2

PACKAGE CONTENT

The KDVRWY300 unit is packed on wood pallets and protected by a carton box.

The package includes:

−

1 KDVRWY300 unit;

−

1 user and maintenance manual

Package dimensions: 820x1220x 540(h) mm;

Gross weight: kg 80

TRANSPORT AND STORAGE

IMPORTANT: The parcel must travel on a pallet and be handled with mechanical means;

handling on site must be carried out with equipment fit for the package weight and volume and

in a way that prevents dents and falls: falls from just a few centimeters may damage the

content. Never turn the parcel over or upside down; should this happen, put it back in

horizontal position for at least 3 hours before installing the machine.

The parcels must be stored upright and in horizontal position, and up to three parcels can be

stacked one on top of the other. Ideal environment conditions -10 °C ÷ 50 °C, relative humidity

lower than 90%.

NOTE

Manual handling must comply with the laws in force.

DESCRIPTION AND MAIN COMPONENTS OF THE UNIT

When combined to a radiant cooling system, the KDVRWY300 unit can perform air treatment

based on the seasonal and wellness requirements. Its functions include:

-

air exchange, both in summer and winter, with at least 90% of heat recovery;

-

air exchange with no heat recovery (with external accessory);

-

summer dehumidification with adjustment of the delivery air temperature;

-

summer cooling with no dehumidification through the radiant system water;

-

winter air heating through the hot water of the radiant system.

The galvanized metal sheet frame of the unit contains the finned coils for air treatment, the

cooling circuit for dehumidification, the vacuum air filter, the condensation collection tray, the

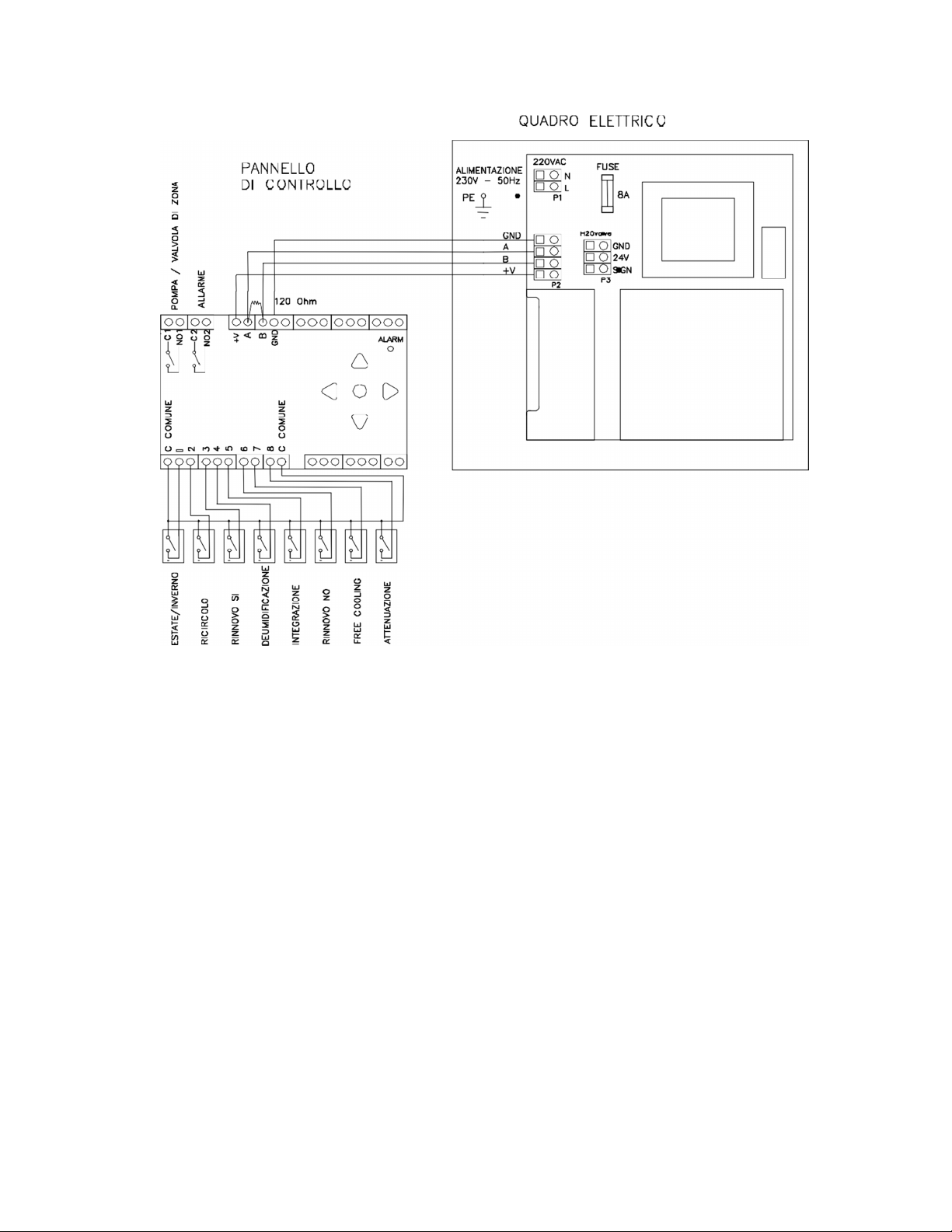

delivery fan, the electric switchboard for control and management.