USER MANUAL 10-2011 PAGE

FELLING GRAPPLE GMT 035

Index

1 GENERAL.........................................................................................................................3

1.1 USING THE MANUAL................................................................................................3

1.2 WARNINGS AND WARNING ICONS ........................................................................4

1.2.1 Serial No. plate. 1................................................................................................4

1.2.2 Type plate Nr. 2...................................................................................................4

1.2.3 Type plate Nr. 3...................................................................................................4

2 SAFETY INSTRUCTIONS................................................................................................5

3 INSTALLATION................................................................................................................8

3.1 Mounting the felling grapple on the crane ..................................................................8

3.1.1 Pressure Level.....................................................................................................9

4 FELLING WITH THE GRAPPLE.....................................................................................10

4.1 Safety Recommendations........................................................................................10

4.2 Felling.......................................................................................................................11

5 MAINTENACE................................................................................................................12

5.1 Safety Recommendations........................................................................................12

5.2 Daily maintenance....................................................................................................12

5.3 Replacement of the saw bar and chain....................................................................13

5.4 Lubricants.................................................................................................................14

5.5 Oil for hydraulic system............................................................................................14

5.5.1 Quality of the hydraulic oil..................................................................................14

5.6 Chainsaw oil.............................................................................................................14

5.7 Working with the chainsaw.......................................................................................15

5.8 Sharpening the chainsaw.........................................................................................16

6. SETTINGS OF THE FELLING GRAPPLE.....................................................................20

6.1 Pressure settings......................................................................................................21

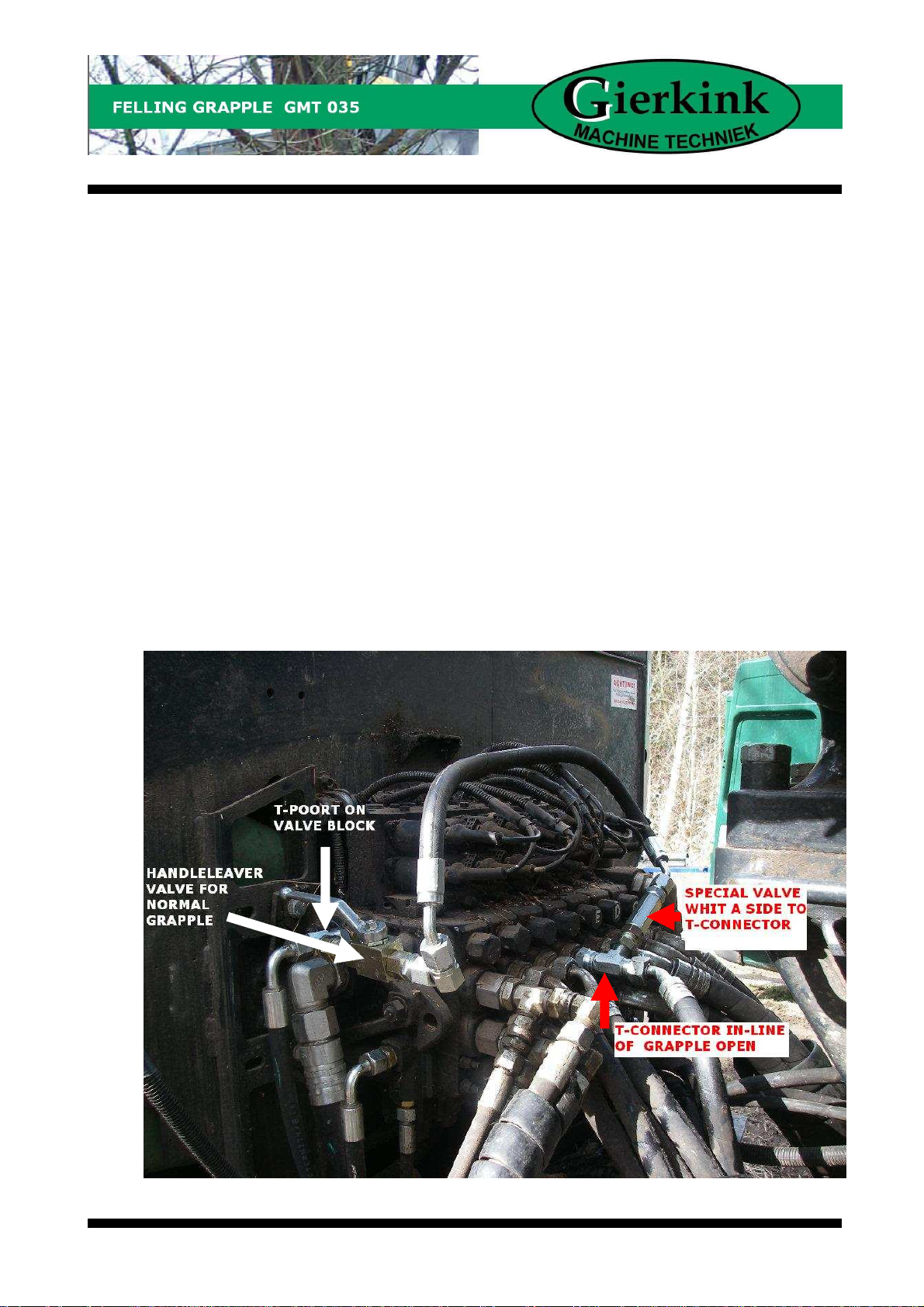

6.1.1 Setup of the valve block.....................................................................................21

6.1.2 Filling of the accumulator...................................................................................23

6.1.3 Chain lubrication...............................................................................................25

6.1.4 Saw bar speed..................................................................................................25

6.2 Safety requirements for the saw...............................................................................26

7 TROUBLESHOOTINGS MANUAL..................................................................................28

7.1 General ....................................................................................................................28

7.2 Checklist...................................................................................................................28

7.3 Problem list ..............................................................................................................29

7.4 Torques....................................................................................................................30

7.4.1 Repair or welding...............................................................................................30

8 TECHNICAL SPECIFICATIONS.....................................................................................31

8.1 Sizes ........................................................................................................................31

9 REMOVAL OF GRAPPLE ..............................................................................................32