Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC Declaration of Conformity ....................................................................... 5

2. Safety .................................................................................................... 6

2.1. Important information ............................................................................. 6

2.2. Warning signs ..................................................................................... 6

2.3. Intended use ...................................................................................... 6

2.4. Safety precautions ................................................................................ 7

3. Installation .............................................................................................. 8

3.1. Unpacking/delivery ............................................................................... 8

3.2. Installation ......................................................................................... 11

3.3. Pre-use check ..................................................................................... 22

3.4. Recycling information ............................................................................. 24

4. Operation ............................................................................................... 25

4.1. Operation/Control ................................................................................. 25

4.2. Troubleshooting ................................................................................... 26

4.3. Cleaning - recommendations .................................................................... 27

4.4. Temperature limits ................................................................................ 27

4.5. Pressure limits ..................................................................................... 28

5. Maintenance ........................................................................................... 29

5.1. General Maintenance ............................................................................. 29

5.2. Replacement of drive unit with bearing frame ................................................. 30

5.3. Replacement of drive unit ........................................................................ 32

5.4. Replacement of drive unit (Motor and shaft unit) .............................................. 34

5.5. Dismantling and mounting shaft (with bearing frame except BC160) ....................... 35

5.6. Replacement of bearings, type B20, B25, B25/30, B35, B35/40, B45, B45/50, B55,

B55/60 ............................................................................................. 37

5.7. Replacement of bearings, type BC160DH ..................................................... 39

5.8. Replacement of bearing, type BC160D ........................................................ 41

5.9. Replacement of bearings type BC160 .......................................................... 43

5.10.Replacement of shaft seal, type D .............................................................. 45

5.11.Replacement of shaft seal, type DC ............................................................ 48

5.12.Replacement of shaft seal, type S (and type S with dust trap) ............................... 51

5.13.Replacement of shaft seal, type S3 ............................................................. 55

5.14.Replacement of shaft seal, type R or G ........................................................ 58

5.15.Replacement of shaft seal, type V .............................................................. 61

5.16.Replacement of wear bushing in intermediate bearing support .............................. 63

5.17.Replacement of wear bushing in bottom support ............................................. 64

6. Technical Data ......................................................................................... 65

6.1. Technical data ..................................................................................... 65

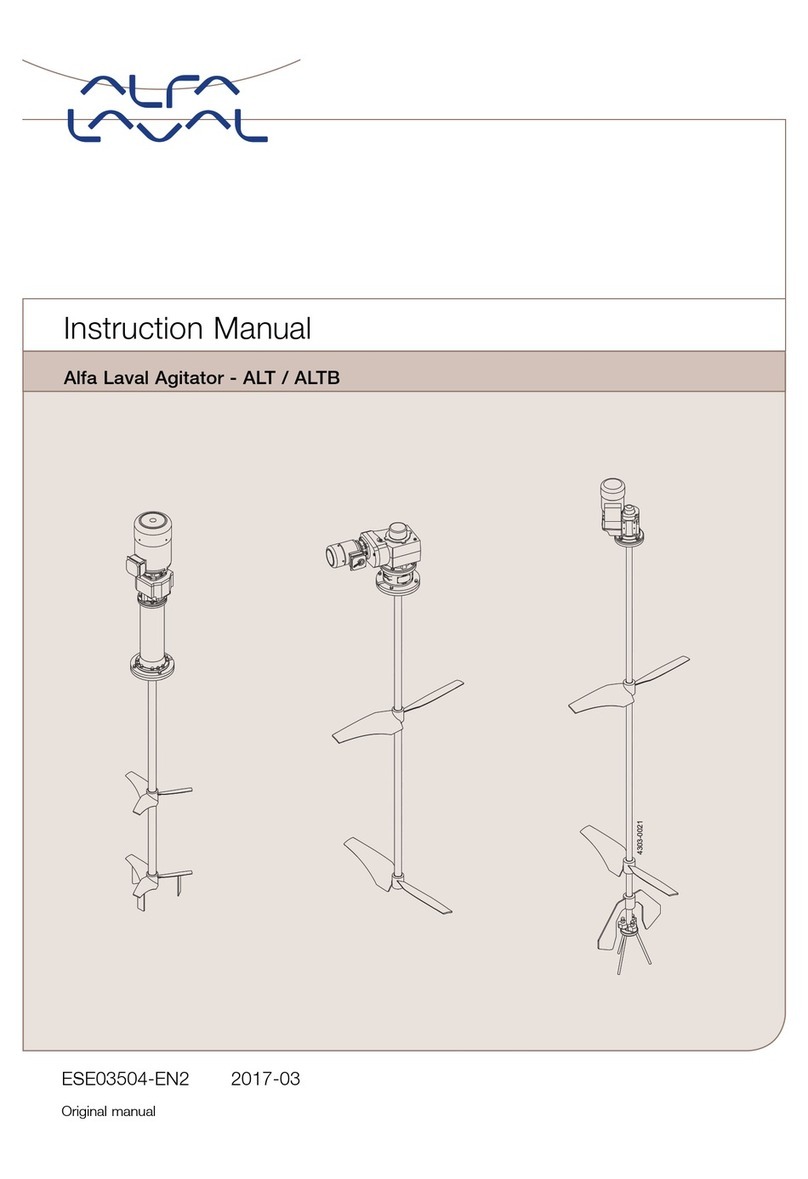

6.2. Mounting angle for top mounting agitator type ALT ........................................... 66

6.3. Mounting angle for top mounting agitator type ALTB ......................................... 68

6.4. Connecting flush – Seal type D .................................................................. 69

6.5. Connecting flush – Seal type DC ................................................................ 71

6.6. Tightening torques for bolt connections ........................................................ 73

6.7. Shaft alignment ................................................................................... 74

6.8. Spider coupling ................................................................................... 76

6.9. Bottom support alignment ....................................................................... 77

6.10.Bottom support positioning ...................................................................... 78

3