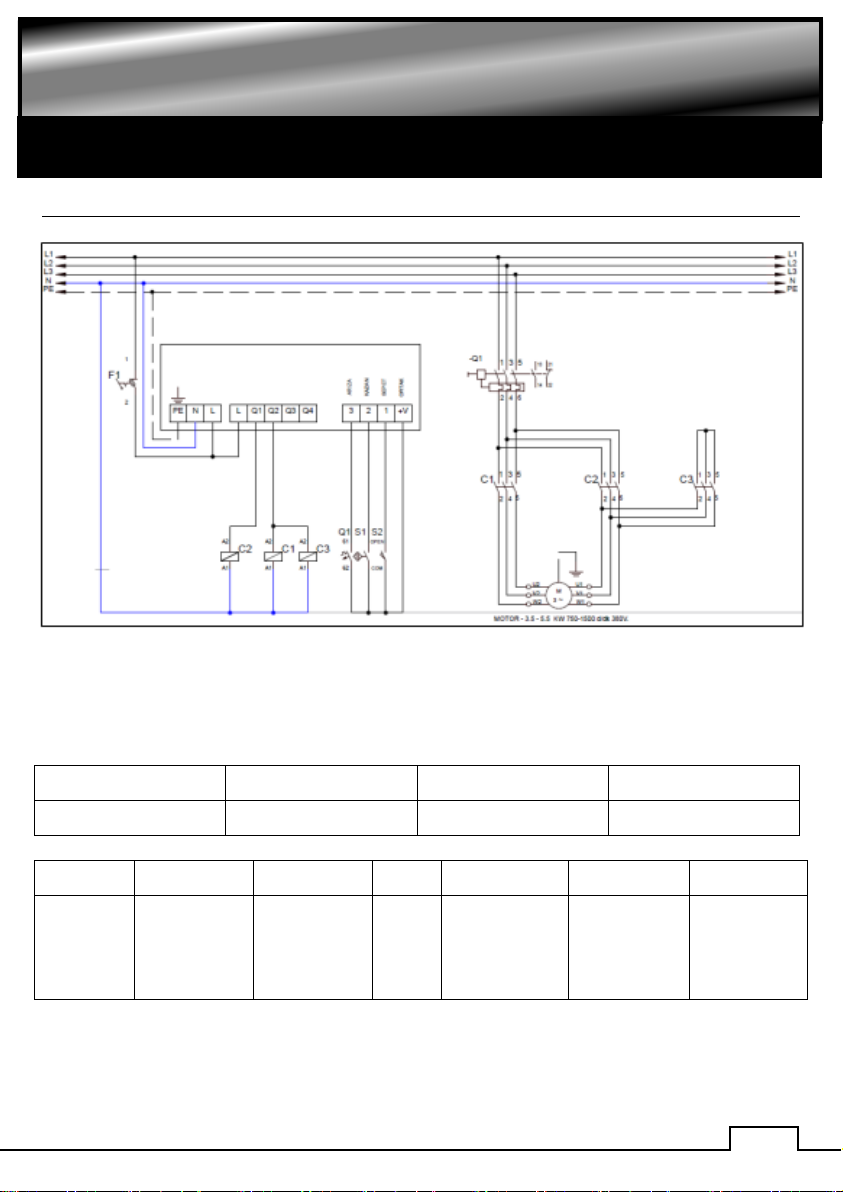

H ELECTRIC CIRCUIT SCHEMA

PRODUCT CODE

POWER (KW)

RPM

VOLTAGE

SD.15

0,60/0,90

750/1500

380

Q1

C2

C3-C4

M

S1

S2

F1

Motor

Safety

Relay

1.Speed

Contactor

2.Speed

Contactor

Motor

Bowl

Magnetic

Sensor

Basket

Magnetic

Swich

Control

Panel Fuse

1X4A

This manual suits for next models

2

Table of contents