Paioli frontforks

Sealstend toshowsignsofleakage atfairlylowmileage.Somelater

bikeshavesmallscrewsatthe top ofeachlegandifyou loosen them

you willreleasesomeairpressure.The twolegsarenotthe same.Both

haveaspring and oil(NordwesthasaspringONLYon the left leg),but

onlythe rightone hasthedampermechanism,soifyou wantto

experimentwithdifferentgradesofoil,youonlyneedtochangetheright

leg. Modified sealswerefitted tobikesafterVIN228-71037soifyou

havean olderbikeyou willneed spacerstoallowthe fitmentofthe

modified seals. Part numbersSeal952633, Spacers952737.

Acompletekitwithall seals, bushesetcisavailablepartnumber344921.

Aspecialtoolisrequired tofit the newsealsbut someSuzukimodelsuse

the sameforks sodealersshouldhaveasuitabletool.(Alternativeseals

areVesrah ref AR4104 asfitted toKX250 1989/91 size41mmX53mm

X8mm).

Supportbikewithfrontwheelclearofground.(ForNordwest, ensurethe

bikeissecured ifusing apaddock stand underthe forklegs,aswhen the

wheelspindleisremoved,therighthandlegcollapsesandthebiketends

tofallover),Disconnectspeedocable,removefairing,mudguard,brake

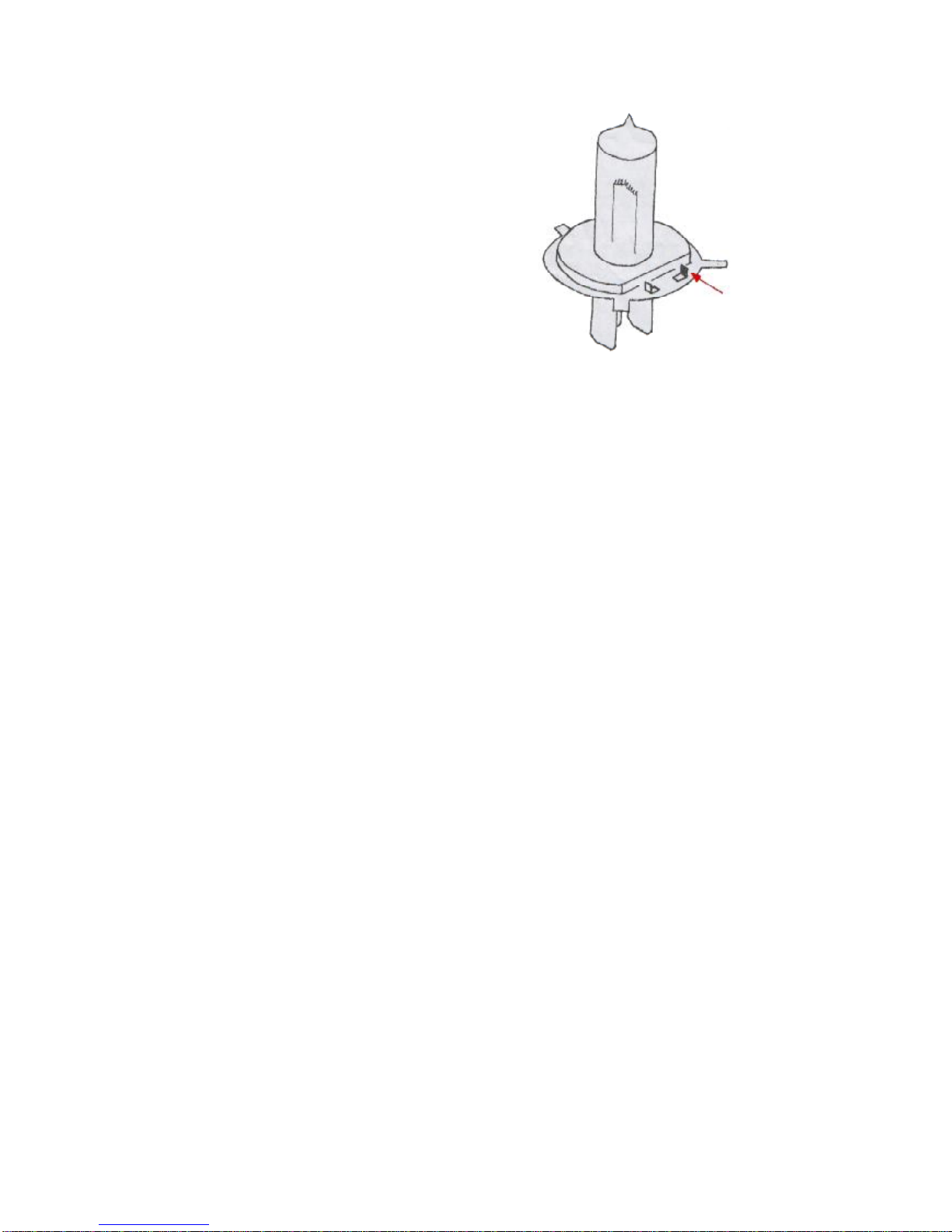

callipersand frontwheel.Nowyou can removethe forklegs.Takethe

top nutsoutandinvertthelegstodraintheoil.You willfindanuton top

of the damperrod inthe endof the forkleg,loosen thisnut bytapping the

spannersharply.Oncethenutisremoved,the twohalvesofthe forkleg

can be separated,butfirstremovethe dustsealand the spring ring

underneath,then holdthebottomofthe lowerleg inaviceand knock

the sealsoutbypullingthe top legupsharply.Fitthe newsealsetcwith

the specialtoolwhichwillensureit allgoesinstraight, reassembleand fill

eachleg with400ccofSAE10 forkoil.Donotforgetthelipofthe sealis

veryfragileandneedstobe inperfectcondition sotakeprecautionsto

keep it perfect during assembly.

Sparkplugs(gap 0.6to0.7mm torque to12to15 Nm)

NGK(heat range)

DPR9EA9(normal)DPR8EA9(cold)DPR9EV9(wide)

NipponDenso(heatrange)

X27 EPU-9(?)X27 EPRU-9(?)X27 EPRZU-9(wide)

Cables -oiling

Clutchand brakecablesusedtoneed oilingregularlywithengine oil.

Moderncablesarenylonlined and will workforageswithno attention.

Whentheystart toget stiff,lube themwithWD40 orsimilar.

Speedo cablesmaybe nylonlined,iftheyareyoushouldbeabletosee

aplastictube around the innercableifyou lookatthe end thatgoesinto

the clock.Disconnectthe cableatbothends,pulltheinnerout and clean

itwithWD40.Alsospraydownthe outer.Nowleavethe WD40todry,

otherwiseitwillend upgetting inthe clock. Ifit isnot nylon lined,pullthe

innerout and cleanit withasolvent. Onceitisdry, lightlygreaseit allthe

wayfromthe bottomtowithin2inchesofthe top.If you greaseitallthe

waytothe top, greasewillworkup intothe clock.

1-1,5