EN

A) TRAINING

1) R ad th instructions car fully. Become

acquainted wit t e controls and t e proper use of

t e mac ine. Learn ow to stop t e engine quickly.

2) Only use t e mac ine for t e purpose for w ic

it was designed, t at is for “f lling, bucking and

d limbing tr s with dim nsions suitabl for

th l ngth of th bar” or wooden objects wit t e

same c aracteristics. Any ot er use may be dan-

gerous and damage t e mac ine.

Examples of improper use may include, but are not

limited to:

– trimming edges;

– intaglio carving;

– sectioning pallets, crates and various packing

materials;

– sectioning furniture or ot er materials wit nails,

screws or ot er metal components;

– butc ering meat;

– using t e mac ine to lift, move or split objects;

– using t e mac ine w ile fastened to fixed sup-

ports.

3) Never allow c ildren or persons unfamiliar wit

t ese instructions to use t e mac ine. Local regu-

lations may restrict t e age of t e operator.

4) T e mac ine must never be used by more t an

one person.

5) N v r us th machin :

– w en people, especially c ildren or pets are in

t e vicinity;

– f t e user is tired or unwell, or as taken medici-

ne, drugs, alco ol or any substances w ic may

slow is reflexes and compromise is jud-

gement;

– if t e user is not capable of olding t e mac ine

firmly wit two ands and/or remaining standing

on t e ground w ilst working.

6) Remember t at t e operator or user is respon-

sible for accidents or azards occurring to ot er

people or t eir property.

B) PREPARATION

1) Always w ar ad quat clothing which do s

not hamp r mov m nts wh n using th ma-

chin .

– Always wear slim-fitting protective clot ing, fitted

wit s ear-proof protection devices.

– Always wear a elmet, protective gloves, eye-

goggles, a alf-mask respirator and safety anti-

s ear boots wit non-slip soles.

– Always wear ear and earing protection devices.

– Never wear scarves, s irts, necklaces, or any

anging or flapping accessory t at could catc

in t e mac ine or in any objects or materials in

t e work area

– Tie your air back if it is long.

2) WARNING: DANGER! Fu l is highly flamma-

bl :

–keep t e fuel in containers w ic ave been

specifically manufactured and omologated for

suc use;

– never smoke w en andling fuel;

– slowly open t e fuel tank to allow t e pressure

inside to decrease gradually;

– top up t e tank wit fuel in t e open air, using a

funnel;

– add fuel before starting t e engine. N v r r -

mov th fu l tank cap or add fu l whil th

ngin is running or wh n th ngin is hot;

– if you ave spilt some fuel, do not attempt to start

t e engine but move t e mac ine away from t e

area of spillage and avoid creating any source of

ignition until t e fuel as evaporated and fuel

vapours ave dissipated;

– immediately clean up all traces of fuel spilt on t e

mac ine or on t e ground;

– never start t e mac ine in t e same place you

refilled it wit fuel;

– make sure your clot ing does not come into con-

tact wit t e fuel, on t e contrary, c ange your

clot es before starting t e engine;

– always put t e tank and fuel container caps back

on and tig ten well.

3) Replace faulty or damaged silencers.

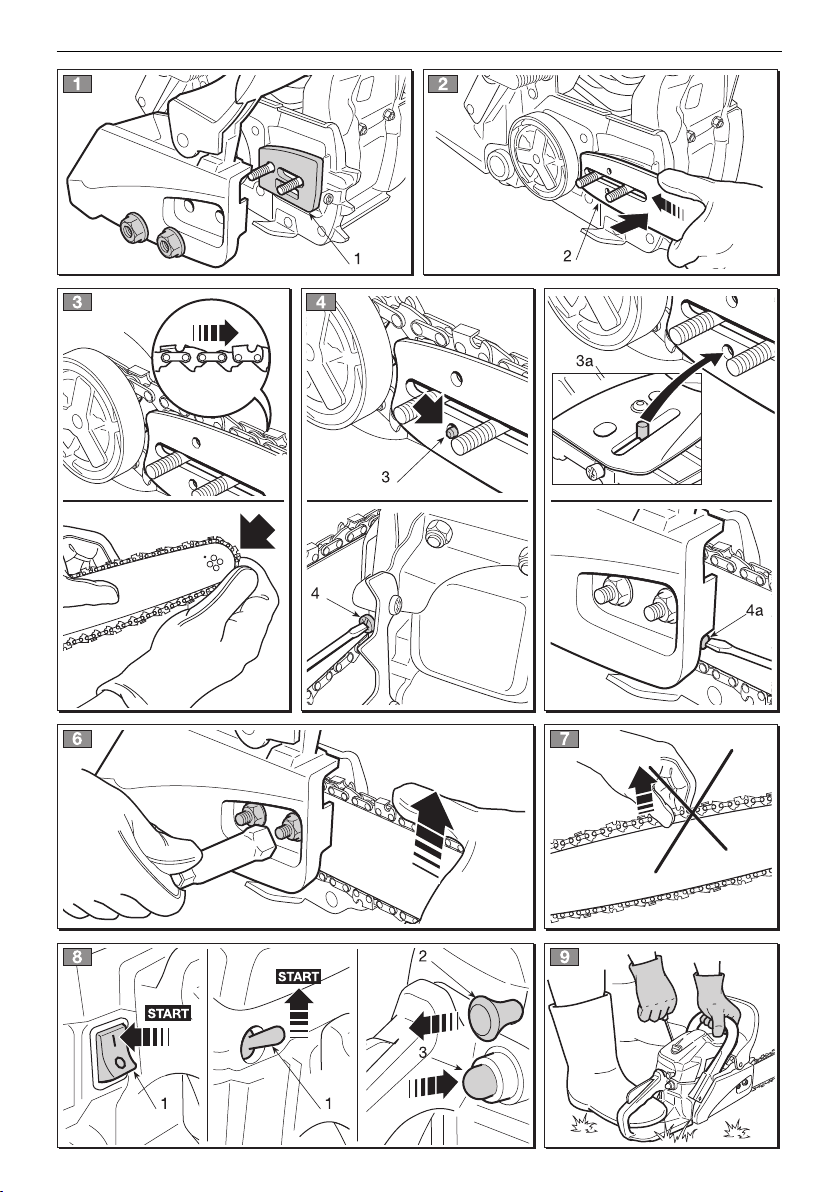

4) B for using th machin , c eck its general

condition and in particular:

– t e t rottle trigger and t e safety lever must

move freely, t ey must not need forcing and

s ould return automatically and rapidly back to

t e neutral position;

– t e t rottle trigger must remain locked until t e

safety lever is pressed;

– t e engine stop switc must easily move from

one position to t e ot er;

– t e electric cables and in particular t e spark

plug cable must be in perfect condition to avoid

t e generation of any sparks, and t e cap must

be correctly fitted on t e spark plug;

– t e mac ine andgrips and protection devices

must be clean and dry and well fastened to t e

mac ine;

– t e c ain brake must be in perfect working order;

– t e bar and t e c ain must be fitted correctly;

– t e c ain must be tensioned correctly.

5) Before starting your work, make sure t at all t e

protection devices are correctly fitted.

C) OPERATION

1) Do not operate t e engine in a confined space

w ere dangerous carbon monoxide fumes can col-

lect.

2) Work only in daylig t or good artificial lig t.

3) Tak on a firm and w ll-balanc d position:

– w ere possible, avoid working on wet, slippery

ground or in any case on uneven or steep gro-

und t at does not guarantee stability for t e

operator;

4SAFETY REQUIREMENTS

3. SAFETY REQUIREMENTS